Introduction

Welcome to the captivating realm of Nitinol heat engines, where science fiction meets reality and innovation knows no bounds. These remarkable devices harness the unique properties of Nitinol wire, a shape memory alloy that can transform energy in ways that traditional materials simply cannot. As we delve deeper into this fascinating technology, you'll discover how Nitinol energy is not just a concept but a burgeoning field with real-world applications.

The Fascinating World of Nitinol Heat Engines

Nitinol heat engines represent a revolutionary leap in engineering, merging thermal dynamics with the extraordinary capabilities of shape memory alloys. Imagine an engine that can convert heat into mechanical work more efficiently than ever before; that's precisely what these ingenious machines promise. By utilizing the remarkable Nitinol wire, these engines can respond dynamically to temperature changes, making them both versatile and efficient.

How Nitinol Wire Powers Innovation

The versatility of Nitinol wire is at the heart of many groundbreaking innovations across various industries. From medical devices to aerospace applications, the unique characteristics of this alloy enable engineers to design solutions that were previously unimaginable. With its ability to generate significant Nitinol force while maintaining lightweight properties, it's no wonder that this material is becoming a staple in cutting-edge projects worldwide.

Exploring the Shape Memory Alloy Engine

At the core of the Nitinol generator lies the concept of shape memory alloys—materials that remember their original shapes when subjected to specific thermal conditions. This unique behavior allows for efficient energy conversion processes within a compact framework, making shape memory alloy engines highly desirable for future technologies. As we explore these innovative designs further, you'll see how they leverage Nitinol voltage and other properties to enhance performance and sustainability.

What is Nitinol?

Nitinol is a remarkable alloy that has captured the attention of engineers and innovators alike, particularly in the realm of heat engines. This unique material, composed primarily of nickel and titanium, exhibits extraordinary properties that make it an ideal candidate for various applications, including Nitinol engines and generators. As we delve deeper into the origins, composition, and applications of Nitinol wire, we uncover the secrets behind its transformative potential in engineering.

Origins and Composition of Nitinol

Nitinol was first discovered in the 1960s by researchers at the Naval Ordnance Laboratory in Maryland, USA. The name Nitinol is derived from its composition—Nickel (Ni) and Titanium (Ti)—and its origin at the Naval Ordnance Laboratory (NOL). This shape memory alloy is known for its unique ability to return to a predetermined shape when heated, making it a game changer for applications ranging from medical devices to innovative Nitinol heat engines.

The specific ratio of nickel to titanium in Nitinol typically hovers around 50:50 but can vary slightly depending on desired properties. This precise composition not only influences its phase transformation temperatures but also dictates how effectively it can harness Nitinol energy in various applications. Understanding this foundational aspect helps engineers design more efficient systems like the Shape Memory Alloy engine.

Unique Properties of Nitinol Wire

One of the most fascinating characteristics of Nitinol wire is its shape memory effect; when deformed at lower temperatures, it can revert to its original shape upon heating above a certain threshold. This property allows for significant energy storage and release capabilities—an essential feature for any effective Nitinol generator or engine design. Additionally, Nitinol exhibits superelasticity near room temperature, allowing it to undergo large strains without permanent deformation—a boon for many engineering solutions.

Another noteworthy aspect is how this alloy generates impressive amounts of force—often referred to as Nitinol force. When used within a heat engine or other mechanical systems, this force translates into enhanced efficiency and performance metrics compared to traditional materials. The ability to manipulate both temperature-induced transformations and mechanical properties makes Nitinol wire an invaluable asset across various engineering domains.

Applications of Nitinol in Engineering

The versatility of Nitinol has led to numerous innovative applications across multiple industries. In medical engineering, devices such as stents and guidewires leverage the unique properties of this alloy for safer patient outcomes while maintaining flexibility under stress—thanks largely to their reliance on principles derived from Nitinol energy dynamics. Similarly, aerospace engineers are exploring how these alloys can contribute valuable solutions in space missions where weight savings are critical.

In addition to healthcare and aerospace sectors, manufacturers are increasingly integrating Nitinol into consumer products like eyeglass frames that return to their original shape after bending or twisting—a perfect example showcasing both functionality and style! Moreover, with advancements in technology surrounding heat engines powered by these materials—including improved designs utilizing Stirling engine principles—the future looks bright for further exploration into sustainable energy solutions using innovative designs based on this exceptional alloy.

The Science Behind Nitinol Memory Metal

Nitinol, a remarkable alloy of nickel and titanium, is more than just a scientific curiosity; it’s a game-changer in the realm of heat engines. At the heart of its innovation lies the concept of shape memory alloys (SMAs), which enable materials to return to a predetermined shape when subjected to specific thermal conditions. This unique property not only enhances the efficiency of Nitinol engines but also opens doors for new applications in various fields, including robotics and medical devices.

Understanding Shape Memory Alloys

Shape memory alloys are materials that can undergo significant deformation at one temperature but return to their original shape when heated above a certain threshold. This transformation occurs due to phase changes within the material's crystalline structure, specifically between martensite and austenite phases. In the context of Nitinol wire, this means that when it is deformed at lower temperatures, it can revert back to its original configuration upon heating, making it an ideal candidate for use in Nitinol generators and heat engines.

The ability of shape memory alloys like Nitinol to remember their shapes allows them to convert thermal energy into mechanical work efficiently. When integrated into a Nitinol heat engine design, these properties can significantly enhance performance by providing consistent force output while minimizing energy loss. Thus, understanding SMAs is crucial for harnessing the full potential of Nitinol in innovative engineering applications.

How Nitinol Energy Works

Nitinol energy exploits the unique characteristics of this alloy through cycles of heating and cooling that cause expansion and contraction in the material. When heated above its transformation temperature, Nitinol wire contracts and generates force—this is where the magic happens! In a well-designed Nitinol engine or generator setup, this generated force can be harnessed to perform useful work or even produce electricity.

The efficiency gains from using Nitinol are impressive; traditional heat engines often lose substantial energy as waste heat during operation. However, with proper design considerations that take advantage of Nitinol voltage characteristics—such as optimizing thermal cycling—the overall efficiency can be dramatically improved compared to conventional systems. This innovative approach not only enhances performance but also contributes positively towards sustainable energy solutions by minimizing environmental impact.

Nitinol Force and Its Implications

The implications of harnessing Nitinol force extend far beyond just powering machines; they touch on numerous industries looking for sustainable alternatives. For instance, in medical technology, devices utilizing this unique alloy are becoming increasingly prevalent due to their reliability and compactness—think stents or guidewires that adapt seamlessly within the human body! Moreover, as we explore space travel further with GEE SMA missions relying on these technologies, we see how vital advanced materials like nitinol will become for future explorations.

Moreover, because nitinol’s properties allow it to operate effectively under varying conditions without significant wear or degradation over time, engineers are excited about its longevity compared to traditional materials used in engines today. As industries continue adapting these innovations into practical applications—from automotive engineering all the way up into aerospace—the importance of understanding how nitinol works will only grow more critical as we strive toward smarter technology solutions.

The Stirling Engine Explained

The Stirling engine is a fascinating example of innovation in thermodynamics, relying on the cyclic compression and expansion of gas to convert heat energy into mechanical work. This unique design allows it to operate efficiently with various heat sources, making it an excellent candidate for integration with Nitinol technology. By utilizing the exceptional properties of Nitinol wire, engineers can create a Nitinol heat engine that maximizes output while minimizing energy loss.

Basics of Stirling Engine Design

At its core, the Stirling engine consists of two cylinders connected by a regenerator, which captures and recycles heat during operation. The engine uses a working fluid—often air or helium—that expands when heated and contracts when cooled, creating motion in the pistons. When paired with a Shape memory alloy engine like one made from Nitinol wire, this design becomes even more compelling due to the high efficiency and power output achievable through clever engineering.

The simplicity of the Stirling engine's design allows for versatility across different applications, from small-scale generators to large power plants. Its closed-loop system means that it can run on any external heat source, whether solar energy or waste heat from industrial processes. This adaptability makes it an ideal partner for harnessing Nitinol energy effectively.

How Nitinol Engines Improve Efficiency

Nitinol engines enhance the efficiency of traditional Stirling designs by leveraging the unique thermal properties of shape memory alloys. When heated above their transformation temperature, Nitinol wire can undergo significant changes in shape and length, producing considerable force—referred to as Nitinol force—that translates into mechanical work within the engine cycle. This remarkable capability enables engineers to design compact engines that generate more power without requiring larger amounts of fuel or energy input.

Moreover, integrating Nitinol wire into Stirling engines reduces reliance on complex moving parts typically found in conventional designs. With fewer components subject to friction and wear-and-tear, maintenance becomes easier while operational longevity increases significantly—a win-win scenario for anyone looking to build a robust Nitinol generator! As such innovations continue to evolve, we may see widespread adoption across multiple industries seeking sustainable solutions.

Nitinol Voltage and Performance Benefits

Another intriguing aspect of using a Nitinol generator lies in its ability to produce electricity through thermoelectric effects when subjected to temperature gradients. In this context, Nitinol voltage refers to the electrical potential generated as temperature differences are established along sections of heated wire within an integrated system—effectively transforming thermal energy into usable electrical energy!

This dual functionality not only enhances overall performance but also opens doors for new applications where both mechanical work and electricity generation are required simultaneously—a true game changer for renewable energy systems! As researchers continue exploring methods to optimize these interactions between thermal dynamics and material science within engines powered by shape memory alloys like nitinol wire, we can expect groundbreaking advancements that push boundaries further than ever before.

Building Your Own Nitinol Generator

Creating your own Nitinol generator can be an exciting project that combines engineering with the fascinating properties of shape memory alloys. By harnessing the unique characteristics of Nitinol wire, you can design a small-scale Nitinol heat engine that demonstrates the principles of energy conversion and mechanical work. This section will guide you through the materials needed, a step-by-step construction guide, and tips for optimizing performance.

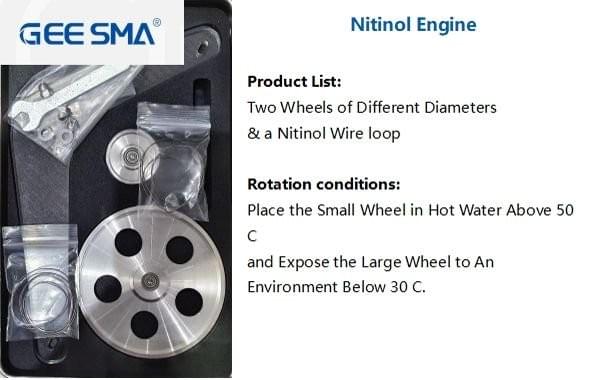

Materials Needed for a Nitinol Engine

To build your own Nitinol engine, you'll need several key materials to ensure functionality and efficiency. First and foremost, you'll require high-quality Nitinol wire, which is crucial for achieving the desired shape memory effect and force generation in your engine design. Additionally, a heat source such as a small burner or hot water bath will be necessary to activate the shape memory alloy engine; don't forget to gather components like metal rods for structural support, springs for returning mechanisms, and a base platform to hold everything together.

Other essential materials include thermal insulation to prevent heat loss during operation and tools like pliers or wire cutters for manipulating the Nitinol wire. You may also want some basic electronic components if you're interested in measuring voltage or integrating sensors into your design. Having these materials on hand will set you up for success as you embark on this innovative engineering adventure.

Step-by-Step Construction Guide

Building your Nitinol generator involves several steps that require attention to detail and creativity. Start by cutting lengths of Nitinol wire according to your design specifications; these wires will serve as actuators when heated. Next, secure one end of each piece of wire to a stationary base while allowing the other end to move freely—this setup is essential for converting thermal energy into mechanical work via the unique properties of Nitinol.

Once you've attached the wires appropriately, connect them to a suitable lever system that translates their movement into rotational motion or linear displacement—this is where you'll see how effective your shape memory alloy engine can be! After assembling all parts securely, apply heat using your chosen method; watch closely as the transformation occurs when the temperature rises! Finally, test different configurations and adjustments until you achieve optimal performance from your newly created Nitinol generator.

Tips for Optimizing Performance

To get the most out of your Nitinol heat engine, consider several optimization strategies that maximize efficiency and output power generation. First off, experiment with varying lengths and thicknesses of Nitinol wire; different configurations can significantly impact both force generation and response time when heated—finding just the right combination can lead to impressive results!

Another tip involves fine-tuning your heat source's temperature; too much or too little can hinder performance significantly. Ensure good thermal contact between your heating element and the part of the structure interacting with the Nitinol wire—this way, you'll enhance energy transfer efficiency while minimizing losses due to poor conduction.

Lastly, keep an eye on friction within moving parts; lubricating joints or using low-friction bearings can help maintain smooth operation over time while reducing wear on components involved in converting stored energy into usable motion from this fascinating shape memory alloy engine!

Real-World Applications of Nitinol Energy

The versatility of Nitinol energy extends far beyond theoretical applications; it has made significant impacts in various fields, particularly in space exploration, medical technology, and sustainable energy solutions. As we delve into these real-world applications, the unique properties of Nitinol wire become apparent as they power innovative devices and systems that redefine efficiency and functionality. From the high-stakes environment of outer space to life-saving medical devices, the Nitinol engine is proving to be a game changer.

Nitinol in Space Missions by GEE SMA

One of the most exciting applications of Nitinol heat engines is found in space missions conducted by GEE SMA (General Electric Engineering Shape Memory Alloy). In these missions, Nitinol generators are utilized for their remarkable ability to transform thermal energy into mechanical work efficiently. The shape memory alloy engine operates effectively under extreme conditions where traditional materials would fail, making it an ideal choice for spacecraft that endure harsh environments.

Nitinol's unique properties allow it to withstand temperature fluctuations while maintaining its structural integrity, which is critical for components used in satellites and exploratory probes. By harnessing Nitinol energy, engineers can create lightweight systems that require less power while delivering high performance—key factors when every ounce counts during a launch. The future looks bright as ongoing research continues to unlock even more potential uses for Nitinol in aerospace technologies.

Medical Devices Utilizing Nitinol Technology

In the realm of healthcare, the impact of Nitinol wire is nothing short of revolutionary. Medical devices such as stents and guidewires leverage the shape memory characteristics of this remarkable alloy to perform functions that were previously unimaginable. When deployed within the human body, a Nitinol engine can adapt its shape based on temperature changes or external forces—this adaptability enhances patient outcomes significantly.

Nitinol's biocompatibility adds another layer of appeal; it minimizes rejection rates compared to other materials used in surgical implants or devices. Moreover, with advancements like smart stents powered by Nitinol voltage adjustments, healthcare professionals can monitor patients’ conditions more effectively than ever before. This innovative use of nitinol energy not only provides immediate benefits but also paves the way for future breakthroughs in personalized medicine.

Sustainable Energy Solutions with Nitinol

As humanity seeks cleaner alternatives to fossil fuels, sustainable energy solutions featuring nitinol technology are gaining traction across multiple sectors. The efficiency improvements offered by a nitinol heat engine make it an attractive option for renewable energy systems such as solar thermal generators or geothermal power plants. By converting heat from natural sources into usable mechanical work through innovative designs utilizing nitinol wire, we can significantly reduce our reliance on traditional energy sources.

Furthermore, the potential integration of nitinol generators within existing infrastructure could revolutionize how we harness waste heat from industrial processes or even residential heating systems—turning what was once considered lost energy into valuable power output through clever engineering techniques involving nitinol force dynamics. As researchers continue exploring these avenues for improvement and optimization using this extraordinary material’s properties, we may soon witness a shift toward more sustainable practices worldwide.

Conclusion

As we wrap up our exploration of the fascinating world of Nitinol heat engines, it’s clear that this remarkable technology holds immense potential for the future. The unique properties of Nitinol wire, combined with its ability to convert thermal energy into mechanical work, position the Nitinol engine as a key player in various innovative applications. With ongoing advancements in Nitinol energy systems, we are just scratching the surface of what this shape memory alloy engine can achieve.

The Future of Nitinol Heat Engines

The future of Nitinol heat engines looks promising, with researchers and engineers continuously pushing boundaries to enhance efficiency and performance. As we refine our understanding of Nitinol force and its applications, we can expect to see more sophisticated designs that leverage the unique characteristics of this material. From powering small devices to potentially larger-scale applications, the versatility of a Nitinol generator could revolutionize how we harness energy.

Innovations in Nitinol Technology

Innovations in Nitinol technology are unfolding at a rapid pace, paving the way for groundbreaking advancements across multiple sectors. Researchers are experimenting with different alloys and configurations to optimize the performance and durability of Nitinol wire used in engines and generators alike. These innovations not only enhance efficiency but also open doors for sustainable energy solutions that align with global environmental goals.

Why Nitinol is a Game Changer

Nitinol is truly a game changer due to its unique combination of properties that offer unparalleled advantages over traditional materials in engineering applications. Its ability to remember shapes allows for dynamic responses in various environments, making it an ideal candidate for robust energy systems like the Shape memory alloy engine. As industries continue to adopt these innovative solutions powered by nitinol voltage and energy conversion capabilities, we can anticipate a transformative impact on how we generate and utilize power.