Introduction

In the ever-evolving world of materials science, shape memory alloys (SMAs) stand out as a remarkable innovation, and among them, nitinol rings are particularly fascinating. These unique materials have the ability to return to their original shape after being deformed, thanks to their special molecular structure. Nitinol, an alloy of nickel and titanium, showcases this extraordinary property in a way that has captivated scientists and engineers alike.

Understanding Shape Memory Alloys

Shape memory alloys are metallic materials that can undergo significant deformation but will revert back to their predetermined shapes when exposed to specific stimuli, such as temperature changes. This characteristic is primarily due to a phase transformation within the material's crystalline structure. The most well-known example of these alloys is nitinol, which combines the best features of both metals while exhibiting a unique ability to remember its original form.

What Makes Nitinol Special

What sets nitinol apart from other shape memory alloys is not just its impressive mechanical properties but also its biocompatibility and corrosion resistance. This makes it an ideal candidate for various applications in fields ranging from medicine to aerospace technology. The versatility of the shape memory nitinol ring allows it to be used in innovative designs that require both strength and flexibility, making it indispensable in modern engineering solutions.

Applications of Nitinol Rings

Nitinol rings have found their place in numerous applications due to their unique properties and reliability under stress. In medicine, they are commonly used in stents and orthopedic implants where flexibility combined with durability is crucial for patient safety and comfort. Beyond healthcare, these rings are also utilized in aerospace technologies for deployment mechanisms that require precise operation under varying conditions—showcasing just how far-reaching the impact of this exceptional material can be.

The Science Behind Shape Memory

Understanding the science behind shape memory is crucial to appreciating how nitinol rings function. At its core, shape memory refers to the ability of certain materials, particularly shape memory alloys like nitinol, to return to a predetermined shape when subjected to specific conditions. This remarkable property is a combination of unique material characteristics and clever engineering.

How Shape Memory Works

The magic of a shape memory nitinol ring lies in its atomic structure. When heated above a certain temperature, known as the transformation temperature, the alloy undergoes a phase change that allows it to revert to its original form. This means that if you bend or deform a nitinol ring at low temperatures, it can spring back into its designed shape when warmed up—an impressive feat that has broad implications for various applications.

This behavior is not just about flexibility; it's about precision and reliability too. For instance, in medical devices where exact shapes are critical for functionality and safety, the predictable behavior of nitinol rings makes them invaluable. Whether used in stents or surgical tools, understanding how shape memory works ensures engineers can harness this property effectively.

The Role of Temperature

Temperature plays an essential role in the functionality of nitinol rings by triggering their unique shape memory properties. Each nitinol alloy has specific transition temperatures which dictate when it will revert from one form to another—this feature is vital for practical applications such as medical devices and aerospace components. By controlling temperature precisely, manufacturers can design products that respond predictably under various conditions.

In practice, this means that when a nitinol ring is cooled below its transformation temperature, it retains whatever deformed state it's been put into until it warms up again—whereupon it snaps back into its original configuration with impressive force and speed. This thermal responsiveness makes the shape memory nitinol ring not only versatile but also highly effective in situations where traditional materials might fail due to lack of adaptability.

Furthermore, understanding how temperature influences performance allows researchers and engineers alike to experiment with different compositions and manufacturing processes for improved results—leading us closer to innovative solutions across industries.

The Mechanism of Transformation

The mechanism behind the transformation in a nitinol ring involves intricate changes at the atomic level during heating and cooling cycles. Initially formed in one structure (the martensite phase), upon heating above its transition temperature, it transforms into another stable structure (the austenite phase). This shift is what enables the material's unique ability—the capacity to remember its original form even after being deformed.

During this transformation process, energy is absorbed or released as atoms rearrange themselves within the alloy's crystalline structure—a phenomenon that can be finely tuned through careful engineering practices during manufacturing processes like heat treatment or cold working techniques used for producing high-quality nitinol rings. Such meticulous attention ensures optimal performance characteristics tailored for specific applications ranging from medical devices such as stents and orthopedic implants all the way through aerospace technologies.

In summary, grasping how this mechanism operates not only enhances our appreciation for these remarkable materials but also opens doors for future innovations utilizing shape memory technology—a field ripe with potential waiting just around the corner!

Nitinol Ring Manufacturing Process

Creating a shape memory nitinol ring is no small feat; it requires precision, expertise, and a dash of scientific magic. The manufacturing process is crucial to ensuring that these rings perform as intended in various applications, from medicine to aerospace technology. Let's dive into the intricate steps involved in crafting these remarkable materials.

Material Selection and Preparation

The journey of a shape memory nitinol ring begins with careful material selection. Nitinol, an alloy of nickel and titanium, is chosen for its unique properties that allow it to return to a predetermined shape when heated. Preparation involves melting the metals together under controlled conditions to achieve the right composition and homogeneity, ensuring that every nitinol ring produced meets strict performance standards.

After melting, the alloy undergoes cold working processes like forging or rolling to refine its structure. This step enhances the mechanical properties of the nitinol ring while also setting the stage for its future transformation capabilities. Finally, precise cutting techniques are employed to create rings of varying sizes and specifications tailored for specific applications.

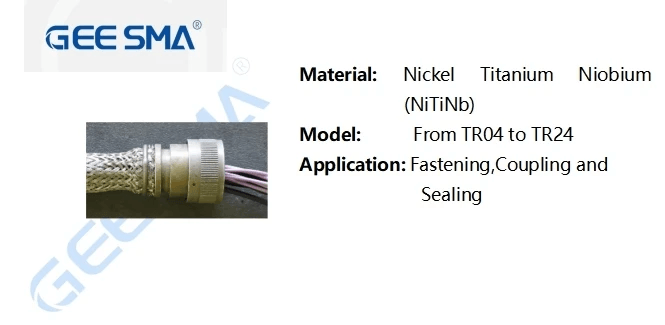

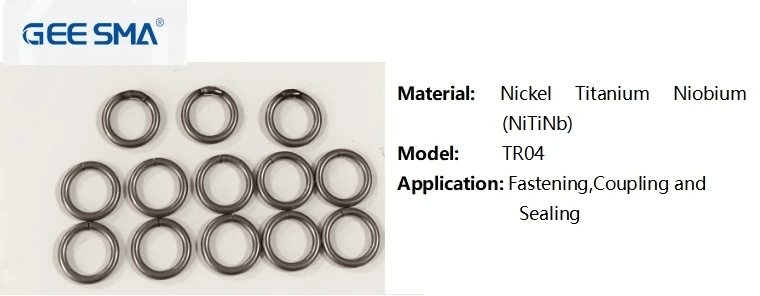

The Role of GEE SMA

GEE SMA plays a pivotal role in elevating the manufacturing process of nitinol rings to new heights. As a leader in shape memory alloys, GEE SMA utilizes advanced technologies and methodologies that enhance both efficiency and quality during production. Their expertise ensures that each shape memory nitinol ring not only meets industry standards but also exceeds expectations in terms of performance.

GEE SMA’s commitment to innovation means they continuously refine their processes based on cutting-edge research and development findings. This dedication translates into superior products that can withstand rigorous testing while maintaining their unique properties—like their ability to revert back after deformation when exposed to heat or other stimuli. By leveraging GEE SMA's advanced techniques, manufacturers can produce reliable nitinol rings suitable for critical applications across various fields.

Quality Control Measures

Quality control measures are paramount in ensuring that each shape memory nitinol ring performs flawlessly when put to use. Manufacturers implement stringent testing protocols at multiple stages throughout production—right from material selection through final inspection—to identify any defects or inconsistencies early on. This proactive approach minimizes risks associated with using subpar materials in sensitive environments such as medical devices or aerospace components.

Each batch of nitinol rings undergoes comprehensive assessments including mechanical property tests, thermal cycling evaluations, and dimensional checks before leaving the facility. These thorough inspections guarantee that only top-quality products reach customers who rely on them for safety-critical applications like stents or satellite deployment mechanisms. Ultimately, these quality control measures solidify trust between manufacturers and end-users by ensuring consistent reliability in every shape memory nitinol ring produced.

Applications of Nitinol Rings in Medicine

Nitinol rings have become a game-changer in the medical field, thanks to their unique properties that blend flexibility and strength. These remarkable shape memory nitinol rings respond to temperature changes, allowing them to return to a predetermined shape when heated. Their applications span various medical specialties, from cardiology to orthopedics, making them indispensable tools for modern healthcare.

Cardiology and Stents

In cardiology, nitinol rings are most famously utilized in stents, which are small mesh tubes inserted into narrowed or blocked arteries. The shape memory nitinol ring expands upon reaching body temperature, ensuring that blood flow is restored effectively without the risk of damage to surrounding tissues. This innovative use not only enhances patient outcomes but also reduces recovery times due to the minimally invasive nature of these devices.

Moreover, the flexibility of nitinol rings allows for easier navigation through complex arterial pathways during procedures. This adaptability is crucial when dealing with varying vessel sizes and shapes throughout the cardiovascular system. As a result, cardiologists can confidently employ these stents knowing they will perform reliably under physiological conditions.

Orthopedics and Implants

The orthopedic field has also embraced nitinol rings for a range of implants and devices designed for bone fixation and stabilization. Shape memory nitinol rings provide an excellent alternative to traditional metal implants due to their ability to adapt under stress while maintaining structural integrity over time. Surgeons appreciate how these implants can be customized for individual patients, ensuring optimal fit and function.

Additionally, the unique properties of nitinol allow these implants to be less invasive during insertion since they can be compressed or bent without losing their effectiveness once deployed inside the body. This minimizes trauma during surgery and promotes faster healing times for patients post-operation. With ongoing advancements in design and application techniques, the future looks bright for incorporating shape memory nitinol rings into orthopedic solutions.

Innovative Surgical Tools

Beyond implants and stents, nitinol rings have revolutionized surgical tools by enabling new designs that enhance precision in various procedures. For instance, some surgical instruments now incorporate shape memory technology that allows them to change form or function based on specific requirements during surgery—think scissors that can adapt their cutting angle based on tissue type!

This innovation not only improves surgical outcomes but also empowers surgeons with tools tailored specifically for each procedure's demands—making surgeries safer and more efficient overall. As research continues into new applications of shape memory nitinol rings within surgical instruments, we can expect even more groundbreaking developments on the horizon.

Nitinol Rings in Aerospace Technology

Nitinol rings have made significant strides in aerospace technology, proving to be invaluable components in various applications. Their unique properties, including shape memory and superelasticity, allow for innovative designs that enhance functionality and reliability in the harsh conditions of space. From satellites to interplanetary missions, the versatility of the shape memory nitinol ring is reshaping our approach to aerospace engineering.

Deployment Mechanisms in Satellites

One of the most fascinating applications of nitinol rings lies in their use as deployment mechanisms within satellites. These shape memory nitinol rings can be programmed to change shape at specific temperatures, enabling them to unfurl solar panels or antennas when they reach their designated orbit. This smart deployment system not only saves space during launch but also ensures that critical components are deployed reliably once they are needed.

The ability of a nitinol ring to return to its original shape means that these mechanisms can withstand the rigors of launch without compromising performance. In addition, the lightweight nature of these rings contributes to overall weight savings for satellite design, which is crucial for maximizing payload efficiency. As engineers continue to explore new designs and applications, it's clear that nitinol's role will only grow more prominent in future satellite technologies.

Supporting Space Exploration Missions

Nitinol rings play a critical role beyond just satellite deployment; they are also integral to various systems used in space exploration missions. Their ability to operate effectively under extreme temperatures and pressures makes them ideal candidates for use in spacecraft and rovers designed for distant planets or moons. The reliability of a shape memory nitinol ring ensures that essential systems function seamlessly during long-duration missions.

Moreover, these rings can facilitate complex mechanical movements necessary for landing gear or robotic arms on exploratory vehicles like Mars rovers or lunar landers. The adaptability of the nitinol ring allows engineers to design systems that can adjust dynamically based on environmental conditions encountered during missions. As we push further into our solar system and beyond, relying on advanced materials like nitinol will be crucial for mission success.

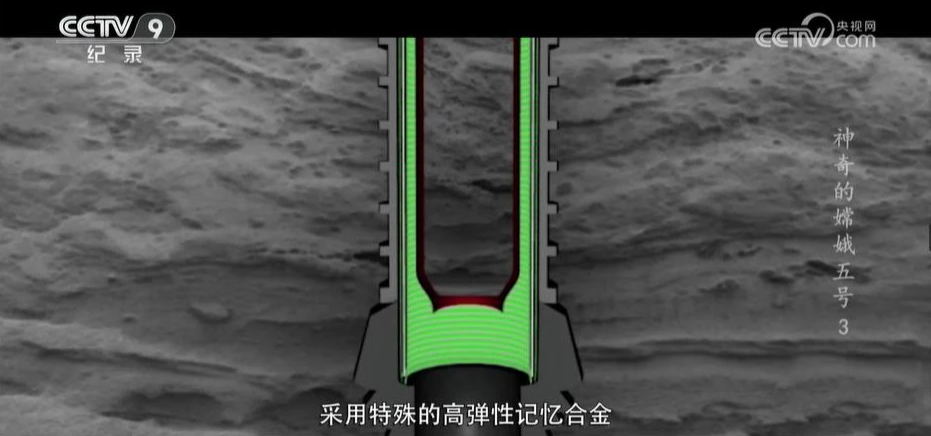

The Chang’e and Tianwen Missions

The Chang’e lunar missions by China have showcased how vital nitinol rings are becoming in modern aerospace endeavors. These missions utilize shape memory nitinol rings within their landing gear mechanisms, allowing for precise adjustments upon touchdown on the lunar surface. The flexibility and durability provided by these innovative components ensure safe landings despite varying terrain challenges.

Similarly, China's Tianwen mission benefits from incorporating nitinol technology into its rover systems deployed on Mars. The use of a shape memory nitinol ring enhances mobility while navigating through rocky Martian landscapes—essentially acting as an adaptive suspension system that responds dynamically as it travels across uneven surfaces. With each successful mission leveraging this cutting-edge material technology, it's evident that the future holds even greater potential for advancements driven by innovations like the nimble yet robust nitinol ring.

Benefits of Using Nitinol Rings

Nitinol rings are revolutionizing various industries, thanks to their unique properties that offer significant advantages. From medical applications to aerospace technology, the benefits of these shape memory nitinol rings are hard to overlook. Let’s dive into some of the most compelling reasons why these innovative materials are gaining traction.

Durability and Flexibility

One of the standout features of a nitinol ring is its remarkable durability combined with flexibility. Unlike traditional materials that can easily break under stress, a shape memory nitinol ring can undergo significant deformation and still return to its original shape when heated or subjected to specific conditions. This unique resilience makes them ideal for applications where reliability is critical, such as in stents used in cardiology or implants in orthopedics.

The ability of nitinol rings to withstand harsh environments without losing functionality is another key point. For instance, in medical devices, they can endure repeated stress cycles without fatigue, ensuring long-lasting performance for patients. This durability not only enhances patient safety but also reduces the need for frequent replacements, cutting down healthcare costs significantly.

Lightweight Design Advantages

When it comes to design considerations, lightweight materials often reign supreme—and nitinol rings are no exception. The lightweight nature of a shape memory nitinol ring allows for easier handling and installation in various applications while maintaining structural integrity. In aerospace technology, this characteristic becomes even more crucial as every ounce matters; lighter components contribute directly to improved fuel efficiency and overall performance.

Moreover, the lightweight design does not compromise strength or functionality; instead, it complements them beautifully. Engineers can create more efficient designs without worrying about excessive weight burdens on structures or devices. This balance between weight and strength makes nitinol rings particularly appealing across diverse sectors.

Customization Options

Customization is another area where shape memory nitinol rings shine brightly. Manufacturers have the ability to tailor these rings according to specific requirements—be it size, shape, or functional characteristics—allowing for a perfect fit in specialized applications like surgical tools or aerospace mechanisms. The versatility offered by these customizable options means that engineers can innovate freely without being limited by material constraints.

Furthermore, advancements in manufacturing processes enable precise control over properties such as transformation temperatures and mechanical behavior when designing a nitinol ring. This level of customization ensures that each application receives a product optimized for its unique demands—whether it's adapting seamlessly within the human body or functioning flawlessly in outer space missions.

In conclusion, the benefits associated with using nitinol rings are extensive and varied—from their exceptional durability and flexibility to their lightweight design advantages and customization potential. As industries continue exploring new frontiers with these remarkable materials, we can expect even more innovative uses for shape memory nitinol rings in the future.

Conclusion

In wrapping up our exploration of nitinol rings and their fascinating capabilities, it's clear that these remarkable shape memory alloys hold a unique position in both medical and aerospace fields. The innovative properties of the shape memory nitinol ring, including its ability to return to a predetermined shape when heated, have opened doors to advancements that were once thought impossible. As we look ahead, it’s exciting to consider the potential of these materials in transforming various industries.

Key Takeaways About Nitinol Rings

Nitinol rings stand out due to their extraordinary combination of flexibility and strength, making them ideal for applications where reliability is paramount. Their ability to undergo significant deformation while returning to their original form is what truly sets the shape memory nitinol ring apart from conventional materials. Whether in stents that adapt seamlessly within the body or components used in aerospace technology, the versatility of nitinol rings cannot be overstated.

Future of Shape Memory Alloys

The future for shape memory alloys like nitinol rings looks promising as researchers continue to unlock new applications and improve existing technologies. Innovations are on the horizon, with potential breakthroughs in areas such as robotics and smart materials that could redefine how we interact with our environments. As industries push for lighter yet more durable components, shape memory nitinol rings will likely play a crucial role in meeting these demands while enhancing performance.

Exploring More Innovations from GEE SMA

GEE SMA is at the forefront of developing cutting-edge solutions using nitinol rings and other shape memory alloys. Their commitment to innovation not only includes refining manufacturing processes but also exploring new applications that can revolutionize sectors beyond medicine and aerospace. As we delve deeper into this material science frontier, it’s evident that GEE SMA will continue leading the charge toward exciting advancements involving shape memory technologies.