Introduction

In the realm of modern engineering, few materials capture the imagination quite like Shape Memory Alloys (SMAs). These remarkable metals possess a unique ability to return to a predetermined shape when subjected to specific temperature changes, making them invaluable in various applications. From aerospace to robotics, understanding SMAs opens the door to innovations that can redefine how we approach design and functionality.

Understanding Shape Memory Alloys

What exactly are these magical materials? At their core, shape memory alloys are metallic compounds that exhibit an extraordinary property: they can remember their original shape. When deformed at lower temperatures, they revert back to this original form when heated above a certain threshold, leading many engineers to ask, What is an SMA actuator? This fascinating behavior is not just a scientific curiosity; it’s the foundation for creating efficient and compact actuators.

The Magic of SMA Actuators

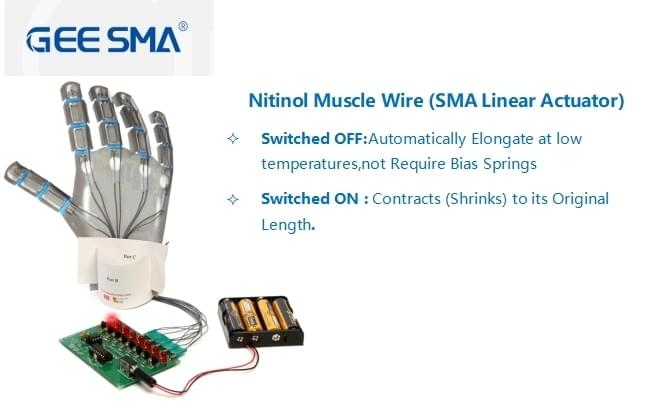

SMA actuators harness the power of shape memory alloys to convert thermal energy into mechanical work. The magic lies in their simplicity and effectiveness; as they heat up or cool down, they expand or contract accordingly. This transformation allows for precise control in applications ranging from medical devices to robotics, demonstrating why these innovative components are gaining traction in various industries.

Real-World Applications of SMAs

The versatility of SMA linear actuators is evident across numerous fields. In aerospace missions, for example, GEE SMAs contribute significantly by providing lightweight and reliable solutions for actuation systems under extreme conditions. Moreover, everyday items like automated window blinds and prosthetic limbs showcase how SMAs can enhance functionality while maintaining elegance—proof that innovation knows no bounds when it comes to real-world applications!

What is an SMA Actuator?

SMA actuators are fascinating devices that leverage the unique properties of shape memory alloys (SMAs) to create motion in response to temperature changes. These materials can remember their original shape and return to it when heated, making them ideal for various applications. Understanding what an SMA actuator is requires delving into the science behind SMAs and how they operate.

Defining Shape Memory Alloys

Shape memory alloys are metallic materials that exhibit a remarkable ability to change shape when subjected to specific thermal conditions. Essentially, they can be deformed at one temperature but will revert to their original, pre-deformed shape upon heating above a certain threshold known as the transformation temperature. This property allows SMA linear actuators to perform tasks that traditional actuators may struggle with, making them a compelling choice for engineers looking for innovative solutions.

How SMA Actuators Work

So, how do these intriguing devices operate? When an SMA linear actuator is heated—often by passing an electric current through it—the alloy undergoes a phase transformation from its low-temperature state (martensite) to its high-temperature state (austenite). This transition generates movement as the material expands or contracts, allowing for precise control over mechanical systems without the need for complex electronics or bulky components.

Key Benefits of Using SMAs

One of the standout advantages of using SMAs in linear actuators is their compact size and lightweight nature compared to traditional options like electric or pneumatic actuators. They also provide silent operation and minimal maintenance requirements since there are fewer moving parts involved. Additionally, because they're capable of functioning in extreme environments where other types may fail, many industries are increasingly asking themselves: “What is an SMA actuator?” The answer reveals not just a mechanism but also a world of possibilities.

The Four Types of Linear Actuators

Linear actuators are pivotal in various applications, providing motion in a straight line rather than the circular motion seen in rotary actuators. Understanding the four main types of linear actuators is essential for selecting the right one for your project needs. Each type has its unique characteristics and applications, including SMA linear actuators, which have gained popularity due to their innovative design and functionality.

Overview of Linear Actuator Types

When discussing What are the 4 types of linear actuators?, it’s crucial to highlight electric, pneumatic, hydraulic, and shape memory alloy (SMA) actuators. Electric actuators use motors to convert electrical energy into linear motion, making them precise and easy to control. Pneumatic actuators utilize compressed air for movement, offering rapid actuation but requiring an air supply system; while hydraulic actuators leverage fluid pressure for substantial force output but can be bulky and complex.

SMA linear actuators stand out among these types due to their unique ability to change shape in response to temperature variations. This characteristic allows them to perform tasks without traditional motors or gears, making them compact and lightweight. In contrast with other actuator types, SMA technology is often more energy-efficient, especially in applications where space is at a premium.

Comparing Electric and Pneumatic Actuators

Electric and pneumatic actuators each bring distinct advantages that cater to different application demands—so why choose one over the other? Electric SMA linear actuators offer high precision control with minimal maintenance requirements; they excel in environments where accuracy is paramount. On the flip side, pneumatic systems deliver swift movements ideal for high-speed applications but may require additional components such as compressors or regulators.

Cost considerations also come into play when comparing these two actuator types; electric systems tend to have higher upfront costs due to their complexity but can save money long-term on maintenance and energy consumption. Conversely, pneumatic systems might appear cheaper initially but can incur costs related to air supply infrastructure over time. Ultimately, selecting between electric or pneumatic solutions often hinges on specific operational needs—speed versus precision.

The Role of Hydraulic Actuators

Hydraulic actuators play a significant role in heavy-duty applications where immense force is necessary—think construction equipment or industrial machinery! These devices utilize pressurized fluid to create powerful movements that electric or pneumatic systems might struggle with under similar conditions. While they excel at delivering significant force quickly, hydraulic systems require careful management of fluid levels and potential leakage issues.

In contrast with SMA linear actuators that boast simplicity through thermal activation mechanisms, hydraulic systems can be intricate due to their reliance on pumps and valves for operation—a complexity that can lead some users questioning: Why are linear actuators so expensive? The answer lies not only in the manufacturing process but also in ongoing maintenance costs associated with hydraulic components compared to simpler alternatives like SMAs.

For those seeking efficient solutions across various industries—from aerospace innovations utilizing GEE SMA technology to everyday automation tasks—understanding these actuator types enables informed decisions tailored precisely for your needs!

Exploring Simple Linear Actuators

When diving into the world of linear actuators, it’s essential to distinguish between simple and complex types. A simple linear actuator typically consists of fewer components and operates on straightforward principles, making it easier to understand and implement. In contrast, complex actuators integrate multiple systems or technologies, offering advanced functionalities but often at a higher cost and increased complexity—this brings us to the question: What is an SMA actuator?

Simple vs. Complex Actuators

Simple linear actuators are generally characterized by their ease of use and straightforward design, often employing mechanisms like screw drives or direct push/pull actions. These designs make them ideal for applications where basic motion control suffices, allowing users to quickly grasp their operation without needing extensive technical knowledge. On the flip side, complex actuators may incorporate sophisticated features such as feedback systems or integrated sensors, which can enhance performance but also complicate maintenance and troubleshooting.

In the realm of SMA linear actuators, simplicity is a significant advantage; these devices can convert thermal energy into mechanical movement with minimal components involved. This simplicity not only leads to lower production costs but also contributes to their reliability in various applications. However, while simple linear actuators shine in basic tasks, they may struggle with more demanding requirements where precision and adaptability become critical.

Applications of Simple Linear Actuators

Simple linear actuators find their niche in various industries due to their versatility and reliability. Common applications include automated doors, robotic arms for basic tasks, and even medical devices that require precise yet uncomplicated movements—demonstrating just how valuable these tools can be in everyday scenarios. Moreover, industries such as manufacturing often utilize these devices for assembly lines where repetitive motions are necessary without excessive complexity.

In addition to industrial uses, simple SMA linear actuators are gaining traction in consumer products like adjustable furniture or home automation systems—think motorized window shades that adapt based on sunlight exposure! Their ability to operate efficiently without intricate programming makes them attractive for both manufacturers and end-users alike. As technology continues evolving, the potential applications for these straightforward yet effective devices will likely expand even further.

Benefits and Limitations

The benefits of using simple linear actuators are numerous; they typically offer lower costs due to fewer parts needed for construction while maintaining a high level of reliability over time—this is particularly appealing when considering why are linear actuators so expensive? Additionally, their ease of installation allows companies to save on labor costs during setup compared to more complex alternatives requiring specialized knowledge.

However, limitations do exist within this category; while they excel at basic functions, they may lack the precision or adaptability required for more advanced tasks—leading some users back toward more complex solutions despite higher expenses involved. Furthermore, simple SMA linear actuators might not perform well under extreme conditions or heavy loads compared to robust alternatives designed specifically for those situations.

In summary, exploring simple linear actuators reveals a world where efficiency meets practicality—ideal for many applications but with certain constraints that users must consider when selecting the right actuator type for their needs.

The Cost of Linear Actuators

When considering the cost of linear actuators, several factors come into play that can significantly influence pricing. Material quality, manufacturing processes, and technological advancements all contribute to the overall expense of these devices. Additionally, the specific requirements of an application can dictate whether a simple linear actuator or a more complex SMA linear actuator is needed, further affecting costs.

Factors Affecting Linear Actuator Prices

The price of linear actuators is influenced by various factors including size, load capacity, and precision requirements. For instance, an SMA linear actuator designed for high precision in aerospace applications will typically command a higher price than one used in less demanding environments. Furthermore, the choice between different types—such as electric, pneumatic, or hydraulic—can also affect costs significantly due to varying production complexities and material needs.

Why Are Linear Actuators So Expensive?

One might wonder why linear actuators are so expensive when compared to other mechanical systems. The answer lies in their engineering complexity and the performance capabilities they offer; SMA actuators provide unique benefits like lightweight design and adaptability under extreme conditions that simpler mechanisms cannot match. Moreover, advanced features such as feedback systems for precise control add to production costs but enhance functionality significantly.

Analyzing Cost-Benefit for SMA Linear Actuators

When evaluating whether to invest in an SMA linear actuator versus traditional alternatives, it's essential to consider both upfront costs and long-term benefits. While initial expenses may be higher for SMAs due to their specialized materials and technology, their efficiency and reliability can lead to reduced maintenance costs over time. Ultimately, understanding what is an SMA actuator helps potential buyers weigh these factors effectively against their specific application needs.

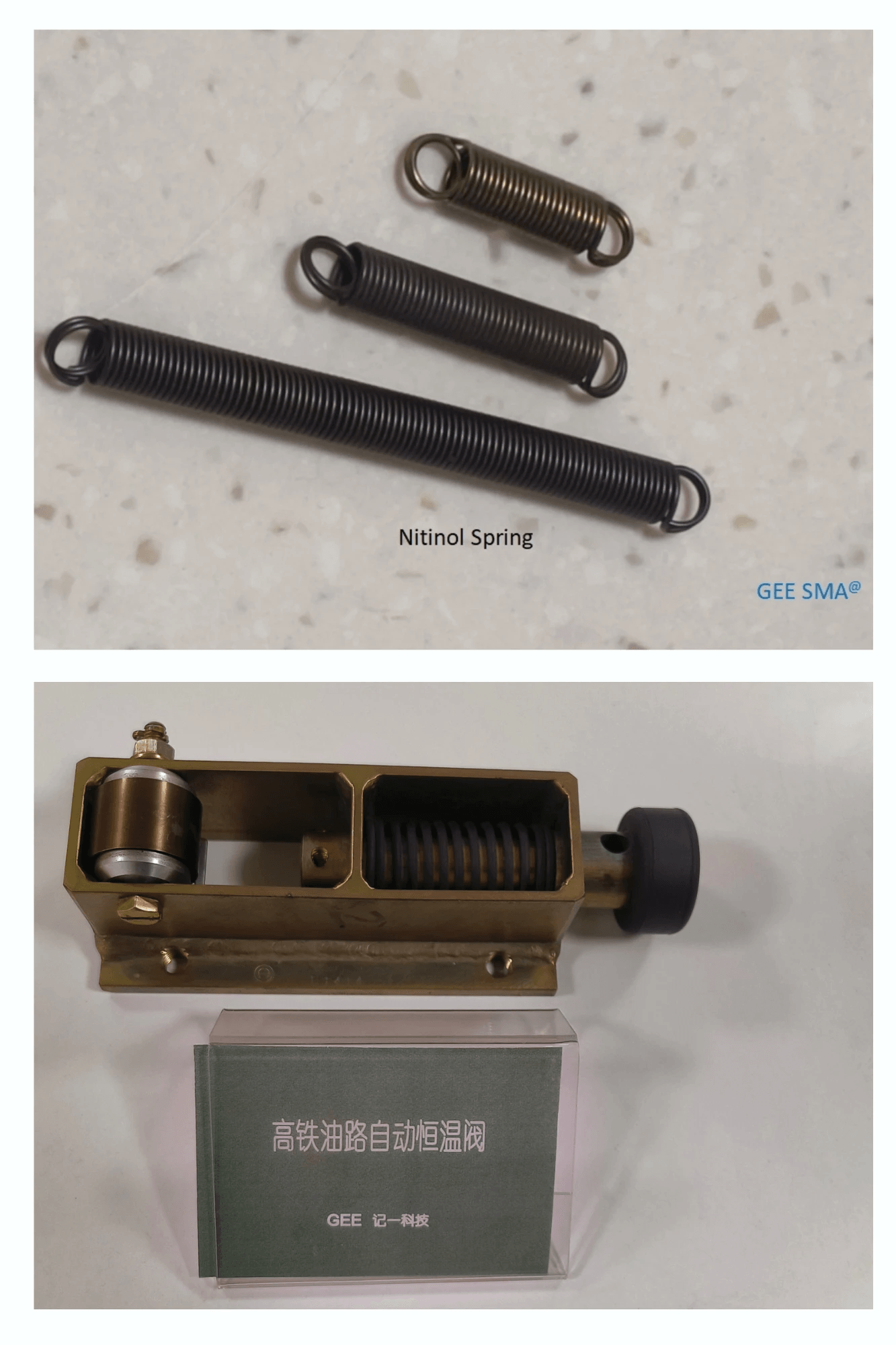

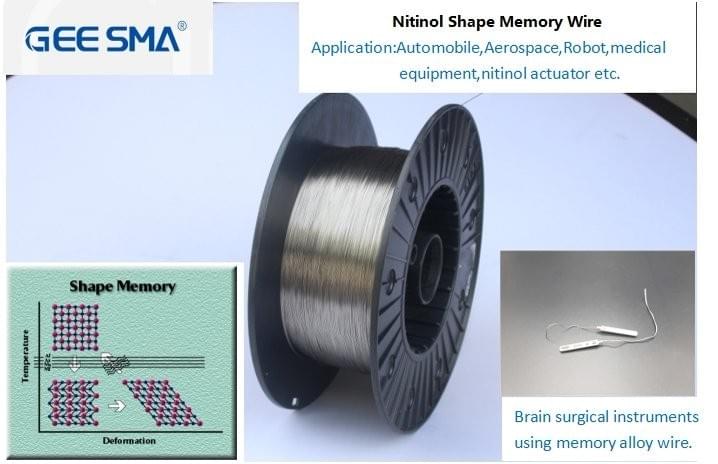

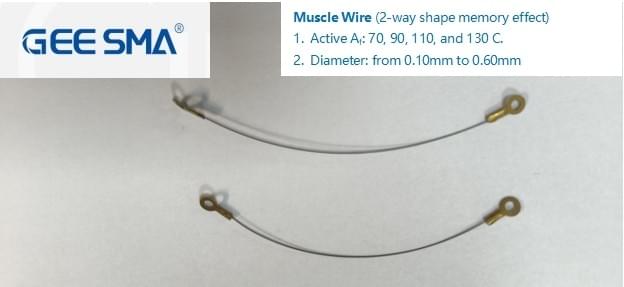

GEE SMA and Nitinol Innovations

In the rapidly evolving landscape of technology, GEE SMA and Nitinol are making waves, especially in fields like aerospace and robotics. These materials are not just fascinating; they redefine what is possible with SMA linear actuators. Their unique properties allow for innovative solutions that cater to specific needs in extreme environments.

GEE SMA’s Role in Aerospace Missions

GEE SMA has emerged as a game-changer in aerospace missions, providing lightweight yet powerful solutions for various applications. What is an SMA actuator? It's a device that utilizes shape memory alloys to convert thermal energy into mechanical work, which is crucial for aerospace systems requiring precise movement and reliability. The use of GEE SMA ensures that components can withstand the rigors of space travel while maintaining optimal performance.

The ability of GEE SMA to operate efficiently under fluctuating temperatures makes it ideal for aircraft and spacecraft where conditions can be unpredictable. Engineers appreciate how these SMAs simplify designs while enhancing functionality, making them a preferred choice over traditional actuators. This innovation leads to reduced weight and increased efficiency—two critical factors when designing aircraft that need to soar high without excessive fuel consumption.

Nitinol’s Advantages in Extreme Conditions

Nitinol, another impressive shape memory alloy, boasts remarkable advantages when used in extreme conditions such as high pressure or temperature fluctuations. What are the 4 types of linear actuators? While there are many options available, Nitinol stands out due to its unique ability to return to a predetermined shape after deformation—making it invaluable where resilience is key. For instance, its applications range from medical devices to automotive components designed for harsh environments.

One significant benefit of using Nitinol is its ability to function effectively without external power sources once activated by temperature changes or electrical currents. This feature significantly reduces operational costs associated with traditional linear actuators that often require complex control systems. So why are linear actuators so expensive? The advanced materials like Nitinol contribute significantly to the overall cost but offer unparalleled reliability and performance gains.

Tailored Solutions for Unique Applications

The versatility of GEE SMA and Nitinol allows engineers to create tailored solutions for unique applications across various industries. Whether it's developing specialized tools or creating adaptive structures that respond dynamically to environmental changes, understanding what is a simple linear actuator becomes essential here—it’s all about customization! By leveraging the properties of these alloys, designers can produce devices that meet specific operational requirements without compromising on efficiency.

Moreover, the ongoing research into these materials continues to unveil new possibilities in actuator design and functionality—paving the way for innovations previously deemed impossible with conventional technologies. As industries seek more efficient means of operation, embracing these advanced SMAs could lead us toward smarter solutions with greater adaptability than ever before. Ultimately, investing in technologies like GEE SMA and Nitinol may seem costly now; however, their long-term benefits certainly outweigh initial expenditures when considering their impact on performance enhancement.

Conclusion

As we wrap up our exploration of shape memory alloys (SMAs) and their applications, it’s clear that innovations in SMA technology are revolutionizing industries. From aerospace to robotics, the unique properties of SMAs allow for unprecedented design possibilities. The versatility of SMA linear actuators is particularly noteworthy, as they provide solutions that were once deemed impossible.

Innovations in SMA Technology

Recent advancements in SMA technology have opened new doors for engineers and designers alike. These innovations not only enhance performance but also improve reliability in various applications, making them essential components in modern systems. With ongoing research, we can expect to see even more refined versions of what an SMA actuator can achieve, pushing the boundaries of engineering creativity.

The Future of Linear Actuators

Looking ahead, the future of linear actuators appears bright and promising. As we delve deeper into understanding what are the 4 types of linear actuators—electric, pneumatic, hydraulic, and now SMAs—the integration of these technologies will continue to evolve. The demand for efficient solutions means that SMA linear actuators will play a pivotal role in shaping how machines interact with their environments.

Embracing the Power of SMAs

In conclusion, embracing the power of SMAs means recognizing their potential to transform various sectors significantly. While many may wonder why linear actuators are so expensive, it’s important to consider the long-term benefits they provide through efficiency and functionality. Whether you’re exploring what is a simple linear actuator or diving into complex systems, understanding these components will undoubtedly enhance your projects’ success.