Introduction

In the realm of modern engineering, nitinol linear actuators are making waves with their unique properties and capabilities. These remarkable devices utilize the extraordinary characteristics of shape memory alloys (SMAs) to provide efficient and reliable actuation in various applications. As we dive deeper into the world of nitinol, we'll explore not only how these actuators work but also their advantages, cost factors, and comparisons with other actuator types.

Understanding Nitinol Linear Actuators

Nitinol linear actuators harness the power of shape memory alloys to create motion in a controlled manner. When exposed to specific temperatures, nitinol can change its shape, allowing it to exert force and produce linear movement effortlessly. This mechanism leads us to ask: what are the 4 types of linear actuators? Understanding this classification helps highlight where nitinol fits within the broader landscape of actuation technologies.

The Magic of Shape Memory Alloys

The true magic lies in how shape memory alloys operate; they remember their original shapes after being deformed when heated or cooled. This ability allows for precise control over movement, making nitinol an attractive option for various applications that require reliability and efficiency. But what are the advantages of nitinol? Its lightweight nature, high strength-to-weight ratio, and low energy consumption set it apart from traditional actuator materials.

Real-World Applications of Nitinol

Nitinol's versatility opens doors to numerous real-world applications across diverse fields such as robotics, medical devices, and aerospace engineering. From powering tiny robotic arms to enabling minimally invasive surgical tools, nitinol linear actuators are transforming industries by providing innovative solutions that were previously unimaginable. Yet as we explore these advancements further, one question remains: why are linear actuators so expensive? Factors like production costs and material quality play significant roles in determining their market price.

Nitinol Linear Actuator Basics

Nitinol linear actuators are fascinating devices that leverage the unique properties of shape memory alloys to create movement. These actuators are capable of converting thermal energy into mechanical work, making them an intriguing option for various applications. Understanding what a nitinol linear actuator is and how it works can provide insight into its advantages and potential uses.

What is a Nitinol Linear Actuator?

A nitinol linear actuator is a device that utilizes nitinol, a nickel-titanium alloy known for its shape memory and superelastic properties, to produce linear motion. When heated above a specific temperature, nitinol changes shape, allowing it to exert force and create movement in a controlled manner. This capability makes nitinol linear actuators particularly valuable in fields such as robotics, medical devices, and aerospace engineering.

What are the 4 types of linear actuators? While there are various types of linear actuators available—such as electric, hydraulic, pneumatic, and mechanical—nitinol stands out due to its unique characteristics. Unlike traditional actuators that rely on external power sources or fluid pressure, nitinol operates based on temperature changes alone.

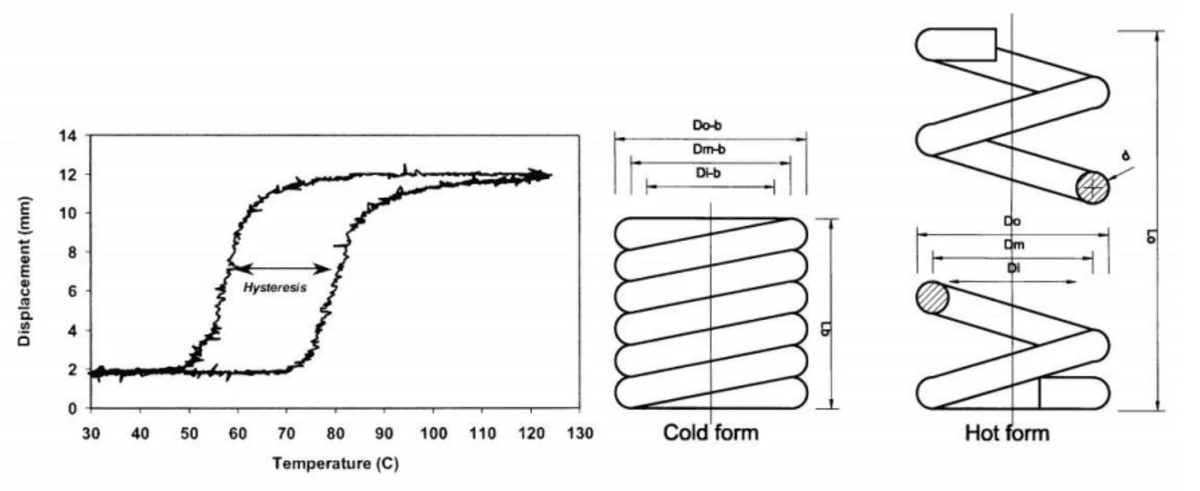

How Nitinol Works in Actuation

Nitinol's actuation mechanism relies on phase transformation between two distinct states: martensite and austenite. In its martensitic state at lower temperatures, the material can be easily deformed; however, when heated above its transformation temperature (the austenitic state), it returns to its original shape with significant force. This transition allows for precise control over the actuator's movement without bulky components or complex mechanisms.

The beauty of using nitinol in actuation lies in its simplicity and efficiency; it requires minimal energy input while delivering impressive output performance. Additionally, this technology can be integrated into compact designs where space is limited—a significant advantage over other types of actuators that may require more extensive setups. As we explore further into comparing nitinol with other actuator types, it's clear that these unique features set it apart from conventional solutions.

Comparing Nitinol with Other Actuator Types

When comparing nitinol with other actuator types—such as electric or hydraulic systems—several factors come into play: size constraints, energy efficiency, response time, and maintenance requirements. Electric actuators often require complex circuitry and can be bulky compared to the sleek design of nitinol linear actuators that operate simply through heat application. Hydraulic systems may deliver greater force but come with challenges like fluid leaks or maintenance issues not present in solid-state materials like nitinol.

Moreover, one might wonder why linear actuators are so expensive? The costs associated with manufacturing high-quality materials like nitinol contribute significantly to their price point; however, their long-term value often outweighs initial expenses due to durability and reliability in demanding environments. Ultimately, understanding what sets nitinol apart from other options helps businesses make informed decisions when selecting the right actuator for their needs.

What Are the 4 Types of Linear Actuators?

When diving into the world of linear actuators, it's essential to recognize that they come in various flavors, each designed to meet specific needs. The four primary types include electric, pneumatic, hydraulic, and shape memory alloy (SMA) actuators like our star player: the nitinol linear actuator. Understanding these categories will help clarify the advantages of nitinol and how it stands out from the rest.

Overview of Linear Actuator Categories

Electric linear actuators use electrical energy to create motion through a motor-driven mechanism. Pneumatic actuators rely on compressed air to generate movement, while hydraulic actuators utilize liquid pressure for powerful actuation. Lastly, we have shape memory alloy (SMA) actuators like nitinol linear actuators that exploit unique material properties to achieve motion when subjected to temperature changes.

Pros and Cons of Each Type

Electric linear actuators are lauded for their precision and ease of control but can fall short in terms of power output compared to hydraulics. Pneumatic options are lightweight and fast but may lack the force needed for heavy-duty applications; they also require an air compressor which can be a hassle. Hydraulic actuators deliver immense power and are great for heavy loads but can be costly due to fluid management systems; however, nitinol linear actuators shine here with their compact design and ability to operate without external power sources.

Nitinol's Unique Position Among Them

Nitinol’s unique position among these actuator types stems from its remarkable ability as a shape memory alloy—returning to its original shape when heated after being deformed. This property allows nitinol linear actuators not only to be compact but also incredibly efficient in energy usage compared to more traditional systems like electric or hydraulic options. Moreover, while many might ponder What are the advantages of nitinol?—the answer lies in its lightweight nature, low maintenance requirements, and reliability across diverse applications where conventional methods might falter.

Advantages of Nitinol

Nitinol linear actuators are rapidly gaining traction in various industries due to their unique properties and benefits. These actuators stand out for their ability to convert thermal energy into mechanical work, making them a versatile choice for many applications. The advantages of nitinol linear actuators not only enhance performance but also open up new possibilities in design and functionality.

Benefits of Using Nitinol Linear Actuators

One of the primary benefits of using nitinol linear actuators is their remarkable efficiency in converting heat into motion. This capability allows for precise control and actuation without the need for complex electrical systems, which can be cumbersome and expensive. Additionally, nitinol's lightweight nature means that these actuators can be integrated into smaller devices without compromising on strength or durability.

Another advantage lies in the actuator's ability to return to its original shape after deformation, thanks to its shape memory effect. This feature makes nitinol linear actuators incredibly reliable and reduces wear and tear over time, leading to longer lifespans compared to traditional actuator types. Furthermore, they operate silently, which is a significant plus in applications where noise reduction is crucial.

Lastly, nitinol offers excellent resistance to corrosion and fatigue, making it suitable for harsh environments where other materials might fail. When considering what are the advantages of nitinol? It's clear that these factors contribute significantly to their growing popularity across various fields such as robotics, medical devices, and aerospace.

Why Nitinol is a Game-Changer

Nitinol has revolutionized the world of actuation by introducing capabilities that were previously unattainable with conventional materials. Its unique properties allow engineers to create more compact designs while maintaining high performance levels—this is especially important when looking at what are the 4 types of linear actuators available today; each has its strengths but pales compared to what Nitinol offers in terms of innovation.

Moreover, the adaptability of nitinol means it can be tailored for specific applications—whether it's for delicate surgical tools or robust industrial machinery. This flexibility not only enhances functionality but also promotes creativity in engineering design processes that were once limited by traditional actuator technologies. As industries continue seeking lighter yet powerful solutions, it's hard not to see why nitinol is being hailed as a game-changer.

In summary, when evaluating why are linear actuators so expensive? The answer often lies in their material composition and manufacturing processes; however, with nitinol's exceptional value proposition—including reduced maintenance costs due to longevity—it becomes clear that investing in this technology pays off over time.

GEE SMA’s Contribution to Advancements

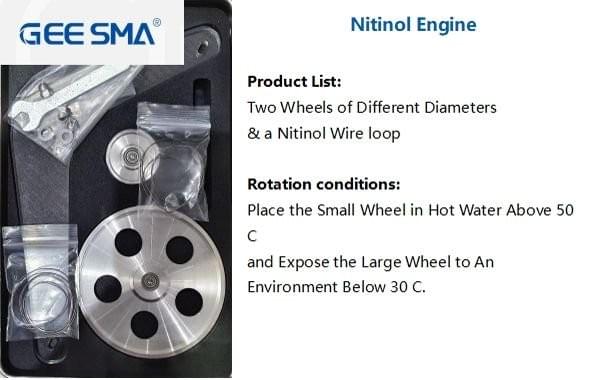

GEE SMA (Shape Memory Alloys) has been at the forefront of advancing nitinol technology through innovative research and development efforts focused on enhancing actuator performance even further. By investing heavily in refining production techniques and material quality control processes, GEE SMA ensures that every nitinol linear actuator meets rigorous industry standards while pushing boundaries on what’s possible with shape memory alloys.

Their commitment extends beyond mere production; GEE SMA actively collaborates with engineers across multiple sectors—from healthcare innovations like minimally invasive surgical tools to cutting-edge robotics—to integrate advanced features into their products effectively. As a result, they have become pivotal players in shaping how we think about actuation technology today.

Ultimately, GEE SMA’s contributions highlight not just advancements within their own product offerings but also serve as a catalyst for broader industry changes—demonstrating how embracing new technologies like nitinol can lead us toward smarter solutions across diverse fields while answering questions about what is the difference between nitinol and Flexinol? The answer lies primarily in application focus and specific material characteristics tailored by innovators like GEE SMA.

Cost Factors: Why Are Linear Actuators So Expensive?

When considering a nitinol linear actuator, one can't help but notice the price tag often attached to these innovative devices. Understanding why linear actuators are so expensive requires delving into several key factors, including production costs, material quality, and the long-term value they provide. By examining these elements, we can better appreciate what makes nitinol linear actuators a worthwhile investment.

Breakdown of Production Costs

The production costs of nitinol linear actuators are influenced by various factors that contribute to their overall expense. First and foremost is the intricate manufacturing process required to create shape memory alloys like nitinol; this involves precise temperature control and specialized techniques that ensure the material retains its unique properties. Additionally, the demand for high-quality components further drives up costs, as manufacturers strive to meet rigorous industry standards in sectors such as aerospace and medical devices.

Another aspect of production costs comes from research and development investments aimed at enhancing nitinol's capabilities. Companies continually invest in exploring new applications for this remarkable alloy, which adds to their operational expenses but ultimately benefits consumers with improved products. As a result, understanding why linear actuators are so expensive becomes clearer when factoring in these essential components of production.

The Role of Material Quality

Material quality plays a critical role in determining both the performance and cost of nitinol linear actuators. Nitinol is renowned for its unique properties—specifically its shape memory effect—which allows it to return to a predetermined shape when heated after being deformed. This exceptional characteristic not only enhances functionality but also necessitates sourcing high-grade materials that can withstand repeated thermal cycles without degradation.

Moreover, ensuring consistent quality throughout production is paramount for manufacturers aiming to deliver reliable products across various applications. This focus on quality assurance contributes significantly to the overall cost of nitinol linear actuators compared to other types available on the market. As we explore what are the advantages of nitinol?, it becomes evident that investing in high-quality materials leads to superior performance and longevity.

Long-Term Value of Nitinol

While upfront costs may be higher for nitinol linear actuators than other actuator types, their long-term value should not be overlooked. These devices typically offer enhanced durability and reliability due to their unique properties, leading to lower maintenance requirements over time—a significant advantage for industries relying on precision engineering like robotics or medical equipment design. In essence, while you may pay more initially for a nitinol actuator, you may save money down the line through reduced replacement rates and maintenance needs.

Additionally, as technology continues evolving with advancements such as smart systems integrating with nitinol actuators, users can expect even greater efficiencies from these devices moving forward. Understanding what are the 4 types of linear actuators? reveals how each type has its pros and cons; however, many users find that investing in high-quality options like those made from nitinol pays off substantially over time due to their exceptional performance characteristics.

In conclusion, while there’s no denying that prices associated with purchasing a nitinol linear actuator can be steep at first glance—considering aspects like production costs tied closely with material quality—the long-term benefits make them an attractive choice for many applications requiring reliable actuation solutions.

Nitinol vs. Flexinol: Key Differences

When discussing advanced materials for linear actuators, the spotlight often falls on nitinol and Flexinol. Both are shape memory alloys that exhibit unique properties, but they cater to different needs in the realm of nitinol linear actuators. Understanding their differences can help you make an informed choice for your specific applications.

Exploring Material Properties

Nitinol is a nickel-titanium alloy known for its remarkable ability to return to a predetermined shape when heated, making it an ideal candidate for nitinol linear actuators. On the other hand, Flexinol is another type of shape memory alloy primarily composed of nickel and copper, which also boasts similar properties but with distinct characteristics. While both materials offer impressive actuation capabilities, the composition affects their thermal response and mechanical strength.

One significant difference lies in their transformation temperatures; nitinol typically operates at higher temperatures compared to Flexinol, which can be advantageous depending on the application requirements. Additionally, nitinol has superior fatigue resistance and durability in demanding environments, making it a reliable choice for long-term use. In contrast, Flexinol may be more suitable for lightweight applications where less force is required.

Performance in Real-Life Applications

In real-world scenarios, the performance of nitinol linear actuators versus Flexinol can vary significantly based on operational demands. For instance, nitinol's ability to generate higher forces makes it ideal for applications such as robotic surgery or aerospace components where precision and reliability are critical. Meanwhile, Flexinol might excel in simpler tasks like small-scale robotics or hobby projects due to its lower cost and sufficient performance.

Moreover, when considering what are the advantages of nitinol? Its versatility shines through in medical devices that require miniaturization without sacrificing power output or responsiveness—qualities that are essential in life-saving technologies. Conversely, while Flexinol offers some advantages like easier processing and lower costs upfront, it may not match the rigorous demands placed upon high-performance systems.

Choosing the Right Alloy for Your Needs

Selecting between nitinol and Flexinol ultimately depends on your project's specific requirements—be it cost sensitivity or performance expectations associated with what are the 4 types of linear actuators? If you're working on a project that requires high strength and durability under varying conditions without frequent replacements or maintenance costs (a nod to why are linear actuators so expensive?), then investing in a nitinol linear actuator might be worth every penny.

However, if your application allows for flexibility with lighter loads and budget constraints come into play—Flexinol could be your go-to option without compromising too much on functionality. Understanding these differences will empower you to choose wisely based on factors such as load requirements, environmental conditions, and long-term operational goals while ensuring you harness the full potential of these remarkable materials.

Conclusion

As we wrap up our exploration of nitinol linear actuators, it's clear that these remarkable devices are not just a passing trend but a significant advancement in technology. The future of nitinol linear actuators looks promising, with continuous innovations and applications emerging across various fields. From robotics to medical devices, the potential for growth is immense, paving the way for smarter and more efficient solutions.

The Future of Nitinol Linear Actuators

The future of nitinol linear actuators is bright, with ongoing research and development aimed at enhancing their performance and application scope. As industries seek more efficient alternatives to traditional actuators, understanding what are the 4 types of linear actuators becomes crucial in identifying where nitinol can excel further. With advancements in material science and engineering techniques, we can expect even more versatile designs that capitalize on the unique properties of nitinol.

How GEE SMA is Shaping Technology

GEE SMA is at the forefront of this revolution, pushing boundaries and setting new standards in actuator technology. Their commitment to innovation has led to groundbreaking developments that exemplify why nitinol is becoming a preferred choice among engineers and designers alike. By incorporating cutting-edge techniques into production processes, GEE SMA not only enhances performance but also addresses concerns about why linear actuators are so expensive by optimizing cost-efficiency without compromising quality.

Embracing Shape Memory Alloys in Innovations

Embracing shape memory alloys like nitinol opens up a world of possibilities for future innovations across multiple sectors. As industries continue to explore what are the advantages of nitinol, they will find its ability to undergo significant deformation while returning to its original shape invaluable in practical applications. In comparison with other materials such as Flexinol, understanding what is the difference between nitinol and Flexinol will help companies make informed decisions tailored to their specific needs.