Introduction

In the world of advanced materials, few substances capture the imagination quite like Nitinol. This remarkable alloy, composed primarily of nickel and titanium, possesses unique properties that set it apart from traditional metals. With its ability to return to a predetermined shape when heated, Nitinol is not just a scientific curiosity; it’s paving the way for innovative applications in technology and engineering.

Discover the Unique Properties of Nitinol

Nitinol is renowned for its shape memory effect, a phenomenon that allows this metal to remember its original form even after being deformed. This property makes nitinol wire particularly versatile, as it can be used in various applications ranging from medical devices to robotics. The combination of flexibility and strength in this metal nitinol opens up new avenues for design and functionality that were previously unattainable with conventional materials.

Applications of Nitinol in Technology

The applications of nitinol muscle wire are vast and varied, showcasing its potential across multiple industries. In medicine, for instance, nitinol is used in stents and guidewires due to its biocompatibility and ability to adapt under different conditions within the human body. Similarly, in robotics, shape memory alloy nitinol provides lightweight actuation solutions that enhance performance while reducing energy consumption—truly a game changer for engineers.

Why Nitinol is the Future of Alloys

As we look towards the future, it's clear that Nitinol will play an increasingly pivotal role in engineering advancements. Its unique properties not only improve existing technologies but also inspire entirely new innovations across sectors such as aerospace and automotive industries. With ongoing research into enhancing its capabilities further, there’s no doubt that nitinol will continue to capture our imaginations—and revolutionize how we think about alloys.

Understanding Nitinol SMA

Nitinol, a remarkable alloy composed primarily of nickel and titanium, is a standout player in the world of materials science. Its name is derived from its origins at the Naval Ordnance Laboratory, where it was first discovered in the 1960s. This unique composition gives rise to extraordinary properties that make nitinol muscle wire and other forms of this shape memory alloy invaluable across various applications.

What is Nitinol?

Nitinol is a specific type of shape memory alloy (SMA) known for its ability to return to a predetermined shape when heated above a certain temperature. This characteristic makes nitinol particularly useful in applications requiring precise movement and control, such as robotics and medical devices. The combination of nickel and titanium in metal nitinol results in an alloy that exhibits both superelasticity and shape memory effects, setting it apart from traditional metals.

Characteristics of Shape Memory Alloys

Shape memory alloys like nitinol possess two key characteristics: the shape memory effect and superelasticity. The shape memory effect allows these materials to remember their original form after being deformed, while superelasticity enables them to undergo significant deformation without permanent change when subjected to stress within certain temperature ranges. These traits make nitinol wire an ideal choice for applications demanding flexibility and resilience, outperforming conventional materials.

How Nitinol Differs from Traditional Metals

Unlike traditional metals that may bend or break under stress, nitinol exhibits unique behavior due to its phase transformations between martensite and austenite states. While typical metals might struggle with fatigue over time, the design of nitinol muscle wire allows it to withstand repeated cycles without losing functionality or structural integrity. This remarkable durability combined with its lightweight nature means that titanium wire products made from nitinol can revolutionize industries ranging from aerospace engineering to healthcare.

Nitinol Muscle Wire: A Game Changer

Nitinol muscle wire is revolutionizing the way we think about actuation and movement in various fields, from robotics to medicine. This remarkable alloy, composed of nickel and titanium, exhibits unique properties that allow it to change shape and exert force when heated. With its ability to return to a predetermined shape, nitinol wire is not just another metal; it's a game changer in the world of materials science.

How Nitinol Muscle Wire Works

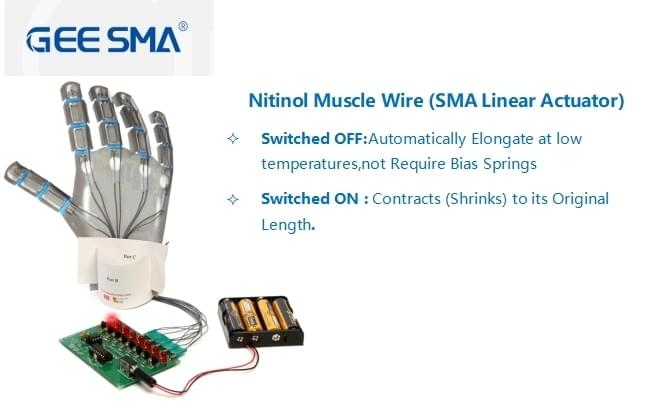

The magic of nitinol muscle wire lies in its shape memory effect, a defining characteristic of shape memory alloys (SMAs). When the metal nitinol is deformed at lower temperatures, it can return to its original form when heated above a specific threshold. This property allows nitinol muscle wire to contract or expand with precision, making it ideal for applications requiring controlled movement and force generation.

When electrical current flows through the nitinol wire, it heats up due to resistance, triggering the phase transformation from martensite (the low-temperature phase) to austenite (the high-temperature phase). As this transformation occurs, the wire contracts dramatically—an action that can be harnessed for various practical applications. In essence, by simply adjusting temperature or applying current, engineers can manipulate this titanium wire into performing tasks traditionally reserved for bulky motors or actuators.

Applications in Robotics and Medicine

Nitinol muscle wire has found its niche in both robotics and medical devices due to its lightweight nature and high strength-to-weight ratio. In robotics, it serves as an innovative actuator that mimics natural muscle movements with great efficiency. This capability allows robots equipped with nitinol wires to perform delicate tasks such as gripping objects or walking with fluidity—tasks that would be challenging with conventional systems.

In medicine, nitinol's unique properties make it indispensable for creating minimally invasive devices like stents and guidewires used during surgeries. The flexibility and strength of shape memory alloy nitinol enable these devices to navigate complex anatomical structures while returning to their functional shapes once deployed within the body. This ensures better patient outcomes while reducing recovery times—truly a win-win scenario!

Benefits Over Conventional Actuators

One of the standout benefits of using nitinol muscle wire over traditional actuators is its compact size combined with significant force output. Unlike bulky electric motors that require extensive space and energy consumption, this metal nitinol solution offers a streamlined alternative capable of fitting into tight spaces without sacrificing performance. Moreover, since it operates on thermal principles rather than mechanical parts prone to wear-and-tear, maintenance becomes less frequent.

Additionally, because shape memory alloy nitinol can operate silently without generating noise typical of mechanical systems or motors, it's perfect for applications where discretion is essential—think surgical robots or assistive devices in quiet environments like libraries or hospitals! The energy efficiency also stands out; less power is consumed compared to conventional actuators which translates into longer operational timeframes between charges—a critical factor in portable technology.

The Science Behind Shape Memory

The science behind shape memory alloys, particularly nitinol, is a fascinating blend of physics and engineering that has revolutionized various fields. Nitinol, a nickel-titanium alloy, exhibits unique properties that allow it to return to a predetermined shape when heated above a specific temperature. This remarkable ability is what makes nitinol muscle wire and other forms of this metal so invaluable in applications ranging from robotics to medical devices.

The Shape Memory Effect Explained

The shape memory effect is the cornerstone of nitinol's functionality as a shape memory alloy. When deformed at lower temperatures, nitinol can remember its original form and return to it once heated above its transformation temperature. This phenomenon occurs due to the unique arrangement of atoms in the metal nitinol, which allows for reversible phase changes between two distinct structural states: martensite (the low-temperature phase) and austenite (the high-temperature phase).

In practical terms, this means that when you cool down your nitinol wire after it's been shaped into one configuration and then heat it up again, it will revert back to its original design. This property is not just intriguing; it's also incredibly useful in applications where precise movements are required without complex mechanical systems. Nitinol muscle wire leverages this effect for actuation purposes in various technologies.

Phase Transformations in Nitinol

Understanding the phase transformations in nitinol is crucial for harnessing its capabilities effectively. At lower temperatures, nitinol exists in the martensitic state, which allows it to be easily deformed into various shapes without permanent damage. However, once heated past a critical threshold—typically around 70°C—the alloy transitions into the stronger austenitic state where it regains its original form.

This transition isn't merely about heat; it's also influenced by factors like composition—specifically the ratio of nickel to titanium—which can alter transformation temperatures and mechanical properties significantly. For instance, variations in these elements can result in different grades of titanium wire that perform better under specific conditions or loads. Understanding these transformations helps engineers design more efficient systems using nitinol wire for both commercial and industrial applications.

Factors Influencing Shape Recovery

Several factors influence how effectively and efficiently shape recovery occurs in nitinol muscle wire or any other form of this alloy. One major factor is temperature control; if the heating process isn’t uniform or sufficient, parts may not fully revert to their intended shapes. Additionally, stress levels during deformation play an important role; excessive stress can lead to incomplete recovery or even permanent deformation.

Another critical element involves processing techniques used during manufacturing; methods such as cold working or annealing can affect how well the material retains its shape memory properties over time. Moreover, environmental factors like corrosion resistance become essential when considering long-term applications—especially for medical implants made from metal nitinol that must endure bodily fluids over extended periods without losing functionality or integrity.

By understanding these underlying scientific principles governing shape memory alloys like nitinol nickel titanium composites, engineers can innovate new solutions across various industries—from advanced robotics utilizing muscle wires for movement to sophisticated medical devices designed with precision engineering at their core.

GEE SMA: Leader in Nitinol Production

When it comes to the forefront of nitinol production, GEE SMA stands out as a trailblazer. This company is dedicated to harnessing the remarkable properties of nitinol, a unique alloy composed of nickel and titanium, to create innovative solutions across various industries. With a mission centered on quality and sustainability, GEE SMA is redefining what’s possible with shape memory alloys.

Overview of GEE SMA and its Mission

GEE SMA is committed to advancing the field of shape memory alloys through cutting-edge research and development. Their focus on nitinol muscle wire has positioned them as industry leaders, providing high-performance components for applications ranging from robotics to medical devices. By prioritizing innovation and environmental responsibility, GEE SMA aims to make nitinol accessible for all sectors that can benefit from its unique properties.

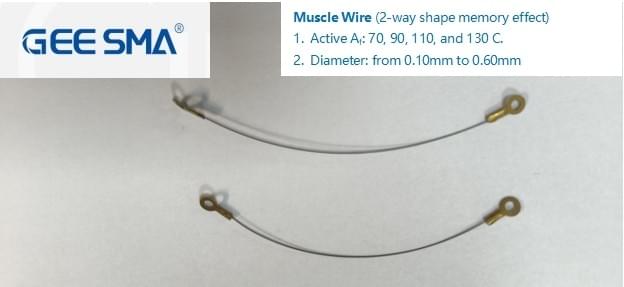

Crafting Quality Nitinol Components

At GEE SMA, crafting quality nitinol components involves meticulous attention to detail and state-of-the-art manufacturing processes. The company specializes in producing various forms of metal nitinol, including wires and sheets that exhibit exceptional shape memory effects. Their expertise in titanium wire fabrication ensures that each piece meets stringent performance standards, making their products reliable choices for engineers seeking effective solutions involving shape memory alloy nitinol.

Role of GEE SMA in Space Exploration

GEE SMA's contributions extend beyond terrestrial applications; they play a pivotal role in space exploration as well. The lightweight yet robust characteristics of nitinol make it an ideal material for spacecraft components where reliability is crucial under extreme conditions. By integrating nitinol muscle wire into aerospace designs, GEE SMA helps push the boundaries of engineering possibilities while ensuring safety and efficiency in missions beyond Earth.

Real-World Applications of Nitinol

Nitinol, with its unique properties as a shape memory alloy, has found its way into various industries, revolutionizing how we approach engineering challenges. From the operating room to aerospace and robotics, the versatility of nitinol muscle wire is truly remarkable. Let's take a closer look at some of its most impactful applications in the real world.

Use in Medical Devices and Implants

Nitinol has made significant strides in the medical field, particularly in devices and implants designed to improve patient outcomes. The shape memory alloy nitinol is often used in stents, where it expands to support blood vessels after being deployed from a compressed state. Additionally, nitinol wire serves as an essential component in guidewires and catheters due to its flexibility and ability to return to a predetermined shape after deformation.

The biocompatibility of nitinol nickel titanium makes it an ideal choice for implants that can remain within the human body without causing adverse reactions. Surgeons appreciate how nitinol muscle wire can be manipulated during procedures but will revert to its original configuration once released. This feature not only simplifies complex surgeries but also enhances recovery times for patients.

Moreover, innovations like self-expanding stents made from metal nitinol have transformed treatment options for cardiovascular issues. These advancements highlight why medical professionals are increasingly opting for devices crafted from this remarkable alloy, ensuring that patients receive cutting-edge care with minimal invasiveness.

Nitinol in Aerospace Engineering

In aerospace engineering, weight reduction and reliability are paramount; this is where nitinol shines brightly! The lightweight nature of titanium wire combined with the strength of metal nitinol allows for innovative designs that were once thought impossible. For example, components such as actuators and couplings made from shape memory alloy nitinol provide exceptional performance while significantly reducing overall aircraft weight.

The ability of nitinol muscle wire to undergo significant deformation while maintaining structural integrity makes it ideal for applications requiring precise movements under varying conditions—think flaps or landing gear systems that need reliable operation at high altitudes or extreme temperatures. Engineers are increasingly incorporating this versatile material into their designs due to its superior fatigue resistance compared to traditional metals.

Furthermore, space agencies have begun exploring the potential uses of shape memory alloys like nitinol beyond Earth’s atmosphere. With missions requiring materials that can withstand harsh conditions while offering adaptability and reliability, it's no wonder that metal nitinol is gaining traction among aerospace engineers looking towards future explorations.

Innovations in Robotics with Nitinol

When it comes to robotics, agility and responsiveness are critical traits; enter nitinol muscle wire! This remarkable material enables robots to perform tasks more efficiently by providing lightweight actuation solutions that traditional motors cannot match. The integration of shape memory alloy technology allows robotic systems not only to move swiftly but also adapt their shapes according to specific tasks or environments—think about robots navigating tight spaces or performing delicate operations!

One exciting application involves using titanium wire made from metal nitinol within soft robotics—where flexibility is key! Robots equipped with this technology can mimic natural movements found in animals or humans thanks to the unique properties offered by these alloys; they contract when heated and return back when cooled down—a feature no conventional actuator could replicate easily.

Moreover, innovations such as robotic prosthetics now leverage the benefits offered by shape memory alloy nitinol for better user experience through enhanced functionality coupled with reduced weight burdens on users’ limbs! As engineers continue pushing boundaries using these advanced materials like muscle wire derived from metal nitrionl—the future looks bright indeed!

Conclusion

In conclusion, the future of shape memory alloys is bright, particularly for nitinol. As industries continue to explore innovative materials, nitinol muscle wire stands out for its unique properties and versatility. With ongoing advancements in technology and research, we can expect even more revolutionary applications of shape memory alloy nitinol in various fields.

The Future of Shape Memory Alloys

The future of shape memory alloys looks promising as they are increasingly integrated into cutting-edge technologies. Nitinol, a remarkable combination of nickel and titanium, offers unparalleled advantages that traditional metals simply cannot match. As researchers continue to unlock the potential of nitinol wire, we may witness breakthroughs in robotics, medicine, and beyond that transform our daily lives.

Nitinol’s Impact on Engineering

Nitinol's impact on engineering is profound; it has redefined how we approach design and functionality across multiple sectors. From medical devices to aerospace applications, the unique characteristics of metal nitinol allow engineers to create lighter, more efficient components that enhance performance while reducing costs. The ability to harness the properties of shape memory alloy nitinol means that engineers can now tackle challenges previously thought insurmountable.

Why You Should Consider Nitinol Wire

If you’re looking for a material that combines strength with flexibility and innovation, consider using nitinol wire in your projects. Its impressive capabilities as a muscle wire make it an ideal choice for applications ranging from robotics to medical devices where precision is paramount. By embracing the advantages offered by this extraordinary alloy—such as its lightweight nature and remarkable recovery properties—you’ll be at the forefront of technological advancement.