Introduction

Nitinol, an intriguing alloy of nickel and titanium, has carved a niche for itself across various industries due to its unique properties. This remarkable material is not only known for its shape memory effect but also for its versatility in applications ranging from medical devices to robotics. As the demand for nitinol continues to grow, understanding who manufactures nitinol and the role of nitinol wire suppliers becomes essential.

Understanding Nitinol and Its Applications

Nitinol's distinct characteristics stem from its ability to return to a predetermined shape when heated, making it a game-changer in many fields. From stents that expand within arteries to actuators in robotics, the applications of nitinol are vast and varied. Exploring these uses sheds light on why nitinol wire suppliers play such a critical role in bringing this innovative material into practical use.

The Role of Nickel in Alloys

Nickel is not just a supporting actor; it’s a key player in the formation of nitinol's unique properties. The combination of nickel with titanium creates an alloy that exhibits exceptional strength and flexibility while maintaining lightweight characteristics. Understanding why nickel is so crucial helps us appreciate the intricacies behind what makes nitinol so expensive compared to other materials.

Overview of Nitinol Wire Suppliers

With the rising popularity of nitinol, numerous suppliers have emerged, each offering their own variations and specialties within this alloy market. Knowing who manufactures nitinol can guide you toward reliable sources for your projects or research needs. As you explore different options among nitinol wire suppliers, consider factors like product quality, pricing, and customer service to ensure you make an informed choice.

What is Nitinol?

Nitinol, a fascinating alloy primarily composed of nickel and titanium, has garnered significant attention in various industries due to its unique properties. This remarkable material exhibits both shape memory and superelasticity, making it a game-changer for applications ranging from medical devices to robotics. But what exactly is nitinol, and why do so many nitinol wire suppliers emphasize its importance?

Definition and Composition

Nitinol stands for Nickel Titanium Naval Ordnance Laboratory, where it was first discovered in the 1960s. The alloy typically consists of approximately 55% nickel and 45% titanium, although variations can occur depending on specific applications or desired properties. Who manufactures nitinol? Various companies have emerged as leading nitinol wire suppliers, producing high-quality materials tailored for diverse uses.

Shape Memory Effect Explained

One of the most intriguing aspects of nitinol is its shape memory effect, which allows the material to return to a predetermined shape when heated above a certain temperature. This phenomenon occurs because the atomic structure of nitinol can switch between two distinct phases: martensite (the low-temperature phase) and austenite (the high-temperature phase). As such, this property makes nitinol an ideal choice for applications like stents in medical devices, showcasing why many manufacturers prioritize this alloy.

Key Properties of Nitinol

Nitinol possesses several key properties that set it apart from other materials, making it highly sought after by various industries. Its superelasticity allows it to undergo significant deformation without permanent changes when stress is applied—this resilience is often highlighted by nitinol wire suppliers as a major advantage over traditional metals. Additionally, the combination of biocompatibility and corrosion resistance further solidifies its position as a top material choice in sectors like healthcare and aerospace.

Nitinol Wire Suppliers You Should Know

When diving into the world of nitinol, it’s essential to know who the key players are among nitinol wire suppliers. These manufacturers not only provide high-quality products but also contribute significantly to advancements in various industries that utilize nitinol. Understanding who manufactures nitinol can help you make informed choices for your projects.

Leading Manufacturers in the Industry

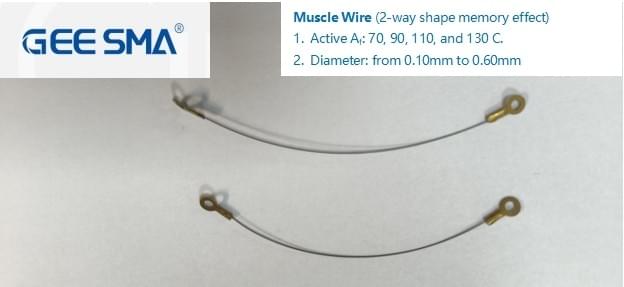

Several leading manufacturers dominate the market for nitinol wire suppliers, each bringing unique offerings and innovations to the table. Companies like Johnson & Johnson, Fort Wayne Metals, and GEE SMA are prominent names that have established themselves as reliable sources of nitinol products. Their extensive experience and commitment to quality ensure that customers receive top-notch materials suitable for applications ranging from medical devices to aerospace technology.

These manufacturers often invest heavily in research and development, paving the way for new advancements in nitinol technology. As a result, they frequently introduce innovative solutions that address some of the common disadvantages of nitinol, such as temperature sensitivity and durability concerns. By keeping an eye on these industry leaders, you can stay updated on emerging trends and product offerings.

Notable Products from GEE SMA

GEE SMA is one of the standout players among nitinol wire suppliers, known for its exceptional range of shape memory alloys (SMAs). Their product line includes various forms of nitinol wire that cater to diverse applications across industries like healthcare, robotics, and aerospace engineering. With a focus on quality control and customization options, GEE SMA has earned a reputation for delivering reliable products tailored to specific customer needs.

One notable product is their superelastic nitinol wire which provides remarkable flexibility while maintaining its original shape under stress—ideal for medical implants where biocompatibility is crucial. Additionally, GEE SMA offers specialized coatings and treatments that enhance performance characteristics while addressing concerns related to long-term durability. When considering which supplier to choose from among numerous nitinol wire suppliers, GEE SMA’s innovative offerings stand out.

How to Choose a Reliable Supplier

Selecting a reliable supplier from the myriad of available nitinol wire suppliers requires careful consideration of several factors. First off, assess their reputation within the industry; look for reviews or testimonials from previous clients regarding their experiences with product quality and customer service. An established track record often indicates reliability—after all, who manufactures nitinol should be trustworthy enough to deliver consistent results.

Next up is evaluating their product range; you want a supplier who offers various options tailored specifically for your project needs while also being responsive when it comes time to address any questions or concerns about their products or services. Additionally, consider pricing structures—while understanding why is nitinol so expensive can help justify costs against competitors’ prices; you still want competitive rates without compromising quality.

Lastly—and perhaps most importantly—ensure they provide comprehensive support throughout your purchasing journey! Whether it involves technical assistance during installation or guidance on best practices for use cases involving potential disadvantages of nitinol like temperature sensitivity or durability issues; having access to knowledgeable support personnel can make all the difference in ensuring successful outcomes with your chosen materials.

The Cost of Nitinol: Why Is It So Expensive?

Nitinol, the remarkable alloy known for its shape memory effect and superelastic properties, comes with a price tag that often raises eyebrows. But what exactly makes nitinol so expensive? Understanding the factors influencing its pricing can shed light on why this unique material is a significant investment for industries ranging from medical devices to aerospace.

Factors Influencing Nitinol Pricing

Several factors contribute to the high cost of nitinol, starting with its complex manufacturing process. The production requires precise control over composition and temperature, making it labor-intensive and time-consuming. Additionally, the raw materials used in nitinol wire suppliers often come at a premium; nickel and titanium prices fluctuate based on market demand, impacting overall costs.

Another consideration is the stringent quality control measures required for nitinol products, especially those used in medical applications where reliability is paramount. Manufacturers must adhere to rigorous standards that ensure safety and performance, adding layers of expense to the production process. Finally, research and development costs are significant as innovations continue to emerge within this field; companies invest heavily in improving nitinol's properties or finding new applications.

Comparison with Other Materials

When comparing nitinol to other materials like stainless steel or aluminum, it's clear that while these alternatives may be cheaper upfront, they lack some of the unique benefits offered by nitinol. For instance, stainless steel may be less costly but does not exhibit the shape memory effect—one of nitinol's standout features—making it less suitable for certain applications like stents or actuators. Similarly, while aluminum might be lightweight and affordable for various engineering solutions, it cannot match nitinol's performance under stress or strain.

Moreover, when considering long-term value rather than just initial costs, investing in nitinol can pay off due to its durability and versatility across multiple industries. This means that while you might pay more initially for products from reputable nitinol wire suppliers, you could save money down the line through reduced maintenance costs or increased efficiency in applications such as robotics or aerospace innovations.

Is the Cost Worth It?

The question Is the cost worth it? ultimately depends on your specific needs and application requirements. For industries where precision and reliability are non-negotiable—like medical devices—the investment in high-quality nitinol is often justified by improved outcomes and patient safety. However, if you're working on projects where budget constraints are tighter or performance requirements are less stringent, exploring alternatives may be advisable.

In conclusion, while many wonder who manufactures nitinol at such high prices or why is it so expensive?—the answer lies in understanding its unique properties coupled with manufacturing intricacies that drive up costs. Ultimately though—with advancements continually emerging—the future looks bright for this extraordinary alloy as new names like shape memory alloys gain traction alongside traditional terms like nitinol.

The Applications of Nitinol Wire

Nitinol wire is rapidly becoming a game-changer across various industries due to its unique properties, particularly the shape memory effect and superelasticity. These characteristics enable it to return to a predetermined shape when heated, making it ideal for applications requiring precision and reliability. Let’s dive into some of the most notable applications of nitinol wire, exploring how it’s transforming fields like medicine, aerospace, and robotics.

Medical Devices and Implants

In the medical field, nitinol wire suppliers are at the forefront of innovation with devices that save lives. Nitinol's biocompatibility and flexibility make it perfect for stents, guidewires, and other implants that must navigate the complexities of human anatomy. Who manufactures nitinol? Many leading companies specialize in creating these life-saving devices that leverage nitinol's unique properties to improve patient outcomes.

The ability of nitinol to expand at body temperature makes it invaluable in minimally invasive surgeries, where doctors can rely on its shape memory effect for precision placement. However, it's essential to consider why is nitinol so expensive? The intricate manufacturing processes and high-quality standards necessary for medical-grade nitinol contribute significantly to its price tag.

Aerospace Innovations

Nitinol is not just limited to healthcare; it's making waves in aerospace innovations as well. Its lightweight yet strong nature allows engineers to design components that can withstand extreme temperatures while maintaining structural integrity. As aerospace technology advances, nitinol wire suppliers are increasingly sought after for components such as actuators and control surfaces that require precise movements under varying conditions.

What is the new name for nitinol? Some refer to it as shape memory alloy, which captures its defining characteristic perfectly—its ability to remember a specific shape when subjected to heat or stress. This innovative material helps reduce weight in aircraft designs without sacrificing performance or safety.

Robotics and Engineering Solutions

In robotics and engineering solutions, nitinol wire is revolutionizing how we think about movement and adaptability in machines. Its superelastic properties allow robots equipped with nitinol components to perform tasks with greater agility than traditional materials would allow. This flexibility opens up new avenues for robotic design—think soft robotics or adaptive grippers that mimic human dexterity.

However, one must also be aware of what are the disadvantages of nitinol? While its benefits are numerous, challenges such as sensitivity to temperature fluctuations can limit its application range in some environments. Engineers must carefully consider these factors when designing systems that incorporate this remarkable material.

Exploring the Disadvantages of Nitinol

While Nitinol boasts impressive properties, it’s not without its drawbacks. Understanding these disadvantages is crucial for industries that rely on this unique material. Let’s delve into some of the key limitations associated with Nitinol.

Limitations in Certain Applications

Nitinol is not a one-size-fits-all solution; it has limitations that can hinder its effectiveness in specific applications. For instance, while its shape memory effect makes it ideal for medical devices, it may not perform as well in high-stress environments like heavy machinery or structural components. Additionally, certain industries may find that alternatives to Nitinol are more suitable due to cost or performance considerations, raising the question: who manufactures nitinol if they’re looking for specialized applications?

Sensitivity to Temperature

One of the most notable disadvantages of Nitinol is its sensitivity to temperature fluctuations. The material's unique properties are closely tied to specific temperature ranges, meaning that any deviation can lead to unpredictable behavior. This sensitivity can pose challenges in environments where temperature control is difficult, making it essential for users to consider the operational conditions when sourcing from nitinol wire suppliers.

Long-Term Durability Concerns

Long-term durability is another concern when working with Nitinol materials. While they exhibit excellent fatigue resistance under normal conditions, their performance may degrade over extended periods or under extreme operational stresses. Manufacturers and users alike must weigh these durability concerns against the benefits of using Nitinol—prompting a deeper exploration into why nitinol is so expensive and whether those costs justify potential long-term issues.

Conclusion

In summary, the future of Nitinol in various industries looks promising, with its unique properties paving the way for innovative applications. As we continue to explore what is the new name for nitinol, it’s clear that this material will remain at the forefront of technological advancements. With a growing number of nitinol wire suppliers entering the market, manufacturers are likely to enhance their offerings and drive competition.

The Future of Nitinol in Industry

The potential for Nitinol in industrial applications is vast, especially as new suppliers emerge and existing ones expand their capabilities. Who manufactures nitinol? Many companies are investing in research and development to unlock further uses for this remarkable alloy. As industries such as medical devices, aerospace, and robotics evolve, Nitinol's role will become increasingly critical.

Innovations in Nitinol Technology

Innovations surrounding Nitinol technology are continuously reshaping its applications and market presence. From advanced manufacturing techniques to novel alloy compositions, these developments address some of the disadvantages of nitinol while enhancing performance characteristics. Moreover, understanding why is nitinol so expensive helps manufacturers justify investments in cutting-edge processes that improve quality and functionality.

Final Thoughts on Nitinol Wire

Nitinol wire remains a fascinating topic within materials science due to its unique attributes and diverse applications. While it's important to weigh its advantages against what are the disadvantages of nitinol—such as sensitivity to temperature—its benefits often outweigh these concerns when used appropriately. As more nitinol wire suppliers emerge with innovative solutions, we can expect a bright future filled with exciting possibilities.