Introduction

Nitinol, a unique alloy of nickel and titanium, has captured the fascination of industries and innovators alike due to its remarkable properties. This material not only boasts superelasticity but also shape memory capabilities, making it a game-changer in various applications. From medical devices to everyday items, understanding the appeal of nitinol wire is essential for grasping its potential impact across multiple sectors.

Understanding Nitinol and its Appeal

What is nitinol wire used for? The answer lies in its ability to return to a predetermined shape when subjected to specific temperatures or stress conditions. This extraordinary quality allows nitinol wire to be utilized in diverse applications, ranging from surgical instruments like the nitinol guide wire to innovative designs such as the nitinol paperclip. As industries explore new frontiers, understanding how this alloy works helps underscore why it’s become such an appealing choice.

The Superelastic and Shape Memory Properties

The superelastic and shape memory properties of nitinol are at the heart of its functionality. When heated above a certain temperature, it can revert back to its original shape after being deformed—this is particularly useful in medical contexts where precision is paramount. However, potential users often wonder about factors like nitinol wire price or what are the disadvantages of nitinol? These considerations are crucial when evaluating whether this high-tech material fits their needs.

Nitinol Applications Across Industries

From medical applications like nitinol wire mesh used in stents to innovative consumer products that utilize these unique properties, the versatility of nitinol is astounding. It’s not just confined to healthcare; robotics and automation have also embraced this resilient material for enhanced performance under stress. As we delve deeper into each application area throughout this piece, we’ll explore how many times can nitinol be used effectively while weighing cost versus benefit in practical scenarios.

What is Nitinol Wire?

Nitinol wire is a unique metal alloy that has gained significant attention due to its remarkable properties, particularly in the medical field and various engineering applications. Comprised primarily of nickel and titanium, this wire can exhibit two fascinating behaviors: shape memory and superelasticity. Understanding what nitinol wire is and how it functions opens the door to exploring its diverse applications, advantages, and even some limitations.

Composition and Structure

Nitinol is an acronym for Nickel Titanium Naval Ordnance Laboratory, where it was first discovered. The alloy typically consists of approximately 55% nickel and 45% titanium, but these ratios can be adjusted slightly to tailor specific properties for different applications. The atomic structure of nitinol allows it to exist in two distinct phases: austenite at higher temperatures and martensite at lower temperatures, which are crucial for its shape memory capabilities.

The Science Behind Shape Memory

The science behind shape memory in nitinol wire lies in its ability to remember a predetermined shape when subjected to heat or stress. When deformed at low temperatures in its martensitic phase, heating the wire will cause it to revert back to its original austenitic form—effectively remembering that initial configuration. This characteristic makes nitinol incredibly useful in various applications such as the creation of medical devices like nitinol guide wires or even playful items like a nitinol paperclip that can return to its original form when warmed.

Advantages of Using Nitinol Wire

Using nitinol wire comes with numerous advantages that make it highly sought after across multiple industries. First off, it's lightweight yet strong, offering excellent tensile strength while being easy to manipulate—ideal for intricate designs like nitinol wire mesh used in biomedical applications or other structural uses. Additionally, the unique properties of nitinol allow for flexibility under stress without permanent deformation; however, one must also consider what are the disadvantages of nitinol? While it's versatile and effective for many purposes—including medical uses such as guide wires—the cost associated with high-quality materials means potential users often inquire about nitinol wire price before making purchasing decisions.

Nitinol Wire in Medical Applications

Nitinol wire has emerged as a game-changer in the medical field, thanks to its unique properties. This material, known for its superelastic and shape memory characteristics, is particularly valuable in various medical devices and procedures. With applications ranging from stents to guide wires, nitinol wire is revolutionizing how healthcare professionals approach treatment.

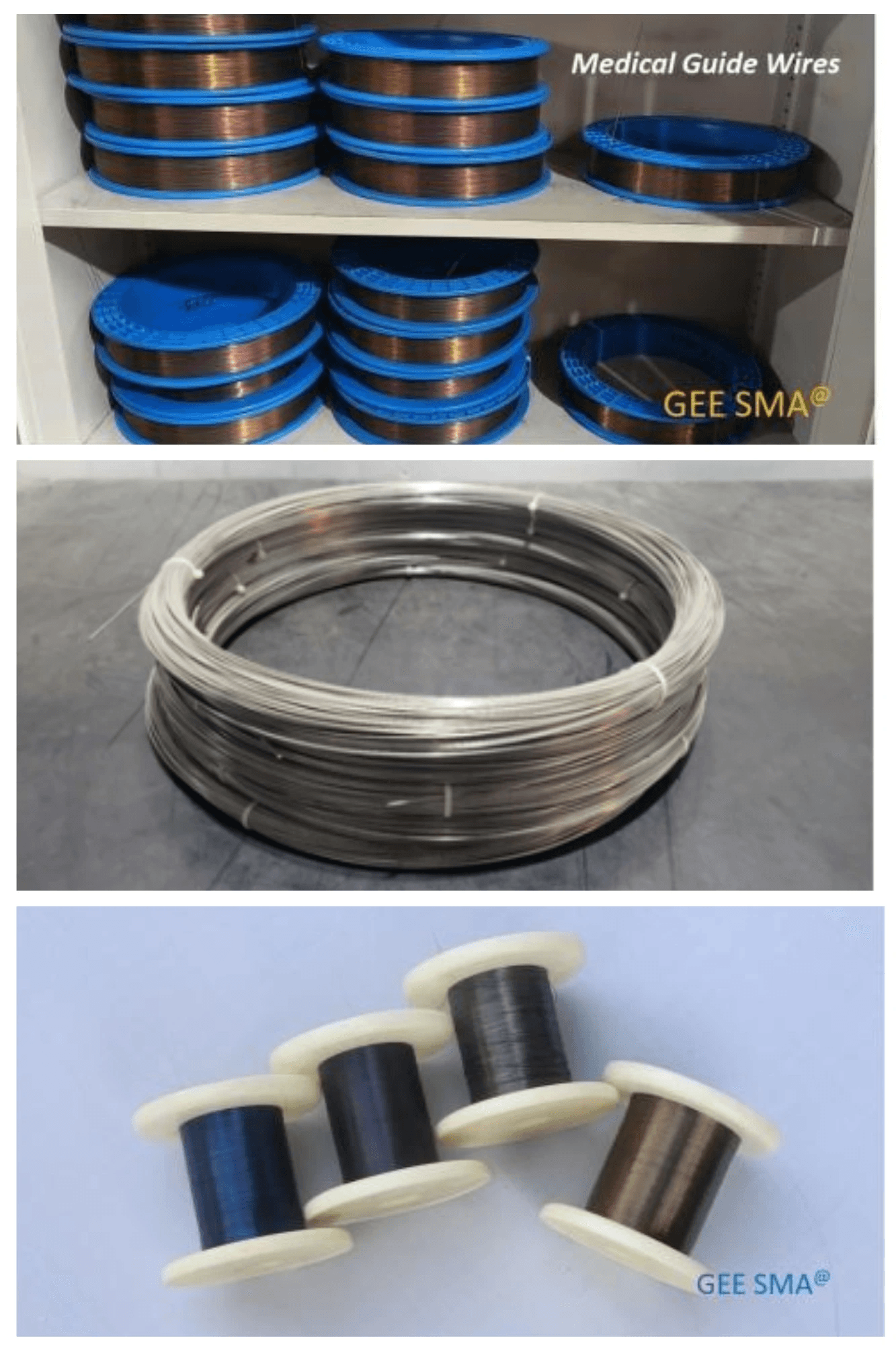

Nitinol Guide Wire in Procedures

One of the most significant uses of nitinol is in the creation of guide wires for minimally invasive procedures. These nitinol guide wires are designed to navigate complex vascular systems with ease, facilitating the placement of catheters or other instruments. The flexibility and strength of nitinol allow these wires to withstand sharp bends without breaking, making them indispensable in modern medicine.

When evaluating the effectiveness of nitinol guide wires, one must consider their role in reducing patient recovery time and improving overall outcomes. The ability to maneuver through tight spaces means less trauma to surrounding tissues, which can lead to shorter hospital stays and lower healthcare costs. However, potential users should also be aware that nitinol wire price can vary significantly based on specifications and suppliers.

Benefits of Nitinol Wire Medical Devices

The benefits of using nitinol wire in medical devices extend beyond just flexibility; they also include biocompatibility and durability. Devices made from this alloy are less likely to cause adverse reactions when implanted into the body, enhancing patient safety. Additionally, the shape memory property allows devices like stents to expand at body temperature after being delivered through a smaller catheter.

Another major advantage is that many nitinol wire medical devices can be reused multiple times without significant degradation—though it’s essential to consider how many times can nitinol be used effectively before performance diminishes. This reusability factor contributes positively when weighing cost versus benefit; while initial investments may seem high due to varying nitinol wire prices across suppliers, long-term savings can be substantial due to reduced need for replacements.

Nitinol Wire Mesh: Uses and Benefits

Nitinol wire mesh is another innovative application that showcases this material's versatility within healthcare settings. Often used for stenting or structural support within various organs or vessels, this mesh provides critical reinforcement while maintaining flexibility—allowing it to adapt dynamically under physiological conditions. Its unique properties help ensure that once deployed within the body, it remains effective over time.

In addition to its mechanical benefits, using a nitinol wire mesh significantly enhances patient comfort compared with traditional materials that may irritate tissue or cause complications post-surgery. However, just like other forms of medical equipment made from this alloy, users should remain informed about what are the disadvantages of nitinol? Factors such as potential fatigue under stress must be considered during design phases for optimal performance.

As we explore these applications further—like those nifty little gadgets such as a nitinol paperclip—we see how this remarkable material continues pushing boundaries across industries while maintaining an essential foothold in medicine.

Evaluating Nitinol Wire Price

When it comes to nitinol wire price, several factors come into play that can significantly affect the overall cost. The composition and quality of the nitinol alloy, its diameter, and the specific manufacturing processes all contribute to variations in pricing. Additionally, market demand and availability can fluctuate, leading to changes in nitinol wire price over time.

Factors Affecting Nitinol Wire Cost

The cost of nitinol wire is influenced by its unique properties, including superelasticity and shape memory capabilities. Higher-quality nitinol wire that meets stringent medical standards often commands a premium due to additional processing steps and certifications required for medical applications. Furthermore, factors such as supplier relationships, production scale, and raw material costs also play critical roles in determining the final price of nitinol wire.

Comparing Prices Across Suppliers

When exploring what is nitinol wire used for? it's essential to compare prices across various suppliers to ensure you're getting the best deal without sacrificing quality. Different manufacturers may offer different pricing structures based on their production techniques and supply chain efficiencies. By conducting thorough research on multiple suppliers, you can find competitive pricing while assessing their reputation for reliability in delivering high-quality products like nitinol guide wires or nitinol mesh.

Cost versus Benefit in Applications

Evaluating the cost versus benefit of using nitinol wire involves understanding its diverse applications across industries. For example, while some might wonder about what are the disadvantages of nitinol?, its advantages often outweigh these concerns when considering long-term performance and functionality in critical medical devices like a nitinol guide wire or medical implants. Moreover, assessing how many times can nitinol be used? is crucial—its durability typically justifies its higher initial investment compared to conventional materials.

Limitations and Disadvantages of Nitinol

While Nitinol is celebrated for its unique properties, it's important to acknowledge some limitations and disadvantages that can impact its applications. Understanding these drawbacks is essential for industries considering using nitinol wire in their products or processes. From cost considerations to performance under stress, let's dive into what you need to know.

What Are the Disadvantages of Nitinol?

One of the primary disadvantages of nitinol is its relatively high cost compared to traditional materials. When evaluating nitinol wire price, potential users must consider whether the benefits justify this expense, especially for applications where cheaper alternatives exist. Additionally, while nitinol offers remarkable properties like shape memory and superelasticity, it can be challenging to process and manufacture, leading to increased production costs and complexity.

Another drawback lies in its sensitivity to temperature changes; if not properly managed, this can lead to unpredictable behavior in certain applications. For example, Nitinol wire medical devices must operate within specific temperature ranges to function correctly. If temperatures fluctuate beyond these limits, the material may fail to perform as intended.

Moreover, nitinol's fatigue resistance can be a concern in high-stress environments where repeated cycling occurs. This brings us to a crucial aspect: how many times can nitinol be used before it loses its effectiveness? Understanding these limitations helps manufacturers make informed decisions when incorporating nitinol wire into their designs.

Performance Under Stress: A Closer Look

When considering what is nitinol wire used for?, one must assess how it performs under stress conditions typical in various applications. While Nitinol exhibits excellent properties like flexibility and resilience during normal use, its performance may degrade when subjected to extreme forces or repeated bending cycles over time. This degradation raises questions about durability in demanding environments such as robotics or medical devices.

In particular, Nitinol guide wires used in surgical procedures face significant mechanical stresses that could compromise their integrity over time. Users should weigh the necessity of using nitinol against possible alternatives that might offer better performance under similar conditions without incurring higher costs associated with nitinol wire price.

Additionally, while innovations like Nitinol wire mesh are designed for strength and flexibility, they too may face limitations under extreme conditions or prolonged use scenarios. Ensuring rigorous testing protocols are followed will help mitigate risks associated with performance failures due to stress factors.

Longevity: How Many Times Can Nitinol Be Used?

The longevity of Nitinol products raises an essential question: how many times can nitinol be used before it loses functionality? In medical applications such as those involving Nitinol guide wires or other devices made from this alloy, understanding fatigue life becomes critical for patient safety and device reliability. Generally speaking, while some products may withstand numerous cycles without failure, others might show signs of wear after just a few uses.

Factors influencing longevity include manufacturing quality and design considerations tailored specifically for each application type—whether that's a simple Nitinol paperclip or complex medical devices utilizing advanced engineering techniques like those found in Nitinol wire mesh structures. Users should always consult manufacturer guidelines regarding expected lifespans based on specific usage scenarios.

Ultimately, balancing the advantages against these limitations will determine whether investing in materials such as nitinol is advantageous based on individual project needs—especially when evaluating overall costs versus benefits derived from using high-performance alloys like this one.

Diverse Uses of Nitinol in Everyday Life

Nitinol, with its unique properties, has found its way into various aspects of everyday life, proving that this remarkable alloy is not just confined to specialized applications. From innovative office supplies to cutting-edge robotics, the versatility of nitinol is astonishing. With a growing interest in its potential, understanding what nitinol wire is used for can reveal exciting possibilities.

Innovative Applications: Nitinol Paperclip

One of the most delightful applications of nitinol is the nitinol paperclip. Unlike traditional paperclips that bend and lose their shape over time, a nitinol paperclip can return to its original form even after being deformed. This quirky yet practical use showcases the shape memory properties of nitinol, making it a reliable tool for organizing documents without the worry of wear and tear.

The price point for these innovative paperclips can vary significantly based on the supplier and quantity purchased; thus, potential buyers should consider comparing prices before making a commitment. While some might question what are the disadvantages of nitinol in such applications—like cost or availability—the benefits often outweigh these concerns. After all, who wouldn’t want a resilient office supply that remains functional through countless uses?

Nitinol in Robotics and Automation

In robotics and automation, nitinol wire has emerged as a game changer due to its superelasticity and ability to perform precise movements without complex mechanisms. Engineers utilize nitinol wires in actuators that mimic muscle contractions, allowing robots to move more fluidly and efficiently than ever before. The incorporation of this material enhances both performance and longevity in robotic systems.

When evaluating how many times can nitinol be used effectively within these devices, it’s essential to understand that fatigue limits do exist but are often higher than those found in conventional materials. The versatility also allows for creative designs where traditional components would fail due to rigidity or weight considerations—making it an ideal choice for modern automation solutions. As industries continue exploring what is nitinol wire used for beyond medical devices or aerospace applications, we can expect even more groundbreaking innovations.

Resilient Designs: Where Else Is Nitinol Used?

Beyond paperwork and robotics, nitinol's resilient designs are finding homes in various other sectors—from eyewear frames to sporting goods like tennis rackets and fishing rods! Its ability to withstand deformation while returning to original shapes makes it perfect for products requiring durability without sacrificing aesthetics or functionality. This adaptability ensures that items made from nitinol not only last longer but also maintain their intended use throughout their lifecycle.

However, when considering purchasing products made from this alloy—especially if you’re looking at options like medical-grade items such as a nitinol guide wire or mesh—it's wise to evaluate the associated costs carefully against their performance benefits. For instance, while the initial investment may seem high due to factors affecting nitinol wire price comparisons across suppliers, the long-term advantages often justify this expense when considering how many times can these products be effectively utilized before showing signs of wear.

In summary, whether you’re intrigued by innovative office supplies like the nifty nitinol paperclip or curious about advancements in robotics using this remarkable alloy's properties—the diverse uses of Nitinol continue expanding into everyday life with impressive results.

Conclusion

In conclusion, Nitinol has carved a niche for itself across various industries due to its unique properties and versatility. As we look ahead, the future of Nitinol in industry appears bright, with ongoing research and development paving the way for innovative applications that could revolutionize how we approach engineering and medical solutions. As companies continue to explore what nitinol wire is used for, we can expect to see even more groundbreaking uses in everyday life.

The Future of Nitinol in Industry

The future of nitinol in industry looks promising as advancements in material science continue to unlock new possibilities. With its superelasticity and shape memory capabilities, nitinol wire is poised to play a significant role in sectors ranging from healthcare to robotics. However, it’s essential to keep an eye on the nitinol wire price as demand increases; balancing cost with innovation will be crucial for widespread adoption.

How GEE SMA is Leading Nitinol Innovation

GEE SMA stands at the forefront of nitinol innovation, pushing boundaries by developing cutting-edge applications for this remarkable material. Their commitment to quality ensures that products like the nitinol guide wire and nitinol wire mesh are not only effective but also reliable in critical medical procedures. By focusing on enhancing performance while keeping an eye on factors such as what are the disadvantages of nitinol?, GEE SMA strives to deliver solutions that meet both industry standards and customer expectations.

Exploring More Applications for Nitinol Wire

The versatility of nitinol wire opens doors for exploration into various applications beyond traditional uses—think about the nifty nitinol paperclip! From advanced medical devices like the nitinol guide wire used during surgeries to innovative designs in everyday items, there’s much more potential waiting to be tapped into. As industries evaluate how many times can nitinol be used? it becomes clear that understanding its limitations will help maximize benefits while addressing concerns regarding longevity and performance under stress.