Introduction

In the ever-evolving landscape of medicine, materials science plays a pivotal role in shaping the tools and devices that enhance patient care. Among these materials, Nitinol wire medical stands out due to its unique properties and capabilities, particularly in surgery devices where precision and reliability are paramount. This introduction sets the stage for exploring how Nitinol products have transformed medical applications, driven by innovative nitinol processing techniques and advancements in machining nitinol.

Understanding Nitinol in Medicine

Nitinol, a nickel-titanium alloy, is renowned for its remarkable superelasticity and shape memory characteristics, making it an ideal choice for various medical applications. Its ability to return to a predetermined shape after deformation allows for the creation of highly effective surgical devices that can navigate complex anatomical structures with ease. As we delve deeper into the world of medical nitinol, we will uncover how this extraordinary material enhances both the functionality and safety of medical procedures.

The Role of Mandrels and Wire

In the intricate manufacturing process of nitinol wire forming, mandrels serve as unsung heroes that ensure precision and consistency in creating complex shapes required for various medical applications. These specialized tools not only facilitate accurate shaping but also influence the overall performance of nitinol products used in surgery devices. By examining different types of mandrels utilized in nitinol processing, we can appreciate their critical contribution to optimizing device performance.

Innovations in Medical Device Development

The landscape of healthcare is continually reshaped by innovations that leverage advanced materials like Nitinol wire medical to improve patient outcomes. From stents to guidewires, advancements in nitinol processing have led to breakthroughs that enhance device efficacy while minimizing invasiveness during procedures. As we explore these innovations further, we'll see how collaboration between engineers and manufacturers fosters new developments that meet evolving patient needs.

What is Nitinol Wire?

Nitinol wire is a unique alloy primarily composed of nickel and titanium, celebrated for its remarkable properties that make it a game-changer in the medical field. This wire exhibits two key characteristics: shape memory and superelasticity, which allow it to return to a predetermined shape when exposed to specific conditions. These attributes are particularly beneficial in the realm of surgery devices, where precision and reliability are paramount.

Properties of Nitinol Wire Medical

The properties of nitinol wire medical are nothing short of extraordinary. Its superelastic nature means that it can undergo significant deformation while maintaining its structural integrity, which is crucial during procedures involving delicate tissues and organs. Additionally, nitinol's biocompatibility ensures minimal adverse reactions when implanted in the human body, making it an ideal choice for various applications in medical nitinol devices.

Moreover, nitinol wire forming techniques allow manufacturers to create intricate shapes that can navigate through complex anatomical pathways with ease. The ability to tailor these wires during machining nitinol processes enhances their performance in surgical applications, ensuring they meet the specific needs of healthcare professionals and patients alike. Ultimately, these properties contribute to improved patient outcomes and increased safety during surgical interventions.

Comparison with Traditional Materials

When comparing nitinol products with traditional materials like stainless steel or plastic, it's clear that nitinol holds several advantages. While stainless steel is durable, it lacks the flexibility and adaptability offered by nitinol wire medical; this flexibility allows for better maneuverability within the body during minimally invasive procedures. Plastic materials may be lightweight but often fall short in terms of strength and biocompatibility when compared to their metal counterparts.

Furthermore, traditional materials can sometimes lead to complications such as corrosion or degradation over time; however, nitinol's unique composition resists these issues effectively. This durability translates into longer-lasting implants and devices that maintain their effectiveness throughout their intended lifespan. In essence, choosing nitinol over conventional materials not only enhances device performance but also prioritizes patient safety.

Applications in Medical Devices

The applications of nitinol wire medical are vast and varied across numerous surgical specialties. From stents used in vascular surgeries to guidewires for catheterization procedures, the versatility of this material has revolutionized how medical professionals approach complex cases. Nitinol products have also found their way into orthopedic implants and dental applications due to their superior mechanical properties.

In addition to traditional uses, ongoing innovations continue to unlock new potential for this remarkable alloy in developing cutting-edge surgical tools and devices tailored specifically for patient needs. The adaptability afforded by machining nitinol allows engineers to design specialized instruments that can cater directly to unique anatomical challenges faced during surgery—an aspect that's becoming increasingly vital as personalized medicine gains traction within healthcare systems worldwide. With each advancement in technology comes new opportunities for integrating medical nitinol solutions into everyday practice.

The Science Behind Superelasticity

Superelasticity is one of the most fascinating properties of nitinol wire medical, transforming how we approach surgical devices and medical applications. This unique phenomenon allows nitinol products to undergo significant deformation while returning to their original shape when stress is removed. Understanding how superelasticity works provides insight into why nitinol has become a preferred material in various medical fields.

How Superelasticity Works

Superelasticity in nitinol wire medical arises from its ability to undergo a phase transformation between two distinct crystal structures: austenite and martensite. When subjected to stress, the material shifts from its stable austenitic state to a more flexible martensitic form, allowing it to bend and stretch without permanent deformation. Once the stress is released, the material reverts to its original austenitic configuration, showcasing its remarkable resilience and flexibility—ideal for surgery devices that require precision and adaptability.

Benefits for Medical Applications

The benefits of superelasticity are manifold, particularly in the realm of medical nitinol applications. First and foremost, this property allows for greater flexibility in surgical instruments like stents and guidewires, enabling them to navigate complex anatomical pathways with ease. Additionally, superelastic nitinol products reduce the risk of damage during procedures since they can absorb significant amounts of energy without breaking—a critical factor in ensuring patient safety during surgeries.

Case Studies of Superelastic Devices

Several case studies highlight the practical advantages of superelastic devices made from nitinol wire forming techniques. For instance, many modern stents utilize superelastic nitinol due to their ability to expand upon deployment while maintaining structural integrity within blood vessels—leading to improved patient outcomes post-surgery. Another example includes guidewires that flexibly navigate through tortuous pathways; these devices showcase how machining nitinol can lead to innovative solutions that enhance procedural efficiency and effectiveness.

Mandrels: The Unsung Heroes

When it comes to the world of medical device manufacturing, mandrels play a pivotal role that often goes unnoticed. These essential tools are used in the shaping and forming of nitinol wire medical products, ensuring precision and reliability in surgery devices. Without effective mandrel design and application, the performance of nitinol medical devices could be significantly compromised.

Importance in Medical Device Manufacturing

Mandrels are crucial for the successful processing of nitinol wire medical applications, as they provide the necessary support during the wire forming process. They ensure that nitinol products maintain their intended shape and functionality throughout various stages of manufacturing and assembly. This importance cannot be overstated; without quality mandrels, surgical devices would lack consistency and reliability, potentially jeopardizing patient outcomes.

The significance of mandrels extends beyond just shaping; they also facilitate machining nitinol to achieve intricate designs required for specialized medical applications. By providing a stable base during fabrication, mandrels enable manufacturers to create complex geometries that enhance device performance. In essence, these unsung heroes are foundational to producing high-quality nitinol medical devices that meet stringent industry standards.

Types of Mandrels Used

There’s a variety of mandrel types utilized in the production of nitinol wire forming processes tailored for specific applications within surgery devices. Common types include solid mandrels, which provide robust support for simple shapes, and collapsible or expandable mandrels designed for more complex configurations that require flexibility during insertion or deployment within the body. Each type serves its purpose based on the intricacies involved in creating specific nitinol products.

Moreover, specialized coated mandrels can enhance the machining nitinol process by reducing friction and wear during production runs. This helps extend tool life while ensuring consistent results across batches of surgical devices. Understanding these different types allows manufacturers to select the appropriate tools for their unique needs when developing innovative medical solutions.

Impact on Device Performance

The impact of mandrel choice on device performance is profound; a well-designed mandrel can elevate a surgical device from mediocre to exceptional levels of efficiency and efficacy in patient care. By allowing precise control over dimensions during manufacturing processes like nitinol processing, they ensure that each component fits together seamlessly within complex assemblies used in various procedures. This precision is vital not only for functionality but also for patient safety.

Furthermore, effective use of mandrels contributes directly to minimizing defects or inconsistencies found in finished products—issues that could lead to complications or failure during surgeries involving nitinol wire medical components. In turn, this enhances overall trust among healthcare providers who rely on these advanced materials for life-saving interventions. Ultimately, choosing high-quality tooling like specialized mandrels is an investment into better health outcomes facilitated by superior nitinol medical technologies.

GEE SMA: Leaders in Nitinol Solutions

In the realm of medical technology, GEE SMA has emerged as a formidable player, renowned for its innovative contributions to nitinol solutions. Their commitment to advancing nitinol wire medical applications has led to significant breakthroughs in surgery devices and other critical medical tools. By prioritizing quality and precision in nitinol processing, GEE SMA ensures that their products meet the stringent demands of the healthcare industry.

Overview of GEE SMA’s Contributions

GEE SMA has carved out a niche by specializing in high-performance nitinol products that are essential for modern medical applications. Their expertise encompasses everything from nitinol wire forming to advanced machining nitinol techniques, allowing them to produce components that enhance the efficacy of surgical devices. This dedication not only improves device functionality but also elevates patient outcomes through enhanced safety and reliability.

Collaborations with Medical Engineers

Collaboration is at the heart of GEE SMA's success, as they work closely with medical engineers to tailor solutions that address specific challenges within the healthcare sector. By engaging in dialogue with professionals who understand the intricacies of surgery devices, they can develop innovative designs using medical nitinol that push boundaries and redefine possibilities. These partnerships are crucial for ensuring that every aspect of their nitinol wire medical offerings aligns with real-world needs and technological advancements.

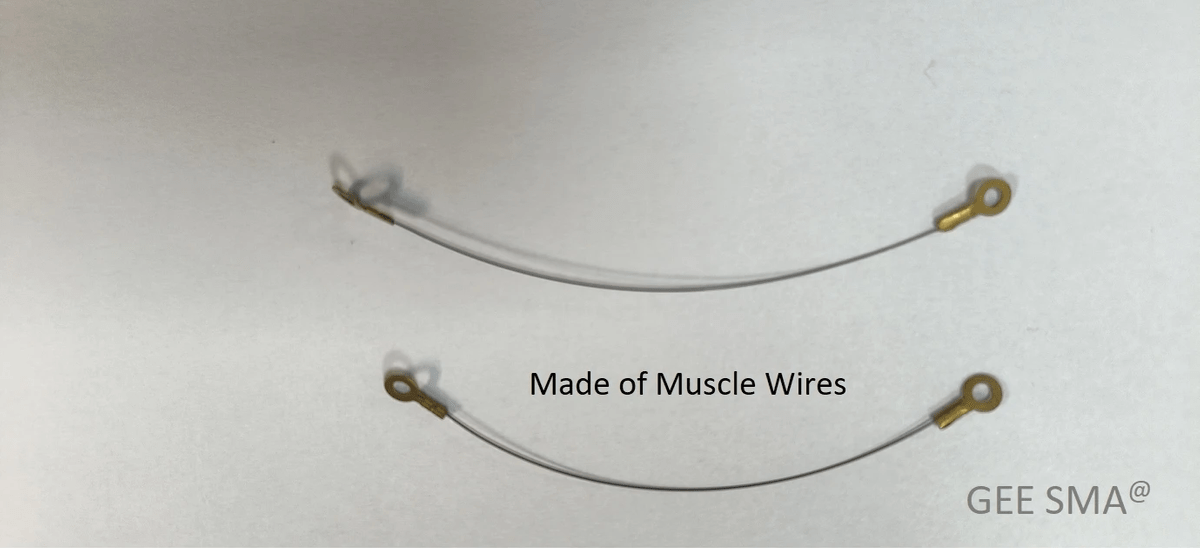

Customization of Nitinol Wire Medical

One of GEE SMA's standout features is their ability to customize nitinol wire medical products according to unique client specifications. This flexibility allows them to cater to various applications, from minimally invasive surgical tools to specialized implants requiring precise dimensions and properties. By focusing on customization, they empower healthcare providers with tailored solutions that enhance both performance and patient care.

Future Trends in Nitinol Applications

The landscape of healthcare is rapidly evolving, and nitinol wire medical is at the forefront of this transformation. As we delve into future trends, it’s essential to recognize how emerging technologies are reshaping the way surgery devices are designed and utilized. From 3D printing to advanced imaging techniques, these innovations are paving the way for more personalized and efficient medical solutions that leverage the unique properties of nitinol products.

Emerging Technologies in Healthcare

In recent years, there has been a significant surge in the development of technologies that enhance surgical precision and patient outcomes. For instance, robotics integrated with nitinol wire forming techniques allow for minimally invasive procedures that reduce recovery times and improve overall patient comfort. Additionally, advancements in nitinol processing have led to improved biocompatibility and durability of medical devices, making them safer for long-term use.

Moreover, machine learning algorithms are being employed to analyze patient data more effectively, enabling tailored treatment plans that incorporate nitinol medical devices specifically designed for individual needs. These technologies not only streamline surgical procedures but also open new avenues for research into innovative applications of nitinol wire medical. As healthcare continues to embrace these advancements, we can expect an exciting future where nitinol products play an even more critical role.

Potential New Uses for Nitinol

With its remarkable properties such as superelasticity and shape memory effect, the potential applications of nitinol extend well beyond traditional uses in stents and guidewires. Researchers are exploring novel uses in orthopedic implants where nitinol's flexibility can provide better integration with bone structures while reducing stress on surrounding tissues during motion. This could revolutionize how surgeries involving joint replacements or fracture repairs are approached.

Additionally, there is growing interest in utilizing nitinol wire medical for dynamic implants that can adapt to physiological changes over time—think smart devices that respond to body movements or changes in temperature! The versatility of machining nitinol allows engineers to create complex geometries that were previously unattainable with conventional materials. As innovation continues to drive exploration into new uses for this remarkable alloy, we might see breakthroughs across various fields within medicine.

The Role of Innovation in Patient Care

Innovation is not just about creating new products; it’s about enhancing patient care through thoughtful design and application of technology—especially when it comes to medical nitinol solutions. By focusing on patient-centric designs that utilize advanced materials like nitinol wire forming techniques, manufacturers can develop devices that offer better performance while minimizing risks associated with traditional surgery devices. This shift towards prioritizing user experience will undoubtedly lead to improved recovery times and overall satisfaction among patients.

Furthermore, collaboration between engineers and healthcare professionals is crucial for driving innovation forward; they bring together clinical insights with technical expertise necessary for developing cutting-edge solutions using nitinol products effectively. As we look ahead at future trends within healthcare technology—particularly those involving medical applications—the synergy between innovation and patient care will be paramount in shaping a healthier tomorrow.

Conclusion

In the ever-evolving landscape of healthcare, the impact of nitinol on medical advancements cannot be overstated. Nitinol wire medical has revolutionized surgery devices, making procedures less invasive and more efficient. As we reflect on its contributions, it becomes clear that nitinol products are not just materials; they represent a transformative approach to patient care.

The Impact of Nitinol on Healthcare

The introduction of nitinol wire medical into surgical practices has significantly improved outcomes for patients across various specialties. Its unique properties, such as superelasticity and shape memory, allow for innovative designs in surgery devices that adapt seamlessly to the human body. This adaptability enhances precision during procedures, ultimately leading to quicker recovery times and better overall patient experiences.

Merging Innovation with Patient Needs

At the heart of every successful medical device lies a commitment to meeting patient needs through innovation. By leveraging advanced nitinol processing techniques and machining nitinol with precision, manufacturers can create custom solutions tailored specifically for individual cases. This focus on personalization not only improves device performance but also fosters trust between healthcare providers and patients.

Why Choose GEE SMA for Nitinol Solutions

When it comes to selecting a partner in developing nitinol medical solutions, GEE SMA stands out as a leader in the industry. Their expertise in nitinol wire forming ensures that every product is crafted with attention to detail and quality standards that meet rigorous medical requirements. With a dedication to innovation and collaboration with engineers, choosing GEE SMA means investing in reliable solutions that prioritize patient safety and satisfaction.