Introduction

Nitinol wire is a remarkable material that has captured the attention of various industries due to its unique properties. This alloy, primarily composed of nickel and titanium, exhibits both shape memory and superelastic characteristics, making it an invaluable component in numerous applications. From medical devices to aerospace technology, understanding what makes nitinol so special can provide insights into its growing importance in modern engineering.

Overview of Nitinol Wire

What is a nitinol guidewire? At its core, nitinol wire is designed to remember a predetermined shape when heated above a specific transformation temperature. This property allows it to return to this original form after being deformed, which is why it's often utilized in medical applications such as guidewires and stents. The versatility of nitinol wire extends beyond medicine; its unique qualities make it suitable for various industrial uses.

Importance of Shape Memory Alloys

Shape memory alloys (SMAs), like nitinol, are crucial in advancing technology across multiple fields. These materials can undergo significant deformation but revert to their original shape when subjected to heat or specific conditions—an attribute that opens doors for innovative designs and applications. In the context of what is nitinol used for?, the answer spans from enhancing medical devices to improving robotic functionality and even aerospace components.

Applications of Nitinol in Various Industries

Nitinol's adaptability shines through its diverse applications across different sectors. In medicine alone, it's commonly used in devices such as stents and catheters; however, the question how to activate nitinol wire? also arises when exploring its functionality in these settings. Beyond healthcare, industries like robotics and consumer products are leveraging this alloy's properties for everything from flexible actuators to innovative fasteners—demonstrating just how integral nitinol has become in modern manufacturing processes.

What is a Nitinol Guidewire?

When diving into the world of medical devices, one term that frequently pops up is nitinol guidewire. But what is a nitinol guidewire, exactly? It's a specialized tool made from Nitinol, a unique alloy of nickel and titanium known for its remarkable shape memory and superelastic properties. This means that the wire can return to a predetermined shape when heated, making it an invaluable asset in various medical procedures.

Definition and Composition

A nitinol guidewire is essentially a thin, flexible wire used to navigate through blood vessels or other pathways in the body during surgical procedures. Its composition primarily includes nickel and titanium, which gives it its distinctive properties. This combination allows the guidewire to be both strong and pliable, enabling it to maneuver around tight corners and obstacles within the human anatomy.

Key Features and Benefits

The key features of nitinol guidewires include their flexibility, strength, and ability to maintain their shape under stress. One major benefit is their superelasticity; they can bend significantly without breaking or losing their original form. Additionally, these wires are biocompatible, meaning they won’t cause adverse reactions when introduced into the body—a crucial factor in medical applications.

Common Uses in Medicine

Nitinol guidewires are commonly used in various medical procedures such as angioplasty and stent placement. They serve as pathways for other instruments or devices to follow into hard-to-reach areas of the body. Beyond vascular applications, these wires also find use in urology and gastroenterology for navigating complex anatomical structures—showcasing just how versatile nitinol can be!

What is Nitinol Used For?

Nitinol, a unique alloy of nickel and titanium, has carved out its niche in various fields due to its remarkable properties. From medical applications to robotics and consumer products, the versatility of nitinol is astounding. This section will explore how nitinol is utilized beyond just the well-known nitinol guidewire.

Medical Applications Beyond Guidewires

While the nitinol guidewire is a prominent example of this alloy's medical applications, it certainly isn’t the only one. Nitinol’s shape memory effect and superelasticity make it an excellent choice for stents, orthopedic devices, and even dental braces. These applications benefit from the material’s ability to return to a predetermined shape when heated or deformed, which aids in minimally invasive procedures and enhances patient comfort.

Moreover, nitinol's biocompatibility reduces the risk of adverse reactions when implanted in the body. This quality has led to its use in various surgical instruments and implants that require flexibility without sacrificing strength. In short, nitinol is revolutionizing not just how we think about medical devices but also how they are designed and implemented.

Role in Robotics and Aerospace

Nitinol isn't just making waves in healthcare; it's also finding its way into robotics and aerospace industries. The unique properties of this alloy allow for lightweight components that can withstand extreme conditions while still functioning effectively—perfect for robotic systems that require precision movement or adaptability under stress.

In aerospace applications, nitinol can be used for actuators that change shape or position with temperature variations, leading to more efficient designs for aircraft wings or other structures requiring dynamic adjustments during flight. The combination of strength and lightweight characteristics makes it an ideal candidate for advancing technology across these high-stakes fields.

Use in Consumer Products

The reach of nitinol extends even into everyday consumer products you might not expect! Items like eyeglass frames made from nitinol are both flexible and durable—ideal for those who lead active lifestyles or have children prone to bending their glasses.

Additionally, you might find this innovative material in self-heating hair styling tools or even certain types of jewelry that retain their shape despite being twisted or bent frequently. As consumers become more aware of materials like nitinol, we can anticipate an increase in creative uses across various sectors.

How to Activate Nitinol Wire?

Nitinol wire is a remarkable material known for its unique shape memory properties, which allow it to return to a pre-defined shape upon activation. Understanding how to activate nitinol wire is essential for harnessing its capabilities in various applications, including the medical field with devices like the nitinol guidewire. This section will delve into the transformation temperature, methods of activation, and real-world examples that illustrate how this fascinating alloy works.

Understanding the Transformation Temperature

The transformation temperature is a critical factor in activating nitinol wire; it determines when the wire will change from one phase to another—specifically from martensite (the low-temperature phase) to austenite (the high-temperature phase). This temperature can vary depending on the specific composition and processing of the nitinol alloy, typically ranging from 10°C to 100°C. For effective use in applications like the nitinol guidewire, it's vital for users to know this temperature as it influences how and when they can activate this versatile material.

Methods of Activation

Activating nitinol wire can be achieved through several methods that primarily involve heating or applying mechanical stress. The simplest way is by immersing the wire in hot water or using an external heat source such as a heat gun; both methods raise the temperature above its transformation point, allowing it to revert to its memorized shape. Another method involves using electrical resistance heating or even body heat in certain medical applications where devices like nitinol guidewires are used inside patients' bodies.

Real-World Examples of Activation

In practical scenarios, activation of nitinol wire plays a crucial role across various fields. For instance, in medicine, when deploying a nitinol guidewire during minimally invasive procedures, doctors often apply heat via saline solution or body warmth to ensure proper functioning and flexibility of the device within blood vessels. Similarly, in robotics and aerospace applications, engineers utilize controlled heating mechanisms that allow structures made from nitinol to adapt dynamically under different operational conditions—showcasing just how versatile and functional activated nitinol can be.

Is Nitinol Wire Safe for MRI?

When it comes to the intersection of advanced materials and medical imaging, one question often arises: is nitinol wire safe for MRI? Nitinol, a nickel-titanium alloy known for its unique shape memory and superelastic properties, is widely used in various medical devices, including the nitinol guidewire. Understanding the safety of nitinol in an MRI environment is crucial for both patients and healthcare providers.

Magnetic Properties of Nitinol

Nitinol has unique magnetic properties that set it apart from other metals commonly found in medical devices. Unlike ferromagnetic materials that can be attracted to magnets, nitinol is generally considered non-magnetic, which makes it less likely to pose risks during an MRI scan. However, while nitinol wire itself doesn’t react strongly to magnetic fields, its behavior can depend on specific compositions and manufacturing processes.

The composition of a nitinol guidewire typically ensures minimal interaction with MRI machines; thus, many healthcare professionals deem it safe for use in patients undergoing scans. Still, it's essential to note that while the wire itself may be safe, any additional components or attachments might not share the same properties. Therefore, understanding what is a nitinol guidewire helps clarify its compatibility with MRI technology.

Guidelines for MRI Procedures

To ensure patient safety when using a nitinol guidewire during an MRI procedure, several guidelines must be followed by healthcare practitioners. First and foremost, it's crucial to consult with the device manufacturer regarding specific recommendations related to their products' compatibility with MRIs. This includes verifying whether any additional components or coatings on the guidewire could interact adversely with the magnetic field.

Moreover, radiologists should always take into account not just the material but also how it’s utilized within medical devices when preparing for an MRI scan. If there are uncertainties about what is nitinol used for beyond guidewires—such as stents or other implants—it's wise to conduct thorough pre-scan assessments. These precautions help ensure that patients remain safe while benefiting from advanced imaging technologies.

Patient Safety Considerations

Patient safety remains paramount when discussing whether nitinol wire is safe for MRI procedures. While most studies indicate that using a nitinol guidewire poses minimal risk during scans due to its non-magnetic nature, individual patient circumstances must always be taken into account. Factors such as device placement within the body and potential interactions with surrounding tissues can influence overall safety.

Additionally, communication between patients and healthcare providers plays a critical role in ensuring safety during MRIs involving any metallic implants or devices made from materials like nitinol. Patients should feel empowered to ask questions about what is a nitinol guidewire and its implications before undergoing procedures involving MRIs or other imaging techniques. Ultimately, informed consent backed by thorough knowledge allows both parties to navigate potential risks effectively.

GEE SMA: Leading the Nitinol Revolution

In the realm of shape memory alloys, GEE SMA stands out as a pioneering force, particularly in the development and application of nitinol wire. This company has made it their mission to push the boundaries of what is possible with nitinol, focusing on both innovation and quality. By harnessing the unique properties of nitinol, they aim to enhance various industries, from medical devices to aerospace technology.

Company Overview and Mission

GEE SMA is committed to revolutionizing how we utilize nitinol wire across multiple sectors. Founded by a team of experts passionate about material science, their mission revolves around creating advanced solutions that address real-world challenges. With a strong emphasis on research and development, GEE SMA strives to lead in the production of high-performance nitinol guidewires and other applications.

Innovations in Nitinol Shape Memory Alloys

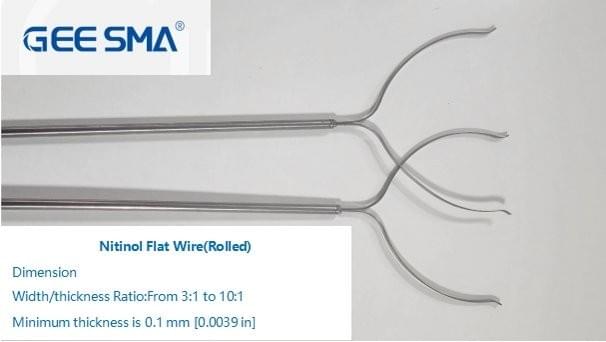

One of GEE SMA's key innovations lies in their proprietary manufacturing techniques that enhance the performance characteristics of nitinol wire. This includes improvements in flexibility, strength, and thermal responsiveness—qualities essential for applications like the nitinol guidewire used in minimally invasive surgeries. By continuously refining these attributes, GEE SMA not only meets but exceeds industry standards for what is nitinol used for? Their advancements promise greater safety and efficiency for medical professionals.

Contributions to Space Missions

The versatility of nitinol extends beyond Earthly applications; GEE SMA has made significant contributions to space missions as well. Their cutting-edge developments have enabled engineers to create components that can withstand extreme conditions while maintaining functionality—an essential trait for any space endeavor. With products derived from their advanced nitinol technologies, they are helping shape the future of exploration beyond our planet.

Conclusion

In wrapping up our exploration of Nitinol wire, it's clear that this remarkable material has diverse applications across various fields. From its pivotal role in medical devices, like the nitinol guidewire, to its innovative uses in robotics and consumer products, Nitinol has proven itself to be an invaluable asset. As we look ahead, the potential for shape memory alloys continues to expand, promising even more groundbreaking advancements.

Recap of Nitinol Wire Applications

Nitinol wire is primarily celebrated for its unique properties that enable it to return to a predetermined shape when activated. One of the standout applications is the nitinol guidewire, which plays a crucial role in minimally invasive surgeries by navigating complex vascular systems with ease. Beyond this, what is nitinol used for? The answer spans across industries including aerospace and robotics, where its strength and flexibility offer innovative solutions.

Future of Shape Memory Alloys

The future of shape memory alloys like Nitinol looks exceptionally bright as researchers continue to unlock new capabilities and applications. With advancements in activation methods—like understanding how to activate nitinol wire more efficiently—these materials could revolutionize areas such as smart textiles and adaptive structures. Moreover, as industries explore how safe is nitinol wire for MRI procedures, we may see even broader acceptance in clinical settings.

How GEE SMA is Shaping the Industry

GEE SMA stands at the forefront of the Nitinol revolution with its commitment to innovation and excellence in shape memory alloys. Their pioneering work not only enhances existing applications but also contributes significantly to emerging technologies and space missions. By addressing questions like what is a nitinol guidewire? or how can we ensure that it remains safe during MRI scans?, GEE SMA continues to lead the industry into an exciting future.