Introduction

Nitinol, a fascinating alloy composed primarily of titanium and nickel, stands out in the world of materials science due to its exceptional properties. Often referred to as a memory metal, superelastic nitinol exhibits remarkable capabilities that allow it to return to a predetermined shape after deformation. This unique behavior is not merely a parlor trick; it opens up a plethora of applications across various industries, making nitinol nickel titanium an essential material in modern engineering.

Understanding Nitinol's Unique Properties

What makes superelastic nitinol so intriguing is its ability to undergo significant deformation while maintaining its structural integrity. Unlike traditional metals, which may fracture under stress, this memory alloy can bend and twist yet revert back to its original form when heated or subjected to specific conditions. The combination of titanium and nickel creates an alloy that responds dynamically to temperature changes, showcasing properties that are both versatile and reliable.

The Science Behind Shape Memory Alloys

At the heart of nitinol's functionality lies the science of shape memory alloys (SMAs). These materials have the extraordinary ability to remember their original shapes thanks to phase transformations that occur at different temperatures. When heated above a certain threshold, superelastic nitinol transitions from one crystalline structure to another, allowing it to spring back into its designated form—a phenomenon that has captivated scientists and engineers alike.

What is Superelasticity in Nitinol?

Superelasticity is one of the hallmark features of nitinol nickel titanium that sets it apart from other memory alloys. This property enables the material to withstand substantial strains without permanent deformation when subjected to stress at or near body temperature. In practical terms, this means that components made from superelastic nitinol can absorb shock and recover their shape even after being stretched or compressed—an invaluable trait for applications ranging from medical devices to aerospace engineering.

The Basics of Nitinol

Nitinol, a fascinating alloy composed primarily of nickel and titanium, is a standout in the realm of materials science. This unique combination not only gives it its name—derived from Nickel Titanium Naval Ordnance Laboratory—but also imparts remarkable properties that have countless applications. Understanding the basics of nitinol sets the stage for appreciating its role as a game-changing shape memory alloy (SMA) and superelastic nitinol.

Composition and Structure of Nitinol

Nitinol is categorized as a shape memory alloy due to its distinct crystalline structure, which allows it to return to a predetermined shape when heated above a specific temperature. The typical composition includes approximately 50-60% nickel and 40-50% titanium, creating an intricate balance that enhances its unique properties. This precise ratio is crucial; even slight variations can significantly alter the behavior of nitinol, making it vital for engineers and manufacturers to adhere closely to these specifications.

The atomic arrangement in nitinol contributes to its ability to exhibit both the shape memory effect and superelasticity. When deformed at lower temperatures, it can revert back to its original form upon heating—a feature that has made it popular in various applications such as medical devices and robotics. Additionally, this structure allows for superelastic nitinol behavior, where the material can undergo significant deformation without permanent change when stress is applied within certain limits.

History and Development of Nitinol

The journey of nitinol began in 1962 at the Naval Ordnance Laboratory when researchers were exploring new materials for military applications. They discovered that an alloy made from titanium and nickel exhibited extraordinary properties unlike any other metal at that time—this was indeed a groundbreaking moment in material science! Over the years, further studies unveiled even more about this memory metal's capabilities, leading to extensive research into its practical uses.

As technology progressed through the late 20th century, industries began recognizing the potential benefits offered by nitinol’s unique characteristics. From aerospace engineering to biomedical applications like stents and guidewires, this remarkable alloy has found itself at home across diverse fields. Today’s advancements continue building on decades of research into superelastic nitinol, pushing boundaries further than ever before.

Applications of Nitinol in Modern Technology

Modern technology has embraced nitinol with open arms due to its versatility as both a shape memory alloy (SMA) and superelastic material. In medicine, for instance, nitinol is widely used in stents because it can be compressed during insertion but expands back into shape once inside the body—providing life-saving support with minimal invasiveness! Beyond healthcare, industries are utilizing this innovative material for actuators in robotics or even eyeglass frames that return to their original form after bending.

Furthermore, with ongoing advancements in manufacturing processes for nitinol nickel titanium alloys—the sky's truly the limit! Engineers are constantly finding new ways to exploit these materials’ unique properties across sectors such as automotive design or consumer electronics where flexibility paired with durability is paramount. As we continue exploring what superelasticity offers us today—and tomorrow—nitinol remains an essential player on our technological landscape.

Exploring the Shape Memory Effect

The shape memory effect is one of the most fascinating phenomena associated with superelastic nitinol, a unique alloy made from nickel titanium. This property allows materials to return to a predetermined shape when subjected to specific thermal conditions, making them incredibly useful in various applications. The underlying mechanism involves a phase transformation that occurs in the crystal structure of the memory metal, enabling it to remember its original form after deformation.

Mechanism of the Shape Memory Effect

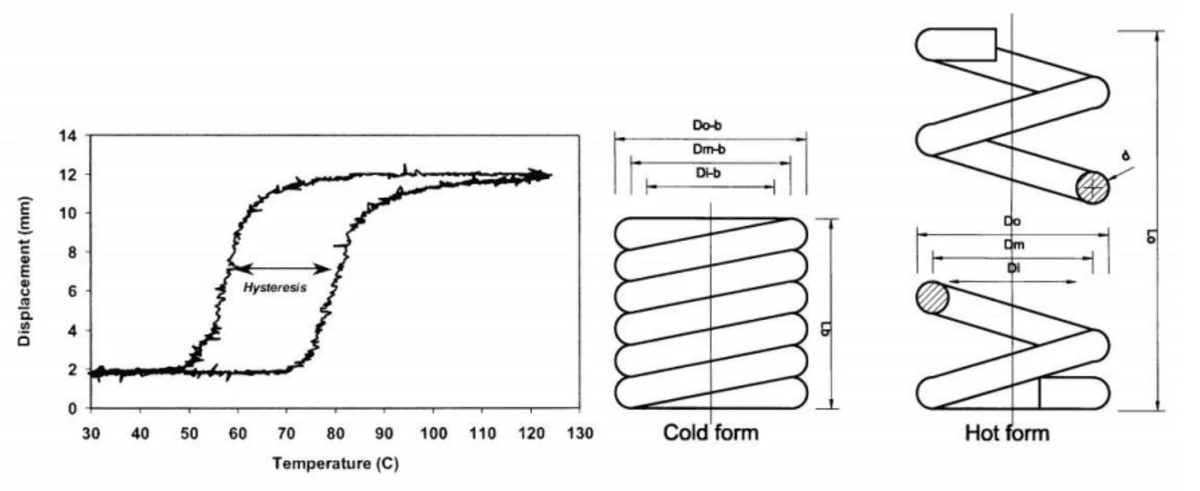

At its core, the shape memory effect relies on two distinct phases: martensite and austenite. When heated above a certain temperature, nitinol nickel titanium transitions from martensite—a low-temperature phase—into austenite, its high-temperature counterpart. This transformation allows the material to revert back to its original configuration after being deformed, showcasing why this memory alloy is so valuable in engineering and medical applications.

When cooled down again, superelastic nitinol can be deformed while still in its martensitic state but will return to its original shape once heated above its transformation temperature. This unique behavior makes SMA alloys like nitinol indispensable for devices that require precise movement or actuation without needing complex mechanical systems. Essentially, these materials combine flexibility with strength—an engineering dream come true!

Real-World Examples of Shape Memory Alloys

Shape memory alloys have permeated various industries due to their remarkable properties and versatility. In medicine, for instance, superelastic nitinol is used extensively in stents and guidewires because they can be inserted into narrow spaces and expand once they reach their target location within the body. Additionally, these memory metals are found in orthodontic wires that gently shift teeth over time by applying consistent force without causing discomfort.

Beyond healthcare, nitinol's applications extend into robotics and aerospace engineering as well! For example, SMA actuators can create movement in robotic arms or deploy mechanisms in spacecraft where traditional motors might fail due to extreme conditions. These real-world examples highlight how integrating nickel titanium into designs can lead to innovative solutions across multiple sectors.

Benefits of Using Shape Memory Metals

The benefits of using shape memory metals like superelastic nitinol are numerous and compelling! First off, their ability to undergo significant deformation while maintaining high energy efficiency means less wear on components—this translates into longer lifespans for devices made with these materials. Furthermore, their lightweight nature combined with strength makes them ideal for applications where reducing weight is crucial without sacrificing performance.

Another significant advantage lies in their biocompatibility; this quality ensures that devices made from nitinol nickel titanium can safely interact with biological tissues without causing adverse reactions—an essential factor for medical implants! Finally, the adaptability of these memory alloys allows engineers and designers more freedom when creating complex shapes or mechanisms that would be challenging using conventional materials alone.

Delving into Superelasticity

Superelasticity is one of the most fascinating properties of superelastic nitinol, a unique alloy composed primarily of nickel and titanium. This property allows the material to undergo significant deformation and then return to its original shape without permanent damage, making it a standout among memory metals. The underlying mechanism involves a reversible phase transformation that occurs under stress, enabling superelastic nitinol to exhibit remarkable resilience and flexibility.

How Superelastic Nitinol Works

The magic of superelastic nitinol lies in its ability to transition between different crystalline structures when subjected to stress. When deformed at temperatures above its transformation temperature, the alloy undergoes a change from its austenite phase to a martensitic phase, allowing it to stretch significantly without breaking. Upon removal of the stress, the material reverts back to its original shape through an equally reversible process, demonstrating why nitinol nickel titanium is so revered in engineering applications.

This unique behavior not only gives superelastic nitinol impressive mechanical properties but also enables it to absorb energy efficiently during deformation. As it bends or twists under load, this memory alloy can recover quickly and maintain its integrity over many cycles of use. Thus, engineers find themselves drawn to this remarkable material for applications where durability and flexibility are paramount.

Advantages of Superelasticity in Engineering

One major advantage of utilizing superelasticity in engineering is the reduction in component failure rates due to fatigue resistance offered by superelastic nitinol. Traditional materials often succumb to wear over time under repetitive stress; however, with memory alloys like nitinol nickel titanium, components can endure extensive use while maintaining their performance characteristics. This leads not only to longer-lasting products but also less frequent replacements—an appealing proposition for manufacturers aiming for efficiency.

Another benefit lies in design versatility; engineers can create intricate shapes that would be impossible with conventional materials while still leveraging the inherent elasticity provided by these SMA alloys. This opens up new possibilities for innovative designs across various industries—from automotive parts that require flexibility under load to consumer products that demand lightweight yet strong materials. Ultimately, this blend of functionality and creativity makes superelasticity an invaluable asset in modern engineering.

Applications in Medical Devices and Beyond

Superelastic nitinol has carved out a niche for itself within medical devices due largely to its biocompatibility and excellent mechanical properties. From stents that expand within blood vessels after being deployed via catheters—thanks to their shape memory effect—to guidewires that navigate complex anatomical pathways without breaking or bending permanently, this memory metal has revolutionized minimally invasive procedures. The ability of these devices made from nitinol nickel titanium alloys ensures patient safety while improving surgical outcomes.

Beyond medicine, superelastic nitinol finds applications across diverse fields such as robotics and aerospace engineering where adaptability is crucial under varying conditions or loads. Its lightweight nature combined with high strength makes it ideal for components requiring both durability and efficiency—think aircraft parts designed for extreme environments or robotic limbs capable of mimicking human movement seamlessly! As industries continue seeking innovative solutions, it's evident that this remarkable memory alloy will remain at the forefront.

Nitinol vs. Other Memory Alloys

When it comes to shape memory alloys (SMAs), Nitinol stands out as a remarkable contender. While there are several types of memory metals, such as copper-aluminum-nickel and iron-based alloys, Nitinol—composed primarily of nickel titanium—offers unique advantages that set it apart. The combination of titanium and nickel in Nitinol results in extraordinary properties like superelasticity and the shape memory effect, making it a favorite in various applications.

Comparing Nitinol with Other SMA Alloys

Nitinol's performance often eclipses that of other SMA alloys due to its superior mechanical properties and versatility. For instance, while copper-based SMAs can exhibit significant shape recovery, they are generally less durable under extreme conditions compared to superelastic nitinol. Moreover, unlike some other memory alloys that require specific thermal conditions to activate their shape memory effect, nitinol can function effectively at body temperature, making it invaluable for medical applications.

Another key difference lies in the fatigue resistance; superelastic nitinol can endure numerous cycles of deformation without losing its effectiveness. This longevity is crucial for devices like stents and guidewires where reliability is paramount. Thus, while other SMAs have their own merits, nitinol’s unique blend of attributes often makes it the material of choice for demanding environments.

The Role of Nickel Titanium in Shape Memory Effect

The magic behind the shape memory effect largely hinges on the alloying elements used—in this case, nickel titanium plays a pivotal role. The precise ratio of nickel to titanium influences the transformation temperatures and mechanical properties of nitinol significantly; tweaking these ratios allows engineers to tailor its characteristics for specific applications. This adaptability sets nickel titanium apart from other SMA combinations that may not offer such a wide range of tunability.

In addition to being foundational for creating superelastic nitinol, nickel also contributes to corrosion resistance—a vital trait for any material intended for use within the human body or harsh environments. As a result, components made from nitinol not only exhibit excellent functional performance but also maintain integrity over time against wear and tear or chemical exposure. This synergy between nickel and titanium is what truly elevates nitinol above many other memory alloys available today.

Why Choose Nitinol for Tough Environments

Choosing materials that can withstand tough environments is no small feat; that's where superelastic nitinol shines brightly among its peers! Its ability to revert back to its original shape after deformation means it's ideal for applications where flexibility is essential—think medical devices navigating through intricate pathways within the body or aerospace components facing extreme pressure changes during flight.

Moreover, due to its biocompatibility thanks to its nickel-titanium composition, it's not just about resilience; it's also about safety when used in medical contexts like implants or surgical tools where human interaction is involved. With superior fatigue resistance and corrosion resistance compared to many other SMAs on the market today, it's clear why engineers increasingly favor choosing nitinol over traditional options when designing products meant for harsh operational demands.

Innovations in Nitinol Technology

Nitinol technology is rapidly evolving, paving the way for exciting advancements and applications. As manufacturers refine their processes, the unique properties of superelastic nitinol and its combination of nickel titanium are becoming increasingly accessible. This section dives into key innovations that are shaping the future of this remarkable memory metal.

Advancements in Nitinol Manufacturing

The manufacturing landscape for nitinol nickel titanium has seen significant enhancements, allowing for greater precision and efficiency. Techniques such as additive manufacturing and advanced heat treatment processes have been developed to optimize the properties of shape memory alloys (SMAs). These innovations not only improve the mechanical performance of nitinol but also expand its usability across various industries, from medical devices to aerospace engineering.

Moreover, new methods in alloy production have led to the creation of tailored compositions that enhance specific attributes like superelasticity or fatigue resistance. By fine-tuning the ratios of titanium and nickel during synthesis, manufacturers can produce specialized SMA alloys suited for demanding applications. The result is a more versatile range of products that leverage the unique characteristics of nitinol while minimizing costs.

GEE SMA and Its Impact on the Industry

One groundbreaking innovation in nitinol technology is GEE SMA (Grain-Engineered Enhanced Shape Memory Alloy), which has made waves across several sectors. This advanced form of superelastic nitinol boasts improved mechanical properties due to its engineered grain structure, leading to enhanced performance under stress. By optimizing how titanium and nickel interact at a microscopic level, GEE SMA offers superior durability compared to traditional memory alloys.

The impact on industries utilizing these materials has been profound; engineers are now able to design components that can withstand extreme conditions without compromising functionality. For example, GEE SMA's resilience makes it particularly appealing for medical devices where reliability is critical—think stents or guidewires that need precision under pressure! With such advancements, it's clear that GEE SMA is setting new standards for performance in shape memory technologies.

Future Trends in Nitinol Applications

Looking ahead, we can expect a surge in innovative applications for nitinol due to ongoing research and development efforts focused on this remarkable material. As industries increasingly seek lightweight yet strong alternatives to traditional metals, superelastic nitinol stands out as an ideal candidate—especially when combined with other materials like polymers or ceramics. This synergy could lead to breakthroughs in fields ranging from robotics to consumer electronics.

Additionally, we may witness a rise in smart materials incorporating memory alloys into everyday products; think self-healing structures or adaptive components that respond dynamically to environmental changes! The versatility offered by nitinol nickel titanium will likely drive further exploration into biocompatible applications as well—catering specifically to healthcare needs with custom implants designed from these advanced SMAs.

In summary, innovations surrounding nitinol technology are transforming how we perceive and utilize shape memory alloys today—and they’re just getting started!

Conclusion

In the world of advanced materials, superelastic nitinol stands out as a remarkable innovation. Its unique properties, stemming from the combination of nickel titanium, allow it to return to its original shape after deformation—an attribute that has profound implications across various industries. The shape memory effect and superelasticity are not just buzzwords; they represent a leap forward in engineering and technology.

The Distinct Advantages of Shape Memory Effect

The shape memory effect is one of the most fascinating characteristics of memory metals like nitinol nickel titanium, enabling them to remember their original form even after significant deformation. This property allows for innovative designs in applications ranging from aerospace components to medical devices, where reliability and performance are crucial. By harnessing the power of SMA alloys, engineers can create solutions that adapt dynamically to different conditions while maintaining structural integrity.

Why Superelastic Nitinol Matters

Superelastic nitinol is more than just a fancy term; it embodies an engineering marvel that offers unparalleled flexibility and resilience. Unlike traditional materials that may fracture under stress, this memory alloy can undergo substantial strain without permanent deformation, making it ideal for high-stress applications such as stents and orthopedic devices. The advantages provided by superelasticity not only enhance product performance but also contribute significantly to patient safety and comfort in medical applications.

GEE SMA's Role in Nitinol Advancements

GEE SMA represents a groundbreaking advancement in the development of nitinol technologies, pushing the boundaries of what’s possible with this extraordinary material. By optimizing manufacturing processes for nitinol nickel titanium products, GEE SMA ensures consistent quality and performance across various applications—from robotics to consumer electronics. As we look ahead, the innovations driven by GEE SMA will undoubtedly play a crucial role in expanding the horizons of superelastic nitinol usage and further solidifying its place as a staple in modern engineering.