Introduction

In the ever-evolving landscape of medical technology, Nitinol has carved out a niche that is hard to overlook. This unique alloy, predominantly made of nickel and titanium, possesses remarkable properties that make it an invaluable asset in various applications. Among its many forms, the Nitinol hypotube stands out as a critical component in the design of advanced medical devices, particularly in minimally invasive procedures.

Understanding Nitinol and Its Properties

Nitinol is renowned for its superelasticity and shape memory effect, which allow it to return to a predetermined shape when heated above a certain temperature. This characteristic is particularly beneficial for creating flexible yet durable components, such as Nitinol tubing. The ability to withstand significant deformation without permanent damage sets Nitinol apart from other materials commonly used in medical applications.

The Role of Nitinol Hypotubes in Medicine

Nitinol hypotubes play a pivotal role in modern medicine by serving as the backbone for various medical devices including stents and catheters. Their unique properties enable them to navigate through complex anatomical pathways while maintaining structural integrity under stress. As healthcare continues to embrace less invasive techniques, the demand for reliable Nitinol tubing stock lists has surged among leading manufacturers.

Benefits of Superelastic Nitinol Tubing

One of the standout benefits of superelastic Nitinol tubing is its exceptional flexibility combined with high durability, making it ideal for intricate procedures where traditional materials might fail. Additionally, this tubing exhibits impressive resistance to fatigue over time, ensuring long-lasting performance even under repeated use. Furthermore, with biocompatibility at its core, Johnson Matthey Nitinol tubing exemplifies how innovation can meet stringent safety standards essential for medical applications.

What is a Nitinol Hypotube?

Nitinol hypotubes are specialized tubes made from a unique alloy of nickel and titanium, known for their remarkable properties that make them ideal for various applications in the medical field. These tubes can undergo significant deformation and return to their original shape, a phenomenon called superelasticity. This ability to flex and adapt without permanent damage makes nitinol hypotubes highly sought after in the design of advanced medical devices.

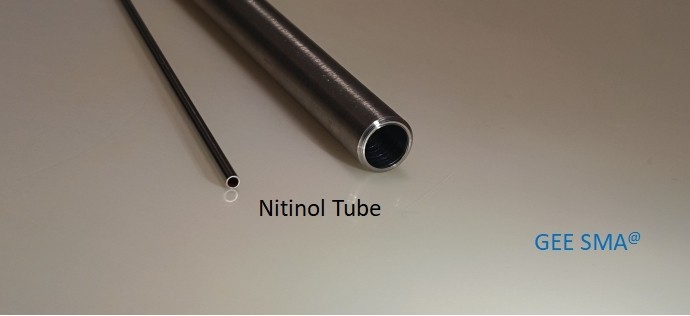

Defining Nitinol Hypotubes

A nitinol hypotube is essentially a thin-walled tube crafted from nitinol, an alloy that exhibits both shape memory and superelastic characteristics. The term hypotube refers specifically to its small diameter, which allows for intricate designs and applications within medical devices such as catheters and stents. The versatility of nitinol hypotubes enables manufacturers to create products that meet stringent medical standards while maintaining flexibility and strength.

Unique Properties of Nitinol

Nitinol possesses several unique properties that distinguish it from traditional metals used in manufacturing tubing. Its superelastic behavior allows it to endure considerable stress without losing its original form, making it resistant to fatigue—a crucial factor in medical applications where reliability is paramount. Additionally, nitinol's biocompatibility means it can be safely used within the human body without adverse reactions, which is essential for any material used in medical devices.

Applications in Medical Devices

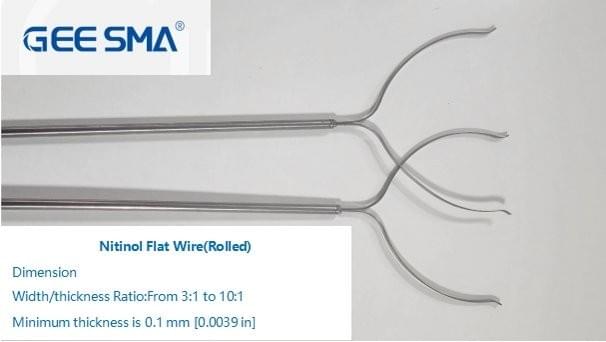

The applications of nitinol hypotubes are vast and varied within the realm of medical devices. They are commonly utilized in the production of nitinol catheters, which benefit from their flexibility during insertion while maintaining structural integrity once deployed inside the body. Furthermore, leading nitinol tube manufacturers often include these hypotubes in stent designs and other minimally invasive surgical tools due to their outstanding performance characteristics.

Key Advantages of Superelastic Nitinol Tubing

Superelastic nitinol tubing has become a game-changer in the medical field, particularly due to its unique properties that enhance performance and reliability. The flexibility and durability of nitinol hypotubes make them ideal for various applications, especially in the design of medical devices such as stents and catheters. With a growing interest in nitinol tubing stock lists, manufacturers are increasingly recognizing the benefits this material brings to their products.

Flexibility and Durability

One of the standout features of superelastic nitinol tubing is its remarkable flexibility. This property allows nitinol hypotubes to navigate complex anatomical pathways without compromising structural integrity, which is crucial during minimally invasive procedures. Coupled with exceptional durability, these tubes can withstand repeated bending and twisting without losing functionality, making them a preferred choice among leading Nitinol tube manufacturers.

In addition to flexibility, the durability of nitinol means that it can handle high-stress environments typical in medical applications. For instance, when used in Nitinol catheters, this combination ensures that devices maintain their shape and effectiveness over time. As healthcare providers continue to seek reliable solutions for patient care, superelastic nitinol's unique characteristics position it as a top contender.

Resistance to Fatigue

Another significant advantage of superelastic nitinol tubing is its impressive resistance to fatigue. Unlike traditional materials that may suffer from wear over time, nitinol hypotubes exhibit excellent performance even after extensive use. This fatigue resistance is particularly vital for devices like stents or guidewires that undergo constant flexing during insertion and navigation through vascular systems.

The ability of Nitinol tubing stock lists to include products designed for high-fatigue applications demonstrates how manufacturers are adapting to meet market demands while ensuring longevity in their offerings. Moreover, Johnson Matthey Nitinol tubing exemplifies this resilience by providing products that not only meet but exceed industry standards for fatigue resistance. As a result, healthcare professionals can trust these devices to perform reliably during critical procedures.

Biocompatibility for Medical Use

Biocompatibility is an essential factor when considering materials for medical applications; fortunately, superelastic nitinol excels in this area as well. The inherent properties of nitinol ensure minimal adverse reactions when implanted or used within the body—vital for any medical device like Nitinol catheters or other implantable technologies. This quality makes it an attractive option for manufacturers aiming to develop safe and effective solutions.

Furthermore, leading Nitinol tube manufacturers prioritize biocompatibility testing throughout their production processes to guarantee patient safety and device efficacy. Johnson Matthey Nitinol tubing stands out by focusing on creating biocompatible products tailored specifically for demanding medical environments where safety cannot be compromised. As innovations continue within this space, superelastic nitinol remains at the forefront due to its unwavering commitment to biocompatibility.

Nitinol Tubing Stock List and Availability

When it comes to sourcing nitinol tubing, the market is filled with options that cater to various medical applications. Nitinol hypotubes are available in different sizes, shapes, and configurations, allowing manufacturers to select the perfect fit for their specific needs. Buyers should consider factors like material properties, dimensions, and compliance with medical regulations when exploring their nitinol tubing stock list.

Sourcing Nitinol Tubing

Finding reliable sources for nitinol tubing is crucial for manufacturers in the medical device industry. Suppliers often provide comprehensive nitinol tubing stock lists that detail available grades, diameters, wall thicknesses, and lengths tailored for various applications such as stents or catheters. Utilizing reputable suppliers ensures access to high-quality materials that meet stringent biocompatibility and performance standards essential in creating effective nitinol catheters.

Leading Nitinol Tube Manufacturers

The landscape of nitinol tube manufacturers is diverse, with several key players leading the charge in innovation and production capabilities. Companies specializing in nitinol hypotubes often invest heavily in research and development to enhance their offerings continuously. Some notable names include Medtronic, Cook Medical, and Boston Scientific—each providing a range of products designed to meet the evolving demands of the healthcare sector.

Specialties of Johnson Matthey Nitinol Tubing

Johnson Matthey stands out among nitinol tube manufacturers due to its dedication to quality and innovation within its product line. Their specialty lies not only in producing high-performance nitinol hypotubes but also in offering customized solutions tailored to specific medical applications like stents or guidewires. With a strong emphasis on biocompatibility and durability, Johnson Matthey's nitinol tubing has become a preferred choice among developers of advanced medical devices.

Innovations in Nitinol Catheter Design

The landscape of medical devices has been transformed by the integration of innovative materials, and nitinol catheters are at the forefront of this evolution. Nitinol hypotubes, known for their unique properties, offer remarkable advantages in catheter design that enhance performance and patient outcomes. As healthcare continues to advance, the role of nitinol tubing becomes increasingly significant in developing more effective and reliable medical instruments.

Benefits of Nitinol in Catheters

Nitinol's superelasticity and shape memory capabilities make it an ideal material for catheters, allowing them to navigate complex anatomical pathways with ease. This flexibility not only reduces the risk of damage during insertion but also enhances patient comfort during procedures. Furthermore, nitinol's biocompatibility ensures that these catheters can be safely used within the human body without adverse reactions, making them a go-to choice among leading nitinol tube manufacturers.

The durability of nitinol tubing is another compelling benefit; it resists fatigue over repeated use, which is crucial for devices intended for multiple applications or extended periods inside the body. This longevity translates into cost-effectiveness for healthcare providers who rely on high-quality materials that withstand rigorous conditions. Overall, incorporating nitinol into catheter design exemplifies how advanced materials can significantly improve medical technology.

Examples of Nitinol Catheters in Use

Several innovative nitinol catheters are currently revolutionizing various medical fields such as cardiology and urology. For instance, some cardiac catheters utilize Johnson Matthey Nitinol tubing to optimize performance during procedures like angioplasty or stent placement. These specialized devices leverage the unique properties of nitinol hypotubes to deliver precise interventions while minimizing trauma to surrounding tissues.

In urology, nitinol catheters have proven invaluable for navigating challenging anatomical structures during procedures such as kidney stone removal or bladder drainage. Their superelastic nature allows these devices to bend without breaking or kinking—an essential feature when maneuvering through intricate pathways within the human body. As these examples illustrate, the application of nitinol tubing is diverse and impactful across multiple medical disciplines.

Future Trends in Nitinol Catheter Technology

Looking ahead, advancements in nitinol catheter technology promise even greater enhancements in functionality and patient care. Researchers are exploring hybrid designs that combine traditional materials with nitinol hypotubes to create multi-functional devices capable of performing various tasks simultaneously—think diagnostic imaging combined with therapeutic delivery systems!

Moreover, ongoing innovations aim to further improve biocompatibility and reduce manufacturing costs associated with producing high-quality Nitinol Tubing stock lists from reputable suppliers like Johnson Matthey and others in the market. As we anticipate these developments, it’s clear that the future of medical devices will be heavily influenced by continued advancements in materials science—especially concerning durable yet flexible options like those found within modern-day Nitinol catheters.

GEE SMA: A Leader in Nitinol Production

GEE SMA stands out as a pioneering force in the production of Nitinol, known for its exceptional expertise and innovative solutions. With a deep understanding of the unique properties of Nitinol, GEE SMA has positioned itself at the forefront of the industry, particularly in applications involving nitinol hypotubes. Their commitment to quality and performance has made them a preferred partner for many leading Nitinol tube manufacturers.

Overview of GEE SMA’s Expertise

GEE SMA specializes in producing high-quality nitinol tubing that meets stringent medical standards. Their extensive experience encompasses various sectors, including medical devices where flexibility and biocompatibility are paramount. By leveraging advanced manufacturing techniques, they ensure that their products consistently meet the demands of modern healthcare applications, making them a trusted source for those seeking a reliable nitinol tubing stock list.

Contributions to Space Missions

In addition to their impressive work in the medical field, GEE SMA has made significant contributions to space missions by utilizing nitinol materials for critical applications. The unique properties of Nitinol allow it to perform exceptionally well under extreme conditions encountered in space exploration. This versatility showcases how nitinol hypotubes can play an essential role beyond terrestrial uses, highlighting GEE SMA's innovative spirit and commitment to excellence.

Custom Solutions for Nitinol Functional Materials

GEE SMA is renowned for its capability to provide custom solutions tailored specifically for various applications involving nitinol functional materials. They work closely with clients to develop specialized designs that cater to unique project requirements while ensuring optimal performance and reliability. Whether it's creating bespoke nitinol catheters or other medical devices, their dedication to innovation positions them as leaders among Nitinol tube manufacturers globally.

Conclusion

In summary, the future of Nitinol hypotubes in medicine looks remarkably promising. As advancements in technology continue to evolve, Nitinol's unique properties will likely drive further innovation in medical devices, particularly in minimally invasive procedures. The increasing demand for high-performance materials such as Nitinol tubing positions it as a staple in modern healthcare.

The Future of Nitinol Hypotubes in Medicine

The trajectory for Nitinol hypotubes is on an upward trend, with ongoing research and development paving the way for new applications. Future innovations may include more sophisticated designs and enhanced functionalities that cater to specific medical needs. This adaptability ensures that Nitinol will remain at the forefront of medical technology, influencing everything from stents to specialized catheters.

Why Choose Nitinol for Medical Applications

Choosing Nitinol for medical applications is akin to choosing a Swiss Army knife; its versatility knows no bounds! With exceptional flexibility and durability, superelastic Nitinol tubing can withstand the rigors of repeated use without compromising performance. Furthermore, its biocompatibility makes it an ideal candidate for various medical devices, including those found on the ever-growing Nitinol tubing stock list.

Key Players in the Nitinol Market

Several key players dominate the landscape of the Nitinol market, each contributing uniquely to its evolution. Notably, Johnson Matthey Nitinol tubing stands out due to its high-quality manufacturing processes and commitment to innovation. Other significant manufacturers are also making strides in refining their offerings and expanding their product lines to meet growing healthcare demands.