Introduction

Welcome to the captivating realm of nitinol muscle, a revolutionary material that has transformed various fields, particularly medicine. This unique alloy, known for its shape memory effect and remarkable strength, has opened new avenues for innovation in medical devices and treatments. However, as we delve deeper into this fascinating topic, we must also consider the strengths and limitations of nitinol muscles and their impact on healthcare.

The Fascinating World of Nitinol Muscle

Nitinol muscle is not just a marvel of modern engineering; it’s a game-changer in how we approach medical solutions. With its ability to remember shapes and respond to temperature changes, nitinol offers unprecedented flexibility in design and function. As we explore the intricacies of this material, we uncover why so many industries are eager to adopt nitinol technology.

Applications of Nitinol in Medicine

The applications of nitinol in medicine are vast and varied, showcasing its versatility beyond traditional materials. From stents that expand within arteries to guidewires used in minimally invasive surgeries, nitinol plays an essential role in enhancing patient care. As we ask ourselves “Where is nitinol used in the body?”, it becomes clear that its presence is felt across numerous medical devices designed to improve health outcomes.

Strength and Limitations of Nitinol Muscles

When pondering “How strong are nitinol muscles?”, one finds that they rival traditional materials like steel while offering additional benefits such as fatigue resistance and longevity. Yet, despite these impressive qualities, there are challenges associated with using nitinol that cannot be ignored. Understanding both the strengths and limitations of nitinol muscles allows us to appreciate their potential while recognizing areas for improvement within this innovative field.

What is Nitinol?

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is a remarkable alloy that has captivated scientists and engineers alike. This unique material combines the properties of nickel and titanium in a way that gives rise to extraordinary characteristics, particularly its shape memory effect and superelasticity. Understanding what nitinol muscle is made of and how it behaves under various conditions is key to appreciating its applications in medicine and beyond.

Composition and Properties

Nitinol's composition primarily consists of nickel (about 55%) and titanium (around 45%), which gives it its distinctive properties. The balance between these two metals allows nitinol to exhibit both shape memory and superelasticity, making it highly adaptable in various applications. These properties are not just theoretical; they translate into practical benefits such as resilience, flexibility, and a remarkable ability to return to its original shape after deformation.

The unique combination of elements also contributes to the alloy’s corrosion resistance, which is crucial for medical applications where exposure to bodily fluids can be detrimental. As we explore how strong nitinol muscles are or where nitinol is used in the body, it's essential to recognize that these foundational properties set the stage for its innovative uses.

Shape Memory Effect Explained

At the heart of what makes nitinol muscle so intriguing is its shape memory effect—a phenomenon that allows the material to remember a predetermined shape when subjected to specific temperatures. When heated above a certain threshold, nitinol will revert back from a deformed state to this original form without any external force applied. This property not only enhances the functionality of devices made from nitinol but also opens up new avenues in minimally invasive surgery techniques.

The ability for nitinol muscles to change shape based on temperature can be likened to an acrobat performing an impressive trick—one moment they’re bent out of shape, but with just the right cue (in this case, heat), they spring back into their original pose! This dynamic behavior makes it invaluable for applications like stents or guidewires where adaptability can significantly improve patient outcomes.

Differences Between Nitinol and Traditional Materials

When comparing nitinol muscles with traditional materials like steel or aluminum, several key differences emerge that highlight why this alloy stands out. First off, while steel boasts impressive tensile strength—often touted as one of its main advantages—nitinol muscles offer comparable strength with added benefits such as flexibility and lower density. This means you get robust performance without compromising on weight or adaptability.

Additionally, traditional materials typically lack the unique thermal properties inherent in nitinol; they don't have a shape memory effect nor do they exhibit superelasticity under stress conditions like high temperatures or significant deformation. These distinctions make nitinol not only special but also essential in fields ranging from healthcare innovations—including prosthetics—to aerospace engineering where weight reduction can lead directly to improved efficiency.

How Strong Are Nitinol Muscles?

Nitinol muscles have gained attention for their impressive strength, particularly when compared to traditional materials. Understanding how strong these nitinol muscles really are requires a closer look at their tensile strength, fatigue resistance, and practical applications in various fields. This section will explore these aspects to provide a comprehensive view of nitinol's remarkable capabilities.

Tensile Strength Compared to Steel

When it comes to tensile strength, nitinol muscle can hold its own against steel, which is often considered the benchmark for strength in materials. In fact, certain formulations of nitinol exhibit tensile strengths that can rival or even exceed those of some steel alloys. This makes nitinol an attractive choice for applications where high strength-to-weight ratios are essential, such as in medical devices and prosthetics.

Comparing the two materials reveals that while steel is undeniably strong, nitinol muscle brings unique advantages like flexibility and shape memory properties that steel simply cannot match. These characteristics allow for more innovative designs that can adapt and respond dynamically within the human body or mechanical systems. So when asking How strong are nitinol muscles? it's clear they are not just tough; they also offer versatility that traditional materials lack.

Fatigue Resistance and Longevity

One of the standout features of nitinol muscle is its exceptional fatigue resistance, which allows it to endure repeated cycles of stress without significant degradation over time. This quality is crucial in medical applications where devices must withstand constant movement or pressure without failing—think stents or guidewires used in minimally invasive surgeries. The longevity offered by nitinol muscles means fewer replacements and repairs, ultimately benefiting both patients and healthcare providers.

Moreover, unlike many traditional materials that may become brittle after extensive use, nitinol maintains its integrity even after thousands of cycles. This resilience ensures that devices made with nitinol can perform reliably over long periods while minimizing the risk of complications associated with material failure. Therefore, when considering What are the problems with nitinol?, one could argue that fatigue resistance is certainly not one of them!

Practical Examples of Strength in Action

To truly appreciate how strong nitinol muscles are, let's look at some practical examples where they shine brightly in action. In the realm of medical devices, self-expanding stents made from nitinol have revolutionized vascular surgery by providing support to blood vessels while adapting smoothly to changes in body temperature and pressure—demonstrating both strength and flexibility simultaneously.

Another exciting application lies within prosthetics; engineers have developed advanced prosthetic limbs using nitinol's unique properties to create joints that mimic natural movement more closely than ever before. These innovations not only enhance functionality but also improve user comfort—a testament to how well-nitinol muscle performs under real-world conditions.

As we explore Where is nitinol used in the body?, we find it plays a crucial role across various medical technologies due to its combination of strength and adaptability—qualities essential for improving patient outcomes across diverse healthcare scenarios.

Where is Nitinol Used in the Body?

Nitinol muscle has carved out a significant niche in the medical field, showcasing its versatility and innovative applications. From stents to guidewires, this unique material is revolutionizing how we approach healthcare solutions. Let’s dive into the various ways nitinol is utilized within the body and why it continues to gain traction.

Applications in Medical Devices

The applications of nitinol muscle in medical devices are nothing short of groundbreaking. One prominent example is its use in stents, which are small mesh tubes inserted into arteries to keep them open. Thanks to the shape memory effect of nitinol, these stents expand automatically at body temperature, providing a reliable solution for patients with cardiovascular issues.

Beyond stents, nitinol is also found in catheters and guidewires, where flexibility and strength are essential. The ability of nitinol muscles to return to their original shape after deformation ensures that these devices can navigate complex vascular pathways without causing damage. As we explore further into the realm of Where is nitinol used in the body?, it becomes clear that its unique properties make it an ideal candidate for many medical applications.

Role in Minimally Invasive Surgeries

Minimally invasive surgeries have transformed how procedures are performed, reducing recovery times and enhancing patient outcomes. Nitinol muscle plays a pivotal role here by enabling surgeons to use smaller incisions while still achieving effective results. For example, surgical instruments made from nitinol can bend and maneuver through tight spaces without compromising their structural integrity.

The strength of nitinol muscles allows for precise movements during surgeries that require a steady hand and unwavering reliability. This capability not only enhances surgical performance but also minimizes trauma to surrounding tissues—an essential factor when considering patient recovery times. So when pondering How strong are nitinol muscles? it's evident that their impressive tensile strength makes them invaluable assets during minimally invasive procedures.

Innovations in Prosthetics and Implants

In recent years, innovations using nitinol muscle have significantly impacted prosthetics and implants design. The adaptability offered by this material allows prosthetic limbs to mimic natural movement more closely than ever before—an exciting development for those requiring mobility aids. By incorporating nitinol's shape memory effect into prosthetic joints, developers can create devices that adjust dynamically according to user activity levels.

Nitinol's biocompatibility also ensures that implants are less likely to cause adverse reactions within the body—a critical consideration when discussing What is so special about nitinol? Furthermore, its lightweight yet durable nature means patients can enjoy greater comfort without sacrificing functionality or performance over time.

While there are advantages associated with these innovations, it’s crucial also to address What are the problems with nitinol? Manufacturing challenges and cost implications remain hurdles for widespread adoption; however, ongoing research aims to mitigate these issues as technology progresses.

What is So Special About Nitinol?

Nitinol muscle stands out in the realm of materials due to its remarkable attributes that set it apart from conventional options. Its unique properties not only enhance its functionality but also open up new avenues for innovation across various fields. This section will delve into what makes nitinol so special, focusing on its thermal properties, biocompatibility, and versatility.

Unique Thermal Properties

One of the standout features of nitinol muscle is its unique thermal properties, particularly the shape memory effect that allows it to return to a predetermined shape when heated. This means that when nitinol is deformed at lower temperatures, applying heat can trigger it to revert back to its original form—an incredible feat that traditional materials simply can't match. The ability to respond dynamically to temperature changes makes nitinol ideal for applications where adaptability and precision are paramount.

Moreover, this thermal responsiveness is not just a party trick; it plays a crucial role in medical applications such as stents and guidewires where precision and reliability are critical. When exploring how strong nitinol muscles are, it's essential to consider how these thermal properties contribute to their performance under varying conditions. In essence, these unique characteristics make nitinol an invaluable asset in countless scenarios.

Biocompatibility and Safety

When discussing where nitinol is used in the body, one cannot overlook its biocompatibility—a vital factor for any material intended for medical use. Nitinol's composition allows it to integrate seamlessly with human tissue without eliciting adverse reactions, making it an excellent choice for implants and devices that reside within the body long-term. This safety profile ensures that patients experience fewer complications during procedures involving nitinol muscle technology.

Furthermore, biocompatibility extends beyond mere acceptance by the body; it also encompasses durability and resistance against corrosion in bodily fluids. As healthcare professionals continue seeking innovative solutions for surgical procedures and prosthetics, the safety offered by nitinol becomes increasingly significant. In a world where patient care is paramount, having materials like nitinol provides peace of mind both for doctors and patients alike.

Versatility Across Multiple Industries

The versatility of nitinol muscle stretches far beyond just medical applications; it's making waves across multiple industries including aerospace, robotics, and consumer electronics. Its remarkable strength-to-weight ratio combined with shape memory capabilities allows engineers to design innovative products that can withstand mechanical stress while maintaining functionality—think flexible actuators or self-repairing systems!

In addition to enhancing performance in existing technologies, this adaptability opens doors for entirely new inventions we have yet to imagine. As we continue exploring what are the problems with nitinol—such as manufacturing challenges or cost implications—it’s essential not to lose sight of the immense potential this material holds across various sectors beyond healthcare alone. With ongoing research dedicated towards overcoming these hurdles, there's no telling how far we can push the boundaries of what's possible with this extraordinary material.

What Are the Problems with Nitinol?

While nitinol muscle technology has made significant strides, it is not without its challenges. Understanding these hurdles is crucial for further advancements in applying nitinol in various fields, particularly in medicine. Let's dive into some of the most pressing issues surrounding this fascinating material.

Challenges in Manufacturing

Manufacturing nitinol muscle presents unique challenges that can hinder its widespread adoption. The alloy's complex phase transformation requires precise control over temperature and composition during production, making the manufacturing process intricate and often time-consuming. Additionally, achieving consistent quality can be difficult, leading to variability in performance and reliability when nitinol is used in critical applications like medical devices.

Cost Implications Compared to Other Materials

When discussing what are the problems with nitinol?, cost implications frequently arise as a major concern. The sophisticated manufacturing processes required for producing high-quality nitinol muscles often translate to higher prices than traditional materials like steel or plastic. This cost barrier can limit its accessibility for smaller medical companies or startups looking to innovate with nitinol technology.

Technical Limitations and Solutions

Despite its impressive properties, there are technical limitations associated with nitinol muscle that need addressing for broader application. For example, while many ask how strong are nitinol muscles?, they may not realize that their strength can diminish under extreme conditions or prolonged stress. However, researchers are actively working on solutions such as developing hybrid materials or enhancing the alloy's composition to improve performance while maintaining affordability—proving that innovation is always just around the corner.

Conclusion

As we wrap up our exploration of nitinol muscle, it's clear that this remarkable material is on the brink of revolutionizing various industries, especially healthcare. The future of nitinol muscle innovations holds immense promise, with ongoing research and development paving the way for new applications and enhancements in its performance. From advanced medical devices to innovative prosthetics, the potential for nitinol is only beginning to be tapped.

The Future of Nitinol Muscle Innovations

The future of nitinol muscle innovations looks bright, with advancements in technology promising to unlock even more capabilities. Researchers are delving into ways to enhance the strength and flexibility of nitinol muscles while addressing some of the challenges associated with their manufacturing processes. As these innovations unfold, we can expect to see applications that push the boundaries of what is possible in medicine and beyond.

Impact on Healthcare and Beyond

Nitinol muscle has already made significant strides in healthcare, but its impact could extend far beyond just medical applications. With unique properties such as shape memory effect and biocompatibility, nitinol can improve patient outcomes through minimally invasive procedures and better prosthetic designs. As industries explore how strong are nitinol muscles?, we may witness a transformative shift in how we approach surgeries and rehabilitation.

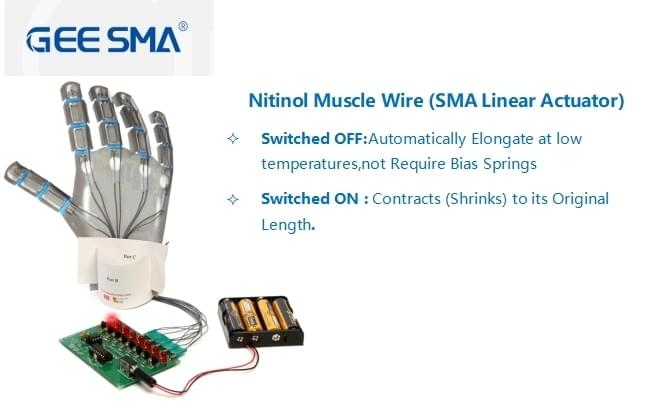

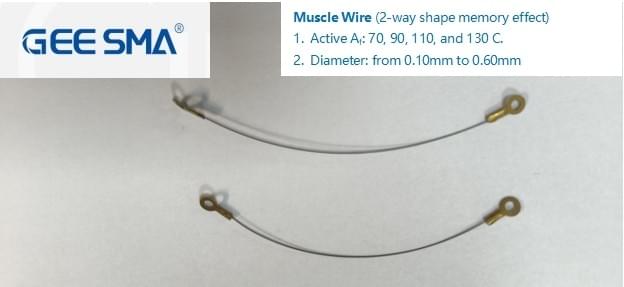

GEE SMA's Role in Advancing Nitinol Technology

GEE SMA is at the forefront of advancing nitinol technology by addressing both its strengths and limitations. By focusing on overcoming manufacturing challenges while optimizing cost-effectiveness, GEE SMA plays a pivotal role in making nitinol muscle more accessible for widespread use. Their commitment to innovation ensures that not only will we understand what is so special about nitinol?, but also leverage it effectively across various sectors.