Introduction

The realm of Shape Memory Alloys (SMAs) is nothing short of captivating, intertwining the principles of materials science with innovative engineering applications. These remarkable materials have the ability to return to a predetermined shape when subjected to specific temperatures, making them invaluable in various industries. As we delve deeper into this fascinating world, we will explore what an SMA actuator is and how it plays a pivotal role in modern technology.

Explore the Fascinating World of SMAs

SMAs are not just another buzzword in engineering; they represent a groundbreaking leap in material capabilities. One of the most intriguing aspects is their unique ability to undergo phase transformations, allowing them to act as effective actuators. When discussing SMA actuators, it's essential to appreciate how these materials can revolutionize mechanisms across sectors—from aerospace to biomedical applications.

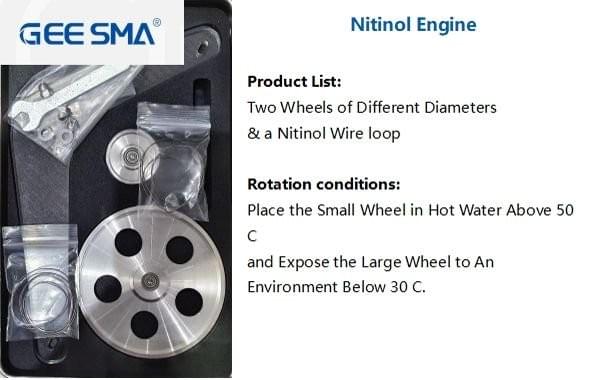

The Role of GEE SMA in Innovation

GEE SMA stands at the forefront of innovation, harnessing the power of shape memory technology for advanced solutions. This pioneering company has been instrumental in developing cutting-edge SMA actuators that enhance performance and efficiency across various applications. By focusing on sustainability and reliability, GEE SMA not only contributes significantly to technological advancements but also sets new standards for future innovations.

Understanding Shape Memory Technology

To fully grasp the potential of SMAs, one must understand shape memory technology's underlying principles and mechanics. At its core, this technology allows materials like Nitinol—an alloy composed primarily of nickel and titanium—to exhibit extraordinary behavior under temperature changes. As we explore questions such as What is an SMA actuator? or What is a spring diaphragm actuator?, it becomes clear that these innovations are reshaping our approach to engineering challenges and opening doors to new possibilities.

What Is an SMA Actuator?

SMA actuators are remarkable devices that leverage the unique properties of shape memory alloys to produce motion. These actuators work by utilizing the phase transformation of SMA materials, allowing them to change shape in response to temperature variations. As a result, they are increasingly popular in various applications where precise movement and control are essential.

Definition and Functionality

So, what is an SMA actuator? Essentially, it’s a device that converts thermal energy into mechanical work through the contraction and expansion of shape memory alloys. When heated above a certain temperature, these alloys revert to their original shape from a deformed state, generating motion that can be harnessed for various tasks. This functionality makes SMA actuators incredibly versatile for applications ranging from robotics to aerospace engineering.

Key Characteristics of SMA Actuators

One striking characteristic of SMA actuators is their ability to provide high force output with minimal input energy—perfect for applications where power efficiency is key! Additionally, they are compact and lightweight compared to traditional actuators like pneumatic or hydraulic systems. This combination of features allows them to fit seamlessly into tight spaces while delivering reliable performance.

Another notable feature is their inherent simplicity; SMA actuators often require fewer components than other actuator types, reducing maintenance needs and potential points of failure. Furthermore, they operate quietly compared to electric or pneumatic options, making them ideal for environments where noise reduction is crucial.

Real-World Applications

Real-world applications of SMA actuators showcase their versatility and effectiveness across numerous industries. In medical devices, for instance, they can be used in stents or minimally invasive surgical tools that expand upon heating within the body—a perfect example of how what is an SMA actuator can save lives!

In robotics, these actuators enable precise movements in robotic arms or grippers, enhancing dexterity without adding unnecessary bulk or weight. Moreover, aerospace engineers utilize SMA technology in deployable structures such as antennas or solar panels on spacecraft—demonstrating just how far-reaching the impact of SMA materials can be across various fields.

What Is a Spring Diaphragm Actuator?

Spring diaphragm actuators are fascinating devices that utilize the principles of elasticity and pressure to control various mechanical systems. They are designed to convert pressure changes into mechanical movement, making them essential in many industrial applications. Unlike other actuator types, spring diaphragm actuators offer unique advantages, including compact design and reliability.

Mechanism and Working Principle

At the heart of a spring diaphragm actuator is a flexible diaphragm that responds to changes in pressure. When fluid or gas is applied, it pushes against the diaphragm, causing it to deflect and compress a spring mechanism connected to it. This deflection translates into linear motion or force output, effectively allowing the actuator to perform its intended function—be it opening a valve or adjusting a mechanism.

The beauty of this design lies in its simplicity; by harnessing basic physical principles, what is a spring diaphragm actuator can achieve remarkable performance without complex components. The combination of the spring's stored energy and the diaphragm's responsiveness results in efficient operation across various conditions. Moreover, these actuators can be easily integrated into existing systems due to their straightforward installation requirements.

Benefits Over Other Actuator Types

One of the standout benefits of using spring diaphragm actuators is their inherent reliability compared to other actuator types like electric or pneumatic options. They require minimal maintenance since there are fewer moving parts subject to wear and tear over time. Additionally, they operate effectively even in harsh environments where electric components might fail due to moisture or dust.

Another advantage is their ability to provide precise control with rapid response times; when you ask yourself what are the 4 types of actuators and their uses, it's clear that spring diaphragm actuators shine in scenarios requiring quick adjustments under varying pressures. Their compact design allows for easy integration into tight spaces where traditional actuators may not fit as seamlessly. Overall, these features make them an attractive choice for industries looking for efficiency without compromising on performance.

Industrial Applications

Spring diaphragm actuators find extensive use across multiple industries due to their versatility and reliability. In process automation, they play crucial roles in controlling valves within pipelines—adjusting flow rates based on system demands while ensuring safety protocols are maintained at all times. Furthermore, they are commonly used in HVAC systems for regulating air dampers and maintaining optimal climate control within buildings.

In addition to process automation and HVAC applications, these actuators also contribute significantly to manufacturing processes where precise control over machinery operation is required—whether it's activating conveyor belts or controlling robotic arms during assembly lines. Their ability to respond quickly makes them ideal candidates for tasks that require real-time adjustments based on feedback from sensors or operators alike.

As we explore more about what is an SMA material next, it's essential not only to appreciate the role played by SMA actuators but also how different types like spring diaphragms complement each other within broader automation frameworks.

What Are the 4 Types of Actuators and Their Uses?

Actuators are essential components in various systems, converting energy into motion to facilitate movement and control. Among the four primary types of actuators—electric, pneumatic, hydraulic, and SMA actuators—each has distinct functionalities and applications. Understanding these types can help you determine which is the best fit for your specific needs.

Electric Actuators

Electric actuators utilize electrical energy to create motion, making them a popular choice in modern automation systems. They convert electrical signals into mechanical movement through motors or solenoids, providing precise control over positioning and speed. The versatility of electric actuators allows them to be used in everything from robotics to industrial machinery.

Electric actuators are known for their efficiency and ease of integration with digital control systems. They require minimal maintenance compared to other actuator types since they have fewer moving parts that can wear out over time. However, they may not be suitable for environments where explosive gases or extreme temperatures are present.

Pneumatic Actuators

Pneumatic actuators operate using compressed air or gas to produce motion, making them ideal for high-speed applications requiring rapid actuation. These devices convert air pressure into mechanical force, allowing for quick movements without the need for complex electronics or heavy machinery. Commonly found in manufacturing processes, pneumatic actuators excel in tasks that demand swift action.

One significant advantage of pneumatic actuators is their ability to generate substantial force relative to their size and weight. This makes them particularly useful in applications such as assembly lines or material handling systems where space is limited but power is essential. However, they do require a reliable air supply system, which can add complexity to installation.

Hydraulic Actuators

Hydraulic actuators use pressurized fluid to create motion, providing immense power density compared to other actuator types like electric or pneumatic options. These devices are particularly effective in heavy-duty applications such as construction equipment and industrial machinery where high force output is necessary for lifting or pushing loads. Their ability to handle large loads makes hydraulic actuators indispensable in many sectors.

While hydraulic systems offer impressive performance capabilities, they also come with some drawbacks; namely the potential for leaks and the need for regular maintenance of fluid levels and filters. Additionally, hydraulic systems can be more complex than electric or pneumatic ones due to their reliance on pumps and reservoirs of hydraulic fluid. Nevertheless, when it comes down to sheer power requirements, hydraulic actuators often take the cake.

SMA Actuators: The Flexible Choice

SMA actuators represent an innovative approach among actuator types by utilizing shape memory alloy (SMA) technology that allows materials like Nitinol to return to a predetermined shape when heated above a certain temperature threshold—fascinating! So what exactly is an SMA actuator? It’s a device that harnesses this unique property of SMAs to achieve precise movements with minimal energy consumption.

The flexibility offered by SMA actuators makes them suitable for diverse applications ranging from medical devices (think stents!) to robotics where compact size and lightweight design are critical factors—talk about versatility! Unlike traditional actuator types that rely on bulky mechanisms or external power sources like electricity or compressed air, SMA technology opens up exciting possibilities across various industries while maintaining simplicity in design.

In summary, understanding what an SMA material brings into play helps highlight its advantages over other actuator types while showcasing its potential impact on future innovations—from aerospace engineering at GEE SMA's forefront all the way down through everyday consumer products designed with smart materials integrated seamlessly throughout their functionality!

What Is an SMA Material?

Shape Memory Alloys (SMAs) are a remarkable class of materials that can remember their original shape after being deformed. This unique characteristic is primarily due to the phase transformation that occurs within the material when subjected to temperature changes. Among various SMAs, Nitinol stands out due to its exceptional properties and versatility, making it a popular choice in numerous applications.

Composition of Shape Memory Alloys

The composition of Shape Memory Alloys typically includes metals such as nickel and titanium, which form a unique intermetallic compound known as Nitinol. This alloy exhibits two distinct phases: the martensite phase, which is low-temperature and easily deformable, and the austenite phase, which is high-temperature and stable. The specific ratio of nickel to titanium can be adjusted to tailor the material's transformation temperatures and mechanical properties, enhancing performance in various applications.

Unique Properties of Nitinol

Nitinol boasts several unique properties that set it apart from traditional materials. One of its most fascinating features is its ability to undergo significant deformation at lower temperatures while returning to its original shape when heated above a certain threshold—this is what makes it an ideal candidate for an SMA actuator. Additionally, Nitinol demonstrates superelasticity, allowing it to endure large strains without permanent deformation, making it invaluable in dynamic environments like robotics or medical devices.

Applications Across Various Industries

The applications of SMA materials are as diverse as they are innovative. In the medical field, Nitinol is used for stents and guidewires due to its biocompatibility and ability to return to predetermined shapes inside the body—perfect for minimally invasive procedures! Beyond medicine, SMA actuators find their way into aerospace engineering for deployable structures or mechanisms that require precise movement under varying conditions; they truly exemplify versatility across industries.

The Future of SMA Technology

As we look ahead, the future of Shape Memory Alloys (SMAs) appears more promising than ever. Innovations in SMA technology are paving the way for enhanced performance, efficiency, and versatility in various applications. With ongoing research and development, we can expect to see SMAs play an increasingly vital role across multiple industries.

Advancements in Shape Memory Alloys

Recent advancements in shape memory alloys have focused on improving their mechanical properties and operational capabilities. Researchers are exploring new alloy compositions that enhance the response time and fatigue resistance of SMA actuators, making them even more reliable for real-time applications. Additionally, integrating smart technologies with SMAs is opening doors to self-sensing capabilities that could revolutionize how we utilize these materials.

These enhancements will not only improve what an SMA actuator can do but also expand its applicability beyond traditional uses. For instance, innovations might lead to lighter and more compact designs suitable for aerospace or automotive industries where space is at a premium. As a result, understanding what is an SMA actuator becomes crucial as these advancements unfold.

GEE SMA's Role in Space Exploration

GEE SMA is at the forefront of leveraging shape memory alloys for space exploration missions. The unique properties of SMAs make them ideal candidates for mechanisms that require high reliability under extreme conditions found in outer space environments. From deploying solar panels to adjusting antennas on satellites, GEE's innovative use of SMA actuators enhances mission success rates while minimizing risks associated with mechanical failures.

Moreover, the lightweight nature of SMAs allows spacecraft to carry additional equipment without compromising fuel efficiency or payload capacity. This capability aligns perfectly with the increasing demand for cost-effective solutions in space exploration endeavors. As we consider what are the 4 types of actuators and their uses within this context, it's clear that SMA actuators stand out due to their adaptability and potential for groundbreaking applications.

Potential Impact on Robotics and Medicine

The impact of shape memory alloy technology extends far beyond aerospace; it holds transformative potential within robotics and medicine as well. In robotics, SMA actuators can mimic muscle movements more naturally than traditional motors due to their ability to change shape under specific temperatures—an incredible feat when considering robotic prosthetics or soft robotics applications where flexibility is key.

In medicine, SMAs are being explored for minimally invasive surgical tools that can perform complex tasks with precision while reducing recovery times for patients. Understanding what is an SMA material helps highlight its significance; Nitinol's superelasticity makes it ideal for stents or guidewires that need both strength and flexibility during procedures. As these developments progress, embracing smart materials like SMAs will undoubtedly lead us toward revolutionary advancements across numerous sectors.

Conclusion

In the ever-evolving landscape of technology, SMA actuators stand out as a beacon of innovation. These remarkable devices not only offer unique functionalities but also pave the way for advancements across various industries. As we reflect on the capabilities and potential of SMA actuators, it becomes clear that they are more than just components; they are catalysts for change.

Innovations Driven by SMA Actuators

SMA actuators have revolutionized how we think about movement and control in mechanical systems. Their ability to return to a predetermined shape when heated makes them invaluable in applications ranging from robotics to aerospace engineering. By answering the question, What is an SMA actuator?, we uncover a world where precision and adaptability work hand in hand, allowing for innovative designs that were previously unimaginable.

The flexibility of SMA actuators enables engineers to create lightweight and compact solutions that outperform traditional mechanisms. For instance, in medical devices, these actuators facilitate minimally invasive procedures by providing precise actuation without bulky components. This innovation not only enhances functionality but also improves patient outcomes—an exciting development in healthcare technology.

GEE SMA's Contribution to Advanced Technologies

GEE SMA has been at the forefront of integrating shape memory alloy technology into cutting-edge applications. By leveraging their expertise, GEE SMA is pushing the boundaries of what is possible with SMA materials and devices. The company's contributions are particularly significant in areas such as space exploration, where reliable actuation systems are crucial for mission success.

When exploring What is a spring diaphragm actuator?, one can appreciate how GEE SMA’s innovations complement traditional technologies by offering improved efficiency and performance metrics. Their commitment to research and development ensures that they remain leaders in the field while continuously enhancing their product offerings across various sectors. As we look ahead, GEE SMA's role will be vital in shaping future technologies.

Embracing the Future of Smart Materials

The future of smart materials like SMAs holds immense promise as industries increasingly seek efficient solutions to complex problems. With ongoing advancements in material science, we can expect even greater capabilities from SMAs—transforming everything from consumer products to industrial machinery. Understanding What are the 4 types of actuators and their uses? reveals how diverse actuator technologies can be integrated with smart materials for enhanced functionality.

As more companies recognize the advantages offered by SMAs, such as reduced weight and energy consumption, their adoption will likely accelerate across multiple fields including automotive engineering and robotics. The question What is an SMA material? opens doors to discussions about new composites that could further enhance performance characteristics while maintaining sustainability goals.

In summary, embracing smart materials like SMAs not only leads us toward innovative solutions but also encourages a forward-thinking mindset essential for tackling tomorrow’s challenges head-on.