Introduction

In the ever-evolving world of technology, SMA actuators stand out as a fascinating innovation that combines efficiency with unique properties. Shape Memory Alloys (SMAs) are materials that can return to a predetermined shape when exposed to specific temperatures, making them ideal for use in actuator systems. Whether you’re designing a complex robotic arm or developing cutting-edge medical devices, understanding SMA actuators is crucial for harnessing their potential.

The Basics of SMA Actuators

SMA actuators utilize the remarkable characteristics of shape memory alloys to convert thermal energy into mechanical work. These actuators can contract and expand in response to temperature changes, offering precise control over movement without the need for complex mechanical components. Their simplicity and effectiveness make SMA actuators an attractive option for various applications, from robotics to aerospace engineering.

Why Choose SMA Over Other Actuators

Choosing an SMA actuator over traditional options can yield numerous advantages, including compact size, lightweight design, and minimal power consumption. Unlike electric or hydraulic actuators that require bulky motors or pumps, SMA actuators operate quietly and efficiently by relying on thermal energy alone. This makes them particularly appealing in environments where space is at a premium or noise reduction is essential.

Key Players in the SMA Market

The market for SMA actuators has seen significant growth, with several key players emerging as leaders in this niche industry. Companies like Johnson Matthey and SAES Getters are at the forefront of developing advanced shape memory alloys tailored for actuator applications. As demand increases across sectors such as healthcare and automation, these companies continue to innovate and expand their offerings to meet diverse customer needs.

Understanding Shape Memory Alloys

Shape memory alloys (SMAs) are fascinating materials that can return to a predetermined shape when subjected to specific temperature changes. This unique property makes them ideal for various applications, particularly in actuator systems. By leveraging the shape memory effect, SMA actuators can deliver precise movements and functionality in a compact and efficient package.

What Are Shape Memory Alloys?

Shape memory alloys are metallic materials that possess the remarkable ability to remember their original shape. When deformed at lower temperatures, they can revert back to their pre-deformed shape upon heating above a certain threshold, known as the transformation temperature. Common examples include nickel-titanium (NiTi) and copper-aluminum-nickel alloys, which are widely used in SMA actuators due to their excellent mechanical properties and biocompatibility.

The unique behavior of SMAs arises from their crystalline structure, which undergoes phase transformations between two distinct forms: martensite and austenite. In the martensitic phase, the alloy is easily deformed; however, when heated into the austenitic phase, it regains its original shape with impressive force. This characteristic makes SMAs particularly suitable for applications where space is limited but reliable actuation is crucial.

How Shape Memory Works

The magic of shape memory alloys lies in their ability to undergo reversible phase transformations triggered by temperature changes. When an SMA actuator is cooled below its transformation temperature, it adopts a low-energy martensitic state that allows for deformation under stress or strain. Once heated above this critical point—often through electrical resistance or environmental factors—the material transitions back to its higher-energy austenitic state, effectively remembering its original configuration.

This process not only enables compact design solutions but also allows for energy-efficient operation compared to traditional actuators that rely on continuous power input for movement. The rapid response time of SMA actuators makes them suitable for dynamic applications where quick actuation is essential. However, it's important to note that while this technology offers many advantages, understanding how heat transfer affects performance is key when integrating actuator controllers with SMA systems.

Applications in Actuator Systems

SMA actuators find themselves at home in various industries due to their versatility and innovative capabilities. In medical devices like stents or surgical tools, SMAs provide minimally invasive solutions that adapt seamlessly within the human body—offering both precision and safety during procedures. Similarly, in robotics and automation systems, SMA actuators enable smooth movements without bulky components while maintaining high efficiency.

In aerospace and automotive sectors, these smart materials contribute significantly by reducing weight without compromising performance or reliability—an essential factor when designing vehicles aimed at fuel efficiency or enhanced maneuverability. Moreover, as technology advances and production techniques improve, we can expect even broader adoption of SMA actuators across diverse fields due to their unique benefits over conventional options.

Exploring SMA Actuator Systems

Shape Memory Alloy (SMA) actuators are fascinating devices that harness the unique properties of shape memory alloys to create motion. These systems consist of various components that work together seamlessly to provide efficient and responsive actuation. Understanding these components, along with the benefits and challenges they present, is crucial for anyone considering integrating SMA technology into their projects.

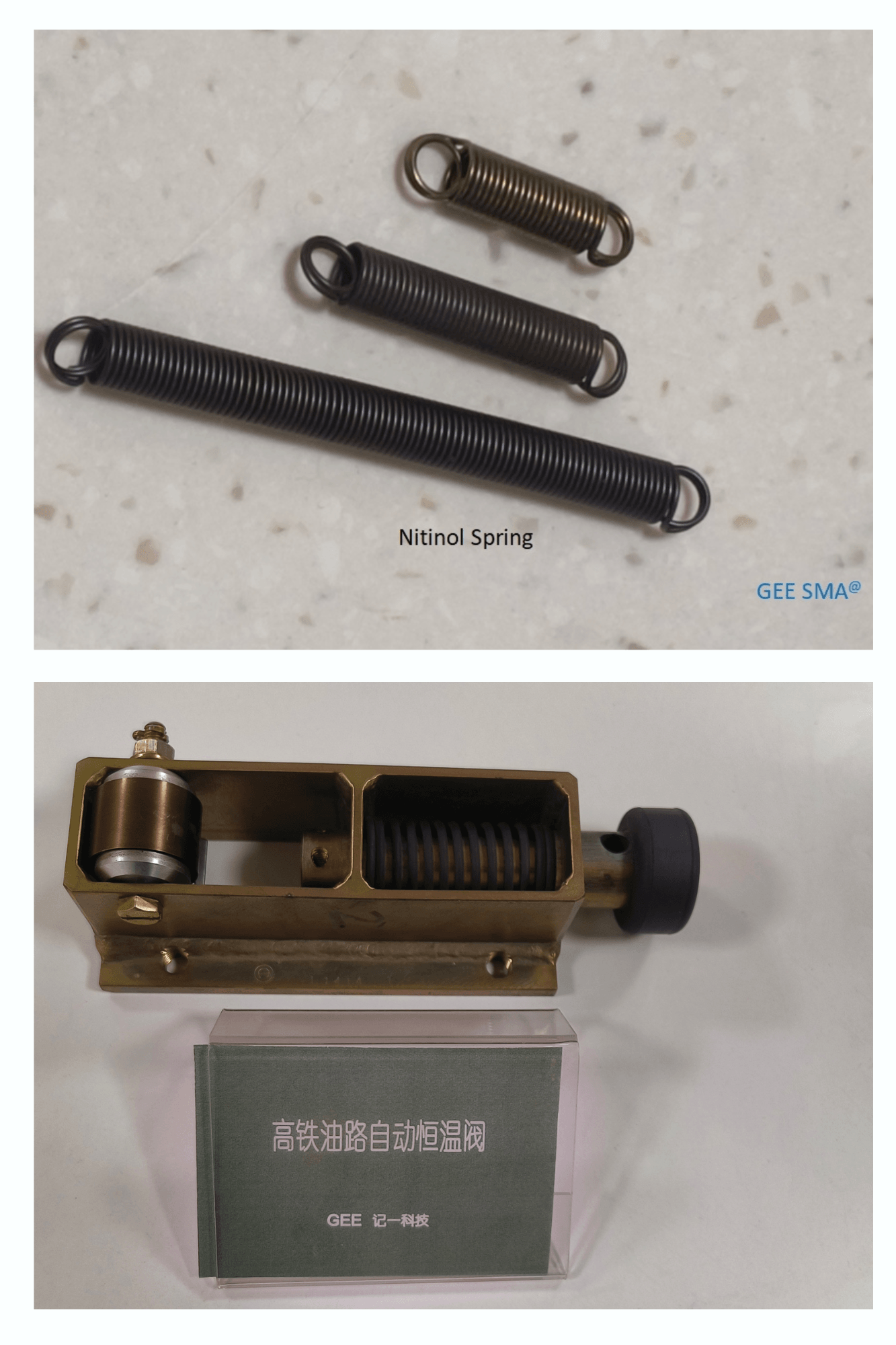

Components of an SMA Actuator

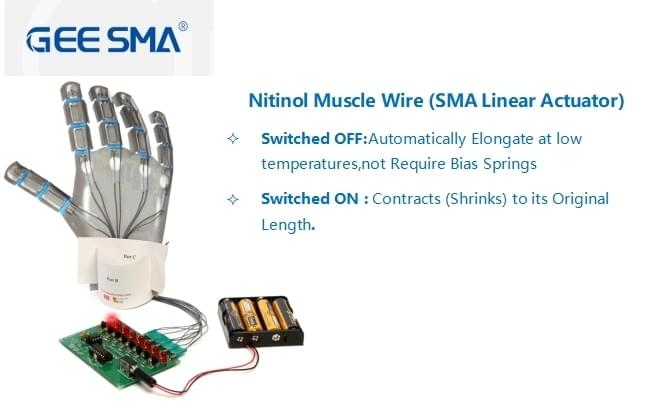

An SMA actuator typically comprises several key components: the shape memory alloy wire or spring, a housing structure, and an actuator controller. The SMA wire or spring is the heart of the actuator; it expands or contracts when subjected to heat, allowing for precise movements. The housing protects the internal mechanisms while providing structural support, and the actuator controller manages the temperature changes necessary for triggering the shape memory effect.

Additionally, you might find sensors integrated into some advanced SMA actuators to provide feedback on position or force exerted. This feedback loop can enhance performance by allowing real-time adjustments based on operational demands. Together, these components work in harmony to create a highly efficient and effective actuation system.

Benefits of SMA Actuators

One of the standout benefits of SMA actuators is their lightweight design compared to traditional actuators like hydraulic or pneumatic systems. This makes them ideal for applications where weight savings are critical, such as in aerospace or portable medical devices. Moreover, SMA actuators offer high power-to-weight ratios and can generate significant force relative to their size.

Another advantage is their simplicity; with fewer moving parts than conventional systems, maintenance requirements are lower, leading to increased reliability over time. Additionally, they operate silently—perfect for environments where noise reduction is essential. With a growing number of applications across various industries, these benefits make SMA actuators an attractive choice for engineers looking to innovate.

Challenges and Limitations

Despite their many advantages, there are challenges associated with using SMA actuators that must be considered before implementation. One notable limitation is their relatively slow response time compared to other types of actuators; this can be a significant drawback in applications requiring rapid actuation cycles. Furthermore, managing heat generation effectively is crucial since overheating can lead to performance issues or even damage.

Another challenge lies in controlling precise movements; while actuator controllers have advanced significantly over recent years, achieving fine-tuned control still requires sophisticated algorithms and programming expertise. Cost can also be a factor; although prices have been decreasing with advancements in technology and production methods, high-quality SMAs may still represent a more considerable investment upfront than traditional alternatives.

The Role of Actuator Controllers

In the realm of SMA actuators, actuator controllers play a pivotal role in ensuring that these innovative devices perform optimally. These controllers are essentially the brains behind the operation, managing how and when the SMA actuator responds to external stimuli or commands. Without a well-designed actuator controller, the potential of SMA actuators could remain untapped.

What is an Actuator Controller?

An actuator controller is an electronic device responsible for regulating the operation of actuators, including SMA actuators. It interprets input signals—whether from sensors or user commands—and translates them into precise movements or actions by adjusting power levels and timing. By providing this level of control, actuator controllers enhance the reliability and efficiency of systems that incorporate SMA technology.

Integrating Controllers with SMA Actuators

Integrating an actuator controller with an SMA actuator is where the magic truly happens. The synergy between these two components allows for smooth and responsive movement, crucial in applications ranging from robotics to medical devices. Moreover, effective integration can help mitigate some challenges associated with SMA actuators, such as slow response times or heat management issues.

Innovations in Control Systems

The landscape of control systems for SMA actuators is rapidly evolving, with innovations that promise to enhance performance further. Advanced algorithms and smart technology are being developed to create more adaptive and responsive controllers tailored specifically for SMA applications. These innovations not only improve efficiency but also open up new possibilities for complex tasks previously deemed impossible with traditional actuation methods.

Real-World Applications of SMA Actuators

SMA actuators are revolutionizing various industries by providing unique solutions that blend efficiency with versatility. From the medical field to robotics and beyond, these innovative devices are enhancing functionality while minimizing size and weight. Let’s dive into some of the exciting real-world applications where SMA actuators truly shine.

Medical Devices and Health Technology

In the realm of medical devices, SMA actuators have made significant strides, particularly in minimally invasive surgeries and prosthetics. Their ability to change shape in response to temperature allows for precise movements that are crucial during delicate procedures. For instance, SMA actuators are utilized in stents that expand within arteries, providing life-saving support with minimal invasiveness.

Moreover, in prosthetic limbs, SMA actuators offer a lightweight alternative to traditional motors, enabling smoother movement and more natural user experiences. The actuator controller plays a vital role here by ensuring that the movements of the prosthetic limbs mimic those of biological limbs as closely as possible. As technology advances, we can expect even more groundbreaking applications of SMA actuators in health technology.

Robotics and Automation Solutions

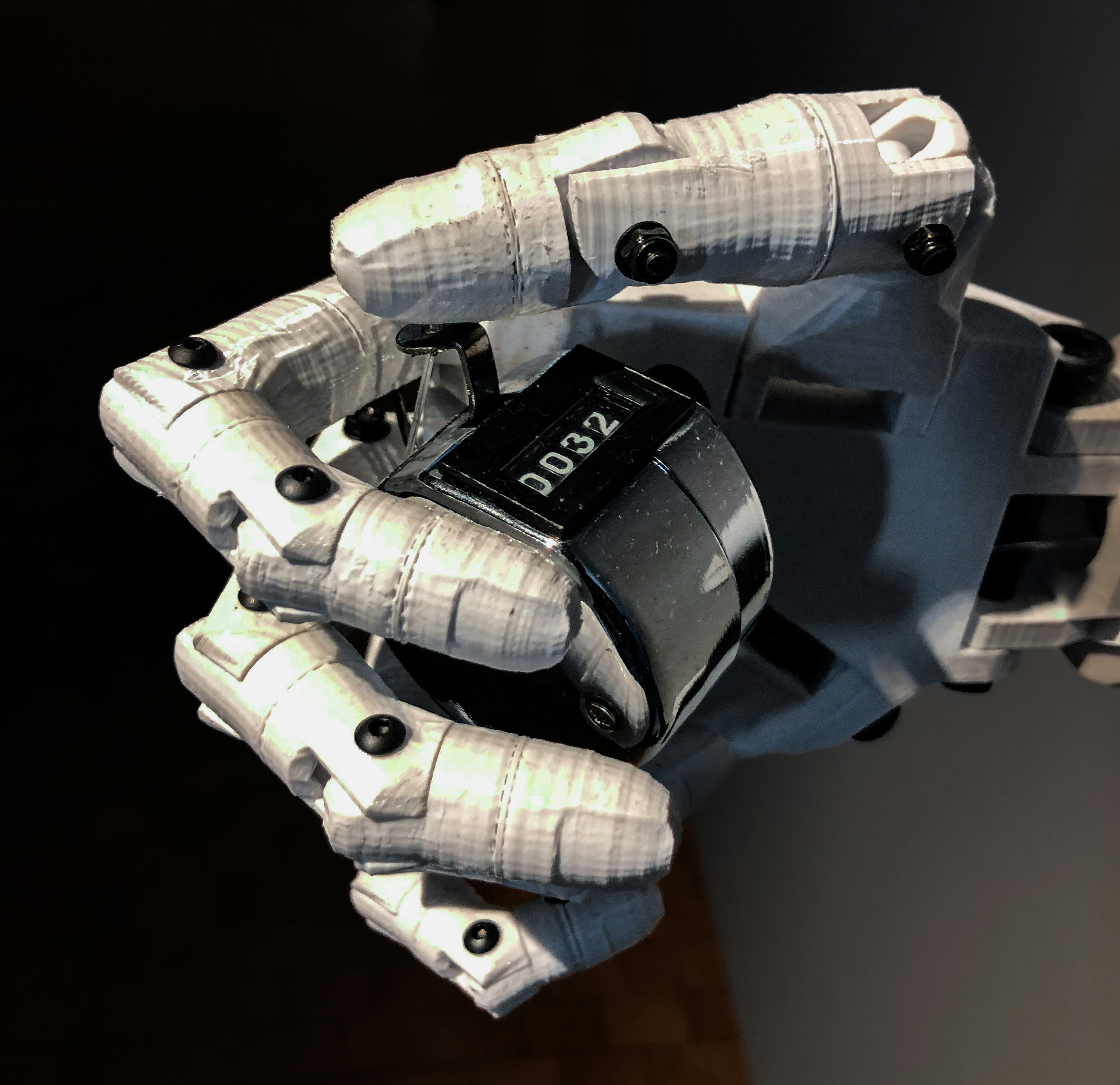

Robotics is another field where SMA actuators have carved out a niche for themselves. These compact devices can be integrated into robotic systems to create lightweight structures that don’t compromise on strength or performance. In many cases, an actuator controller is employed to manage the precision movements required for tasks ranging from assembly line work to intricate surgical robots.

Additionally, their ability to return to a predetermined shape after deformation makes them ideal for soft robotics applications—think flexible grippers or adaptive surfaces that can handle various objects without damage. With ongoing research and development in this area, we’re likely to see even more innovative uses of SMA actuators in automation solutions.

Aerospace and Automotive Uses

The aerospace and automotive industries have also recognized the potential of SMA actuators for improving efficiency and performance while reducing weight—a critical factor in both sectors. In aerospace applications, these actuators can be found in wing flaps or landing gear systems where weight savings directly translate into fuel efficiency gains. The actuator controller ensures precise operation under varying conditions which is essential for safety-critical components.

In automotive engineering, manufacturers utilize SMA actuators for features like automatic seat adjustments or adaptive suspension systems that respond dynamically to changing road conditions. This not only enhances passenger comfort but also improves vehicle handling overall. As sustainability becomes increasingly important across industries, expect more companies to explore how SMA technology can contribute positively toward greener solutions.

The Future of SMA Technology

The future of Shape Memory Alloy (SMA) technology is poised for exciting developments that could revolutionize various industries. As demand for more efficient and compact actuator solutions grows, SMA actuators are becoming increasingly attractive due to their unique properties and versatility. Innovations in actuator controllers will further enhance the performance of these systems, making them indispensable in modern applications.

Trends in Shape Memory Alloys

Current trends indicate a significant push towards miniaturization and increased functionality in SMA actuators. Researchers are exploring new alloy compositions and processing techniques to improve the responsiveness and durability of these materials. Additionally, integration with smart technologies such as IoT devices is on the rise, allowing for real-time monitoring and control of SMA actuators.

As industries seek more sustainable solutions, there’s also a growing emphasis on developing environmentally friendly SMA materials. The trend toward lightweight designs is particularly evident in aerospace applications where every gram counts; hence, advanced SMA actuators are being designed to meet these stringent requirements without compromising performance. Overall, the future looks bright for shape memory alloys as they continue to evolve alongside technological advancements.

GEE SMA's Impact on the Industry

GEE SMA has emerged as a key player in driving innovation within the SMA actuator market. Their commitment to research and development has led to groundbreaking advancements that enhance the efficiency and reliability of actuator controllers paired with SMA technology. By focusing on high-performance alloys that cater specifically to industry needs, GEE SMA is setting new benchmarks for what can be achieved with these materials.

Moreover, GEE's collaboration with various sectors—ranging from medical devices to robotics—has fostered an environment ripe for innovation. This synergy not only accelerates product development but also ensures that their solutions remain at the forefront of industry demands. As GEE continues to lead by example, other manufacturers will likely follow suit, pushing the boundaries of what’s possible with SMA actuators.

Sustainable Practices in SMA Production

Sustainability is becoming an essential consideration in all manufacturing processes, including those involving shape memory alloys. Companies are increasingly adopting eco-friendly practices aimed at reducing waste during production while ensuring that their products remain competitive in quality and cost-effectiveness. This shift not only benefits the environment but also appeals to consumers who prioritize sustainability when choosing products such as SMA actuators.

Furthermore, innovations like recycling used SMAs into new products are gaining traction within the industry—promoting a circular economy approach that minimizes resource depletion while maximizing utility from existing materials. As manufacturers embrace greener practices alongside technological advancements in actuator controllers, we can expect a future where sustainability becomes synonymous with reliability and performance across all applications involving SMAs.

Conclusion

In wrapping up our exploration of SMA actuators, it’s clear that these innovative devices offer a multitude of benefits that set them apart in the actuator landscape. From their unique ability to change shape in response to temperature variations to their lightweight and compact design, SMA actuators are making waves across various industries. Understanding these advantages not only highlights the potential of SMA technology but also emphasizes its growing importance in modern applications.

Recap of SMA Actuator Benefits

SMA actuators stand out due to their remarkable efficiency and versatility, making them ideal for applications ranging from medical devices to robotics. With minimal power requirements and the ability to operate in challenging environments, they provide solutions where traditional actuators may falter. Additionally, the compact nature of an SMA actuator allows for integration into spaces that larger mechanisms simply cannot fit, enhancing design flexibility.

Why Innovation Matters in Actuator Design

Innovation is at the heart of actuator design, especially when it comes to SMA technology. As industries evolve and demands shift towards more sustainable and efficient solutions, staying ahead with cutting-edge designs becomes crucial. The integration of advanced actuator controllers with SMA actuators not only enhances performance but also opens doors for smarter automation systems that can adapt dynamically to changing conditions.

Choosing the Right SMA Solutions for Your Needs

When selecting an SMA actuator for your specific application, it's essential to consider factors such as load requirements, response time, and environmental conditions. Different projects may necessitate varying degrees of precision or power output; thus, understanding your needs is key to making an informed choice. Ultimately, partnering with reliable manufacturers who offer tailored solutions will ensure you harness the full potential of your chosen SMA actuator while achieving optimal results.