Introduction

In the ever-evolving world of robotics, shape memory actuators are becoming a game-changer. These innovative devices leverage the unique properties of shape memory alloys to create motion and force in a compact form factor. Essentially, a shape memory actuator uses wire made from these alloys to achieve impressive mechanical movements that can adapt to various conditions.

What is a Shape Memory Actuator

A shape memory actuator, often referred to as an SMA actuator, is a device that can change its shape in response to temperature variations or electrical stimuli. This transformation allows it to perform work, making it an ideal choice for applications requiring precise movement and control. Typically constructed using shape memory alloy wire, these actuators can return to their original form after being deformed, showcasing their remarkable versatility.

The Role of Shape Memory Alloys

Shape memory alloys play a pivotal role in the functionality of SMA actuators by providing the necessary material properties that enable this unique behavior. When heated above a certain temperature, the alloy undergoes a phase change, allowing it to revert back to its pre-deformed state and exert force in the process. This characteristic makes shape memory alloy wire not only lightweight but also efficient for various robotic applications.

Applications in Modern Robotics

The applications of shape memory actuators in modern robotics are vast and varied, ranging from soft robotics to precision surgical tools. Their ability to provide controlled motion with minimal energy consumption makes them an attractive option for engineers and designers alike. As we continue exploring new technologies, SMA wires are paving the way for more innovative solutions that enhance efficiency and performance across numerous fields.

Understanding Shape Memory Actuators

Shape memory actuators are fascinating devices that leverage the unique properties of shape memory alloys (SMAs) to convert thermal energy into mechanical work. These materials can remember their original shapes and return to them when heated, making them ideal for various robotic applications. By utilizing SMA wire, robots can achieve remarkable movements and functionalities that traditional actuators may struggle with.

Mechanism of Shape Memory Alloys

The mechanism behind shape memory alloys is rooted in their ability to undergo phase transformations between two distinct solid states: austenite and martensite. When an SMA wire is deformed at a lower temperature, it adopts the martensite phase; upon heating, it transforms back into the austenite phase, resulting in a return to its original shape. This transformation allows the shape memory alloy actuator to exert significant force despite being lightweight, making it an attractive option for robotics.

How SMA Wires Function

SMA wires function by exploiting the thermal expansion characteristics of shape memory alloys. When an electrical current passes through the wire, it heats up and initiates the transition from martensite to austenite, causing it to contract and produce motion. Conversely, when cooled down or allowed to relax, the SMA wire returns to its deformed state—an elegant cycle that enables precise control over robotic movements with minimal energy consumption.

Advantages of Using SMA Actuators

Using SMA actuators offers several advantages over traditional actuator technologies in robotics. First and foremost, they are compact and lightweight, which is crucial for applications where space and weight are at a premium—think drones or miniature robots! Additionally, their ability to operate silently without mechanical noise makes them suitable for environments where stealth is essential. Finally, because these actuators use SMA wires instead of bulky motors or gears, they can be integrated seamlessly into designs requiring flexibility and adaptability.

GEE SMA and Quality Nitinol Alloys

Shape memory actuators are revolutionizing the field of robotics, and at the forefront of this transformation is GEE SMA. This innovative technology utilizes high-quality shape memory alloys (SMAs) that respond to temperature changes, enabling precise movements in robotic applications. With a focus on performance and reliability, GEE SMA is setting new standards in the industry.

Overview of GEE SMA

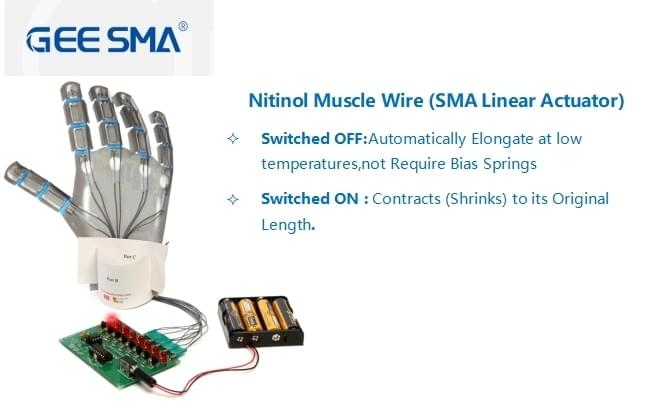

GEE SMA specializes in producing top-tier shape memory alloy actuators that leverage the unique properties of Nitinol, a nickel-titanium alloy known for its remarkable shape memory characteristics. These SMA wires can return to their original shape after deformation when exposed to specific temperatures, making them ideal for dynamic robotic applications. The versatility of GEE SMA products allows engineers to design intricate systems that require minimal power while delivering maximum efficiency.

Importance of High-Quality SMA Wires

When it comes to shape memory alloy actuators, the quality of the SMA wire is paramount. High-quality Nitinol wires ensure consistent performance and longevity, which are critical factors in robotic systems where failure is not an option. By utilizing superior materials, GEE SMA guarantees that its shape memory actuator products will withstand rigorous operational demands while maintaining their functionality over time.

Tailoring Materials for Robotics

Tailoring materials specifically for robotics applications means developing SMAs that can handle unique challenges such as varying loads and environmental conditions. The ability to customize these shape memory alloy wires allows engineers to optimize their designs for specific tasks or environments, whether it's a delicate surgical robot or a rugged industrial machine. As technology advances, the potential for creating specialized SMA actuators tailored precisely to robotic needs continues to expand.

Innovative Applications in Robotics

The integration of shape memory actuators into robotics has revolutionized the way machines interact with their environments. These devices leverage the unique properties of shape memory alloys (SMAs) to create movements that mimic biological systems, enhancing flexibility and adaptability. From soft robotics to precise surgical instruments, the applications are as diverse as they are innovative.

Shape Memory Actuators in Robotics

Shape memory actuators are at the forefront of robotic technology, providing a lightweight and efficient means of generating motion. Utilizing SMA wire allows these actuators to change shape with temperature variations, making them ideal for applications where space and weight are critical factors. With their ability to contract and expand rapidly, SMA actuators enable robots to perform complex tasks with ease and precision.

In recent years, the demand for advanced automation has prompted engineers to explore more creative uses for shape memory alloy actuators. For instance, in soft robotics, these SMA wires can be used to create flexible structures that can navigate through tight spaces or adapt to uneven terrains. This adaptability is crucial for robots designed for search-and-rescue missions or those operating in hazardous environments.

Moreover, the efficiency of shape memory alloy wire contributes significantly to energy conservation in robotic systems. By using SMA wire instead of traditional motors, robots can achieve greater energy efficiency while maintaining high performance levels. This not only reduces operational costs but also extends the lifespan of robotic components.

Case Studies: Real-World Implementations

Several pioneering projects have successfully incorporated shape memory actuators into their designs, showcasing their potential across various industries. One notable example is a robotic gripper that utilizes SMA wires to mimic human fingers' dexterity and grip strength effectively. This design allows for delicate handling of fragile objects while maintaining a secure hold on heavier items, demonstrating how versatile a shape memory alloy actuator can be.

Another impressive implementation is found in medical robotics where precise movements are paramount. A surgical robot equipped with SMA actuators has been developed to perform minimally invasive procedures with remarkable accuracy; its ability to contract and expand smoothly enhances the surgeon's control during operations. Such applications highlight how integrating SMAs can lead not only to improved functionality but also better patient outcomes.

Furthermore, research teams have explored using SMA wire in soft exoskeletons aimed at assisting individuals with mobility impairments. By harnessing the unique properties of shape memory alloys, these exoskeletons can provide support and enhance movement without bulky machinery or heavy components—transforming lives one step at a time.

Enhancing Efficiency and Precision

The advantages offered by shape memory alloy actuators extend beyond mere functionality; they also significantly enhance efficiency and precision within robotic systems. The lightweight nature of SMA wires means that robots equipped with these actuators consume less power while achieving comparable—or even superior—performance compared to traditional actuation methods like electric motors or pneumatic systems.

Additionally, due to their rapid response times when subjected to temperature changes, shape memory actuator systems allow for real-time adjustments during operation—crucial for tasks requiring high levels of accuracy such as assembly lines or delicate surgical procedures. This capability ensures that robots remain responsive under varying conditions without sacrificing control or reliability.

Finally, employing SMAs opens up new avenues for innovation in design thinking within robotics engineering; engineers can explore more compact shapes without compromising on performance attributes typically associated with larger mechanisms powered by conventional actuation methods such as motors or hydraulics—making it an exciting frontier worth exploring further.

Challenges and Limitations

While shape memory actuators hold great promise in the world of robotics, they are not without their challenges. Technical hurdles can hinder the widespread adoption and integration of SMA technology into existing systems. Understanding these limitations is crucial for engineers and designers who wish to leverage shape memory alloy actuators effectively.

Technical Hurdles for SMA Actuators

One of the primary technical hurdles for shape memory actuators lies in their response time. Unlike traditional actuators, which can provide immediate feedback and movement, SMA wires often require a significant amount of heat to transition between shapes, causing delays in actuation. Additionally, the thermal management necessary to control these temperature changes can complicate designs, demanding more sophisticated control systems that may increase overall costs.

Another challenge is the limited operational lifespan of shape memory alloy wires under continuous cycling. Repeatedly heating and cooling SMA wire can lead to fatigue over time, resulting in decreased performance or failure. Engineers must account for this wear when designing applications that rely heavily on SMA technology, necessitating additional testing and validation before deployment.

Lastly, the force output from a shape memory actuator can be relatively low compared to traditional electric or pneumatic actuators. While SMAs excel in applications requiring precise movements or small-scale actuation, they may struggle in scenarios demanding higher torque or load-bearing capabilities. This limitation necessitates careful consideration when selecting an actuator type based on application requirements.

Comparing SMA with Traditional Actuators

When comparing a shape memory alloy actuator with traditional actuators like electric motors or hydraulic systems, several factors come into play. Traditional actuators generally offer higher efficiency and faster response times than their SMA counterparts due to direct power input mechanisms such as electricity or pressurized fluids. In contrast, an SMA actuator relies on thermal energy conversion through the heating of wires—a process inherently slower than direct mechanical action.

Furthermore, while traditional actuators often have robust designs capable of handling various environmental conditions without significant degradation, shape memory alloys can be sensitive to temperature fluctuations and external conditions that affect their performance. This sensitivity means that while SMAs are lightweight and compact—ideal for certain robotic applications—they may not be suitable for all environments where ruggedness is required.

Nonetheless, one cannot overlook the unique advantages offered by shape memory alloy wires—namely their ability to return to a predetermined shape upon heating without complex mechanical components. This quality allows them to integrate seamlessly into innovative designs where space constraints exist or where conventional solutions would be impractical due to size limitations.

Future Improvements in Shape Memory Technologies

The future of shape memory technologies looks promising as ongoing research aims to address current limitations faced by SMA actuators today. Innovations like enhancing material properties through advanced alloys could lead to stronger and more resilient shape memory alloy wires capable of withstanding greater cycling without degrading performance over time. These advancements would significantly improve reliability across various robotic applications while expanding their use cases beyond niche markets.

Moreover, integrating smart materials with advanced sensors could revolutionize how we utilize SMAs in robotics by providing real-time feedback about actuator performance and environmental conditions directly influencing operation efficiency. Such developments might pave the way for adaptive systems that optimize actuation based on situational demands—making SMA technology even more compelling for future robotics solutions.

Finally, researchers are exploring hybrid systems combining traditional actuation methods with SMAs; this approach aims at leveraging each technology's strengths while mitigating weaknesses inherent within them individually—for example using electric motors paired with shape memory alloy actuators for precision tasks requiring both speed and fine control capabilities simultaneously.

The Future of Robotics with SMA Technology

The future of robotics is increasingly intertwined with the development and application of shape memory actuator technology. As we delve deeper into innovative solutions, the potential of shape memory alloys (SMAs) becomes even clearer, particularly in enhancing robotic capabilities. With their unique ability to transform and adapt, SMA actuators are set to revolutionize various sectors, from manufacturing to healthcare.

Trends in Robotics Utilizing SMA Wires

One of the most exciting trends emerging in robotics is the integration of SMA wires for more compact and efficient designs. These shape memory alloy wires allow robots to achieve greater flexibility while maintaining strength, making them ideal for applications requiring intricate movements. As industries seek lighter and more energy-efficient solutions, the demand for SMA actuators will likely surge.

Moreover, advancements in control systems for SMA actuators are enabling more precise movements and responsiveness in robotic applications. This trend is particularly evident in soft robotics, where flexibility is paramount; here, using shape memory alloy actuators can lead to safer interactions with humans and delicate objects alike. Expect to see a rise in collaborative robots (cobots) that utilize these smart materials for improved performance.

Predictions for Shape Memory Alloy Applications

Looking ahead, we can anticipate a broadening scope of applications for shape memory alloy actuators across various fields. In healthcare robotics, SMAs could be employed in minimally invasive surgical tools that require precise movement and adaptability—think robotic arms that can bend and twist with ease. Additionally, as wearable technology continues to evolve, shape memory alloy wires may play a crucial role in developing flexible exoskeletons that assist individuals with mobility challenges.

In industrial settings, the efficiency gains from using SMA actuators could lead to significant cost savings and productivity improvements. For instance, automation systems utilizing shape memory alloy wire could reduce maintenance needs due to their durability under stress compared to traditional materials. The versatility of SMAs positions them as key players not just now but well into the future.

The Next Generation of Robotics Solutions

The next generation of robotics solutions promises an exciting synergy between artificial intelligence (AI) and shape memory alloy technology. By incorporating AI-driven algorithms with sma actuator functionality, robots will become smarter at learning from their environments and adapting accordingly—think about robots capable of adjusting their grip based on object texture or weight through real-time feedback from their sma wires!

Additionally, innovations such as 3D printing techniques tailored for creating custom shapes out of shape memory alloys will pave the way for bespoke robotic components designed specifically for unique tasks or environments. This level of customization will enhance performance while reducing waste—a win-win situation!

In summary, as we embrace these advancements in SMA technology within robotics, we are poised on the brink of a revolution that could redefine how machines interact with our world.

Conclusion

In summary, the impact of shape memory actuators on modern robotics cannot be overstated. These innovative devices, powered by shape memory alloys, are revolutionizing how we think about movement and functionality in machines. By harnessing the unique properties of SMA wire, engineers can create actuators that respond dynamically to environmental changes, enhancing robotic capabilities.

The Impact of Shape Memory Actuators

Shape memory actuators represent a significant leap forward in actuator technology, offering unparalleled flexibility and efficiency. The ability of a shape memory alloy actuator to revert to its original shape when heated allows for compact designs that can perform complex tasks with minimal energy consumption. This unique characteristic not only optimizes performance but also paves the way for more sophisticated robotics applications across various industries.

Advancements in Robotics Technology

Advancements in robotics technology have been greatly influenced by the integration of SMA wire into designs. As robotic systems become increasingly intricate and require precise movements, the role of shape memory alloy wire becomes crucial in achieving these goals. The continuous development of SMA actuators is leading to smarter robots that can adapt to their environments with remarkable agility and precision.

Why Choose GEE SMA for Your Needs

When considering which materials to use in your robotic projects, GEE SMA stands out as a leader in quality and innovation. Their high-quality shape memory alloy wires ensure reliable performance and durability, making them an excellent choice for any application requiring an SMA actuator. By selecting GEE SMA products, you are investing in cutting-edge technology that is designed to meet the evolving demands of modern robotics.