Introduction

In the realm of modern engineering, shape memory actuators have emerged as a fascinating innovation, captivating the attention of researchers and industry professionals alike. These unique devices leverage the properties of shape memory materials, enabling them to return to a predetermined shape when subjected to specific stimuli. This remarkable ability raises questions such as: What is a shape memory actuator? How does the shape memory process work? Understanding these concepts is crucial for anyone interested in the future of robotics and automation.

The evolution of robotics has been significantly influenced by advancements in materials science, particularly with the advent of Shape Memory Alloys (SMAs). Initially discovered in the 1930s, SMAs have undergone substantial refinement and integration into various robotic applications over the decades. As we explore this evolution, it becomes evident that understanding what are the applications of SMA can unlock new potential for robotic systems across diverse industries.

The importance of Shape Memory Alloys cannot be overstated; they bring a unique combination of versatility and efficiency to both industrial and medical fields. From enhancing device functionality to enabling groundbreaking surgical techniques, real-life examples of shape memory alloys showcase their transformative impact on technology. As we delve deeper into this topic, we will examine how NASA's use of shape memory alloy projects further illustrates their vital role in pushing the boundaries of aerospace engineering and beyond.

The Science Behind Shape Memory Actuators

The world of shape memory actuators is a fascinating intersection of materials science and engineering, where unique properties of certain alloys are harnessed to create devices that can change shape in response to temperature changes. These remarkable materials, known as shape memory alloys (SMAs), have the ability to remember a predetermined shape and return to it when heated. This opens up a plethora of possibilities in various fields, from aerospace to medicine.

What is a shape memory actuator?

At its core, a shape memory actuator is a device that converts thermal energy into mechanical work through the unique properties of shape memory materials. So, what is a shape memory actuator? It utilizes the phase transformation characteristics of SMAs to achieve movement or force generation when subjected to specific temperature thresholds. This means that these actuators can perform tasks such as opening or closing mechanisms without the need for complex motors or electronics, making them incredibly efficient and compact.

Shape memory actuators are particularly valuable in applications where precision and reliability are paramount. They can be found in everything from robotics to automotive systems, showcasing their versatility across several industries. As we delve deeper into the mechanics behind these devices, it becomes clear why they are gaining traction in modern engineering solutions.

The shape memory process explained

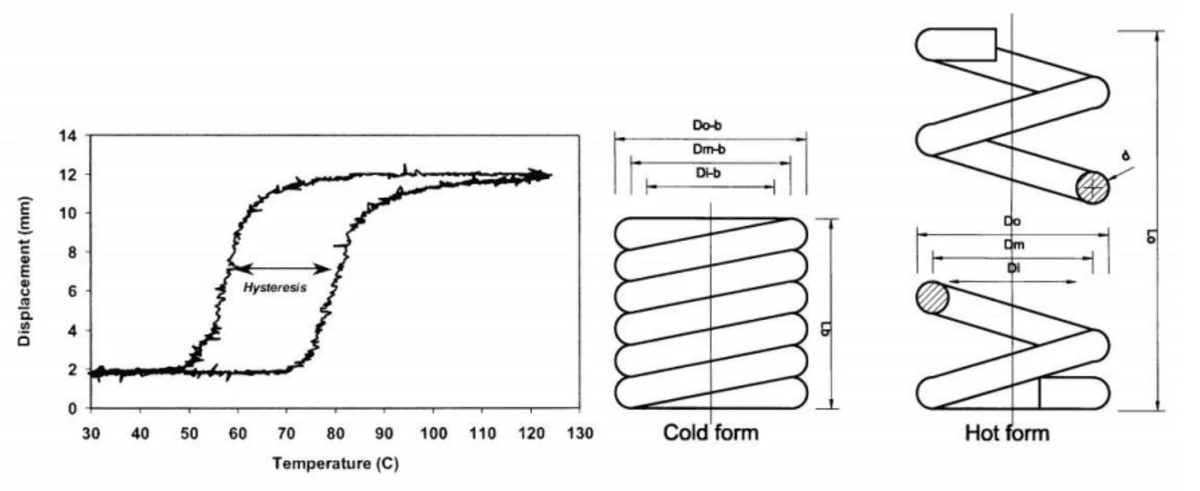

What is the shape memory process? It refers to the ability of certain materials to undergo phase changes between two distinct crystal structures: martensite and austenite. When an SMA is deformed while in its martensitic state—typically at lower temperatures—it retains this new configuration until it reaches its transformation temperature; upon heating, it transforms back into its original austenitic form, thus remembering its initial shape.

This process can be triggered by simply applying heat or through other stimuli like electrical current or stress changes. The efficiency with which these materials respond makes them ideal for applications requiring quick actuation without significant energy expenditure. Understanding this fundamental principle behind SMAs allows engineers and scientists alike to innovate new designs and functionalities for various technologies.

How shape memory materials work

How do shape memory materials work? Essentially, they operate on principles rooted in thermodynamics and crystallography; specifically, their ability to transition between two crystalline structures enables them to exhibit unique mechanical properties under varying temperatures. When heated above their transition temperature, SMAs undergo an instantaneous change that allows them to return from their deformed state back into their original configuration—this phenomenon is what gives rise to the term shape memory.

These remarkable materials have broad applications due primarily to their lightweight characteristics combined with high strength-to-weight ratios—perfect for sectors like aerospace engineering where every gram counts! Moreover, real-life examples of shape memory alloys include uses in medical devices such as stents that expand at body temperature or robotic grippers that adapt based on environmental conditions. As we continue exploring innovations like NASA's use of these alloys in spacecraft design, it's evident that understanding how these actuators function will be key for future advancements across multiple industries.

Real Life Applications of Shape Memory Alloys

Shape Memory Alloys (SMAs) have carved out a niche in various industries due to their unique properties and capabilities. These materials can remember their original shapes, allowing them to return to that form when subjected to specific thermal conditions. This fascinating characteristic leads to a plethora of applications, making shape memory actuators indispensable in modern technology.

What are the applications of SMA?

What are the applications of SMA? The versatility of shape memory actuators allows them to be employed in numerous fields, ranging from aerospace and automotive industries to healthcare and robotics. In aerospace, for instance, SMAs are utilized for morphing wing structures that adapt during flight for improved aerodynamics, while in medical devices, they enable minimally invasive surgical tools that expand or contract as needed.

The shape memory process is at the heart of these applications; it enables SMAs to undergo phase transformations that result in mechanical work without complex control systems. This simplicity is appealing across various sectors where reliability and efficiency are paramount. Moreover, as industries continue to innovate, the range of SMA applications is expected to grow even further.

Shape Memory Alloy actuator applications in various industries

Shape Memory Alloy actuator applications span multiple sectors, showcasing their adaptability and effectiveness. In the automotive industry, SMAs contribute significantly by powering self-adjusting components such as seatbelts and engine valves that enhance safety and performance. Additionally, these materials are increasingly being used in consumer electronics for smart devices that can change shape or function based on user interaction.

In the field of robotics, shape memory actuators enable more flexible designs with lightweight structures capable of performing complex movements with minimal energy consumption. As robots become more integrated into daily life—from household helpers to industrial automation—the demand for efficient actuation systems like SMAs will continue to rise. Furthermore, NASA's use of shape memory alloys demonstrates their potential beyond Earth’s atmosphere; these materials help create adaptive mechanisms essential for spacecraft functionality.

GEE SMA: Innovating with Nitinol

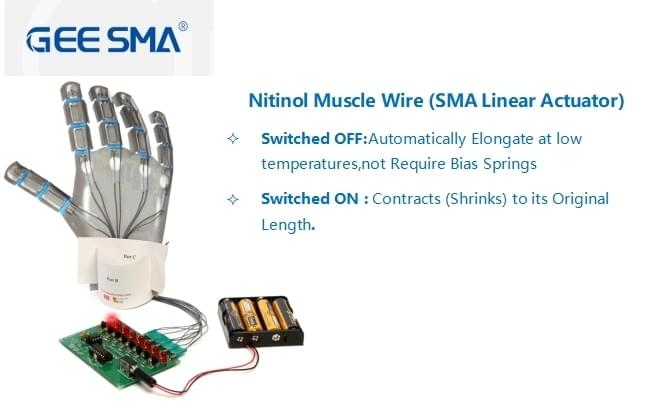

GEE SMA has taken innovation a step further by focusing on Nitinol—an alloy known for its remarkable properties as a shape memory material. Nitinol's ability to return from deformation makes it an ideal candidate for advanced applications where precision is crucial yet challenging environments must be navigated. As one of the leading suppliers and developers in this field, GEE SMA continuously explores new avenues for integrating Nitinol into various technologies.

From medical stents that expand upon reaching body temperature to robotic grippers mimicking human dexterity through precise movements—Nitinol showcases how far we’ve come with shape memory actuators. The ongoing research into optimizing Nitinol’s performance opens doors not only within existing markets but also into unexplored territories like soft robotics or adaptive architecture designs tailored for sustainability challenges ahead.

Shape Memory Actuators in Medical Devices

Shape memory actuators are revolutionizing the field of medical technology, offering innovative solutions that enhance patient care and surgical procedures. These remarkable devices utilize shape memory materials, which can change their shape in response to temperature variations, making them ideal for various applications in healthcare. As we delve deeper into the world of SMAs, it becomes clear that their potential is only just beginning to be realized.

Enhancing medical technology with SMAs

What is a shape memory actuator? Simply put, it's a device that can remember its original shape and return to it when activated by heat or other stimuli. This unique capability allows for precise control in medical devices, such as stents and surgical tools, significantly improving their functionality and effectiveness. By integrating shape memory alloys (SMAs) into these devices, manufacturers can create products that respond dynamically to changes in the body’s environment.

The shape memory process involves heating the material above its transformation temperature, allowing it to revert to its pre-deformed state. This process not only enhances the performance of medical instruments but also leads to less invasive procedures with shorter recovery times for patients. The seamless integration of SMAs into everyday medical technology illustrates how they are reshaping healthcare practices for the better.

Real life examples of shape memory alloys in healthcare

What are real life examples of shape memory alloys? One prominent application is in self-expanding stents used for treating cardiovascular diseases; these devices expand automatically upon reaching body temperature, ensuring optimal placement without requiring complex maneuvers from surgeons. Another example includes SMA-based orthopedic implants that adapt their form during insertion and then stabilize once positioned correctly within the body.

In addition to stents and implants, SMA technology has found its way into surgical tools like laparoscopic instruments that can change shapes during procedures without needing large incisions. Shape Memory Alloy actuator applications extend beyond traditional uses; they also include innovative therapies such as drug delivery systems where actuators release medication at controlled rates based on body conditions. The versatility of SMAs continues to inspire new developments across various sectors within healthcare.

Impact on minimally invasive surgeries

The impact of shape memory actuators on minimally invasive surgeries cannot be overstated; they have transformed how operations are performed by reducing trauma associated with larger incisions. With SMAs at play, surgeons can utilize smaller entry points while maintaining high levels of precision and control over surgical instruments—what's not to love about that? This advancement leads not only to quicker recovery times but also minimizes scarring and post-operative complications for patients.

Moreover, the ability of these materials to adapt during surgery allows for real-time adjustments based on patient anatomy or unforeseen challenges encountered during procedures. As we explore further advancements driven by NASA's research into shape memory alloy technologies—often aimed at aerospace applications—we see exciting crossovers into medicine as well. In essence, the marriage between robotics and healthcare through SMA innovation sets a promising trajectory toward future breakthroughs.

NASA’s Use of Shape Memory Alloys

NASA has been at the forefront of exploring and implementing shape memory actuators, recognizing their potential to revolutionize aerospace technology. Through various projects, NASA has successfully integrated shape memory materials into spacecraft systems and components, enhancing performance and efficiency. The unique properties of these materials make them ideal for applications where weight savings and reliability are crucial, particularly in the harsh environment of space.

The role of NASA shape memory alloy projects

NASA's shape memory alloy projects are pivotal in developing innovative solutions for space exploration challenges. By leveraging the ability of these materials to return to a predetermined shape when heated, engineers can create lightweight actuators that perform complex movements without the need for bulky motors. This not only reduces weight but also simplifies design and maintenance, making it a win-win for mission success.

Innovations in aerospace engineering with SMAs

Innovations stemming from the use of SMAs in aerospace engineering have led to remarkable advancements in flight control systems and deployable structures. For example, NASA has utilized shape memory actuators in wing morphing technology that allows aircraft to adapt their shapes during flight for improved aerodynamics and fuel efficiency. Additionally, SMA-based mechanisms are being explored for satellite deployment systems, showcasing how these materials can enhance operational capabilities while minimizing risks.

Future possibilities for space exploration

The future possibilities for space exploration using shape memory alloys are both exciting and transformative. As we look toward long-duration missions to Mars or beyond, the adaptability offered by SMAs could play a critical role in creating self-repairing structures or adaptive habitats that respond to environmental changes autonomously. Furthermore, ongoing research into new alloys may unlock even more applications, solidifying the position of shape memory actuators as essential tools in humanity's quest to explore outer space.

Future Trends in Shape Memory Actuators

The landscape of shape memory actuators is rapidly evolving, with innovative technologies emerging that harness the unique properties of shape memory materials. These materials, known for their ability to return to a predetermined shape when subjected to specific temperatures, are being integrated into various cutting-edge applications. From advanced robotics to smart textiles, the potential for shape memory alloys (SMAs) is vast and exciting.

Emerging technologies utilizing shape memory materials

Emerging technologies harnessing the power of shape memory materials are paving the way for breakthroughs across numerous fields. For instance, researchers are developing self-healing materials that can repair themselves using SMA properties, which could revolutionize product longevity and sustainability. Additionally, smart devices incorporating these actuators can adapt their form based on environmental stimuli, making them highly responsive and user-friendly.

In aerospace engineering, NASA's projects have explored how SMAs can be used in deployable structures such as solar panels and antennas that need to unfold in space. These applications demonstrate not only the versatility of SMAs but also their critical role in enhancing functionality while reducing weight—an essential factor in aerospace design. Furthermore, advancements in 3D printing technology are enabling the creation of complex shapes from SMA materials that were previously impossible to fabricate.

The potential of SMA in soft robotics

The field of soft robotics stands to benefit immensely from the integration of shape memory actuators. Soft robots made with SMAs can mimic biological movements more effectively than traditional rigid robots due to their flexibility and adaptability. This opens up new avenues for creating robots capable of delicate tasks such as handling fragile objects or navigating through confined spaces.

What is particularly fascinating about using SMAs in soft robotics is their ability to change shape dynamically based on temperature changes—a process rooted in what is known as the shape memory process. This allows for more fluid movement patterns that can adjust according to environmental conditions or specific tasks at hand. As research continues into optimizing these materials for performance and efficiency, we may soon see a new generation of robots capable of performing intricate operations with minimal human intervention.

Predictions for SMA advancements

Looking ahead, predictions suggest a bright future filled with advancements in shape memory actuators across diverse sectors. As industries recognize the advantages offered by these remarkable materials—such as reduced weight and increased energy efficiency—we’re likely to see widespread adoption beyond just aerospace or medical devices. For instance, automotive manufacturers may implement SMAs for adjustable seating systems or adaptive body parts that enhance safety and comfort.

Moreover, ongoing research aims at improving the thermal response times of SMAs so they can operate even more efficiently under varying conditions—a crucial factor when considering real life examples of shape memory alloys at work today. With continued innovation driven by both academic institutions and industry leaders alike, we anticipate groundbreaking applications that will redefine how we interact with technology daily.

In conclusion, from smart textiles adapting to wearers' needs to soft robots revolutionizing automation processes—shape memory actuators hold immense potential for transforming our world into one where technology seamlessly integrates into our lives while responding intelligently to our needs.

Conclusion

As we wrap up our exploration of shape memory actuators, it's clear that these remarkable devices are revolutionizing various fields, from medicine to aerospace. Understanding what a shape memory actuator is and how the shape memory process works opens the door to innovative applications that can enhance efficiency and functionality. The versatility of shape memory materials continues to inspire advancements, making them indispensable in modern technology.

Key Takeaways on Shape Memory Actuators

The core takeaway about shape memory actuators is their unique ability to change form in response to temperature variations, which is central to what makes these materials so fascinating. The applications of SMA span a multitude of industries, showcasing their potential in everything from robotics to medical devices. Real-life examples of shape memory alloys demonstrate their effectiveness and adaptability, proving that these materials are not just theoretical concepts but practical solutions for contemporary challenges.

The Future of Robotics and SMAs

Looking ahead, the future of robotics intertwined with SMAs appears bright and full of possibilities. As we continue to innovate with shape memory materials, we can expect enhanced functionalities in robotic systems that mimic natural movements more closely than ever before. With ongoing research into NASA's shape memory alloy projects and other initiatives, the integration of SMAs into robotics could lead us toward smarter machines capable of complex tasks in unpredictable environments.

Encouraging Innovations with Shape Memory Alloys

To foster further innovations with shape memory alloys, collaboration across disciplines will be crucial; engineers, designers, and scientists must come together to unlock new potentials for SMA applications. By encouraging experimentation with these versatile materials, industries can discover novel uses that may not yet be on our radar—imagine robots equipped with advanced SMA technology performing intricate procedures or even contributing to space exploration missions! The possibilities are endless when creativity meets the science behind shape memory actuators.