Introduction

In the ever-evolving landscape of technology, SMA motors have carved a niche that is both innovative and indispensable. These remarkable devices leverage the unique properties of shape memory alloys to provide efficient actuation solutions across various industries. With applications ranging from robotics to aerospace, understanding the significance of SMA hydraulic motors is crucial for appreciating their growing impact.

The Importance of SMA Motors

SMA motors, particularly the Small SMA Radial Piston Motor, are gaining traction due to their ability to deliver precise motion with minimal energy consumption. Their compact design allows for integration into tight spaces where traditional motors may falter, making them ideal for modern engineering challenges. As industries seek more efficient and sustainable solutions, the role of SMA actuation becomes increasingly vital.

A Brief History of SMA Technology

The journey of shape memory alloy technology began in the 1930s with the discovery of Nitinol—a nickel-titanium alloy known for its unique ability to return to a pre-defined shape when heated. Over decades, research and development led to significant advancements in SMA applications, culminating in today’s sophisticated small SMA radial piston motors that are revolutionizing various sectors. This rich history underscores how far we've come in harnessing these materials for practical use.

Key Applications of SMA Actuation

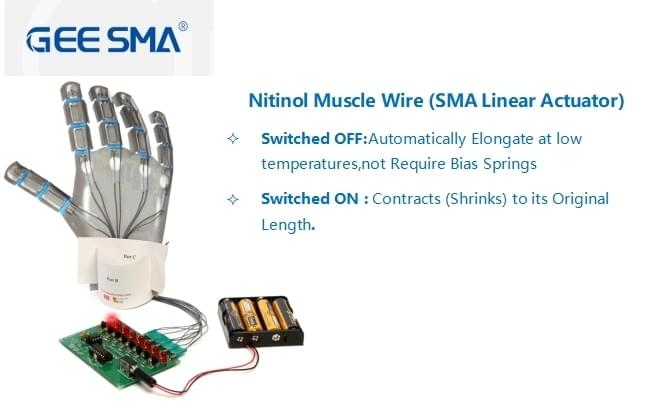

SMA actuation finds itself at home in diverse fields such as robotics, where precision and adaptability are paramount; aerospace technology, which demands lightweight yet powerful components; and medical devices that benefit from gentle yet effective operation. The versatility offered by Nitinol wire makes it an attractive option for manufacturers looking for high-quality solutions at competitive prices. As we explore these applications further, it becomes evident that SMA motors hold transformative potential across multiple industries.

Understanding SMA Motor Mechanics

The mechanics behind SMA motors are a fascinating blend of materials science and engineering ingenuity. At their core, these motors utilize the unique properties of shape memory alloys (SMAs) to convert thermal energy into mechanical motion. This section will delve into how SMA motors operate, particularly focusing on the Small SMA Radial Piston Motor, its components, and the underlying science that makes these remarkable devices work.

How SMA Motors Work

SMA motors function by harnessing the shape memory effect found in materials like Nitinol. When an SMA is heated above a specific temperature, it transforms from a low-temperature phase (martensite) to a high-temperature phase (austenite), resulting in significant dimensional changes. This transformation creates movement that can be precisely controlled, making SMA actuation an attractive solution for various applications where traditional motors might fall short.

In a typical scenario, an electrical current is passed through Nitinol wire or another shape memory alloy, causing it to heat up and contract. This contraction can then be harnessed to drive pistons or other mechanical components within devices such as the Small SMA Radial Piston Motor. The ability to control this heating and cooling process allows for highly efficient operation and precise movements in applications ranging from robotics to medical devices.

Components of a Small SMA Radial Piston Motor

A Small SMA Radial Piston Motor consists of several key components that work together seamlessly to produce motion. The primary elements include the Nitinol wire actuator, housing structure, piston assembly, and control mechanism. Each part plays a vital role in ensuring that the motor operates efficiently while delivering reliable performance under varying conditions.

The Nitinol wire serves as the actuator by responding to thermal stimuli; when heated or cooled appropriately, it drives the piston forward or backward within its chamber. The housing structure encases these components while providing necessary support and protection against external factors that could impair functionality. Lastly, an effective control mechanism allows operators to regulate temperature changes accurately—essential for achieving desired actuation speeds and responses.

The Science Behind Shape Memory Alloys

Shape memory alloys like Nitinol are remarkable materials with unique properties that set them apart from conventional metals. Their ability to remember their original shapes means they can revert back after being deformed when exposed to specific temperatures—a phenomenon known as the shape memory effect. This property is what enables SMAs used in applications such as SMA hydraulic motors where precision movement is crucial.

Nitinol's behavior is rooted in its crystalline structure; transitions between martensite and austenite phases facilitate changes in shape under varying thermal conditions. Additionally, this material exhibits superelasticity at certain temperatures—allowing it to undergo significant deformation without permanent change—making it ideal for dynamic applications requiring flexibility alongside strength. Understanding these principles not only illuminates how SMAs function but also highlights why they are increasingly popular across various industries seeking innovative actuation solutions.

The Role of Nitinol in SMA Motors

Nitinol, a nickel-titanium alloy, plays a pivotal role in the functionality and efficiency of SMA motors. Its unique shape memory and superelastic properties make it an ideal candidate for applications requiring precise movements and actuation, such as in Small SMA Radial Piston Motors. When considering Nitinol Wire Price, quality becomes an essential factor since it directly impacts performance and durability in various SMA hydraulic motor applications.

Nitinol Wire Price and Quality Considerations

When delving into the world of Nitinol wires, price is often at the forefront of decision-making. However, it's crucial to remember that not all Nitinol wire is created equal; quality can vary significantly among suppliers. Investing in high-quality Nitinol wire for sale can lead to enhanced performance in SMA motors, ensuring that your Small SMA Radial Piston Motor operates efficiently over time.

Advantages of Using Nitinol Wire for Sale

Choosing to use Nitinol wire comes with a plethora of advantages that make it a go-to material for SMA actuation systems. First off, its excellent fatigue resistance means that components made from this material can withstand repeated cycles without significant wear or failure—ideal for demanding environments like aerospace technology or robotics. Additionally, the availability of diverse forms of Nitinol wire allows engineers to tailor their designs specifically for each application within the realm of SMA hydraulic motors.

Nitinol's Unique Properties and Benefits

Nitinol's unique properties extend beyond just being a reliable choice for SMA motors; they also include remarkable thermal responsiveness and shape memory capabilities. This means that when subjected to specific temperatures, Nitinol can return to its original shape after deformation—a vital characteristic for any effective SMA actuation mechanism. Moreover, these features enable compact design possibilities while maintaining high efficiency, making it an invaluable asset across various industries relying on Small SMA Radial Piston Motors.

Applications of SMA Hydraulic Motors

Small SMA radial piston motors have carved out a niche in various industries due to their unique capabilities. These innovative machines leverage the properties of shape memory alloys (SMAs), particularly Nitinol, to provide precise actuation and control. From robotics to aerospace and medical devices, the applications of SMA hydraulic motors are both diverse and impactful.

Uses in Robotics and Automation

In the realm of robotics and automation, SMA motors are revolutionizing how machines operate. Their compact design allows for integration into tight spaces, making them ideal for intricate robotic systems that require precision movement without bulky components. The responsiveness of SMA actuation enables robots to mimic human-like movements, enhancing their functionality in tasks such as assembly, inspection, and even delicate surgeries.

Moreover, the lightweight nature of small SMA radial piston motors contributes to improved energy efficiency in robotic applications. This efficiency is crucial as industries increasingly seek sustainable solutions that reduce energy consumption while maintaining performance. As manufacturers look for reliable actuation methods, Nitinol wire for sale becomes an attractive option due to its balance of cost and quality.

SMA Motors in Aerospace Technology

Aerospace technology is another field where SMA hydraulic motors shine brightly. The ability of these motors to withstand extreme temperatures while providing reliable performance makes them suitable for aircraft systems that demand high reliability under varying conditions. Whether it's controlling flaps or adjusting landing gear, small SMA radial piston motors offer a lightweight alternative that doesn’t compromise on power or precision.

Additionally, the use of SMAs can lead to reduced maintenance costs since these materials often exhibit greater durability compared to traditional actuators. As aerospace engineers continue pushing boundaries toward more efficient designs, integrating Nitinol-based systems will likely become standard practice. The focus on Nitinol wire price versus performance will drive innovation as companies strive for cost-effective solutions without sacrificing quality.

Medical Devices Powered by SMA Actuation

The medical field has also embraced the advantages offered by SMA hydraulic motors through various devices designed for surgical procedures or rehabilitation therapies. These innovative actuators can perform complex movements with remarkable accuracy while being compact enough to fit into minimally invasive tools or prosthetics. The flexibility provided by small SMA radial piston motors allows healthcare professionals to enhance patient outcomes significantly.

Moreover, because SMAs can be activated at body temperature or through electrical stimulation, they offer unique opportunities for developing responsive medical devices that adapt dynamically during procedures or treatments. As demand grows for advanced medical technologies powered by reliable actuation methods like those found in Nitinol components, manufacturers are keenly interested in sourcing high-quality Nitinol wire for sale at competitive prices.

Challenges in SMA Motor Technology

While the potential of SMA motors is immense, they are not without their challenges. Understanding these limitations is crucial for developers and engineers looking to optimize Small SMA Radial Piston Motors for various applications. As we delve into these challenges, it becomes clear that addressing them will be key to advancing SMA actuation technologies.

Limitations of Small SMA Radial Piston Motors

Small SMA Radial Piston Motors face several inherent limitations that can hinder their performance. One prominent issue is the relatively low force output compared to traditional motors, which can restrict their use in high-demand applications. Additionally, the operational speed of these motors tends to be slower than conventional alternatives, making them less suitable for tasks requiring rapid actuation.

Another limitation lies in the energy efficiency of SMA motors; they often require significant energy input to achieve desired movements and may not be ideal for battery-operated devices. Furthermore, the complexity of integrating these motors into existing systems can pose challenges during development phases. Ultimately, understanding these limitations helps engineers innovate and improve upon current designs.

Addressing Thermal Management Issues

Thermal management is a critical concern when working with SMA hydraulic motors due to the heat generated during operation. Excessive heat can lead to reduced performance or even damage components over time, necessitating effective cooling solutions. Implementing thermal management strategies—such as heat sinks or active cooling systems—can help maintain optimal operating temperatures and enhance motor longevity.

Moreover, understanding Nitinol's properties plays a vital role in addressing thermal issues since this material exhibits distinct thermal behavior during phase transitions. Engineers must carefully consider Nitinol wire price and quality when selecting materials that best suit their thermal management needs while ensuring cost-effectiveness and performance reliability. By prioritizing effective thermal management strategies, developers can significantly improve the functionality of SMA actuation systems.

Solutions for Reliability and Longevity

To ensure reliability and longevity in Small SMA Radial Piston Motors, engineers must focus on robust design principles and high-quality materials like Nitinol wire for sale that meet specific application requirements. Utilizing advanced manufacturing techniques can enhance component durability while minimizing wear over time—an essential factor as repeated cycling takes its toll on any actuator system.

Additionally, regular maintenance protocols should be established to monitor motor performance and identify potential issues before they escalate into significant failures. This proactive approach not only extends the lifespan of SMA hydraulic motors but also reduces downtime associated with repairs or replacements—a crucial consideration in industries where reliability is paramount.

Ultimately, by tackling these challenges head-on through innovative design solutions and rigorous maintenance practices, we can unlock the full potential of SMA technology across various sectors.

Future Trends in SMA Technology

As the landscape of technology evolves, so too does the potential for advancements in shape memory alloy (SMA) motors. The innovative designs of SMA motors are set to revolutionize various industries by enhancing efficiency and performance. With a growing focus on sustainability and miniaturization, innovations in Small SMA Radial Piston Motor designs will likely lead to more compact and powerful actuation solutions.

Innovations in SMA Motor Design

Recent innovations in SMA motor design focus on optimizing performance while minimizing size and weight. Engineers are exploring new geometries and configurations for Small SMA Radial Piston Motors that promise greater output with less energy consumption. This trend not only enhances the functionality of SMA hydraulic motors but also opens avenues for integration into applications where space is at a premium.

Furthermore, advancements in material science are paving the way for more robust SMAs that can withstand higher operational stresses without compromising their unique properties. The exploration of hybrid systems combining traditional motor technologies with SMAs could yield even greater efficiencies, particularly in robotics and aerospace applications where performance is critical. As these innovations unfold, we can expect an exciting future for SMA actuation technologies.

The Growing Market for SMA Actuation

The market for SMA actuation is experiencing significant growth as industries recognize the advantages offered by these unique systems. With increasing demand across sectors such as robotics, aerospace, and medical devices, manufacturers are keenly interested in developing reliable Small SMA Radial Piston Motors that deliver superior performance at competitive costs. As a result, we anticipate a surge in investment towards research and development aimed at refining these technologies.

Moreover, as production methods become more efficient, Nitinol wire price considerations will likely become more favorable for manufacturers seeking high-quality materials at reasonable costs. The availability of Nitinol wire for sale from multiple suppliers means that companies can source materials easily while benefiting from competitive pricing structures. This trend will further enhance the adoption of SMA technology across various applications.

Potential Developments in Nitinol Applications

Nitinol's remarkable properties make it an ideal candidate for an array of innovative applications beyond traditional uses in actuators or motors. Researchers are actively investigating how Nitinol can be utilized to create self-healing materials or smart structures that respond dynamically to environmental changes—an exciting frontier that could redefine engineering standards across multiple fields. Additionally, developments aimed at improving the thermal management capabilities of Nitinol-based systems will enhance their reliability and longevity.

The future may also see breakthroughs involving advanced alloys or composites that incorporate Nitinol's shape memory effects while offering improved mechanical properties or resistance to fatigue over time. Such advancements could lead to novel products like adaptive automotive components or next-generation medical devices powered by sophisticated SMA hydraulic motors designed specifically for precision tasks within healthcare settings. Overall, the potential developments surrounding Nitinol applications promise an exhilarating trajectory ahead.

Conclusion

In wrapping up our exploration of SMA motors, it's clear that these devices represent a fascinating intersection of materials science and engineering. The versatility and efficiency of the Small SMA Radial Piston Motor make it an invaluable asset in various applications, from robotics to aerospace. As we look to the future, the potential for SMA actuation continues to expand, driven by innovations in Nitinol technology.

Key Takeaways on SMA Motors

SMA motors leverage the unique properties of shape memory alloys to deliver remarkable performance in compact packages. The Small SMA Radial Piston Motor exemplifies how these systems can provide reliable actuation with minimal energy input, making them ideal for applications where space and weight are critical factors. Understanding the mechanics behind SMA actuation is essential for engineers looking to incorporate this technology into their designs.

Future of SMA Actuation in Various Industries

The future of SMA actuation looks promising as industries increasingly adopt these innovative solutions for more efficient operation. With advancements in Nitinol wire quality and accessibility—such as competitive Nitinol wire prices—manufacturers can explore new possibilities for integration into products like medical devices and aerospace systems. As demand grows, we can expect a surge in research focused on enhancing the capabilities of SMA hydraulic motors across diverse sectors.

Final Thoughts on Nitinol and SMA Technologies

Nitinol stands out as a game-changer in the realm of shape memory alloys, offering unique benefits that enhance the functionality of sma motors across various applications. As manufacturers continue to innovate with this material, we may soon see even more refined versions of Small SMA Radial Piston Motors that push boundaries further than ever before. Ultimately, Nitinol's adaptability ensures that it will remain at the forefront of technological advancements within this exciting field.