Introduction

In the world of modern engineering, SMA wire actuators have emerged as a fascinating solution for converting thermal energy into mechanical motion. These innovative devices leverage the unique properties of shape memory alloys (SMAs) to achieve precise linear movements, making them a popular choice in various applications. Understanding how SMA wire actuators operate is not just an academic exercise; it's essential for harnessing their full potential in technology.

Overview of SMA Wire Actuators

SMA wire actuators are specialized devices that utilize shape memory alloys to create motion when subjected to temperature changes. At their core, these linear actuators can contract or expand based on heat application, allowing for seamless integration into mechanical systems. Unlike traditional electric linear actuators, which rely on motors and gears, SMA linear actuators offer a compact and lightweight alternative that excels in specific scenarios.

Importance of Understanding their Operation

Grasping the operational principles behind SMA wire actuators is crucial for engineers and designers aiming to implement them effectively in their projects. The unique behavior of these soft actuators under varying temperatures can lead to groundbreaking advancements in automation and robotics. Moreover, insight into control mechanisms such as the linear actuator controller can enhance performance and reliability across diverse applications.

Applications in Modern Technology

The versatility of SMA wire actuators opens doors to numerous applications across multiple industries, from robotics to aerospace engineering. In medical devices, they enable minimally invasive procedures by providing precise movement without bulky components. As technology continues to evolve, the integration of heating actuator variants promises even more innovative uses that could redefine how we approach design challenges today.

What is an SMA Wire Actuator?

SMA wire actuators are innovative devices that utilize the unique properties of shape memory alloys (SMAs) to produce linear motion. These actuators are particularly notable for their ability to change shape in response to temperature variations, making them a fascinating option in the realm of linear actuators. By harnessing the thermal expansion and contraction of SMAs, these actuators can achieve precise movements with minimal energy consumption.

Definition and Basic Functionality

At its core, an SMA wire actuator consists of a wire made from a shape memory alloy that can remember its original shape after deformation. When heated, the SMA wire contracts, generating force and enabling linear motion—this is where it shines as a type of electric linear actuator. The basic functionality revolves around this transformation: applying heat causes the wire to return to its pre-deformed state, resulting in movement that can be harnessed for various applications.

Comparison with Other Actuators

When comparing SMA wire actuators with traditional electric linear actuators, several distinctions emerge. Electric linear actuators typically rely on motors and gears to produce movement, which can be bulky and energy-intensive compared to the sleek design of SMA technology. Additionally, while soft actuators may provide flexibility in certain applications, they often lack the precision and efficiency offered by SMA wire actuators when it comes to controlled movements.

Unique Advantages of SMA Technology

One standout advantage of SMA technology is its compactness; unlike many conventional actuation systems that require extensive mechanical components, SMA wire actuators are lightweight and easy to integrate into various designs. They also boast low power consumption since they only require heat activation for operation—no continuous power supply needed once activated! Furthermore, their inherent simplicity leads to reduced maintenance requirements over time compared to more complex systems like heating actuators or electric linear actuator setups.

How the SMA Wire Actuator Works

Understanding how an SMA wire actuator operates is crucial for harnessing its unique capabilities. At the heart of this technology lies the fascinating behavior of shape memory alloys (SMAs), which allow these actuators to perform precise movements in response to thermal changes. This section will delve into the intricate mechanisms that enable SMA linear actuators to function effectively, including their response to temperature variations.

The Role of Shape Memory Alloys

Shape memory alloys are metallic materials that can remember their original shape after being deformed when subjected to specific conditions, primarily temperature changes. In an SMA wire actuator, these alloys undergo a phase transformation that allows them to contract and expand, enabling motion in a controlled manner. This remarkable property makes SMAs ideal candidates for applications requiring compact and efficient linear actuators.

When an SMA wire actuator is heated, it transitions from a low-temperature phase (martensite) to a high-temperature phase (austenite), causing it to return to its predetermined shape. This transformation is not only swift but also highly repeatable, making SMAs superior choices over traditional electric linear actuators in many applications. The ability of SMAs to operate without complex mechanical components simplifies designs and enhances reliability.

Mechanism of Action in Linear Motion

The mechanism by which an SMA wire actuator achieves linear motion is both elegant and efficient. When electrical energy is applied to heat the SMA wire, it contracts, pulling on connected components and producing linear movement. This action can be finely tuned by varying the amount of current supplied through the linear actuator controller.

Unlike conventional electric linear actuators that rely on gears or motors for movement, SMA wire actuators provide a direct conversion from electrical input into mechanical output with minimal lag time. This results in faster response rates and reduced wear on moving parts due to fewer mechanical interactions. Consequently, engineers often favor soft actuators using SMAs for applications where smooth operation and precision are paramount.

The Behavior of SMA in Response to Temperature

Temperature plays a pivotal role in determining how effectively an SMA wire actuator performs its intended function. As previously mentioned, heating causes the alloy’s transformation from martensite back into its original shape (austenite), leading to contraction and movement; however, cooling has equally significant effects as well. When an SMA wire cools down below its transformation temperature, it reverts back into its deformed state until heated again.

This unique behavior allows for precise control over actuation cycles through careful management of temperature fluctuations—essentially creating a “thermal toggle” effect that can be exploited in various applications such as robotics or medical devices where exact positioning is crucial. However, one must consider potential challenges related to heat dissipation during prolonged operations; overheating can lead not only to performance issues but also potentially damage the material properties over time if not properly managed by integrating effective heating actuator designs.

In summary, understanding how SMA wire actuators work provides valuable insights into their application potential across various fields—from robotics automation systems utilizing soft actuator designs for delicate tasks all the way through aerospace engineering innovations requiring reliable yet lightweight solutions powered by advanced control systems like those found within modern electric linear actuators.

Types of SMA Wire Actuators

Shape Memory Alloy (SMA) wire actuators come in various forms, each tailored to specific applications and functionalities. Understanding these types can help engineers and developers select the right actuator for their needs, whether it’s for robotics, medical devices, or aerospace engineering. This section delves into the nuances of soft actuators, electric linear actuators, and heating actuator variants.

Overview of Soft Actuators

Soft actuators represent a fascinating category within the SMA wire actuator family. These actuators are designed to mimic natural movements with a gentle touch, making them ideal for applications requiring flexibility and compliance. The unique material properties of SMAs allow soft actuators to deform easily under low forces while returning to their original shape when activated by heat—perfect for delicate tasks in robotics or biomedical fields.

The versatility of soft actuators is further enhanced by their ability to operate in confined spaces where traditional rigid mechanisms might struggle. Their lightweight nature means that they can be integrated into wearable technology without adding significant bulk or weight. As a result, these SMA linear actuators have gained traction in industries focusing on human-robot interaction and advanced prosthetics.

Introduction to Electric Linear Actuators

Electric linear actuators are another prominent type within the realm of SMA wire actuators, offering precise control over motion through electrical input. Unlike traditional electric motors that rely on gears and complex mechanisms, these SMA linear actuators utilize the unique properties of shape memory alloys to achieve straight-line motion efficiently. This simplicity not only reduces mechanical wear but also enhances reliability in various applications.

The integration of electric linear actuator technology with modern control systems allows for seamless operation across different platforms. Linear actuator controllers can easily regulate temperature changes in the SMA wire, enabling accurate positioning and movement based on real-time feedback. This adaptability makes electric linear actuators particularly attractive for automation tasks where precision is paramount.

Exploring the Heating Actuator Variants

Heating actuator variants showcase yet another innovative application of SMA technology by using heat as a driving force behind actuation movement. These heating actuation systems typically incorporate built-in heating elements that rapidly change the temperature of the SMA wire when activated—prompting it to contract or expand as needed for motion generation. This feature allows users to achieve quick response times essential in dynamic environments like robotics or aerospace applications.

One key advantage of heating actuator variants lies in their ability to maintain performance across diverse operating conditions without complex mechanical components getting involved. They offer an elegant solution where traditional methods may falter due to size constraints or environmental factors such as humidity and temperature fluctuations. By harnessing the power of shape memory alloys effectively through innovative heating methods, these sma wire actuators pave new paths toward efficient design solutions.

Control Mechanisms for SMA Actuators

The control mechanisms for SMA wire actuators are crucial in maximizing their efficiency and functionality. Understanding how to effectively manage these systems can significantly impact performance, especially in applications where precision is key. This section will delve into the various control strategies employed for SMA linear actuators, including the nuances of integrating them with modern technology.

Understanding the Linear Actuator Controller

At the heart of every effective SMA wire actuator system lies the linear actuator controller, which regulates motion based on input signals. This controller interprets commands and translates them into precise movements by heating or cooling the shape memory alloy wire, allowing it to contract or expand accordingly. The sophistication of these controllers can vary from simple on/off switches to advanced programmable systems that allow for intricate motion profiles.

Linear actuator controllers must be tailored to accommodate the unique characteristics of SMA technology, particularly its temperature-dependent behavior. They need to monitor temperature closely and adjust power delivery in real-time to ensure optimal performance without overheating or underutilizing the actuator's capabilities. By understanding how these controllers function, engineers can create more responsive and reliable systems that leverage the unique advantages of SMA actuators.

Integrating SMA with Modern Control Systems

Integrating SMA wire actuators with modern control systems is a game-changer in automation and robotics. With advancements in technology, it's now possible to connect these soft actuators seamlessly with IoT devices and sophisticated software platforms that facilitate real-time monitoring and adjustments. This integration allows for enhanced operational efficiency, as users can program specific movement patterns or respond dynamically to changing conditions.

One major benefit of this integration is improved feedback mechanisms; modern control systems can provide immediate data on actuator performance, enabling quick adjustments if necessary. Furthermore, electric linear actuators equipped with smart controllers can be programmed for energy efficiency by optimizing power usage based on task requirements—an essential feature for sustainable design practices today. As we embrace Industry 4.0 principles, leveraging these integrations will become even more critical.

Challenges in Controlling SMA Wire Movement

Despite their potential advantages, controlling SMA wire movement presents several challenges that engineers must navigate carefully. One significant hurdle stems from the inherent lag between heating and cooling cycles; this delay can lead to overshooting or undershooting desired positions during operation if not managed properly through precise calibration within linear actuator controllers. Consequently, achieving accurate positioning often requires extensive tuning of both hardware and software components.

Another challenge lies in environmental factors affecting temperature regulation; variations in ambient temperatures may influence how quickly an SMA linear actuator responds during operation—potentially leading to inconsistencies across different applications such as medical devices or aerospace engineering tools where precision is paramount. Additionally, maintaining consistent heating across longer lengths of wire becomes increasingly complex as size increases—resulting in uneven actuation unless meticulously designed heating elements are implemented.

Ultimately, addressing these challenges necessitates a comprehensive understanding of both materials science related to shape memory alloys and sophisticated programming skills within modern control frameworks—a combination that ensures effective use of sma wire actuators across diverse applications while minimizing risks associated with their unique operational characteristics.

Real-World Applications of SMA Wire Actuators

Shape Memory Alloy (SMA) wire actuators are making waves across various industries due to their unique properties and versatility. From robotics to medical devices and aerospace engineering, the applications of SMA wire actuators demonstrate their potential to revolutionize how we approach motion control. Let’s dive into some intriguing real-world uses of these innovative linear actuators.

Use in Robotics and Automation

In the realm of robotics and automation, SMA wire actuators shine as they provide efficient and compact solutions for movement. Their lightweight nature allows for the design of agile robotic systems that can perform intricate tasks without adding unnecessary bulk. The integration of SMA technology into soft actuators enables robots to mimic natural movements, enhancing their adaptability in dynamic environments.

Moreover, the ability to control these SMA linear actuators with precision through a linear actuator controller opens up new avenues for automation processes. They can be utilized in grippers, joints, and other moving parts, offering a level of finesse that traditional electric linear actuators may struggle to achieve. As industries continue to embrace automation, the demand for reliable SMA wire actuators is only set to grow.

Applications in Medical Devices

SMA wire actuators are also making significant strides in the medical field by enabling advancements in various devices used for diagnosis and treatment. For example, heating actuators powered by shape memory alloys are employed in minimally invasive surgical tools that require precise motion control while maintaining a compact size. This capability is crucial during delicate procedures where every millimeter counts.

Furthermore, SMA technology is being harnessed in prosthetics and orthotics, where soft actuator designs allow for more natural movement patterns compared to traditional mechanical alternatives. The responsiveness of these SMA linear actuators can closely mimic human muscle behavior, providing users with improved functionality and comfort. As healthcare continues evolving towards more personalized solutions, the role of SMA wire actuators becomes increasingly vital.

Impact on Aerospace Engineering

The aerospace industry has also recognized the transformative potential of SMA wire actuators due to their lightweight characteristics combined with high performance under varying conditions. These linear actuators are particularly useful in applications such as wing morphing technologies where adaptive structures enhance aircraft efficiency during flight phases. By utilizing heating actuator mechanisms within these designs, engineers can achieve remarkable aerodynamic improvements without sacrificing weight or structural integrity.

Additionally, SMA technology facilitates actuation systems that respond quickly to changes in temperature or pressure—critical factors when dealing with extreme environmental conditions at high altitudes or speeds. The integration of advanced control systems allows seamless management of these systems through a sophisticated linear actuator controller setup tailored for aerospace requirements. As innovation drives advancements within this sector, it’s clear that SMA wire actuators will play an essential role moving forward.

Conclusion

As we wrap up our exploration of SMA wire actuators, it’s clear that these remarkable devices are not just a fleeting trend but a cornerstone of future technological advancements. With their unique ability to convert thermal energy into mechanical motion, SMA linear actuators are poised to revolutionize various industries, from robotics to aerospace. The ongoing research and development in this field promise even more innovative applications and enhancements in actuator performance.

The Future of SMA Wire Actuators

The future of SMA wire actuators looks incredibly promising as advancements in materials science continue to evolve. Researchers are developing new alloys and refining existing ones, which will enhance the efficiency and responsiveness of these linear actuators. We can expect to see more sophisticated heating actuator designs that integrate seamlessly with smart technologies, leading to greater automation and precision across various applications.

Benefits of Choosing SMA Technology

Choosing SMA technology brings a multitude of benefits that make it an attractive option for engineers and designers alike. For starters, the compact size of soft actuators allows for innovative design solutions where space is at a premium, unlike traditional electric linear actuators that often require bulky components. Furthermore, the energy efficiency and simplicity of control associated with SMA wire actuators make them cost-effective over time while offering reliability in demanding environments.

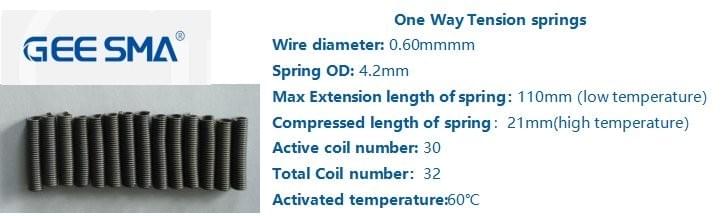

Why GEE SMA is a Leader in SMA Solutions

GEE SMA stands out as a leader in the field due to its commitment to quality, innovation, and customer satisfaction when it comes to sma wire actuator solutions. With extensive experience in developing cutting-edge products like advanced linear actuator controllers and heating actuator variants, GEE continually pushes the envelope on what’s possible with shape memory alloy technology. Their focus on research-driven development ensures that clients receive state-of-the-art solutions tailored precisely to their needs.