Introduction

Shape memory materials are fascinating substances that can return to a predetermined shape when subjected to specific stimuli, such as heat or stress. This unique property, known as the shape memory effect, allows these materials to perform remarkable feats, making them invaluable in various fields. From medical devices to aerospace engineering, the versatility of shape memory materials is reshaping how we approach technology and innovation.

What Is Shape Memory Material

At its core, a shape memory material is a type of alloy or polymer that remembers its original form after being deformed. When exposed to certain temperatures or environmental conditions, these materials undergo a phase transformation that restores them to their initial configuration. Nitinol, an alloy of nickel and titanium, is one of the most well-known examples of shape memory materials and serves as a cornerstone for many applications due to its exceptional properties.

The Role of Shape Memory Materials in Technology

Shape memory materials play a pivotal role in advancing technology across multiple sectors by providing solutions that were previously thought impossible. In medicine, for instance, they enable the creation of minimally invasive devices that can adapt and change shape within the body for optimal performance. Moreover, industries like aerospace and robotics leverage these materials to enhance efficiency and functionality in environments where traditional components may fail.

Why Shape Memory Materials Matter

The significance of shape memory materials extends beyond mere novelty; they offer practical advantages that can revolutionize how we design products and systems. Their ability to respond dynamically to environmental changes makes them ideal for applications requiring adaptability and resilience—qualities essential in today’s fast-paced technological landscape. As we continue exploring their potential, it becomes clear that shape memory materials could be key players in tackling some of our most pressing challenges.

The Science Behind Shape Memory Materials

Shape memory materials, particularly Nitinol alloys, are fascinating examples of how advanced materials can exhibit unique properties that mimic living systems. These materials have the ability to return to a predefined shape when subjected to specific stimuli, such as temperature changes. This remarkable behavior is not only intriguing but also opens up a world of possibilities across various industries.

Understanding Nitinol Alloys

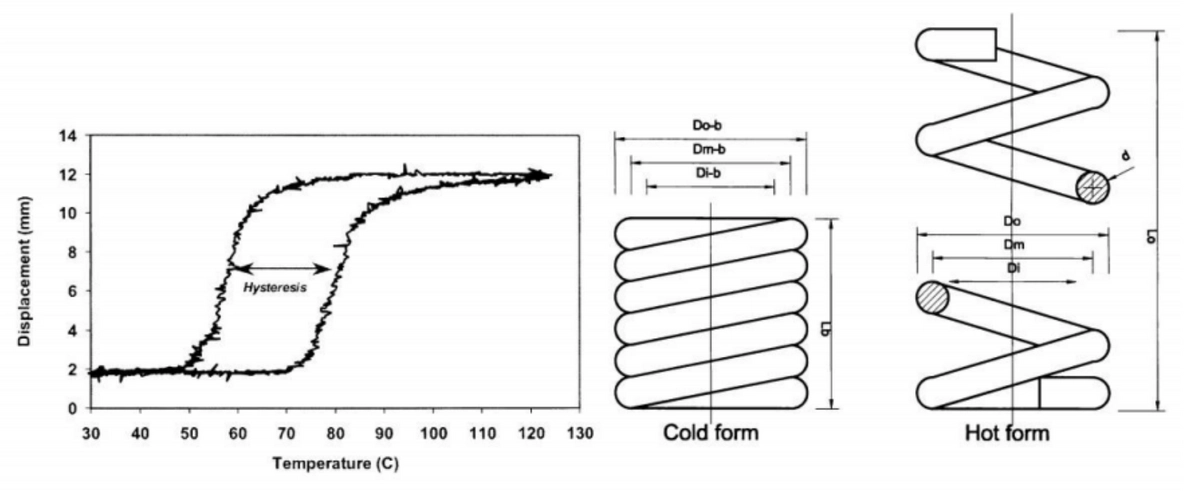

Nitinol, a nickel-titanium alloy, is the most well-known shape memory material and serves as a prime example of how these materials function. Composed primarily of nickel and titanium, Nitinol exhibits both superelasticity and the shape memory effect, allowing it to undergo significant deformation and then revert back to its original form upon heating. Its unique crystalline structure plays a pivotal role in this process; by transitioning between martensite (a low-temperature phase) and austenite (a high-temperature phase), Nitinol can remember its original shape even after being bent or twisted.

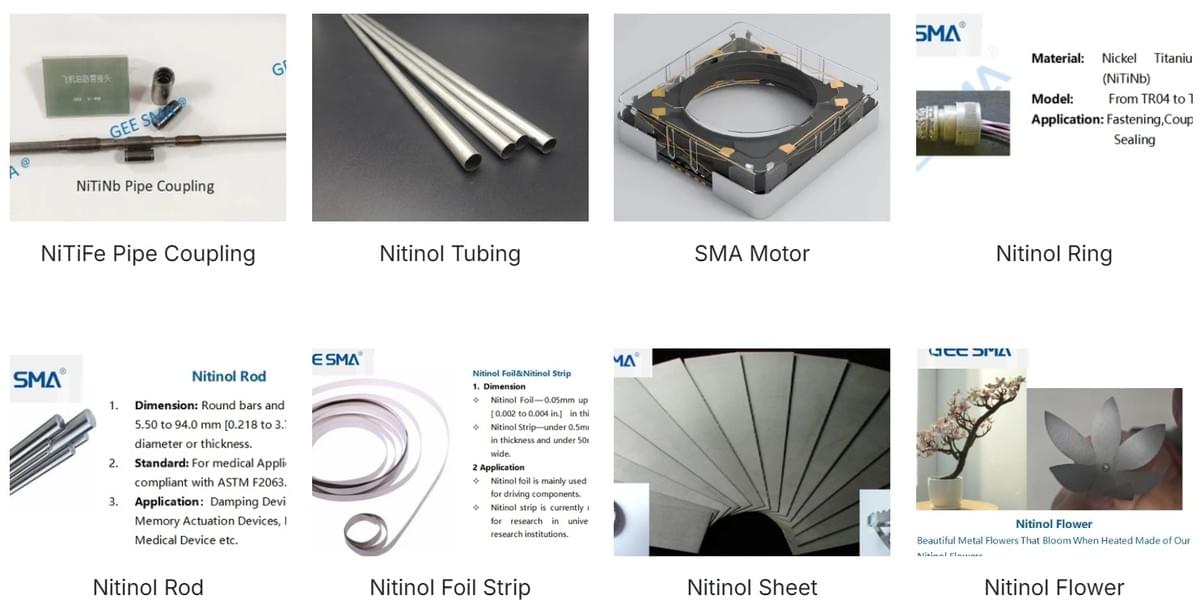

The versatility of Nitinol alloys makes them suitable for various applications beyond just medical devices; they are also utilized in automotive components and even in eyeglass frames that can withstand bending without breaking. Understanding the properties of these shape memory materials allows engineers to design innovative products that leverage their unique capabilities. As research continues into optimizing Nitinol's performance characteristics, we can expect even more exciting developments in this field.

The Physics of Shape Memory Effect

At the heart of the shape memory effect lies an intricate interplay between thermal energy and material structure. When heated above a certain temperature threshold, known as the transformation temperature, shape memory materials like Nitinol undergo a phase change that enables them to return to their pre-deformed configuration. This phenomenon arises from changes in atomic arrangement within the material's crystalline lattice; when cooled below this threshold, it adopts a different arrangement that allows for deformation.

The physics behind this transformation is what makes shape memory materials so compelling for engineers and scientists alike. By manipulating temperature or stress conditions, researchers can control how these materials behave—effectively programming them for specific tasks or functions while maintaining their lightweight properties. This adaptability is crucial for applications where precision and reliability are paramount.

Applications in Medicine

Shape memory materials have found significant traction in the medical field due to their unique properties that enhance patient care and surgical outcomes. One prominent application is in stents—tiny tubes inserted into blood vessels—that expand upon reaching body temperature, providing support where it's needed most without invasive procedures. These stents made from Nitinol not only improve blood flow but also reduce recovery times for patients.

Another exciting application involves surgical tools designed with shape memory technology that allow surgeons greater flexibility during procedures; instruments can change shapes mid-operation based on real-time feedback from imaging systems or tactile inputs from surgeons themselves. Furthermore, advancements continue toward developing smart implants capable of responding dynamically to physiological changes within the body—an innovation set to redefine patient treatment paradigms entirely.

In summary, understanding Nitinol alloys reveals much about how shape memory materials work at both microscopic levels and practical applications across industries like medicine where they genuinely shine through transformative capabilities.

Shape Memory Materials in Aerospace

The aerospace industry has long been a playground for innovation, and shape memory materials are at the forefront of this revolution. These remarkable materials have the unique ability to return to a predetermined shape when exposed to specific stimuli, making them invaluable in various aerospace applications. With their lightweight nature and robust performance characteristics, shape memory materials are transforming how we approach design and functionality in space missions.

How GEE SMA Powers Space Missions

GEE SMA, or General Electric's Shape Memory Alloys, play a crucial role in powering modern space missions. By leveraging the properties of shape memory materials, GEE SMA enables mechanisms that can withstand extreme conditions while maintaining reliability. For example, these alloys can be used in actuators that deploy solar panels or antennas once a spacecraft reaches orbit—ensuring that vital systems are operational without manual intervention.

The adaptability of GEE SMA is particularly beneficial during launch and re-entry phases when mechanical stress is at its peak. Traditional components often suffer from fatigue or failure under such conditions; however, shape memory materials have shown resilience by reverting to their original form after deformation. This characteristic not only enhances mission success rates but also reduces maintenance costs associated with spacecraft operations.

Deployment Systems in Satellites

Deployment systems in satellites have greatly benefited from the integration of shape memory materials like GEE SMA. These systems often require precision and reliability for critical operations such as antenna deployment or solar panel unfurling—tasks that can be complicated by the harsh environment of space. Utilizing shape memory technology allows engineers to design lighter and more compact mechanisms that can perform these tasks efficiently.

Moreover, the use of shape memory material allows for simplified designs with fewer moving parts, which translates into increased reliability during satellite operations. The inherent ability of these materials to remember their original shapes means they can function effectively even after being subjected to extreme temperatures and radiation exposure found beyond our atmosphere. This innovation not only enhances satellite performance but also extends mission lifespans significantly.

Enhancing Performance in Harsh Conditions

One of the most compelling features of shape memory materials is their ability to thrive under harsh environmental conditions—a critical factor for aerospace applications where extremes are commonplace. Whether it's the freezing vacuum of space or intense heat during re-entry, these materials maintain structural integrity while performing essential functions seamlessly. Their unique thermal properties allow them to respond predictably to temperature changes, ensuring optimal operation regardless of external factors.

In addition to temperature resilience, shape memory materials exhibit excellent corrosion resistance—an essential attribute when dealing with atmospheric elements over long durations in orbit or during atmospheric re-entries. This durability contributes significantly to reducing wear-and-tear on spacecraft components, leading engineers toward longer-lasting solutions that save both time and resources over multiple missions. The future looks bright as ongoing research continues unlocking new potential applications for shape memory technologies across various aerospace domains.

Innovations in Consumer Electronics

In the rapidly evolving world of consumer electronics, shape memory materials are making waves by introducing innovative functionalities that were once thought to be the stuff of science fiction. These materials, particularly shape memory alloys like Nitinol, provide unique properties that enable devices to adapt and respond to user needs dynamically. As technology continues to advance, the integration of shape memory materials into everyday gadgets is paving the way for smarter, more efficient devices.

Smart Devices Utilizing Shape Memory Materials

Smart devices are increasingly leveraging shape memory materials to enhance user experience and functionality. For instance, some smartphones now feature components that can change shape based on temperature or electrical stimuli, allowing for features like self-healing screens or adjustable grips. This adaptability not only improves durability but also transforms how users interact with their devices, creating a seamless blend of form and function.

Moreover, wearables are utilizing shape memory materials to create more comfortable and responsive designs. Imagine smartwatches that can adjust their size for a better fit or fitness trackers that conform perfectly to your wrist. These innovations showcase how shape memory technology is revolutionizing personal electronics by prioritizing comfort without sacrificing performance.

Flexible Displays and Wearable Tech

The emergence of flexible displays is one of the most exciting applications of shape memory materials in consumer electronics. With the ability to bend and twist without losing functionality, these displays open up new possibilities for product design—think foldable smartphones or rollable tablets! The incorporation of shape memory technologies allows these devices not only to maintain their integrity but also adapt dynamically to different usage scenarios.

Wearable tech is another area where shape memory materials shine brightly. From smart fabrics that adjust their thermal properties based on body temperature to fitness gear that molds itself according to an athlete's movements, these innovations enhance performance while providing unprecedented comfort. As wearable technology becomes more integrated into our daily lives, the role of shape memory materials will undoubtedly expand further.

Future Trends in Electronics

Looking ahead, we can expect an explosion of creativity driven by advancements in shape memory materials within consumer electronics. Researchers are exploring new alloys and composites that could lead to even more responsive and versatile applications across various sectors—from health monitoring systems that adapt based on real-time data analysis to home automation systems capable of morphing according to user preferences.

Furthermore, as sustainability becomes a focal point in technology development, the potential for eco-friendly applications using recyclable or biodegradable shape memory materials may arise. This shift could redefine how we think about product lifecycles and waste management in electronics while still harnessing the unique advantages offered by these remarkable materials.

Ultimately, as we embrace this technological evolution powered by innovations in shape memory materials, we stand on the brink of a future where our devices not only respond intelligently but also enhance our everyday experiences in ways we’ve yet to imagine.

Shape Memory Materials in Robotics

In the ever-evolving field of robotics, shape memory materials are emerging as game-changers, providing innovative solutions that enhance functionality and versatility. Their unique properties allow robots to adapt to various tasks and environments, making them highly efficient and capable of performing complex functions. As we delve deeper into the applications of shape memory materials in robotics, it becomes clear that these materials are not just a trend; they represent a significant leap forward in robotic technology.

Actuation Systems for Robots

Actuation systems are crucial for the movement and functionality of robots, and shape memory materials play a pivotal role in this area. By utilizing the shape memory effect, these materials can change their form when exposed to specific stimuli such as heat or electrical current, enabling precise movements with minimal energy consumption. This capability allows for lightweight actuation systems that can significantly reduce the overall weight of robotic designs while maintaining high performance.

The integration of shape memory materials into actuation systems also enhances reliability and responsiveness. Unlike traditional motors or servos that may require complex control mechanisms, shape memory actuators can provide simpler yet effective solutions for motion control. As a result, robots equipped with these advanced actuation systems can perform tasks more efficiently while also being easier to maintain.

Soft Robotics and Adaptability

Soft robotics is an exciting branch of robotics focused on creating flexible and adaptable machines capable of navigating complex environments. Shape memory materials are at the forefront of this innovation, allowing robots to mimic natural movements found in living organisms. By incorporating these materials into soft robotic structures, engineers can design robots that change their shape dynamically based on environmental conditions or specific tasks.

The adaptability offered by shape memory materials is particularly beneficial in applications where precision is paramount—think surgical robots or delicate handling mechanisms in manufacturing settings. These robots can adjust their stiffness or form instantly without requiring bulky components or power-hungry systems typically associated with rigid designs. With soft robotics powered by shape memory technologies, we’re witnessing a shift towards more versatile and responsive machines capable of tackling challenges previously deemed impossible.

Improving Efficiency with Shape Memory

Efficiency is a key concern across all industries utilizing robotics, and integrating shape memory materials offers numerous advantages in this regard. These innovative materials reduce energy consumption by enabling actuators to operate without continuous power supply; they only require energy during the transition phase between shapes. Consequently, robots employing these smart solutions can achieve longer operational periods without frequent recharging or maintenance interruptions.

Moreover, the lightweight nature of many shape memory components contributes to enhanced mobility and speed within robotic systems—factors critical for success in competitive environments like manufacturing lines or search-and-rescue missions. The combination of reduced weight and increased efficiency makes it possible for robots powered by shape memory technologies to outperform traditional counterparts significantly while conserving resources.

In conclusion, as we explore the potential applications of shape memory materials within robotics further, it’s evident that they hold incredible promise for transforming how machines interact with their surroundings—making them smarter, more efficient, and adaptable than ever before.

Challenges and Future of Shape Memory Materials

Shape memory materials, while revolutionary, face several challenges that hinder their broader adoption. Current limitations include issues related to cost, processing techniques, and performance consistency across various applications. These factors can restrict the use of shape memory materials in critical industries where reliability is paramount.

Current Limitations of Shape Memory Materials

One significant limitation of shape memory materials is their high production cost, particularly for advanced alloys like Nitinol. This expense can deter manufacturers from investing in these innovative solutions when cheaper alternatives are available. Additionally, the processing techniques required to fabricate shape memory materials can be complex and time-consuming, adding another layer of difficulty to their widespread implementation.

Moreover, the performance of shape memory materials can vary depending on environmental conditions such as temperature and pressure. This variability raises concerns about their reliability in demanding applications like aerospace or medical devices where consistent performance is crucial. As a result, researchers continue to seek ways to enhance the durability and predictability of these unique materials.

Breakthroughs on the Horizon

Despite current limitations, exciting breakthroughs are emerging in the field of shape memory materials that promise to address these challenges head-on. Researchers are exploring novel fabrication methods that could reduce costs while maintaining or even improving performance characteristics. These innovations may lead to more accessible shape memory options for various industries.

Furthermore, advancements in material science are paving the way for new types of shape memory materials with enhanced properties such as higher thermal stability and improved fatigue resistance. Such developments could open doors for applications previously thought impossible due to existing material constraints. The future looks bright as scientists work tirelessly to unlock the full potential of these remarkable substances.

The Future Landscape of Applications

The future landscape for shape memory materials is ripe with possibilities across multiple sectors including medicine, aerospace, robotics, and consumer electronics. As technology evolves, we can expect an increase in smart devices that utilize these innovative materials for better functionality and user experience. Flexible displays and wearable tech will likely benefit significantly from advancements in shape memory technology.

In robotics, we may see a new generation of machines equipped with actuation systems that leverage the unique properties of shape memory materials for enhanced adaptability and efficiency. This could revolutionize how robots interact with their environments by allowing them to change shapes or functions on demand seamlessly. Overall, as research continues into optimizing these fascinating materials, we stand on the brink of a transformation across numerous industries.

Conclusion

In wrapping up our exploration of shape memory materials, it’s clear that their unique properties extend far beyond mere novelty. These materials are not just scientific curiosities; they have profound implications across various sectors, from medicine to aerospace. Their ability to remember shapes and revert to them under specific conditions positions them as game-changers in technology.

The Impact of Shape Memory Materials

The impact of shape memory materials is nothing short of transformative. By enabling devices to adapt and respond dynamically, these materials enhance functionality and efficiency in countless applications. From self-repairing structures to advanced medical devices that adjust to patient needs, the influence of shape memory cannot be overstated.

The Potential to Revolutionize Industries

The potential for shape memory materials to revolutionize industries is vast and exciting. Industries such as aerospace, healthcare, and consumer electronics stand on the brink of significant advancements thanks to these innovative materials. With ongoing research and development, we can expect breakthroughs that will redefine how products are designed and utilized.

GEE SMA's Contributions to Innovation

GEE SMA has been at the forefront of leveraging shape memory technology for innovative solutions across various fields. Their contributions highlight the versatility of shape memory materials in creating smarter, more efficient systems that push the boundaries of what’s possible today. As we look ahead, GEE SMA’s commitment to harnessing the power of shape memory will undoubtedly lead us into a future filled with remarkable technological advancements.