Introduction

In the ever-evolving landscape of medical technology, materials like Nitinol have carved out a niche that is hard to ignore. This remarkable alloy, known for its unique shape memory and superelastic properties, has found widespread applications in various fields, particularly in the realm of medical devices such as stents. With the Nitinol stents market expanding rapidly, understanding its uses and implications becomes crucial for stakeholders and consumers alike.

Understanding Nitinol and Its Uses

Nitinol, a nickel-titanium alloy, stands out due to its ability to return to a predetermined shape when heated—a feature that is particularly beneficial in medical applications. Is Nitinol used in stents? Absolutely! The material's flexibility and strength make it an ideal choice for creating stents that can navigate through the complex vascular system while providing necessary support once deployed. Beyond healthcare, Nitinol's unique properties also find applications in aerospace and robotics, showcasing its versatility.

The Importance of Precise Sizes and Tolerances

When it comes to manufacturing Nitinol stents, precision is paramount. The importance of precise sizes and tolerances cannot be overstated; even minor discrepancies can lead to significant complications during implantation or function within the body. Industry standards dictate rigorous specifications for these devices since any deviation could impact their effectiveness or safety—factors critical in the ever-competitive market for medical stents.

Overview of the Nitinol Stents Market

The market for medical stents has seen substantial growth over recent years, with a notable shift towards advanced materials like Nitinol due to their superior performance characteristics. What is the market share of stents? As health systems increasingly prioritize minimally invasive procedures, the demand for high-quality stenting solutions continues to rise—reinforcing the position of Nitinol within this sector. Furthermore, as innovations unfold within this space—including biodegradable options—the future looks bright for both suppliers and patients navigating this dynamic nitinol stents market.

Nitinol: The Allure of Shape Memory Alloys

Nitinol, a remarkable shape memory alloy, has captured the attention of various industries due to its unique properties. It exhibits the ability to return to a predetermined shape when heated, making it incredibly versatile for applications requiring precision and reliability. This characteristic is particularly valuable in the nitinol stents market, where performance can be a matter of life and death.

What Makes Nitinol Unique

What truly sets nitinol apart from other materials is its combination of shape memory and superelasticity. These properties allow it to undergo significant deformation while maintaining structural integrity, which is crucial in medical devices like stents. The question Is nitinol used in stents? often arises because its unique characteristics make it an ideal choice for expanding within blood vessels and providing support where it's needed most.

In addition to its mechanical advantages, nitinol also boasts excellent biocompatibility, reducing the risk of adverse reactions within the body. As such, it has become a staple material in the medical field, particularly within the ever-growing market for medical stents. With increasing demand for innovative solutions in healthcare, understanding what makes nitinol unique is essential for grasping its role in this competitive landscape.

Applications in Medical Technologies

The applications of nitinol extend far beyond just stents; they encompass various critical components within medical technologies. From guidewires to surgical instruments, its versatility enhances performance across numerous devices designed for minimally invasive procedures. Given that more than 80% of coronary stents are made from this extraordinary material, it's clear that the nitinol stents market plays a pivotal role in modern medicine.

Moreover, as technology advances and new techniques emerge, there’s a growing interest in biodegradable stents as well—another area where nitinol's properties shine brightly. These biodegradable options promise not only effective treatment but also reduced long-term complications associated with permanent implants. Thus, understanding how nitinol fits into these applications helps illuminate its significance within both current and future markets.

Benefits in the Aerospace Industry

While much attention is given to medical technologies when discussing nitinol's applications, we must not overlook its benefits in the aerospace industry as well. Here too lies an arena where precision matters immensely; components made from nitinol offer exceptional fatigue resistance and lightweight characteristics that enhance overall aircraft performance. This brings us back full circle to our earlier discussion about market share—what is the market share of stents compared to aerospace applications?

As aerospace engineers continue seeking ways to improve fuel efficiency and reduce emissions through innovative materials like nitinol alloys, it's clear that this metal isn't just confined to hospitals or clinics; it's soaring high above us too! With increasing investments directed towards research and development focused on optimizing these materials further still adds intrigue around their evolving roles across multiple sectors.

Sourcing Nitinol: Top Suppliers

When diving into the nitinol stents market, identifying reliable suppliers is paramount. Nitinol, with its unique shape memory properties, has carved a niche in various sectors, particularly in medical applications like stents. This section will spotlight leading players in the industry, compare global suppliers, and discuss how to evaluate their reliability.

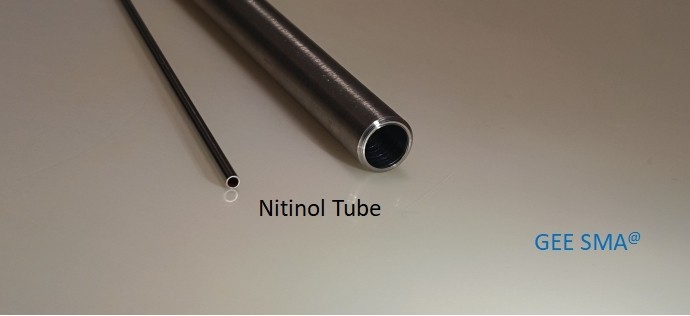

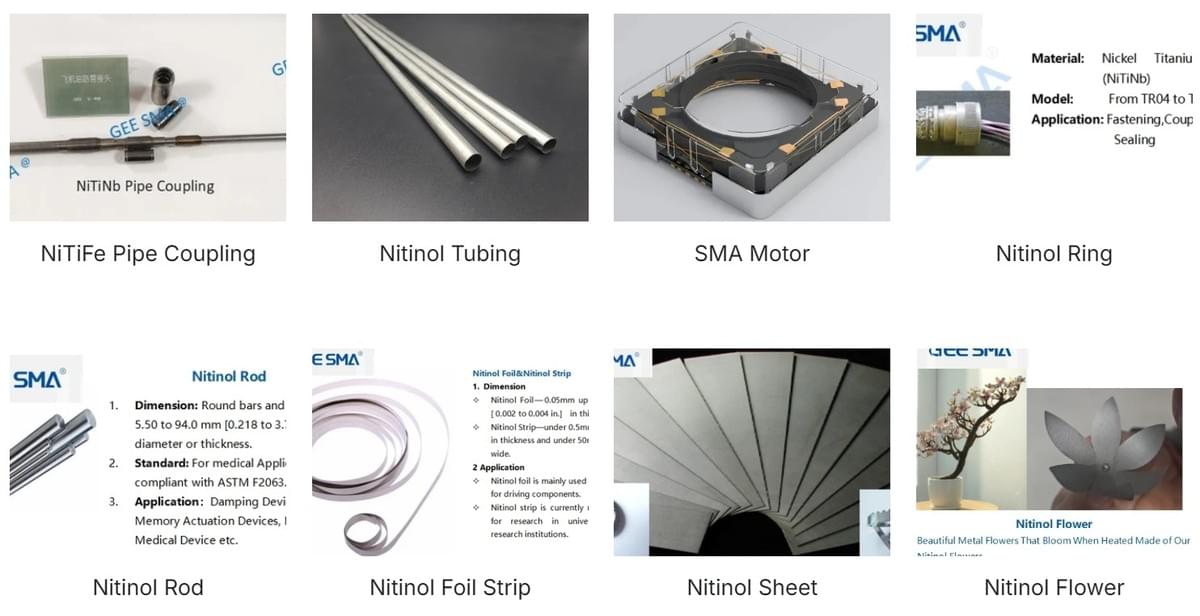

Spotlight on GEE SMA

GEE SMA stands out as a notable supplier within the nitinol stents market due to its commitment to quality and innovation. Specializing in shape memory alloys, they have developed advanced manufacturing processes that ensure their products meet stringent medical standards. With an impressive portfolio of applications ranging from cardiovascular devices to orthopedic implants, GEE SMA has positioned itself as a trusted name for those asking, Is nitinol used in stents?

Their focus on research and development allows them to stay ahead of trends affecting the market for medical stents. By leveraging cutting-edge technology and materials science expertise, GEE SMA continues to push the boundaries of what’s possible with nitinol alloys. As demand for reliable medical devices grows—especially biodegradable stents—GEE SMA's proactive approach ensures they remain competitive.

Comparing Global Nitinol Suppliers

In evaluating the global landscape of nitinol suppliers, it’s essential to consider factors like production capacity, technological advancements, and customer service reputation. Various companies are vying for market share within the burgeoning nitinol stents market; however, not all can deliver consistently high-quality products or maintain compliance with regulatory standards. When assessing what is the market for medical stents looks like today, potential buyers should weigh each supplier's strengths against their specific needs.

Some suppliers may excel in producing specialized forms of nitinol tailored for certain applications while others might offer broader product lines but lack focus on quality control processes. Understanding these nuances can help manufacturers choose partners that align with their objectives and ensure optimal outcomes when utilizing nitinol in critical applications such as cardiac interventions or minimally invasive surgeries. Additionally, knowing what is the market share of stents can provide context on which suppliers dominate specific niches.

Evaluating Supplier Reliability

Reliability is crucial when sourcing materials from suppliers in the nitinol industry; after all, lives often depend on these products! To assess supplier reliability effectively within the context of the growing nitinol stents market requires more than just looking at certifications or past performance records; it involves thorough due diligence and ongoing communication. Start by examining customer feedback and case studies that illustrate how well a supplier has responded to challenges related to production timelines or compliance issues.

Moreover, it's vital to ask questions regarding their supply chain transparency—can they demonstrate consistent sourcing practices? What measures do they take against potential disruptions? With rising interest in biodegradable stents and other innovative solutions within this sector, understanding each supplier's operational resilience becomes increasingly important as companies navigate evolving regulatory landscapes and shifting consumer demands.

Sizes and Tolerances: Why They Matter

When it comes to the nitinol stents market, precision is not just a luxury; it’s a necessity. Nitinol, known for its unique shape memory properties, is often used in stents that must fit seamlessly within the human body. The right size and tolerance can mean the difference between a successful procedure and complications, making this an area of paramount importance.

The Role of Precision in Nitinol Applications

Precision plays an essential role in the application of nitinol, especially when considering its use in medical devices like stents. In the nitinol stents market, even minor deviations from specified sizes can lead to significant clinical consequences. For instance, if a stent is too large or too small, it may fail to expand properly or could cause injury to surrounding tissues—an outcome no medical professional wants on their hands.

Industry Standards for Nitinol Specifications

The industry has established rigorous standards for nitinol specifications to ensure safety and efficacy in applications like stenting. Organizations such as ASTM International have set guidelines that dictate acceptable tolerances for nitinol used in medical devices. These standards help maintain consistency across products and assure healthcare providers that they are using reliable materials when they ask themselves: Is nitinol used in stents? The answer is yes—provided those materials meet stringent specifications.

Common Tolerance Challenges

Despite these established standards, challenges with tolerances still arise within the nitinol stents market. Manufacturers often grapple with maintaining tight tolerances due to variations in production processes or material inconsistencies. Additionally, as demand grows—especially with trends toward biodegradable stents—the pressure on suppliers increases, leading to potential compromises on quality if not carefully managed.

Innovations in Nitinol Production

The landscape of the nitinol stents market is rapidly evolving, driven by groundbreaking innovations in production techniques. Manufacturers are harnessing advanced technologies to enhance the properties of nitinol, leading to improved performance and reliability in medical applications. As a result, these innovations not only bolster the effectiveness of nitinol stents but also contribute to a more competitive market for medical stents overall.

Advances in Manufacturing Techniques

Recent advancements in manufacturing techniques have revolutionized how nitinol is produced, particularly for use in stents. Processes such as additive manufacturing and advanced heat treatment methods allow for greater control over material properties, including shape memory and superelasticity. These enhancements ensure that nitinol is not only effective but also tailored to meet specific requirements within the nitinol stents market.

Moreover, these new methods enable manufacturers to create complex geometries that were previously unattainable with traditional fabrication techniques. This flexibility opens doors for innovation in design and functionality, catering specifically to diverse patient needs across various medical applications. The combination of precision engineering and innovative materials has positioned the nitinol stents market at the forefront of medical technology advancements.

The Impact of Technology on Quality

In an industry where quality is paramount, technological advancements have significantly impacted the production standards of nitinol components used in stents. Automation and real-time monitoring systems help ensure consistent quality throughout the manufacturing process, reducing defects and increasing reliability. This level of precision is crucial when considering what is the market for medical stents; patients’ lives depend on it!

Furthermore, enhanced testing methodologies allow manufacturers to assess material performance under various conditions before reaching consumers. This proactive approach ensures that only high-quality products enter the marketplace while addressing concerns regarding what is the market share of stents globally. As technology continues to evolve, so too will the standards by which these critical devices are assessed.

Case Studies of Successful Innovations

Several case studies highlight successful innovations within the nitinol production sphere that have made waves in the nitinol stents market. One notable example involves a leading manufacturer who integrated 3D printing technology into their production line for biodegradable stents made from a specialized form of nitinol alloy. This innovative approach allowed them to create customizable designs tailored specifically for individual patients while maintaining high performance standards.

Another compelling case study showcases a collaboration between researchers and industry leaders aimed at developing next-generation bioresorbable scaffolds using advanced nitinol formulations. Their efforts not only addressed growing concerns about long-term implant retention but also aligned with trends indicating rising demand for biodegradable options within what is the market for biodegradable stents? Such initiatives demonstrate how innovation can drive both growth and sustainability within this dynamic sector.

As we look ahead, it's clear that ongoing innovations will continue shaping both product offerings and consumer expectations within this thriving marketplace.

Trends Influencing the Nitinol Stents Market

The nitinol stents market is experiencing dynamic shifts driven by various factors, particularly in medical applications. As healthcare continues to advance, the demand for innovative solutions such as nitinol stents is on the rise. This surge is largely due to their unique properties, which enable them to perform effectively in a variety of challenging environments.

Rising Demand in Medical Applications

Is nitinol used in stents? Absolutely! Nitinol's shape memory and superelasticity make it an ideal material for stent manufacturing, allowing these devices to expand and adapt within blood vessels. The market for medical stents is growing rapidly as healthcare providers seek more effective treatments for cardiovascular diseases and other conditions requiring vascular support.

The increasing prevalence of heart disease globally has contributed significantly to the rising demand for nitinol stents. Patients are benefiting from minimally invasive procedures that use these advanced devices, leading to shorter recovery times and improved outcomes. As a result, the market share of stents made from nitinol continues to expand, with manufacturers striving to meet this growing need through innovation and enhanced production capabilities.

Regulatory Changes and Their Effects

Navigating the regulatory landscape can be challenging for suppliers in the nitinol stents market. Recent changes have introduced stricter guidelines aimed at ensuring patient safety and product efficacy, which can impact how quickly new products reach consumers. These regulations often require more rigorous testing and validation processes before a new design can enter the market.

While these regulations may pose hurdles initially, they ultimately foster greater trust among healthcare professionals and patients alike regarding the quality of nitinol-based products. Suppliers who adapt swiftly can gain a competitive edge by demonstrating compliance with all necessary standards while continuing to innovate within their offerings. The increased scrutiny may also lead to an overall improvement in product quality across the entire marketplace.

Future Prospects for Nitinol Suppliers

Looking ahead, what is the future of the nitrnol stents market? The prospects appear bright as ongoing research continues to unveil new applications beyond traditional uses—such as biodegradable stents that integrate seamlessly into biological systems without leaving permanent implants behind. This innovation could reshape not only how we view vascular interventions but also broaden market opportunities for suppliers focused on sustainability.

Furthermore, advancements in manufacturing techniques will likely enhance production efficiency while maintaining high-quality standards across all products offered by suppliers like GEE SMA and others in this space. As competition heats up among global players vying for a slice of this lucrative pie, those who stay ahead of trends will undoubtedly thrive amidst evolving consumer demands.

Conclusion

In wrapping up our exploration of the nitinol stents market, it's clear that this unique material has revolutionized medical technologies and continues to shape the future of healthcare. Nitinol's remarkable properties, such as its shape memory and superelasticity, make it an ideal candidate for stents, ensuring they can adapt to the dynamic environment within the human body. As we look ahead, understanding the dynamics of this market is crucial for both suppliers and medical professionals alike.

Key Takeaways on Nitinol Suppliers

When considering suppliers in the nitinol stents market, several key factors emerge that can influence decision-making. First and foremost is reliability; choosing a supplier with a proven track record ensures that quality standards are consistently met. Additionally, understanding what makes nitinol unique—its applications in various industries—can provide insights into how these suppliers cater to specific needs within medical technology and beyond.

Why GEE SMA Stands Out

Among the various players in the nitinol stents market, GEE SMA distinguishes itself through innovation and commitment to quality. Their advanced manufacturing techniques guarantee precision in sizes and tolerances, which are critical in applications like stenting where even minor deviations can have significant consequences. Moreover, GEE SMA’s focus on customer service ensures that clients receive tailored solutions that meet their specific requirements for nitinol products.

The Future of the Nitinol Stents Market

Looking forward, the future of the nitinol stents market appears promising as demand for medical applications continues to rise alongside regulatory advancements aimed at improving patient outcomes. With growing interest in biodegradable stents also entering discussions around sustainable solutions in healthcare, there’s potential for new innovations to emerge from existing technologies like nitinol. As these trends unfold, suppliers who stay ahead of developments will likely capture greater market share while contributing positively to patient care.