Introduction

Understanding Nitinol's Unique Properties

At its core, nitinol combines the best features of both nickel and titanium, resulting in an alloy that is not only strong but also remarkably flexible. The most fascinating aspect of nitinol is its ability to remember specific shapes; this shape memory effect is what sets it apart from traditional materials like standard nickel wire or titanium wire. Whether it's in medical devices or robotics, understanding these unique properties allows creators to leverage nitinol wire's full potential in their designs.

The Versatility of Nitinol Wires

Nitinol wires come in various forms—round, flat, and beyond—making them suitable for an array of applications across multiple industries. The adaptability of nitinol flat wire particularly stands out; it provides enhanced surface area for bonding or anchoring while maintaining excellent mechanical properties. From aerospace components to intricate medical instruments, the versatility of nitinol wires ensures they can meet diverse project requirements with ease.

Why Choose Nitinol for Your Projects

Choosing nitinol for your projects means opting for innovation and reliability; the unique characteristics of this alloy make it an ideal choice over conventional materials like plain nickel or titanium wires. Nitinol’s resilience against corrosion and fatigue enhances longevity in applications ranging from surgical tools to actuators in robotics. By selecting trusted nitinol wire manufacturers who prioritize quality and performance, you ensure that your projects are equipped with cutting-edge technology that stands the test of time.

What is Nitinol?

Nitinol, a remarkable alloy of nickel and titanium, has garnered significant attention in various industries due to its unique properties. Its name is derived from its composition—Nickel Titanium Naval Ordnance Laboratory—where it was first developed. This distinctive blend results in an extraordinary material that exhibits both shape memory and superelasticity, making it a favorite among engineers and designers alike.

Composition and Characteristics

The composition of nitinol primarily consists of nickel and titanium, typically with a nickel content ranging from 50% to 60%. This specific ratio is crucial as it dictates the alloy's transformation temperatures, which are pivotal for its shape memory effect. Nitinol flat wire stands out in the market for its excellent fatigue resistance, corrosion resistance, and biocompatibility—qualities that make it ideal for applications in medical devices such as stents and guidewires.

Nitinol wire manufacturers have harnessed these characteristics to create products that can withstand extreme conditions while maintaining their integrity. The versatility of nitinol allows it to be produced in various forms, including flat wire, which provides even more options for customization based on project requirements. With ongoing innovations in the production processes by leading manufacturers, nitinol continues to push the boundaries of what materials can achieve.

Shape Memory Effect Explained

The shape memory effect is one of the most fascinating aspects of nitinol wire. This phenomenon allows the material to remember its original shape after being deformed when heated above a certain temperature threshold known as the transformation temperature. When cooled down or subjected to stress below this temperature, nitinol flat wire can be manipulated into different shapes but will revert back to its pre-deformed form upon heating.

This property has practical implications across several sectors; for instance, it's used extensively in orthodontics where wires can adjust their shape according to temperature changes within the mouth. Additionally, this unique characteristic makes nitinol particularly valuable for applications requiring precision movement or actuation systems like robotic arms or surgical instruments. The ability of nitinol wire manufacturers to produce consistent quality ensures reliability in these critical applications.

Applications Across Industries

Nitinol's incredible properties have led to widespread adoption across numerous industries beyond just medical applications. In aerospace engineering, nitinol flat wire is utilized for actuators due to its lightweight nature combined with strength—ideal for enhancing fuel efficiency without compromising performance. Similarly, automotive sectors are increasingly using this alloy for components like fasteners and brackets that require resilience under varying temperatures.

Moreover, consumer electronics have also begun integrating nitinol due to its flexibility and durability; think about those innovative eyeglass frames that bend without breaking! As research continues into new potential uses for this versatile material, we can expect even more exciting developments on the horizon from both established players and emerging nitinol wire manufacturers looking to make their mark.

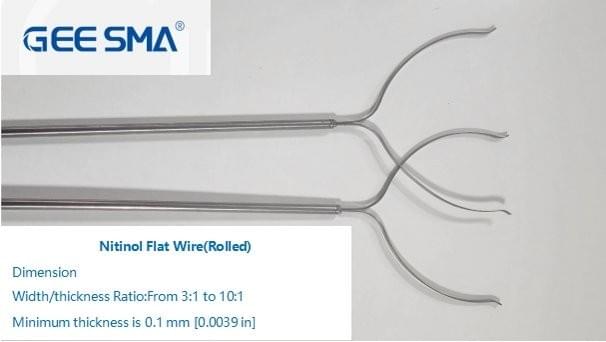

Exploring Nitinol Flat Wire

Nitinol flat wire is a fascinating material that combines the unique properties of Nitinol with a versatile flat shape, making it an essential choice for many applications. Its shape memory effect allows it to return to a predetermined shape when heated, which can be particularly useful in various industries. The adaptability of nitinol flat wire means that it can be engineered for specific requirements, enhancing its appeal to engineers and designers alike.

Benefits of Nitinol Flat Wire

One of the standout benefits of nitinol flat wire is its remarkable flexibility combined with strength, allowing it to perform under stress while maintaining its original form. This makes it an ideal candidate for applications where space is limited but performance cannot be compromised. Additionally, the corrosion resistance associated with nitinol wire ensures longevity and reliability in demanding environments, setting it apart from traditional nickel wire or titanium wire options.

Another advantage lies in its lightweight nature; nitinol flat wire contributes to overall weight reduction in devices without sacrificing functionality. This characteristic is especially critical in medical devices where minimizing patient load can significantly improve comfort and outcomes. Furthermore, the ability to customize nitinol flat wire dimensions enhances its usability across various sectors—from aerospace engineering to robotics.

Comparing Flat Wire to Other Forms

When comparing flat wire forms of nitinol with other configurations like round or square wires, it's clear that each has its advantages depending on application needs. Flat wires provide greater surface area contact which can lead to improved heat dissipation and better bonding capabilities in assemblies—benefits not as easily achieved with round or square profiles. Moreover, the flattened profile allows for stacking or layering in designs that require compactness without compromising structural integrity.

In terms of manufacturing processes, nitinol flat wire can often be produced more efficiently than other forms due to streamlined production techniques tailored specifically for this geometry. While round wires may excel in tensile strength applications, the versatility and adaptability of nitinol flat wire make it a superior choice for dynamic environments where movement and flexibility are pivotal. Ultimately, selecting between these forms hinges on understanding specific project requirements—something that savvy engineers know all too well.

Key Applications in Medical Devices

Nitinol flat wire plays a crucial role in several key medical device applications due to its unique properties and adaptability. One prominent use is within stents; here, the shape memory effect allows them to expand upon reaching body temperature after being delivered through minimally invasive procedures—leading to improved patient outcomes and recovery times compared to traditional materials like nickel wire or stainless steel alternatives.

Another important application involves guidewires used during surgical procedures; their flexibility enables navigation through complex anatomical structures while maintaining sufficient support during interventions. Moreover, nitinol flat wires are increasingly being utilized in orthopedic devices such as plates and screws due to their biocompatibility and ability to endure cyclic loading without failure—a significant advantage over conventional titanium wire manufacturers' offerings.

In summary, whether it's enhancing stent performance or revolutionizing surgical tools through innovative designs, nitinol flat wires are paving the way for advancements in medical technology that prioritize patient care without compromising on quality or performance.

Sizes and Shapes of Nitinol Wires

When it comes to nitinol wires, one of the most compelling features is their versatility in sizes and shapes. Understanding the options available can significantly impact the performance of your projects, particularly in specialized applications like medical devices or robotics. With advancements in manufacturing techniques, nitinol flat wire is now more customizable than ever, allowing for tailored solutions that meet specific needs.

Customization Options Available

Customization is a hallmark of nitinol wire production that sets it apart from traditional nickel wire or titanium wire options. Manufacturers often offer a range of diameters, lengths, and shapes to suit various applications; this flexibility means you can find the perfect fit for your project requirements. Whether you need thin nitinol flat wire for delicate instruments or thicker versions for heavy-duty applications, customization ensures optimal performance.

Tailored designs can also enhance functionality; for instance, some manufacturers allow you to specify unique geometries that align with your engineering specifications. This level of personalization not only improves usability but also opens doors to innovative applications across industries—from aerospace to healthcare. With a little creativity and collaboration with leading nitinol wire manufacturers, the possibilities are virtually endless.

Standard Sizes Versus Custom Shapes

When comparing standard sizes versus custom shapes of nitinol wires, it's essential to weigh the pros and cons based on your project's demands. Standard sizes are readily available and often come at lower costs due to mass production, making them an attractive option for many applications. However, if your project requires specific characteristics—like enhanced flexibility or unique stress responses—custom shapes may be worth the investment.

Nitinol flat wire can be manufactured in standard widths and thicknesses that cater to general use cases; yet custom profiles may provide advantages like improved thermal conductivity or better shape memory effects tailored specifically for high-stakes environments such as surgical tools or actuators in robotics. Ultimately, choosing between standard sizes and custom shapes depends on balancing budget constraints with performance needs—a decision best made after consulting with experienced nitinol wire manufacturers.

Innovations in Nitinol Wire Design

The world of nitinol wire design is constantly evolving thanks to technological advancements that push boundaries further than ever before. Innovations such as advanced processing techniques enable manufacturers to create finer wires with superior mechanical properties—think lighter yet stronger designs capable of enduring extreme conditions without compromising functionality. These innovations pave the way for exciting new applications across various fields.

Moreover, developments like hybrid materials combining nitinol flat wire with other metals are emerging as game-changers in product design; these composites leverage the unique properties of each component while minimizing drawbacks associated with individual materials alone. As research progresses into even more sophisticated alloys and structures within the realm of nitinol wires, we can expect breakthroughs that redefine what’s possible in engineering solutions today.

Leading Nitinol Wire Manufacturers

When it comes to sourcing high-quality nitinol wire, the market is filled with various manufacturers that cater to different needs and applications. Among them, GEE SMA stands out as a leading provider of innovative nitinol flat wire solutions. Their commitment to quality and customer satisfaction has made them a preferred choice for many in the industry.

Spotlight on GEE SMA

GEE SMA specializes in producing top-notch nitinol wire, including a range of nitinol flat wire options that are ideal for diverse applications. With advanced manufacturing processes and stringent quality control measures, GEE SMA ensures that their products meet the highest standards. Their expertise in the field allows them to offer customized solutions tailored to specific project requirements, making them a valuable partner for engineers and designers alike.

Other Notable Players in the Market

While GEE SMA is certainly a key player, several other notable nitinol wire manufacturers also contribute significantly to the market landscape. Companies like Fort Wayne Metals and Memry Corporation are recognized for their extensive experience and innovation in producing both nitinol wire and titanium wire products. Each manufacturer brings unique strengths to the table, ensuring that customers have access to a variety of options when selecting materials for their projects.

How to Choose the Right Manufacturer

Choosing the right manufacturer for your nitinol flat wire or general nitinol wire needs can be daunting with so many options available. Start by assessing their reputation within the industry; look for customer reviews and case studies showcasing successful projects using their products. Additionally, consider factors such as customization capabilities, material specifications (like nickel content), and lead times—after all, you want a reliable partner who can deliver quality materials on time without compromising on performance.

The Future of Nitinol Technology

The future of nitinol technology is brimming with possibilities, especially as advancements in nitinol wire production continue to evolve. Manufacturers are exploring innovative techniques that enhance the performance and reliability of nitinol flat wire, making it an even more attractive option for various industries. As we look ahead, it’s clear that the adaptability and unique properties of nitinol will play a significant role in shaping its future applications.

Advances in Nitinol Wire Production

Recent breakthroughs in the production processes of nitinol wire have led to improved consistency and quality across the board. Techniques such as advanced heat treatment and precise alloy composition adjustments are being refined by leading nitinol wire manufacturers to optimize the shape memory effect and superelasticity characteristics. These enhancements not only make nitinol flat wire more reliable but also enable manufacturers to produce custom shapes that meet specific project requirements.

Additionally, automation and digitalization are streamlining production lines, allowing for quicker turnaround times without sacrificing quality. This means that customers can expect faster delivery of their desired products while still enjoying the benefits of high-performance materials like nickel wire and titanium wire from reputable manufacturers. As these advances continue, we can anticipate a surge in demand for customized solutions made from nitinol wires.

Potential Applications on the Horizon

The versatility of nitinol flat wire opens up exciting potential applications across diverse fields such as robotics, aerospace, and medical devices. In robotics, for instance, developers are keenly interested in utilizing nitinol's shape memory effect to create soft actuators that mimic natural movements with precision and adaptability. Meanwhile, in medicine, innovations like self-expanding stents made from advanced forms of nitinol wires could revolutionize patient care by improving recovery times and reducing complications.

Moreover, industries focused on sustainable energy solutions are beginning to explore how nitinol can contribute to more efficient systems—think smart materials that respond dynamically to environmental changes! The possibilities seem endless as researchers continue to push boundaries; every new application discovered broadens our understanding of what this remarkable material can achieve.

Market Trends to Watch

As we move forward into an era where customization is king, expect a noticeable trend toward tailored solutions offered by leading nitinol wire manufacturers. Companies specializing in manufacturing both standard sizes and custom shapes will likely see increased demand as industries recognize the importance of bespoke components in optimizing performance outcomes. This shift aligns with broader market trends emphasizing efficiency and innovation across all sectors.

Furthermore, sustainability is becoming a critical factor influencing purchasing decisions; consumers are increasingly inclined towards materials that promise longevity without compromising environmental integrity—traits inherent in high-quality titanium wire alongside its counterpart nitrogen wires like those made from nickel alloys. Keeping an eye on these evolving trends will be essential for stakeholders looking to navigate the dynamic landscape surrounding advanced materials like nitinol.

Conclusion

As we wrap up our exploration of nitinol wires, it's clear that these materials are not just a passing trend but rather a revolutionary innovation in multiple industries. From medical devices to robotics, the unique properties of nitinol flat wire offer unparalleled advantages. By incorporating nitinol wire into your projects, you can enhance functionality and performance while also embracing cutting-edge technology.

Enhancing Projects with Nitinol Wires

The versatility of nitinol wires makes them an ideal choice for various applications, especially in sectors requiring precision and reliability. Whether you're developing intricate medical devices or innovative engineering solutions, using nitinol flat wire can significantly improve your project's outcomes. This material's unique shape memory effect allows it to return to its original form after deformation, which adds an extra layer of resilience and adaptability.

The Impact of GEE SMA Innovations

GEE SMA stands out among nitinol wire manufacturers for its commitment to quality and innovation in the field. Their advancements in producing high-performance nitinol flat wire have made significant strides in enhancing the capabilities of medical devices and other applications. With GEE SMA leading the charge, we can expect even more exciting developments that will push the boundaries of what is possible with nitinol technology.

Making Informed Choices in Nitinol Supply

When selecting from various nitinol wire manufacturers or titanium wire manufacturers, it's essential to consider factors such as product quality, customization options, and industry reputation. The right choice can make all the difference in achieving your project goals effectively and efficiently. By staying informed about market trends and innovations like those offered by GEE SMA, you can ensure that you are making well-informed decisions regarding your supply of nitinol products.