Introduction

In the realm of advanced materials, few can match the versatility and innovative potential of nitinol wire. This unique shape memory alloy, composed primarily of nitinol nickel titanium, is making waves across various industries due to its remarkable properties. Nitinol wire manufacturers are increasingly harnessing its capabilities to create tailored solutions that meet the specific needs of their clients.

The Versatility of Nitinol Wire

Nitinol wire stands out not only for its unique ability to return to a predetermined shape when heated but also for its adaptability in diverse applications. From medical devices that rely on precise movements to aerospace components requiring lightweight yet durable materials, nitinol's versatility knows no bounds. The combination of titanium material and nickel in this alloy allows it to perform under extreme conditions while maintaining resilience and flexibility.

Why Customization Matters

In today's fast-paced industrial landscape, customization is no longer a luxury; it's a necessity. Nitinol wire manufacturers understand that each application may demand different specifications, whether it's diameter, stiffness, or temperature response. By customizing nitinol products during manufacturing, they ensure optimal performance tailored specifically for each use case—be it in medical technology or automotive engineering.

Nitinol in Industrial Applications

The applications of nitinol extend far beyond traditional uses; they are revolutionizing multiple sectors with their innovative properties. In the medical field, devices like stents and guidewires utilize the unique characteristics of nitinol wire for enhanced patient outcomes. Meanwhile, industries such as aerospace and automotive are tapping into this titanium metal's strength-to-weight ratio and shape memory features to push boundaries in design and functionality.

Understanding Nitinol Wire

Nitinol wire is a fascinating material that has garnered attention across various industries due to its unique properties and versatility. Composed primarily of nickel and titanium, this shape memory alloy can return to its original shape after deformation when exposed to specific temperatures. Understanding the composition and characteristics of nitinol wire is crucial for anyone looking to work with nitinol wire manufacturers or delve into the world of advanced materials.

Overview of Nitinol Composition

The primary components of nitinol are nickel and titanium, which together create a remarkable alloy known for its shape memory effect and superelasticity. This specific ratio of titanium material and nickel creates a unique crystalline structure that allows the wire to remember its original form even after being bent or twisted. Additionally, some manufacturers may incorporate niobium material in their production processes to enhance certain properties, making it essential to know what goes into manufacturing the product before making a selection.

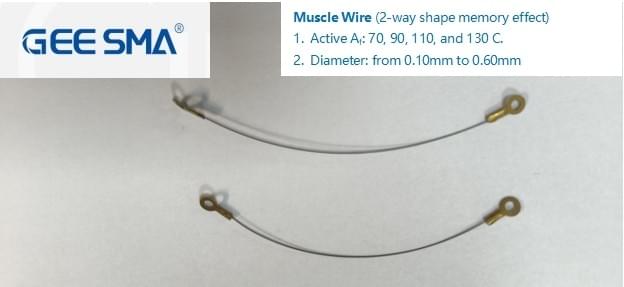

Unique Properties of Shape Memory Alloys

Shape memory alloys like nitinol exhibit two extraordinary behaviors: the ability to return to their pre-deformed shape upon heating and their superelasticity at certain temperatures. These characteristics make nitinol wire an ideal choice for applications where flexibility and strength are paramount, such as in medical devices or aerospace components. The combination of these properties results from the unique interactions between titanium metal and nickel within the alloy, showcasing why it's vital for manufacturers to understand these principles when working with nitinol.

Role of Titanium and Nickel

Titanium plays a pivotal role in determining the mechanical properties of nitinol wire, contributing significantly to its strength-to-weight ratio while also offering excellent corrosion resistance. On the other hand, nickel enhances ductility and helps stabilize the alloy's phase transformations during temperature changes, which are critical for achieving desired performance characteristics in applications across industries. Recognizing how these two metals interact not only aids in selecting reliable nitinol wire manufacturers but also ensures that one gets high-quality products tailored for specific needs.

The Customization Process

When it comes to nitinol wire, customization is the name of the game. The unique properties of shape memory alloys allow for tailored solutions that can significantly enhance performance in various applications. This process involves meticulous attention to detail and a deep understanding of how different specifications affect the final product.

Tailoring Specifications for Performance

Tailoring specifications for performance is crucial when working with nitinol wire manufacturers. Each application may require specific attributes, such as temperature sensitivity or mechanical strength, which can be achieved through careful selection of titanium material and nickel-titanium compositions. By adjusting parameters like wire diameter, heat treatment processes, and alloy ratios, manufacturers can create a product that meets stringent performance criteria.

Moreover, understanding the role of niobium material in enhancing certain properties can lead to innovative solutions. For instance, incorporating niobium into the alloy can improve fatigue resistance and overall durability without compromising the unique shape memory effects inherent in nitinol. This level of customization not only enhances functionality but also allows industries to push the boundaries of what’s possible with titanium metal applications.

Working with Nitinol Wire Manufacturers

Partnering with experienced nitinol wire manufacturers is essential for successful customization. These manufacturers possess specialized knowledge about manufacturing processes and can guide clients through selecting the right materials and configurations for their needs. They understand that each project has its own set of challenges and requirements; thus, they are equipped to offer tailored recommendations based on years of expertise.

Effective communication between clients and manufacturers is vital during this phase; it ensures that everyone is aligned on expectations regarding timelines, costs, and desired outcomes. Manufacturers who prioritize collaboration will often demonstrate flexibility in adapting their processes to meet specific demands while maintaining high standards in quality control—especially important when dealing with complex materials like titanium metal or alloys containing niobium material.

Additionally, working closely with your manufacturer fosters an environment where innovation thrives. By sharing insights about application-specific challenges or exploring new ideas together, both parties benefit from a richer understanding of how customized nitinol solutions can be developed effectively.

Importance of Collaboration in Manufacturing

Collaboration is at the heart of successful manufacturing processes involving nitinol wire—and for good reason! When teams work together seamlessly—be it engineers from different disciplines or various departments within a manufacturing facility—the results often exceed initial expectations. This collaborative spirit enables teams to tackle potential issues proactively instead of reactively addressing them later on.

In fact, many groundbreaking advancements in shape memory alloy technology stem from collaborative efforts between researchers and nitinol wire manufacturers who share a common goal: creating superior products that meet evolving industry demands. Such partnerships often lead to innovative uses for titanium material beyond traditional applications while pushing forward sustainable practices within production environments.

Ultimately, investing time into building strong relationships with your chosen manufacturer pays off immensely when it comes time for production—ensuring that every aspect aligns perfectly from design through delivery! With an emphasis on teamwork throughout all stages—from concept development through final testing—clients gain confidence knowing their custom-made solutions will perform exceptionally well under real-world conditions.

Applications Across Industries

Nitinol wire has made significant strides across various industries, showcasing its unique properties and versatility. The applications of this remarkable shape memory alloy span from medical devices to aerospace innovations and automotive advancements. Understanding how nitinol wire manufacturers leverage these attributes is key to appreciating its impact on modern technology.

Medical Devices Using Nitinol

In the medical field, nitinol wire is a game-changer, particularly in the development of minimally invasive devices. Its shape memory properties allow for devices that can change shape at body temperature, providing superior functionality in applications such as stents and guidewires. With the collaboration of nitinol wire manufacturers, these innovative solutions are manufactured with precision using high-quality titanium material combined with nickel titanium for optimal performance.

Nitinol's biocompatibility makes it an ideal choice for various surgical instruments and implants. Manufacturers focus on tailoring specifications to meet stringent regulatory requirements while ensuring that the products can withstand bodily conditions over time. As a result, medical professionals benefit from tools that enhance patient outcomes through reduced recovery times and improved procedural efficiency.

Moreover, the use of niobium material in some nitinol formulations can further enhance strength and flexibility, allowing for even more advanced medical applications. This combination leads to innovations such as self-expanding stents that adapt to arterial changes or flexible catheters designed for complex procedures. By investing in high-quality manufacturing processes, nitinol wire manufacturers ensure that these life-saving devices perform reliably when needed most.

Aerospace Innovations with Nitinol

The aerospace industry has also embraced nitinol wire due to its lightweight nature and exceptional strength-to-weight ratio. Aircraft components made from this shape memory alloy contribute to fuel efficiency while maintaining structural integrity under extreme conditions. Collaborating with specialized nitinol wire manufacturers enables aerospace engineers to create components that respond dynamically to environmental changes, enhancing overall performance.

One notable application is in actuators where nitinol’s ability to return to a predetermined shape upon heating allows for compact designs without sacrificing power or reliability. These actuators find uses in systems ranging from wing flaps to landing gear mechanisms, demonstrating how titanium metal's unique properties can revolutionize traditional aircraft designs. Furthermore, advancements in manufacturing techniques ensure that these components are produced with consistent quality standards.

As the demand for sustainable aviation practices grows, utilizing materials like nitinol offers exciting possibilities for developing energy-efficient systems within aircraft design frameworks. The incorporation of niobium material not only improves performance but also aligns with eco-friendly initiatives aimed at reducing carbon footprints in aviation technology. In this evolving landscape, collaboration between engineers and manufacturers becomes essential for pushing boundaries further than ever before.

Automotive Uses of Nitinol Wire

In the automotive sector, nitinol wire is increasingly recognized for its potential in creating smart systems within vehicles—think self-adjusting seatbelts or adaptive suspension systems! The unique properties of this shape memory alloy allow it to respond dynamically based on temperature changes or mechanical stressors encountered during operation—an innovation driven by collaboration between automotive engineers and specialized nitinol wire manufacturers.

For example, incorporating titanium metal into engine components enhances durability while reducing weight—a crucial factor when optimizing fuel consumption across various vehicle types—from electric cars to high-performance sports models! Additionally, integrating niobium material into certain applications can lead not only toward improved resilience but also contribute positively towards achieving stricter emissions regulations imposed by governments worldwide.

As electric vehicles gain traction globally alongside traditional combustion engines’ evolution towards hybridization strategies; leveraging advanced materials like nitinol will be pivotal moving forward—ensuring safety features remain uncompromised while enhancing overall driving experiences through smarter integrations across all facets of automobile engineering!

Sourcing Quality Nitinol Wire

Finding the right nitinol wire manufacturers is crucial for ensuring high-quality products that meet specific requirements. With the rise of shape memory alloys in various industries, it’s essential to partner with a manufacturer who understands the intricacies of nitinol, including its composition and properties. This section will guide you through selecting a reliable manufacturer, evaluating niobium materials in production, and spotlighting GEE SMA’s capabilities.

Criteria for Selecting a Manufacturer

When selecting a nitinol wire manufacturer, several criteria should be top of mind. First and foremost, look for experience in working with titanium materials and shape memory alloys; this indicates they have honed their processes over time. Additionally, consider their ability to customize nitinol nickel titanium products to fit your specific applications—because one-size-fits-all rarely works in the world of advanced materials.

Quality certifications are also vital; manufacturers should adhere to industry standards that ensure consistency and reliability during manufacturing the product. Don’t shy away from asking about their sourcing practices for titanium metal and niobium material—transparency here can save you headaches later on. Finally, customer service plays a significant role; responsive communication can make all the difference when navigating complex projects.

Evaluating Niobium Materials in Nitinol Production

Niobium materials play an essential role in enhancing the properties of nitinol wire, making them worth evaluating closely during your selection process. When assessing potential manufacturers, inquire about their niobium sourcing practices and whether they utilize high-purity niobium that can improve mechanical properties while maintaining shape memory characteristics. The integration of quality niobium into nitinol production can significantly enhance performance attributes such as fatigue resistance and thermal stability.

It’s also beneficial to understand how these manufacturers incorporate niobium into their processes; innovative techniques can lead to better product outcomes while optimizing costs. Moreover, consider how well they balance this element with titanium material to achieve desired alloy compositions without compromising quality or efficiency during manufacturing the product. Ultimately, choosing a manufacturer who prioritizes high-quality niobium will ensure that your final products exceed expectations.

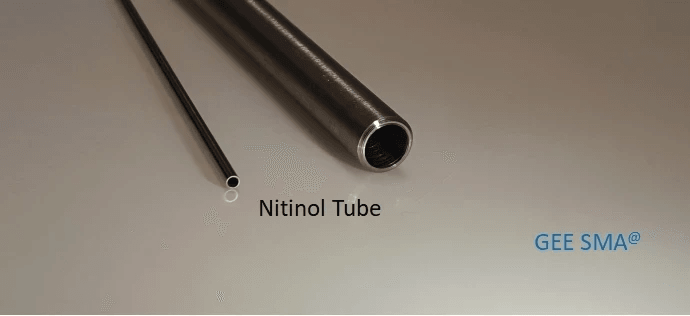

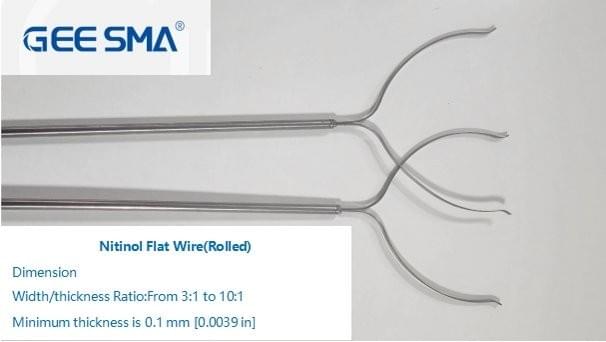

Spotlight on GEE SMA’s Capabilities

GEE SMA stands out among nitinol wire manufacturers due to its commitment to innovation and quality assurance throughout every step of production. Their extensive experience with both titanium metal and shape memory alloys positions them as leaders in customization capabilities tailored specifically for various industries—from medical devices to aerospace applications. GEE SMA not only focuses on delivering exceptional nitinol nickel titanium solutions but also emphasizes sustainable practices throughout their manufacturing processes.

Their rigorous evaluation of raw materials includes sourcing premium-grade titanium material along with high-purity niobium material which ensures superior performance characteristics in every batch produced. Furthermore, GEE SMA prides itself on collaborative relationships with clients; understanding unique needs allows them to manufacture the product efficiently while maintaining open lines of communication at all times. With state-of-the-art technology combined with expert craftsmanship, GEE SMA is truly paving the way for future advancements in nitinol wire applications.

The Future of Nitinol Manufacturing

The future of nitinol manufacturing is bright, with continuous advancements in technology and materials science driving innovation. As industries increasingly recognize the unique properties of shape memory alloys, particularly nitinol wire, we can expect to see a surge in applications across various sectors. This evolution will be shaped not only by the demand for high-performance materials but also by the need for sustainable practices within manufacturing.

Emerging Trends in Shape Memory Alloys

Emerging trends in shape memory alloys are paving the way for more versatile applications and enhanced performance capabilities. Nitinol wire manufacturers are focusing on refining their processes to produce wires that exhibit improved fatigue resistance and greater recovery properties when subjected to stress. With ongoing research into niobium material integration, these innovations promise to expand the functionality of nitinol nickel titanium products even further.

Moreover, as industries evolve, there is an increasing emphasis on customization and precision in manufacturing the product. This shift allows manufacturers to tailor nitinol wire specifications to meet specific operational needs across diverse fields such as medical devices and aerospace technologies. The collaboration between engineers and nitinol wire manufacturers will be crucial as they explore new formulations that optimize both strength and flexibility.

Sustainable Practices in Titanium Material Production

Sustainability is becoming a cornerstone of modern manufacturing processes, especially concerning titanium material production for nitinol wires. Manufacturers are increasingly adopting eco-friendly practices that minimize waste and energy consumption while ensuring high-quality output. By utilizing advanced recycling techniques for titanium metal scrap, companies can significantly reduce their environmental impact while maintaining the integrity of their products.

Additionally, incorporating niobium material into production processes offers potential benefits by enhancing corrosion resistance without compromising sustainability goals. This innovative approach not only meets market demands but also aligns with global efforts toward greener manufacturing solutions. As consumers become more environmentally conscious, manufacturers that prioritize sustainable practices will likely gain a competitive edge in the marketplace.

The Role of Nitinol in Future Technologies

Nitinol's role in future technologies cannot be overstated; its unique attributes make it indispensable across numerous applications poised for growth. From robotics to smart materials, nitinol wire’s ability to return to a predetermined shape under specific conditions opens doors to revolutionary advancements that were once merely theoretical concepts. As researchers continue exploring its capabilities alongside emerging technologies like artificial intelligence and automation, we can anticipate exciting developments ahead.

Furthermore, the integration of advanced data analytics into manufacturing processes will enable nitinol wire manufacturers to predict performance outcomes more accurately than ever before. This predictive capability could lead to breakthroughs in designing tailored solutions using nitinol nickel titanium alloys specifically suited for complex environments or demanding applications such as space exploration or biomedical implants. As these trends converge, they will redefine how industries utilize this remarkable shape memory alloy.

Conclusion

In the ever-evolving landscape of materials science, customized nitinol solutions stand out as a beacon of innovation and adaptability. The unique properties of nitinol wire, particularly its shape memory alloy capabilities, allow for tailored applications that meet specific industry needs. By collaborating with experienced nitinol wire manufacturers, businesses can harness these advantages to create products that not only perform better but also push the boundaries of what’s possible.

The Benefits of Customized Nitinol Solutions

When it comes to manufacturing the product, customization is key for maximizing efficiency and performance. Nitinol nickel titanium alloys offer unparalleled versatility in various applications, from medical devices to aerospace innovations. Tailored specifications ensure that the final product meets rigorous standards while addressing unique challenges faced by different industries.

Investing in Quality Nitinol Wire

The investment in quality nitinol wire is crucial for any company looking to leverage this advanced material effectively. Selecting reliable nitinol wire manufacturers who prioritize high-grade titanium material and niobium material can significantly impact the durability and functionality of the final product. Quality assurance during production not only enhances performance but also ensures compliance with industry regulations.

GEE SMA’s Commitment to Innovation

GEE SMA stands at the forefront of nitinol manufacturing, driven by a commitment to innovation and excellence in every aspect of their operations. As a leading manufacturer metal provider, they understand that investing in top-tier titanium metal and niobium materials is essential for creating superior shape memory alloys. Their dedication to continuous improvement guarantees that clients receive cutting-edge solutions tailored specifically for their needs.