Introduction

Nitinol, a remarkable alloy of nickel and titanium, has captured the attention of industries ranging from medical to aerospace with its unique qualities. This extraordinary material exhibits properties such as superelasticity and shape memory, making it a game-changer in the realm of medical nitinol devices. With its ability to return to a predetermined shape when heated, nitinol is revolutionizing how we approach design and functionality across various applications.

Discovering Nitinol's Unique Qualities

The true magic of nitinol lies in its dual nature: it can be both superelastic and shape-memory depending on temperature changes. This means that when used in medical devices like stents in nitinol applications, they can expand or contract effortlessly within the body while maintaining their integrity. ASTM F2063 sets the standard for these materials, ensuring that medical nitinol meets rigorous safety and performance criteria.

The Versatile World of Nitinol Applications

Beyond the operating room, nitinol showcases its versatility across multiple sectors including robotics and aerospace technology. In these fields, nitinol tubing is utilized for its lightweight yet durable characteristics, allowing for innovative designs that were once thought impossible. The adaptability of this alloy demonstrates why so many industries are eager to incorporate it into their products.

Why Nitinol is a Game-Changer

Nitinol's unique properties not only enhance existing technologies but also pave the way for groundbreaking innovations in medical devices and beyond. For instance, advancements in nitinol stent designs have significantly improved patient outcomes by providing better support within blood vessels while minimizing risks associated with traditional materials. As more companies recognize the potential of partnering with a reliable nitinol manufacturer, we are likely to witness an explosion of creative solutions fueled by this fascinating material.

Understanding Nitinol

Nitinol, a unique alloy of nickel and titanium, is celebrated for its remarkable properties that set it apart from conventional metals. Its ability to undergo significant deformation while returning to its original shape makes it an ideal candidate for various applications, particularly in the medical field. The combination of superelasticity and shape memory effects makes medical nitinol a game-changer in the design of devices like stents and tubing.

Properties of Nitinol

The standout properties of nitinol include its superelasticity, shape memory effect, and biocompatibility. Superelastic nitinol can stretch significantly without permanent deformation, allowing it to adapt to dynamic environments within the body. Additionally, its biocompatibility ensures that devices made from nitinol can be safely used within human tissues, making it a preferred material for critical medical applications such as nitinol stents and tubing.

Nitinol also exhibits excellent fatigue resistance, which is crucial for long-term use in medical devices. This property ensures that products like nitinol tubing can endure repeated flexing without failure over time. Furthermore, nitinol's corrosion resistance enhances its durability when exposed to bodily fluids or harsh industrial environments.

What is Superelastic Nitinol?

Superelastic nitinol refers specifically to the form of this alloy that can return to its original shape after being deformed at room temperature. This phenomenon occurs due to a phase transformation between two crystalline structures: martensite and austenite. When subjected to stress beyond a certain limit, superelastic nitinol will deform but will revert back once the stress is removed—perfect for applications such as stent in nitinol where flexibility is essential.

In practical terms, this means that stents made from superelastic nitinol can navigate through complex vascular pathways before expanding into their intended shape at the target site—enhancing patient outcomes significantly. The ability of superelastic nitinol to absorb energy during deformation also reduces stress on surrounding tissues during implantation procedures.

Moreover, superelasticity not only benefits medical devices but also opens doors in other fields such as robotics and aerospace technology where adaptable materials are needed for high-performance applications.

The Role of ASTM F2063

ASTM F2063 plays an essential role in standardizing the specifications for nickel-titanium alloys used in medical devices like those made from medical nitinol. This standard outlines key requirements regarding material composition, mechanical properties, and performance criteria necessary for safe use within healthcare settings. Adhering to ASTM F2063 ensures that manufacturers produce reliable products such as nitinol stents and tubing that meet stringent safety standards.

For manufacturers looking to produce high-quality medical devices using superelastic nitinol or other forms of this alloy, compliance with ASTM F2063 offers assurance both in quality control processes and regulatory approvals necessary for market entry. It acts as a benchmark against which all aspects—from raw materials sourcing through production techniques—can be measured.

Ultimately, understanding ASTM F2063 helps healthcare professionals trust that the products they use are built on solid foundations of safety and efficacy—essential when dealing with life-saving technologies like those found in modern medicine’s arsenal.

Nitinol in Medical Devices

Nitinol has revolutionized the medical device landscape with its remarkable properties, especially in terms of flexibility and shape memory. The unique characteristics of superelastic nitinol allow for innovative designs that can adapt to dynamic environments within the human body. This adaptability is crucial, as it enhances patient outcomes and expands the possibilities for medical interventions.

Innovations in Medical Nitinol

The innovations surrounding medical nitinol are nothing short of groundbreaking. From stents to guidewires, the use of nitinol has led to significant advancements that improve both efficacy and safety in procedures. Notably, ASTM F2063 sets the standard for the composition and properties of nitinol used in these applications, ensuring that manufacturers adhere to rigorous quality benchmarks.

With superelastic nitinol, devices can withstand considerable deformation while returning to their original shape upon release of stress. This feature is particularly beneficial in creating devices that navigate complex anatomical pathways without damaging surrounding tissues. As a result, medical professionals are increasingly turning to nitinol for solutions that require both resilience and precision.

Nitinol Stent Breakthroughs

Nitinol stents have become synonymous with innovation in cardiovascular treatments, providing a less invasive option for patients suffering from arterial blockages. The flexibility of stent in nitinol allows it to conform seamlessly to varying vessel geometries, minimizing trauma during implantation while maximizing blood flow restoration post-procedure. These breakthroughs have made it possible for patients to experience faster recovery times compared to traditional metal stents.

Moreover, superelastic properties mean that these stents can expand fully upon deployment without compromising structural integrity over time. This adaptability reduces the risk of restenosis—re-narrowing of arteries—which has been a challenge with earlier stent technologies. As more studies validate their effectiveness, nitinol stents are becoming a preferred choice among healthcare providers worldwide.

Design of Nitinol Tubing

The design capabilities offered by nitinol tubing are transforming how medical devices are conceptualized and manufactured. With its unique mechanical properties, this tubing can be engineered into various shapes and sizes tailored specifically for different applications such as catheters or endoscopes. The versatility inherent in nitinol allows manufacturers greater freedom when designing complex systems intended for minimally invasive procedures.

Furthermore, compliance with ASTM F2063 ensures that all produced tubing meets stringent safety requirements necessary for patient care products. By utilizing superelastic nitinol tubing, healthcare professionals benefit from devices that maintain functionality under pressure while providing enhanced maneuverability through intricate anatomical regions. This innovation not only improves procedural efficiency but also elevates overall patient satisfaction and outcomes.

Nitinol's Industrial Applications

Nitinol, with its unique properties, is making waves beyond the medical field and into various industrial applications. From robotics to aerospace technology, this remarkable alloy is proving to be a game-changer, thanks to its superelasticity and shape memory capabilities. As industries evolve, the potential for nitinol manufacturing continues to grow, promising exciting advancements on the horizon.

Nitinol in Robotics

In the realm of robotics, nitinol is revolutionizing how machines interact with their environment. Its ability to undergo large deformations while returning to its original shape allows for highly efficient actuators and sensors that can mimic human-like motions. This adaptability not only enhances robotic functionality but also enables more compact designs that are lighter and easier to maneuver.

Moreover, medical nitinol has found a niche in soft robotics—an emerging field where flexibility is paramount. By utilizing nitinol tubing and components, engineers can create robots capable of delicate tasks like surgical procedures or handling fragile objects without damage. As research progresses, we can expect even more innovative applications of nitinol in creating responsive robotic systems that enhance our daily lives.

Uses in Aerospace Technology

Aerospace technology is another area where nitinol shines brightly due to its lightweight yet robust nature. The aerospace industry demands materials that can withstand extreme temperatures and pressures while maintaining structural integrity; superelastic nitinol fits the bill perfectly. Its application in components such as actuators and fasteners reduces overall weight without compromising performance or safety.

Additionally, the use of stents made from nitinol has extended beyond medical devices into aerospace applications where they serve as deployable structures or mechanisms for satellite deployment systems. The unique properties of stent in nitinol allow these structures to expand under specific conditions while retaining strength—a crucial factor when designing equipment meant for space travel. As we explore new frontiers in aerospace engineering, expect further integration of this versatile material into aircraft design and satellite technology.

The Future of Nitinol Manufacturing

The future of nitinol manufacturing looks bright as advancements continue to unlock new possibilities for this extraordinary material across various industries. With growing demand for customized solutions from different sectors—including robotics and aerospace—nitinol manufacturers are investing heavily in R&D efforts focused on improving production techniques and material properties compliant with standards like ASTM F2063.

Emerging technologies such as additive manufacturing are also paving the way for innovative uses of medical nitinol beyond traditional forms like tubing or stents; intricate designs can now be produced with precision at lower costs than ever before. This shift may lead us toward a future where tailored solutions become commonplace across all applications involving superelastic nitinol—from specialized tools used in surgery to advanced components found within cutting-edge machinery.

Choosing a Nitinol Manufacturer

When it comes to selecting the right nitinol manufacturer, the stakes are high, especially in fields like medicine and aerospace where precision is paramount. The quality of medical nitinol can mean the difference between life-saving devices and subpar products that fail to perform. Therefore, understanding what sets a manufacturer apart is crucial for ensuring that your nitinol needs are met effectively.

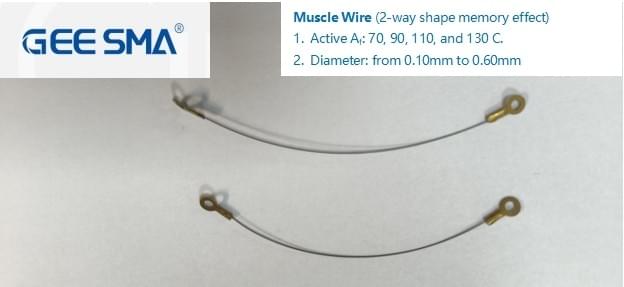

Why GEE SMA Stands Out

GEE SMA has established itself as a leader in the production of medical nitinol, thanks to its unwavering commitment to quality and innovation. Their expertise in superelastic nitinol allows them to create products that not only meet but often exceed industry standards set by ASTM F2063. With a focus on both research and development, GEE SMA continually pushes the boundaries of what's possible with nitinol stents and other medical devices.

Moreover, their dedication to customer satisfaction means they actively engage with clients to understand their unique requirements for nitinol tubing and other applications. This level of personalized service is rare in the industry and positions GEE SMA as a go-to choice for those seeking reliable solutions in medical nitinol manufacturing. As they say, Quality isn't an act; it's a habit, and GEE SMA embodies this philosophy every step of the way.

Quality Assurance in Nitinol Production

Quality assurance is not just an afterthought at GEE SMA; it’s woven into every aspect of their production process for medical nitinol. Each batch undergoes rigorous testing to ensure compliance with ASTM F2063 standards before it ever reaches the customer’s hands. This meticulous attention to detail guarantees that each stent in nitinol or piece of tubing meets stringent safety and performance criteria.

Additionally, GEE SMA employs advanced technologies such as automated inspections and real-time monitoring systems during manufacturing processes. These innovations help identify potential issues before they become problems, ensuring that every product—be it a stent or specialized tubing—is nothing short of exceptional. When you choose GEE SMA as your nitinol manufacturer, you're not just buying products; you're investing in peace of mind.

Custom Solutions for Nitinol Needs

One size does not fit all when it comes to medical devices made from superelastic nitinol; that's why custom solutions are essential for many applications today. At GEE SMA, customization isn't just an option—it’s part of their core philosophy aimed at meeting diverse client needs across various industries including healthcare and aerospace technology. Whether you need specific dimensions or tailored properties for your stent in nitinol or specialized tubing configurations, they've got you covered.

Their team works closely with clients from concept through production, ensuring that every detail aligns perfectly with project specifications while utilizing state-of-the-art manufacturing techniques. This collaborative approach not only enhances product functionality but also fosters innovation within fields reliant on advanced materials like medical nitinol. With custom solutions from GEE SMA, you can be confident that your unique requirements will be met without compromise.

Real-World Success Stories

Nitinol has made a significant impact across various industries, showcasing its versatility and innovative potential. From space exploration to life-saving medical devices, the success stories of nitinol are as varied as they are inspiring. Let’s explore some remarkable examples that highlight the transformative power of this unique alloy.

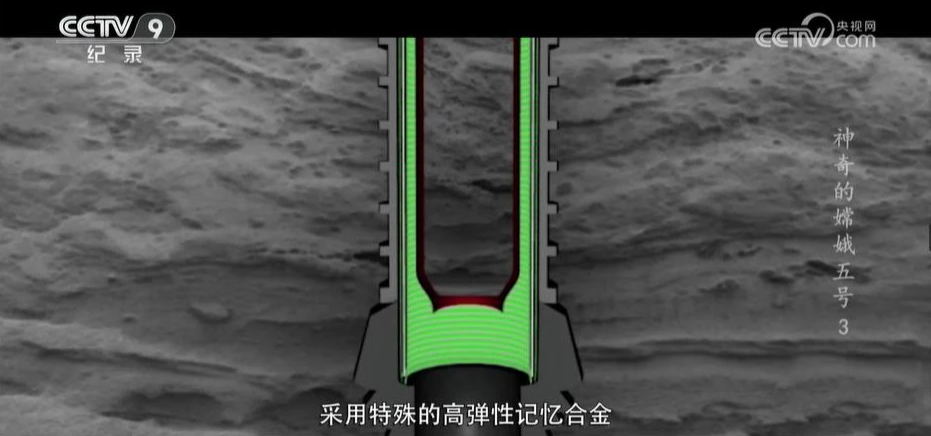

Chang’e Missions Utilizing Nitinol

The Chang’e missions, China's ambitious lunar exploration projects, have harnessed the unique qualities of nitinol to enhance their technological capabilities. Superelastic nitinol components have been employed in various instruments and mechanisms aboard the spacecraft, providing reliable performance under extreme conditions. The ability of nitinol to return to its original shape after deformation makes it ideal for applications requiring flexibility and resilience in space.

These missions utilize nitinol tubing for essential functions like thermal management and structural support, demonstrating how this material can withstand the harsh environment of outer space. Additionally, the lightweight nature of nitinol has helped reduce overall mission weight without compromising functionality. It’s clear that medical nitinol is not just limited to healthcare; it plays a crucial role in pushing the boundaries of human exploration.

Case Studies of Nitinol in Action

Across numerous sectors, case studies illustrate how medical nitinol is revolutionizing product design and functionality. One prominent example is the development of advanced stents made from superelastic nitinol, which have drastically improved patient outcomes in vascular surgeries. These nitinol stents are designed to expand within arteries upon deployment, reducing complications related to traditional stenting methods while promoting faster recovery times.

Another fascinating application involves using nitinol tubing for minimally invasive surgical tools that require precision and flexibility during procedures. The adaptability offered by ASTM F2063 compliant materials ensures consistent quality and performance across various medical devices. By integrating these innovations into everyday practices, healthcare providers can offer more effective treatments with lower risks associated with conventional methods.

Testimonials from Nitinol Users

Feedback from users highlights how vital medical devices made from nitinol have become in modern medicine today. Surgeons frequently praise the effectiveness of stents in nitinol for their durability and success rates; many report enhanced patient recovery experiences thanks to these groundbreaking innovations. “The superelastic properties allow us to navigate complex anatomy with ease,” says Dr. Smith, a leading cardiologist who frequently employs these devices in his practice.

Patients also share their positive experiences after receiving treatments involving medical nitinol products; they often express relief at how quickly they regained mobility post-surgery thanks to innovative designs like those found in stent technology or minimally invasive tools incorporating thin-walled tubing made from this remarkable alloy. As testimonials pour in from both practitioners and patients alike, it becomes apparent that choosing a reliable nitinol manufacturer is essential for ensuring high-quality outcomes.

Conclusion

As we wrap up our exploration of Nitinol, it's clear that this remarkable alloy is not just a scientific curiosity but a transformative force in various industries. The future of Nitinol technology looks incredibly promising, especially with ongoing research and development aimed at enhancing its properties and applications. With innovations in superelastic nitinol and adherence to standards like ASTM F2063, the potential for new breakthroughs continues to grow.

The Future of Nitinol Technology

The future of Nitinol technology is bright, fueled by advancements that could redefine its capabilities and applications. As we see more integration of medical nitinol into everyday devices, the landscape of manufacturing will evolve significantly, allowing for more tailored solutions. With companies focusing on quality assurance and innovative designs in nitinol tubing and stents in nitinol, we can expect a wave of enhancements that will push boundaries further than ever before.

How Nitinol Shapes Modern Medicine

Nitinol is already shaping modern medicine in ways that were once thought impossible. Medical devices made from nitinol have revolutionized procedures; think about the impact of nitinol stents which have become vital for minimally invasive surgeries. These innovations not only improve patient outcomes but also reduce recovery times, showcasing how essential medical nitinol has become in contemporary healthcare practices.

Embracing Nitinol Innovations for Tomorrow

Embracing innovations in Nitinol means embracing a future filled with possibilities—especially as the demand for advanced medical devices continues to rise. Manufacturers are now tasked with creating custom solutions that meet specific needs while adhering to rigorous standards like ASTM F2063. By partnering with reputable nitinol manufacturers who prioritize quality and innovation, industries can ensure they remain at the forefront of technological advancements.