Introduction

In the realm of advanced materials and engineering, few innovations have garnered as much attention as nitinol. This remarkable alloy, known for its unique properties, including shape memory and superelasticity, is revolutionizing various fields with its applications. Among these, the nitinol linear actuator stands out as a game-changer in medical manufacturing, robotics, aerospace, automotive industries, and home automation.

Understanding Nitinol Properties

Nitinol is a nickel-titanium alloy that exhibits extraordinary characteristics due to its nitinol properties. The most notable of these are its shape memory effect and superelasticity—allowing it to return to a predetermined shape when heated or deformed under stress. These exceptional traits make nitinol wire an ideal candidate for applications requiring precision and reliability, such as in nitinol medical devices where performance is paramount.

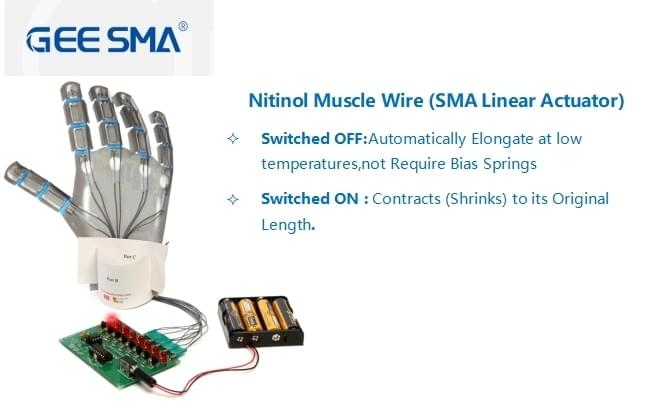

The Rise of Nitinol Linear Actuators

The emergence of the nitinol linear actuator has transformed the landscape of actuation technology. With their ability to convert thermal energy into mechanical movement efficiently, these wire actuators have gained traction in numerous sectors. As industries increasingly seek compact and lightweight solutions for their devices, the demand for nitinol linear actuators continues to rise.

Transforming Industries with Nitinol

From enhancing surgical instruments in healthcare to improving automation processes in robotics, nitinol is making waves across various industries. Its versatility allows manufacturers to create innovative solutions that enhance functionality while reducing weight and complexity—attributes that are particularly valuable in sectors like aerospace and automotive engineering. As we delve deeper into the myriad applications of this extraordinary material, it becomes clear that nitinol’s impact on modern technology is just beginning.

Nitinol Linear Actuator in Medical Devices

Nitinol linear actuators are making waves in the medical field, transforming how devices operate and improving patient outcomes. With their unique properties, such as shape memory and superelasticity, nitinol wire is becoming an essential component in various medical applications. The versatility of nitinol shape memory alloys allows for innovative designs that enhance functionality and efficiency in surgical instruments and prosthetics.

Revolutionizing Surgical Instruments

The integration of nitinol linear actuators into surgical instruments is nothing short of revolutionary. Surgeons can now utilize tools that respond dynamically to the body's movements, thanks to the unique properties of nitinol wire. These advanced surgical instruments not only improve precision during procedures but also reduce recovery times for patients by minimizing tissue damage.

Nitinol's ability to return to its original shape after deformation makes it ideal for creating compact, lightweight tools that can navigate tight spaces within the human body. This innovation leads to less invasive surgeries with better outcomes, a win-win for both doctors and patients alike. As more medical manufacturing companies adopt these materials, we can expect a surge in next-generation surgical devices equipped with nitinol linear actuators.

Enhancing Prosthetic Functionality

When it comes to prosthetics, the functionality provided by nitinol linear actuators is game-changing. The adaptability of nitinol properties allows prosthetic limbs to mimic natural movement more closely than ever before. Users benefit from enhanced comfort and control as these devices adjust seamlessly during daily activities.

Moreover, incorporating nitinol wire into prosthetic designs enables lighter constructions without sacrificing strength or durability. This advancement not only improves user experience but also encourages higher adoption rates among amputees seeking mobility solutions tailored to their needs. As research continues on how best to integrate these innovative materials into prosthetics, we can anticipate even greater enhancements in user satisfaction.

Improving Medical Manufacturing Processes

The impact of nitinol shape memory alloys extends beyond individual devices; it's reshaping entire medical manufacturing processes as well. By leveraging the unique characteristics of nitinol wire, manufacturers are able to streamline production techniques while maintaining high-quality standards across various applications. This results in reduced costs and faster turnaround times for new products entering the market.

Additionally, using a wire actuator made from nitinol helps minimize waste during manufacturing due to its efficient energy use and design flexibility. Companies focused on sustainability will find that integrating these materials aligns well with their goals while also enhancing product performance. As we look ahead, it's clear that embracing nitinol technology will be crucial for future advancements in medical device manufacturing.

Nitinol Wire Actuators in Robotics

Nitinol wire actuators are revolutionizing the field of robotics by providing unique properties that enhance efficiency and performance. With their ability to change shape in response to temperature variations, nitinol linear actuators offer a lightweight solution that can drive movement without the need for complex motors or heavy components. This innovative technology is paving the way for smarter and more agile robots capable of performing intricate tasks with ease.

Creating More Efficient Robots

The integration of nitinol properties into robotic systems allows for the creation of more efficient robots that consume less energy while delivering exceptional performance. By leveraging nitinol shape memory alloys, engineers can design robots that mimic natural movements, improving dexterity and reducing wear on mechanical parts. These advancements not only enhance operational efficiency but also extend the lifespan of robotic devices, making them a wise investment for industries reliant on automation.

Versatile Applications in Automation

Nitinol wire actuators are finding versatile applications across various sectors of automation, from manufacturing to logistics. Their compact size and lightweight nature enable seamless integration into existing systems, facilitating automation without significant redesigns or weight penalties. Whether it’s in assembly lines or warehouse operations, nitinol linear actuators contribute to streamlined processes and improved productivity by allowing machines to adapt quickly to changing tasks.

Boosting Performance in Consumer Electronics

In consumer electronics, nitinol wire actuators are boosting performance by enabling sleek designs and enhanced functionality in devices like smartphones and tablets. The flexibility provided by these innovative materials allows manufacturers to create thinner products without sacrificing durability or usability. As a result, consumers enjoy devices that not only look good but also perform exceptionally well thanks to the clever incorporation of nitinol properties.

Aerospace Innovations with Nitinol

The aerospace industry is always on the lookout for innovative materials that can enhance performance while reducing weight. Enter nitinol, a remarkable alloy known for its unique properties, including shape memory and superelasticity. By integrating nitinol linear actuators into aircraft design, engineers are not only improving functionality but also revolutionizing how we think about lightweight solutions in aviation.

Lightweight Solutions for Aircraft

One of the standout features of nitinol properties is its incredible strength-to-weight ratio, making it an ideal candidate for aircraft components. When used as a linear actuator, nitinol can significantly reduce the overall weight of flight systems without compromising performance or safety. This reduction in weight translates to more efficient designs that can carry heavier payloads or increase passenger capacity without additional fuel costs.

Additionally, the compact nature of nitinol wire actuators allows for more streamlined designs in aircraft interiors and exteriors alike. As manufacturers strive to create sleeker, more aerodynamic shapes, incorporating these innovative materials becomes essential. The result? Aircraft that are not just lighter but also more visually appealing and aerodynamically efficient.

Enhancing Flight Control Systems

Nitinol shape memory alloys are making waves in flight control systems by providing precise actuation capabilities that were previously unattainable with traditional materials. These wire actuators respond quickly to changes in temperature and stress, allowing for real-time adjustments during flight operations. This responsiveness enhances safety and stability during critical maneuvers.

Moreover, the integration of nitinol linear actuators into control surfaces—like flaps and rudders—enables smoother transitions and improved handling characteristics across various flight conditions. Pilots benefit from enhanced control responsiveness, resulting in a better flying experience overall. As these technologies evolve, we can expect even greater advancements in automated flight controls powered by nitinol innovations.

Increasing Fuel Efficiency

Fuel efficiency is paramount in the aerospace sector; every ounce saved contributes to significant cost reductions over time. By utilizing nitinol medical devices' principles—such as those found within linear actuators—aircraft designers are crafting systems that optimize fuel consumption through advanced aerodynamic features controlled by nimble actuators made from this unique alloy.

Nitinol's ability to operate effectively at varying temperatures means it can adapt seamlessly to changing environmental conditions during flight without added complexity or weight from traditional hydraulic systems. Consequently, airlines benefit from lower operational costs while contributing positively to sustainability efforts through reduced emissions—a win-win scenario if there ever was one!

Nitinol Shape Memory Alloys in Automotive

The automotive industry is witnessing a transformative shift with the integration of nitinol shape memory alloys. These innovative materials are not just lightweight but also possess unique properties that allow them to return to a predetermined shape when heated. This adaptability makes them ideal for various applications, enhancing vehicle performance and comfort while contributing to energy efficiency.

Smart Seats and Adjustable Features

Nitinol linear actuators are revolutionizing the concept of smart seats in vehicles, providing unparalleled comfort and adjustability. With the ability to respond quickly to temperature changes, these wire actuators can automatically adjust seat positions based on user preferences or body heat, ensuring optimal ergonomics during drives. This technology not only enhances passenger experience but also aligns with modern automotive trends toward personalization and convenience.

Active Suspension Systems

Incorporating nitinol properties into active suspension systems allows for remarkable advancements in vehicle handling and ride quality. Nitinol shape memory alloys can dynamically adjust suspension stiffness based on road conditions and driving behavior, delivering a smoother ride without compromising performance. This responsive technology minimizes wear on traditional components, potentially extending the lifespan of vehicles while improving overall safety.

Contributing to Fuel Economy

One of the most significant advantages of using nitinol in automotive applications is its contribution to fuel economy. By reducing weight through efficient design—thanks to the lightweight nature of nitinol wire—vehicles can achieve better fuel efficiency without sacrificing power or performance. As manufacturers continue exploring nitinol linear actuators for various systems, we may see an industry-wide shift towards more sustainable practices that benefit both consumers and the environment.

Home Automation and Nitinol

Home automation is becoming increasingly sophisticated, and the integration of nitinol technology is a game-changer. The unique properties of nitinol shape memory alloys allow for innovative designs that enhance convenience and functionality in our daily lives. From smart window openers to adjustable furniture, the potential applications of nitinol linear actuators are vast and exciting.

Smart Window Openers

Imagine a home where your windows can open at the touch of a button or even automatically adjust based on temperature! Nitinol linear actuators make this dream a reality by harnessing their remarkable ability to change shape with temperature fluctuations. These wire actuators provide smooth, reliable movement, ensuring that your windows can be effortlessly opened or closed without manual effort.

The use of nitinol wire in smart window systems not only enhances user convenience but also contributes to energy efficiency by optimizing ventilation in living spaces. This means you can enjoy fresh air without sacrificing comfort or safety. With the rise of smart homes, incorporating nitinol linear actuators into window technology is sure to elevate modern living standards.

Adjustable Furniture Designs

Furniture that adapts to your needs? Yes, please! Nitinol's unique properties allow for adjustable furniture designs that can transform your living space on demand. Whether it's a coffee table that rises to dining height or a sofa that shifts its angle for optimal comfort, nitinol shape memory alloys are paving the way for versatile home furnishings.

The incorporation of these innovative linear actuators into furniture not only adds aesthetic appeal but also improves functionality in small spaces where adaptability is key. Imagine having a piece of furniture that responds to your lifestyle changes—whether hosting friends or enjoying some quiet time alone! With nitinol wire technology, designers can create pieces that blend style with practicality seamlessly.

Improving Home Security Systems

When it comes to home security, every detail counts, and that's where nitinol comes into play! By integrating nitinol linear actuators into security systems, homeowners can enjoy enhanced protection through automated locking mechanisms and surveillance features. These wire actuators respond rapidly to security commands while maintaining durability under various conditions.

Nitinol’s ability to return to its original shape after deformation ensures long-lasting performance in critical applications like door locks or window sensors. This reliability gives homeowners peace of mind knowing their property is secure at all times—even when they’re away! As we move towards smarter homes, leveraging the benefits of nitinol medical devices and technologies will undoubtedly redefine how we approach home security.

Nitinol in Consumer Products

Nitinol, with its unique properties, is making waves in the consumer products sector. From innovative gadgets to everyday tools, the applications of nitinol linear actuators are transforming how we interact with technology daily. As manufacturers harness the capabilities of nitinol wire and shape memory alloys, consumers can expect a new level of convenience and functionality in their everyday lives.

Innovative Gadgets and Tools

The integration of nitinol linear actuators into gadgets has led to some truly groundbreaking designs. These wire actuators can create compact mechanisms that are both lightweight and efficient, allowing for more versatile tools that fit seamlessly into our lives. Imagine a multi-tool that not only fits in your pocket but also expands and contracts at the press of a button—thanks to the remarkable properties of nitinol.

Moreover, these innovative gadgets often boast enhanced durability due to the unique characteristics of nitinol properties. For instance, tools made with nitinol shape memory alloys can return to their original shape after deformation, ensuring they withstand daily wear and tear better than traditional materials. This combination of innovation and resilience makes them a must-have for tech enthusiasts.

Enhancing Everyday Comfort

Nitinol's role extends beyond just gadgets; it’s also enhancing comfort in various consumer products around us. Items such as adjustable eyeglasses or ergonomic furniture now utilize nitinol wire technology to provide personalized experiences tailored to individual needs. With a simple adjustment mechanism powered by a linear actuator, users can achieve optimal comfort without sacrificing style.

Additionally, products incorporating nitinol medical devices principles offer health benefits too—think wearable tech that adjusts based on your activity level or temperature changes throughout the day. By leveraging the remarkable properties of nitinol shape memory alloys, these items adapt dynamically to enhance user experience continuously. It's not just about functionality; it's about creating an everyday lifestyle that feels tailor-made for you.

Goodgifts Product Line Featuring Nitinol

One exciting development is the emergence of specialized product lines like Goodgifts that showcase what nitinol can do for consumers seeking unique gifts or practical solutions. The Goodgifts collection features items designed with nimble mechanics powered by nitinol linear actuators—perfect for anyone looking for something out-of-the-ordinary yet functional! Whether it's an adjustable phone stand or a smart kitchen gadget, this product line emphasizes creativity while harnessing advanced technology.

These offerings not only highlight how far we've come in integrating advanced materials into consumer goods but also serve as great conversation starters at gatherings! Imagine giving someone a gift that not only looks cool but also showcases cutting-edge technology—it's sure to impress! With each item reflecting the versatility and advantages provided by nitinol wire applications, Goodgifts sets itself apart from ordinary gift shops.

Future Trends of Nitinol Technology

Nitinol technology is poised for an exciting future, particularly in manufacturing sectors where innovation is key. The unique properties of nitinol shape memory alloys are leading to new applications that could revolutionize how products are made and utilized. As industries continue to explore the benefits of nitinol wire, we can expect to see a surge in creative uses that leverage its remarkable capabilities.

Emerging Applications in Future Manufacturing

Emerging applications for nitinol linear actuators in future manufacturing processes are becoming increasingly diverse and sophisticated. For instance, these linear actuators can facilitate automation with precision and reliability, allowing manufacturers to enhance productivity while minimizing waste. Additionally, the adaptability of nitinol wire means it can be integrated into various machinery designs, enabling more efficient production lines that respond dynamically to operational needs.

The healthcare sector stands out as a promising area for applying nitinol medical devices in manufacturing environments. By utilizing the unique properties of nitinol shape memory alloys, manufacturers can create surgical instruments that adapt seamlessly during procedures, enhancing safety and effectiveness. This innovation not only streamlines medical manufacturing but also improves patient outcomes through more precise interventions.

Research and Development Focus Areas

Research and development efforts surrounding nitinol technology are gaining momentum as industries recognize its potential. Key focus areas include enhancing the mechanical properties of nitinol wire to improve performance under stress while maintaining its shape memory capabilities. Researchers are also investigating how to reduce production costs associated with nitinol linear actuators, making them more accessible for widespread adoption across various sectors.

Moreover, interdisciplinary collaboration is becoming essential in advancing the understanding of nitinol properties and their applications. By bringing together experts from materials science, engineering, and design fields, innovative solutions can emerge that push the boundaries of what’s possible with nitinol medical devices and other technologies using this remarkable alloy. This collaborative spirit is likely to accelerate breakthroughs that will benefit multiple industries.

Potential Market Growth

The potential market growth for products utilizing nitinol technology appears robust as demand increases across several sectors including aerospace, robotics, and healthcare. With advancements in manufacturing techniques making it easier to produce high-quality nitinol wire at scale, companies are investing heavily in developing new applications that capitalize on its unique characteristics. As these innovations come to fruition, we can expect a ripple effect throughout related markets as well.

Additionally, consumers' growing interest in smart technologies bodes well for the future of linear actuators powered by nitinol shape memory alloys. From adjustable furniture designs to home automation systems like smart window openers—these gadgets not only enhance convenience but also appeal to eco-conscious consumers seeking energy-efficient solutions. As awareness grows about the benefits offered by these products powered by innovative materials like Nitinol wire or linear actuators incorporating this technology will likely experience significant market expansion.

Conclusion

As we wrap up our exploration of the fascinating world of Nitinol, one thing is clear: the impact of nitinol linear actuators on various industries is nothing short of revolutionary. These remarkable devices leverage nitinol properties, such as shape memory and superelasticity, to deliver innovative solutions that enhance efficiency and functionality across sectors like medicine, robotics, aerospace, automotive, and home automation. The versatility and performance of nitinol wire actuators signify a transformative shift in how we approach engineering challenges.

Nitinol Linear Actuator Impact on Industries

The integration of nitinol linear actuators into industrial applications has led to significant advancements in technology and design. In medical manufacturing, for instance, these wire actuators are streamlining processes while improving the precision and effectiveness of medical devices. From surgical instruments to prosthetics, the unique characteristics of nitinol shape memory alloys are enabling manufacturers to create more adaptable and responsive tools that cater to specific needs.

Benefits of Nitinol Wire in Daily Life

Nitinol wire has seamlessly woven itself into the fabric of our daily lives by enhancing convenience and comfort in everyday products. Whether it's smart window openers or adjustable furniture designs, the benefits are palpable; these innovations not only provide comfort but also contribute to energy efficiency in homes. Moreover, as consumers continue to embrace technology-driven solutions with a focus on sustainability, the demand for products utilizing nitinol properties is likely to grow exponentially.

The Future of Nitinol Medical Devices

Looking ahead, the future for nitinol medical devices appears promising with ongoing research and development focused on expanding their capabilities. As we delve deeper into understanding nitinol properties and their potential applications in healthcare technologies, new avenues will surely emerge that could redefine patient care standards. With advancements in manufacturing processes tailored for nitinol wire actuators expected soon, we can anticipate a wave of innovative medical solutions that will improve outcomes while enhancing overall quality of life.