Introduction

Nitinol shape memory wire is a fascinating material that has captured the attention of engineers and scientists alike. This unique alloy, primarily composed of nickel and titanium, exhibits remarkable properties that allow it to return to a predetermined shape when heated above a specific temperature. With its ability to remember shapes, nitinol wire has opened doors to innovative applications across various fields.

What is Nitinol Wire?

Nitinol wire is a type of shape memory alloy (SMA) known for its extraordinary elasticity and strength. When deformed at lower temperatures, it can be heated to regain its original form, making it an ideal choice for applications requiring precision and reliability. The versatility of nitinol wire extends beyond mere functionality; it also presents opportunities for creative designs in engineering and medicine.

Applications of Shape Memory Alloys

The applications of shape memory alloys are as diverse as they are exciting, with nitinol wire leading the charge in many industries. From medical devices like stents and guidewires that improve patient outcomes to innovative robotics solutions that enhance movement capabilities, the potential uses are vast. As demand grows, understanding where to buy nitinol wire becomes increasingly important for manufacturers looking to harness its unique properties.

The Science Behind Nitinol

At the heart of nitinol's impressive capabilities lies its scientific foundation in phase transformation—a process where the material shifts between two distinct crystalline structures based on temperature changes. This phenomenon allows shape memory nitinol wire to exhibit both superelasticity and shape memory effects, making it incredibly adaptable in various conditions. As researchers continue to explore this exciting field, we can expect even more groundbreaking advancements in how we utilize this remarkable alloy.

Understanding Nitinol Shape Memory Wire

Nitinol shape memory wire is a fascinating material that combines unique properties with practical applications across various industries. This section delves into the properties of nickel titanium alloys, highlights the unique characteristics of shape memory nitinol wire, and compares its advantages over other alloys.

Properties of Nickel Titanium Alloys

Nickel titanium alloys, commonly known as Nitinol, exhibit remarkable mechanical and thermal properties that make them ideal for numerous applications. The most notable feature is their ability to undergo phase transformations between austenite and martensite, allowing them to remember a predetermined shape. This property enables nitinol wire to return to its original form when heated above a specific temperature, making it an essential component in the realm of shape memory alloys.

In addition to their shape memory capabilities, nickel titanium alloys possess excellent corrosion resistance and biocompatibility, which are vital for medical applications such as stents and guidewires. The flexibility and strength of nitinol wire further enhance its usability in challenging environments where conventional materials might fail. As you explore options to buy nitinol wire, understanding these properties will help you appreciate why this alloy stands out in various fields.

Unique Characteristics of Shape Memory Nitinol Wire

The unique characteristics of shape memory nitinol wire are what truly set it apart from other materials. One standout feature is its superelasticity; when subjected to stress beyond its yield point at certain temperatures, it can deform significantly but revert back to its original shape once the stress is removed. This behavior allows for innovative designs in products ranging from medical devices to robotics.

Additionally, nitinol wire exhibits high fatigue resistance and durability under repeated cycles of deformation—traits that are crucial for applications requiring longevity without failure. Its lightweight nature combined with these extraordinary characteristics makes shape memory nitinol wire an attractive option for engineers looking to push the boundaries of design while maintaining performance standards.

Comparison with Other Alloys

When comparing nitinol wire with other alloys like stainless steel or aluminum, it's clear that each material has its strengths; however, none quite match the versatility offered by Nitinol's unique properties. While stainless steel provides good strength and corrosion resistance at lower costs, it lacks the remarkable shape recovery capabilities that define nitinol as a true game-changer in many scenarios.

Aluminum may be lightweight but often falls short in terms of elasticity and fatigue life compared to nitinol wire's superelasticity features. These comparisons highlight why many industries are increasingly turning towards purchasing shape memory alloy solutions like nitinol—especially when they need reliable performance coupled with innovative design possibilities.

Applications in Medical Devices

When it comes to the medical field, nitinol shape memory wire is nothing short of a game-changer. The unique properties of this shape memory alloy make it an ideal material for various medical devices, particularly in minimally invasive procedures. From stents to guidewires and orthopedic implants, the applications are vast and impactful.

Nitinol Wire in Stents and Guidewires

Nitinol wire has revolutionized the design of stents and guidewires used in cardiovascular procedures. Its ability to return to a predetermined shape after deformation allows for easy navigation through complex vascular pathways. Surgeons can deploy stents with precision, thanks to the flexibility and resilience of nitinol shape memory wire, which enhances patient outcomes and reduces recovery times.

The use of nitinol wire in guidewires provides significant advantages during catheterization procedures as well. Its superelastic properties enable it to withstand high levels of stress without permanent deformation, making it easier for doctors to maneuver through narrow arteries or veins. As a result, patients experience less trauma during these interventions, leading to quicker recoveries.

Moreover, the biocompatibility of nitinol ensures that these devices can be safely implanted within the human body without adverse effects. This makes nitinol wire an indispensable component in modern medical technology aimed at improving cardiovascular health and overall patient care.

Advancements in Orthopedic Implants

The orthopedic field has also seen remarkable advancements thanks to nitinol shape memory wire. With its unique ability to adapt under varying temperatures, this alloy allows for innovative designs in implants that can conform precisely to the anatomy of patients' bones or joints. This adaptability leads to better integration with surrounding tissues and improved long-term outcomes.

Nitinol's superelasticity is particularly beneficial when used in fracture fixation devices like plates and screws; they can absorb mechanical loads while maintaining their structural integrity over time. These features reduce complications associated with traditional metal implants, such as breakage or misalignment after surgery. Surgeons now have more reliable tools at their disposal when performing complex orthopedic procedures.

Additionally, ongoing research into using nitinol wire for smart implants shows promise for future applications where devices could respond dynamically based on physiological conditions within the body—an exciting frontier that could redefine orthopedic care altogether!

Benefits of Using Nitinol in Healthcare

The benefits of using nitinol shape memory wire extend beyond just its physical properties; they also encompass improved patient experiences and outcomes across various healthcare settings. For starters, because devices made from this alloy are often less invasive than their traditional counterparts, patients can enjoy shorter hospital stays and quicker recoveries post-surgery.

Furthermore, the customization options available with nitinol allow healthcare providers greater flexibility when designing solutions tailored specifically for individual patients’ needs—whether it's a stent that fits perfectly within a patient's artery or an implant designed uniquely for their bone structure. This personalized approach enhances not only safety but also effectiveness during treatment processes.

Lastly, investing in high-quality materials like nitinol is essential from both clinical efficacy and cost perspectives; although some may hesitate due to initial concerns about nitinol wire price points compared with other materials on the market today—the long-term savings derived from fewer complications ultimately justify those upfront costs!

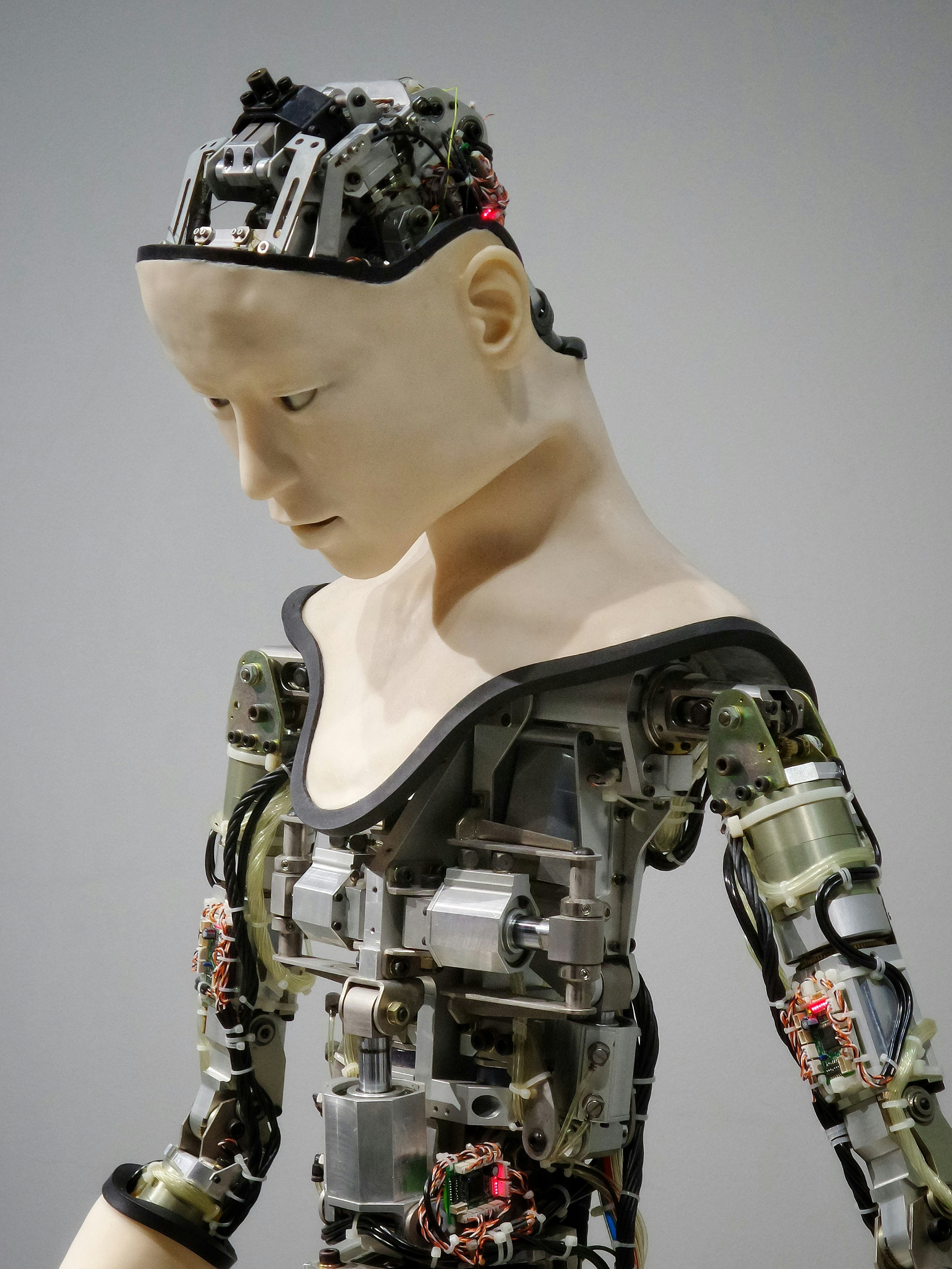

Nitinol Wire in Robotics and Automation

Nitinol shape memory wire is revolutionizing the field of robotics and automation, providing unique solutions that traditional materials simply can't match. This remarkable alloy can change shape in response to temperature fluctuations, allowing for innovative designs that mimic natural movements. As industries increasingly seek adaptable and efficient components, the demand for nitinol wire continues to rise.

How Nitinol Shape Memory Wire Enables Motion

At the heart of the magic of nitinol shape memory wire is its ability to remember its original form after being deformed. When heated above a certain temperature, this shape memory alloy returns to its pre-set shape, enabling precise and controlled motion in robotic systems. This property allows engineers to design compact actuators and mechanisms that require minimal space while delivering maximum performance.

The versatility of nitinol wire extends beyond simple motion; it can be used in various applications from gripping mechanisms to complex robotic limbs. With the ability to create movement without bulky motors or complex gears, nitinol shape memory wire offers a sleek alternative that enhances both efficiency and aesthetics. As robots become more integrated into everyday tasks, the role of this innovative material will only expand.

Examples of Nitinol in Robotics

Several cutting-edge robotics projects are already utilizing nitinol wire for enhanced functionality. For instance, researchers have developed soft robotics that employ nitinol as actuators, enabling gentle yet effective manipulation of delicate objects like fruits or medical supplies. These advancements showcase how nitinol can contribute to safer interactions between robots and humans.

Another exciting application is found in prosthetics, where nitinol shape memory wire provides movement similar to natural limbs by mimicking muscle contractions. This not only improves user experience but also reduces energy consumption compared to traditional mechanical systems. As these applications demonstrate, the future looks bright for integrating nitinol into various robotic platforms.

Future Trends in Nitinol Usage

The future holds immense potential for further innovation with nitinol wire across multiple sectors within robotics and automation. Researchers are exploring ways to enhance the performance of this shape memory alloy through advanced processing techniques or by combining it with other materials for hybrid systems. Such developments could lead to even lighter and more efficient robotic solutions tailored for specific tasks.

Moreover, as industries continue pushing towards automation and smart technologies, we can expect an increased focus on materials like nitinol that offer adaptability and resilience under varying conditions. The ongoing research into optimizing cost-effective production methods will also make it easier for businesses looking to buy nitinol wire without breaking the bank—making this technology accessible across different markets.

In conclusion, whether it's enhancing healthcare devices or powering next-generation robots, the applications of nitinol shape memory wire are vast and varied—ensuring its place at the forefront of technological advancement.

Exploring Nitinol Wire Price Factors

Understanding the price factors surrounding nitinol wire is crucial for anyone looking to incorporate this remarkable shape memory alloy into their projects. The market demand for nitinol shape memory wire has surged due to its unique properties and diverse applications, making it a sought-after material in various industries, especially healthcare and robotics. As a result, fluctuations in supply and demand can significantly influence the nitinol wire price.

Market Demand for Nitinol Wire

The demand for nitinol wire has been on an upward trajectory, driven by its versatility and innovative uses in medical devices, robotics, and even consumer products. Shape memory alloys like nitinol are increasingly recognized for their ability to return to a predetermined shape when subjected to heat, making them invaluable in applications such as stents and guidewires. This growing recognition has led manufacturers to ramp up production, but the balance of supply and demand continues to affect the overall pricing of nitinol shape memory wire.

Comparing Prices from Different Suppliers

When it comes to buying nitinol wire, price comparison is essential. Different suppliers offer varying prices based on factors such as quality, quantity purchased, and specific alloy compositions within the realm of shape memory alloys. By shopping around and comparing prices from multiple sources, you can find competitive rates that suit your budget while ensuring you receive high-quality nitinol wire tailored for your needs.

How to Buy Nitinol Wire Affordably

Finding ways to buy nitinol wire affordably doesn't mean sacrificing quality; it just requires a bit of savvy shopping! Start by exploring bulk purchasing options or establishing long-term relationships with suppliers who specialize in shape memory alloys—this can lead to discounts or better pricing structures over time. Additionally, keeping an eye on market trends will help you make informed decisions about when to buy your nitinol shape memory wire at the best possible price.

GEE SMA: A Leader in Nitinol Production

In the ever-evolving world of materials science, GEE SMA stands out as a pioneering force in the production of nitinol shape memory wire. With a commitment to innovation and excellence, their mission is to provide high-quality shape memory alloys that meet the diverse needs of various industries. Whether for medical devices or advanced robotics, GEE SMA is dedicated to pushing the boundaries of what's possible with nitinol wire.

Overview of GEE SMA's Mission

GEE SMA’s mission revolves around harnessing the unique properties of nitinol to create solutions that enhance functionality and performance across multiple sectors. They strive to be at the forefront of research and development, ensuring their products not only meet but exceed industry standards. By focusing on sustainable practices and cutting-edge technology, GEE SMA aims to provide reliable and affordable options for customers looking to buy nitinol wire.

Innovations in Nitinol Shape Memory Alloys

Innovation is at the heart of GEE SMA’s operations, particularly in refining the properties and applications of shape memory nitinol wire. Their research teams are continually exploring new methods for enhancing durability, flexibility, and responsiveness—key traits that make nitinol wire so desirable in various applications. With each breakthrough, they set new benchmarks for what can be achieved with shape memory alloys, ensuring that clients receive state-of-the-art materials.

Supporting Space Missions with Nitinol

One fascinating application of nitinol shape memory wire lies in its potential role in space exploration—a field where precision and reliability are paramount. GEE SMA collaborates with aerospace engineers to develop components that can withstand extreme conditions while maintaining functionality through innovative use of shape memory alloys. As space missions become more ambitious, leveraging the unique properties of nitinol will be crucial for success, showcasing how versatile this material truly is.

Conclusion

As we wrap up our exploration of nitinol shape memory wire, it's clear that this remarkable material has carved out a significant niche in various industries. The unique properties of shape memory alloys, particularly nitinol wire, make it an invaluable asset in applications ranging from healthcare to robotics. Choosing nitinol means opting for innovation, reliability, and efficiency.

Why Choose Shape Memory Nitinol Wire?

When you consider the advantages of shape memory nitinol wire, the decision becomes simple. Its ability to return to a predetermined shape when heated makes it an ideal choice for dynamic applications where precision is paramount. Additionally, the durability and biocompatibility of nitinol wire make it particularly appealing for medical devices like stents and guidewires.

Moreover, the versatility of shape memory alloys opens doors to creative solutions across various fields beyond medicine. Whether you're designing a robotic arm or developing advanced orthopedic implants, using nitinol can enhance performance and functionality. In short, if you're looking for a material that combines strength with adaptability, look no further than nitinol shape memory wire.

The Future of Nitinol in Various Industries

The future looks bright for nitinol wire as industries continue to innovate and expand its applications. With ongoing advancements in technology and materials science, we can expect even more sophisticated uses of shape memory alloys in sectors such as aerospace, automotive engineering, and consumer products. As manufacturers recognize the benefits of incorporating nitinol into their designs, we may see an increase in demand that drives further research and development.

Furthermore, sustainability is becoming increasingly important across industries; thus utilizing materials like nitinol that offer both performance and longevity could be a game changer. Imagine smart devices that adapt their form based on environmental conditions or medical implants that respond dynamically to bodily changes—this is just the tip of the iceberg! As we look ahead, it's clear that the potential for growth with shape memory nitinol wire is limitless.

Tips for Purchasing Nitinol Wire

If you’re ready to buy nitinol wire but are unsure where to start or how to navigate pricing options effectively—fear not! First off, understanding the factors influencing nitinol wire price will help you make informed decisions; these include market demand and supplier variations. Always compare prices from different suppliers while keeping quality standards in mind; sometimes cheaper isn’t always better!

Next up: don’t hesitate to ask questions about specifications before making your purchase; knowing whether you're getting standard or customized shapes can save you headaches down the road. Finally, consider bulk purchasing options if your project requires significant quantities—this often leads to cost savings over time! With these tips under your belt, you'll be well-equipped to procure high-quality shape memory alloy products without breaking the bank.