Introduction

In the world of materials science, few innovations have made as significant an impact as superelastic NiTi wire. This remarkable material, known for its unique properties and versatility, is revolutionizing various industries, particularly in orthodontics. As we delve into the science behind Nitinol alloys, we will uncover how these innovations are reshaping treatment methods and improving patient outcomes.

Applications of Superelastic NiTi Wire

Superelastic NiTi wire is not just a game-changer in orthodontics; its applications span numerous fields including aerospace, robotics, and medical devices. The ability of this wire to undergo significant deformation while returning to its original shape makes it ideal for applications requiring flexibility and resilience. From stents that expand within arteries to components in robotic arms, the versatility of superelastic NiTi wire is truly astounding.

The Science Behind Nitinol Alloys

So, what is superelastic nitinol? At its core, nitinol is a nickel-titanium alloy that exhibits both shape memory and superelastic properties. When subjected to stress or temperature changes, it can revert to predetermined shapes or maintain elasticity beyond typical limits—making it an exciting subject for researchers and engineers alike.

Innovations in Orthodontic Treatment

Orthodontics has seen a remarkable transformation thanks to innovations utilizing superelastic NiTi wire. These wires allow for more efficient tooth movement with less discomfort compared to traditional materials. Furthermore, understanding what are the different types of NiTi wires in orthodontics helps practitioners select the most suitable options tailored for individual patient needs—an essential factor for successful treatment outcomes.

Understanding Superelastic Nitinol

Superelastic Nitinol, a remarkable alloy of nickel and titanium, has revolutionized various fields, particularly orthodontics. This unique material exhibits superelasticity, allowing it to undergo significant deformation and return to its original shape upon unloading. Understanding what makes superelastic NiTi wire so special is essential for appreciating its diverse applications.

What is Superelastic Nitinol?

So, what is superelastic nitinol? It’s a type of shape memory alloy that can dramatically change its properties based on temperature and stress. When heated above a certain temperature, superelastic NiTi wire can revert to its predetermined shape after being deformed, making it an ideal choice for applications that require flexibility combined with strength.

The term superelastic refers to the ability of this material to withstand strains beyond the elastic limit without permanent deformation. This property allows orthodontists to use superelastic NiTi wire effectively in braces and other dental devices. The adaptability of this alloy not only enhances patient comfort but also improves treatment efficiency.

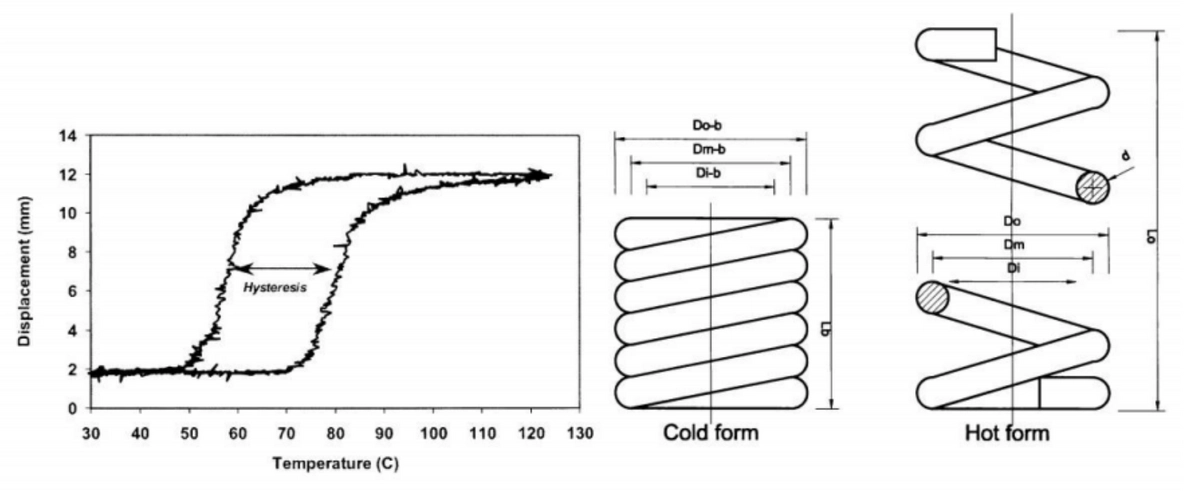

Behavior of Superelastic NiTi Wire

The behavior of superelastic NiTi wire is fascinating and crucial for its application in orthodontics and beyond. When stress is applied to the wire at room temperature, it can undergo significant elongation without breaking; this phenomenon is known as superelasticity. As a result, the wire can exert consistent forces on teeth throughout treatment while maintaining its structural integrity.

In practical terms, this means that orthodontic treatments using superelastic NiTi wires can be more comfortable for patients since the forces applied are gentle yet effective. Moreover, these wires are less likely to cause discomfort or pain compared to traditional materials like stainless steel (SS) wire due to their flexibility and ability to adapt during movement. Overall, understanding how superelastic NiTi behaves under various conditions helps practitioners optimize their techniques for better patient outcomes.

Applications Beyond Orthodontics

While many people associate superelastic NiTi wire primarily with orthodontics, its applications extend far beyond dental practices. Industries such as aerospace engineering and medical devices have begun adopting this innovative material due to its unique properties—think stents that expand within blood vessels or components in space missions designed by GEE SMA’s Nitinol Shape Memory Alloys team.

In addition to medical uses, researchers are exploring how superelastic nitinol could revolutionize robotics by creating more flexible actuators that mimic natural motion patterns found in living organisms. The versatility of this material opens doors across various sectors—showcasing just how indispensable understanding different types of NiTi wires truly is!

Comparing NiTi and Stainless Steel Wire

When it comes to orthodontic materials, the choice between superelastic NiTi wire and stainless steel (SS) wire can significantly impact treatment outcomes. Understanding these differences is crucial for practitioners and patients alike. This section will delve into what sets these two materials apart, analyze their performance, and consider cost implications in material selection.

What is the Difference Between NiTi and SS Wire?

At the core of orthodontic applications lies the distinction between superelastic NiTi wire and stainless steel wire. Superelastic NiTi wire, composed of nickel-titanium alloy, exhibits unique properties such as shape memory and superelasticity, allowing it to return to its original shape after deformation. In contrast, stainless steel wire is known for its strength and rigidity but lacks the flexibility that superelastic nitinol offers.

One key difference is how each material reacts under stress; while superelastic NiTi can handle significant deformation without permanent change, SS wire tends to bend or break under similar conditions. Additionally, superelastic nitinol's ability to exert consistent forces on teeth makes it a preferred choice in many orthodontic scenarios. Therefore, understanding what is the difference between NiTi and SS wire helps practitioners select the right tool for effective treatments.

Performance Analysis of NiTi vs. SS Wire

The performance analysis of superelastic NiTi wire compared to stainless steel reveals some fascinating insights into their respective strengths and weaknesses. Superelastic nitinol provides gentle continuous force over time, which promotes tooth movement while minimizing discomfort for patients—a significant advantage in orthodontics. On the other hand, while SS wires offer superior strength for certain applications like anchorage or when high forces are necessary, they can be less forgiving during initial adjustments.

Moreover, when considering flexibility versus rigidity in treatment plans—superelastic NiTi’s unique properties allow it to navigate complex dental structures more effectively than traditional SS wires can manage. This adaptability leads to more efficient tooth alignment processes with fewer appointments needed overall. Thus, a thorough performance analysis demonstrates that each material serves distinct roles within orthodontics.

Cost Considerations in Material Selection

Cost considerations play a pivotal role when deciding between superelastic NiTi wire and stainless steel options in orthodontics. While stainless steel wires tend to be less expensive upfront due to lower production costs, their limited versatility may lead practitioners towards longer treatment times or additional visits—potentially increasing overall costs for patients over time. In contrast, although superelastic nitinol may come with a higher price tag initially due to advanced manufacturing processes involved in creating this specialized alloy, its efficiency often offsets these expenses through quicker results.

Furthermore, assessing long-term benefits versus short-term savings becomes essential when evaluating what are the different types of NiTi wires available today alongside traditional materials like SS wires; investing in superior technology might save both time and money down the road as patient satisfaction improves with faster results from using cutting-edge materials like superelastic nitrile wires instead of conventional options alone! Ultimately balancing initial costs against potential savings ensures optimal choices are made within dental practices.

Varieties of NiTi Wires in Orthodontics

In the realm of orthodontics, superelastic NiTi wire has revolutionized treatment approaches by offering a range of wire types tailored to specific needs. The flexibility and adaptability of these wires make them essential for various orthodontic applications. Understanding what are the different types of NiTi wires in orthodontics can help practitioners choose the right option for their patients.

What are the Different Types of NiTi Wires in Orthodontics?

Orthodontic practices utilize several types of NiTi wires, each designed to meet distinct clinical requirements. The most common varieties include round NiTi wires, rectangular NiTi wires, and closed coil springs made from superelastic nitinol. Each type serves a unique purpose, from aligning teeth to providing continuous force during treatment.

Round superelastic NiTi wire is often used for initial alignment due to its gentle force application and ability to maintain shape under stress. Rectangular variants are typically employed later in treatment for more precise movements and anchorage control. Meanwhile, closed coil springs offer targeted force delivery, making them ideal for space closure or retraction purposes.

Specific Benefits of Each Type

The benefits associated with each type of superelastic NiTi wire extend beyond mere functionality; they also enhance patient comfort and treatment efficiency. Round NiTi wires provide a smooth surface that minimizes irritation to oral tissues while promoting gradual tooth movement without excessive pressure. This gentle approach is particularly beneficial during the initial phases when patients may be more sensitive.

Rectangular superelastic nitinol wires allow for better torque control and tooth positioning due to their geometry, making them invaluable during complex cases requiring precise adjustments. Closed coil springs excel at delivering consistent forces over time, ensuring effective space management without compromising on patient comfort or treatment duration.

Common Applications in Dental Practices

In dental practices, understanding what are the different types of NiTi can significantly influence treatment outcomes and patient satisfaction levels. Round superelastic NiTi wire is commonly used during the early stages of orthodontic therapy when teeth require gentle alignment forces. As treatment progresses, practitioners often transition to rectangular variants that enable more intricate adjustments based on individual case needs.

Closed coil springs crafted from superelastic nitinol find their place in various applications as well—chiefly where space closure is necessary or where retraction forces must be applied consistently over time. By leveraging these diverse types of NiTi wires effectively, orthodontists can optimize both efficiency and effectiveness throughout their patients' journeys toward achieving that perfect smile.

The Role of GEE SMA in NiTi Production

When it comes to the production of superelastic NiTi wire, GEE SMA stands out as a key player in the market. Their expertise in Nitinol shape memory alloys has positioned them at the forefront of innovation, particularly within orthodontics and other medical applications. Understanding what is superelastic nitinol? is crucial, as it allows us to appreciate how GEE SMA harnesses its unique properties for diverse uses.

Overview of GEE SMA’s Nitinol Shape Memory Alloys

GEE SMA specializes in producing high-quality Nitinol shape memory alloys that exhibit remarkable superelasticity and shape memory effects. These materials are engineered to respond dynamically to temperature changes, making them ideal for applications ranging from medical devices to automotive components. By understanding what are the different types of NiTi wires in orthodontics?, we can better appreciate how GEE SMA tailors their products to meet specific industry requirements.

The versatility of superelastic NiTi wire enables its use across various sectors, but GEE SMA's focus on orthodontic applications highlights their commitment to improving dental treatments. Their advanced manufacturing processes ensure that each batch meets stringent quality standards while maintaining competitive pricing—a vital factor when considering what is the difference between NiTi and SS wire?

Quality Control and Customer Focus

Quality control is paramount at GEE SMA; they employ rigorous testing protocols throughout production to guarantee that every piece of superelastic NiTi wire meets or exceeds industry benchmarks. This commitment ensures that customers receive reliable products suitable for critical applications, such as orthodontic treatments where precision matters most. Furthermore, by emphasizing customer focus, they cultivate strong relationships with dental professionals who rely on their materials.

In an environment where understanding what are the different types of NiTi is essential for making informed choices, GEE SMA provides comprehensive support and resources for clients seeking optimal solutions tailored to their specific needs. Whether it's guiding practitioners through product selection or addressing technical inquiries about performance characteristics, they prioritize customer satisfaction above all else.

Innovations Supporting Space Missions

GEE SMA isn't just limited to terrestrial applications; their innovations also extend into space missions where reliability and performance are non-negotiable factors. Superelastic NiTi wire plays a crucial role in developing components used in aerospace technology due to its lightweight yet durable nature—qualities essential for successful space exploration endeavors. As we explore potential new industries for Nitinol beyond traditional uses, it's clear that advancements made by companies like GEE SMA will pave the way.

By leveraging cutting-edge research and development initiatives focused on enhancing material properties further, GEE SMA contributes significantly towards future technologies that could revolutionize various fields—including aerospace engineering—demonstrating just how far superelastic NiTi wire can go beyond orthodontics alone.

Future Developments in NiTi Applications

The future of superelastic NiTi wire is brimming with potential as advancements in technology and materials science continue to evolve. The unique properties of superelastic nitinol, such as its ability to return to a predetermined shape when heated, make it an attractive option for various applications beyond traditional uses. As we delve into the trends shaping this field, it becomes clear that the versatility of superelastic NiTi wire will only expand.

Trends in Superelastic NiTi Wire Usage

In recent years, there has been a noticeable uptick in the adoption of superelastic nitinol across multiple sectors. This trend is driven by its exceptional flexibility and strength compared to alternatives like stainless steel; thus, many industries are exploring how superelastic nitinol can enhance their products. Whether it's in medical devices or aerospace engineering, the question What is superelastic nitinol? is becoming increasingly relevant as more professionals seek innovative solutions that leverage these remarkable properties.

Moreover, orthodontics remains a key area where trends are evolving rapidly. Orthodontists are increasingly favoring different types of NiTi wires due to their superior performance characteristics over traditional materials. As techniques improve and new formulations emerge, practitioners are finding creative applications for superelastic NiTi wire that optimize patient outcomes while maintaining efficiency.

Potential New Industries for Nitinol

The potential new industries for Nitinol are vast and varied, with researchers actively investigating its applications beyond conventional realms like orthodontics and medical devices. For instance, sectors such as robotics and automotive engineering have begun to recognize the advantages of integrating superelastic nitinol into their designs for enhanced functionality and durability. This brings us back to understanding What is the difference between NiTi and SS wire?—the unique properties of Nitinol can lead to innovations that stainless steel simply cannot match.

Additionally, energy storage systems are starting to explore how Nitinol's shape memory effects can be harnessed for better efficiency and performance. The adaptability offered by different types of NiTi allows engineers to design components that respond dynamically under varying conditions—a game changer in many fields! As these industries continue to grow, expect even more exciting developments showcasing what this remarkable material can do.

Environmental Impact and Sustainability

As we look toward the future of superelastic NiTi wire applications, environmental impact and sustainability must also be considered vital components of development strategies. The production processes surrounding Nitinol can be optimized not only for performance but also for reduced ecological footprints—an essential factor in today’s world where sustainability matters more than ever before. By focusing on environmentally friendly practices while producing various types of NiTi wires in orthodontics or other fields, manufacturers can help pave the way toward a greener future.

Furthermore, utilizing recycled materials in creating new products from superelastic nitinol could significantly lessen waste while maintaining high-performance standards across multiple industries. This dual focus on innovation coupled with environmental responsibility aligns perfectly with modern consumer expectations—where quality meets eco-consciousness! Ultimately, embracing sustainable practices will ensure that advancements made using superelastic NiTi wire contribute positively not just technologically but also socially.

Conclusion

As we wrap up our exploration of superelastic NiTi wire, it’s clear that its versatility is a game changer across multiple industries. From orthodontics to aerospace, the unique properties of what is superelastic nitinol? make it an invaluable material. The ability to undergo significant deformation and return to its original shape opens doors for innovative applications that were once deemed impossible.

The Versatility of Superelastic NiTi Wire

Superelastic NiTi wire stands out due to its remarkable ability to adapt under stress while maintaining structural integrity. This adaptability makes it a preferred choice not just in orthodontics but also in medical devices and robotics. With ongoing advancements, the potential applications for superelastic NiTi wire continue to expand, promising exciting developments in technology and healthcare.

Key Differences in Wire Types Explained

When considering what is the difference between NiTi and SS wire?, one must look at their mechanical properties and applications. While stainless steel (SS) wire offers strength and durability, superelastic NiTi wire provides flexibility and resilience that are unmatched in specific conditions. Understanding these distinctions helps practitioners select the right material based on desired outcomes, especially when exploring what are the different types of NiTi wires in orthodontics?

Future Prospects for Nitinol in Technology

The future looks bright for Nitinol as industries recognize its potential beyond traditional uses. With trends pointing towards increased adoption of superelastic NiTi wire across various sectors, we can anticipate innovative solutions that enhance efficiency and performance. As researchers continue to explore what are the different types of NiTi? we may soon see even more groundbreaking applications emerge, making Nitinol a cornerstone material for future technological advancements.