Introduction

In the world of advanced materials, few substances capture attention quite like superelastic nitinol wire. This remarkable alloy, composed of nickel and titanium, exhibits unique properties that allow it to return to its original shape after deformation—an ability that has made it a cornerstone in various high-tech applications. Often referred to as a shape memory alloy, nitinol nickel titanium combines flexibility with strength, making it ideal for industries ranging from medicine to aerospace.

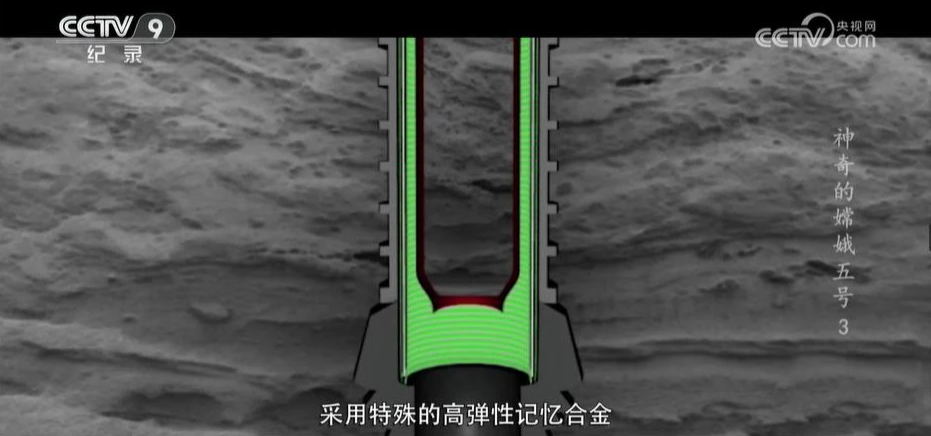

What is Nitinol Superelastic Wire

Nitinol superelastic wire is a fascinating material that stands out due to its exceptional mechanical properties. It belongs to the family of shape memory alloys (SMAs), which can remember their original shape when subjected to specific temperature conditions or stress levels. The unique combination of nickel and titanium gives this memory metal extraordinary resilience and adaptability, enabling it to perform in demanding environments while maintaining its structural integrity.

Applications of Nitinol in Various Industries

The versatility of nitinol nickel titanium extends across numerous industries, showcasing its innovative potential. In the medical field, super elastic nitinol wire is used in stents and guidewires, revolutionizing minimally invasive procedures and improving patient outcomes. Beyond healthcare, this memory metal finds applications in aerospace technologies and robotics, where its ability to withstand extreme conditions proves invaluable.

The Importance of ASTM F2063 Standards

To ensure quality and safety in the use of super elastic nitinol wire, adherence to established standards like ASTM F2063 is crucial. These standards provide guidelines for the composition and performance characteristics of nitinol nickel titanium products, ensuring they meet industry requirements for reliability and efficacy. By following these quality benchmarks, manufacturers can guarantee that their memory alloy components are not only effective but also safe for end-users across various applications.

Understanding Superelastic Nitinol Wire

Superelastic nitinol wire is a fascinating material that combines the unique properties of nickel titanium to create a versatile shape memory alloy. This remarkable blend allows the wire to undergo significant deformation and then return to its original shape when heated or subjected to stress. The ability of this memory metal to retain its form under various conditions makes it invaluable across multiple industries, particularly in medical and aerospace applications.

Properties of Nitinol Nickel Titanium

Nitinol nickel titanium boasts exceptional mechanical properties, including high elasticity, corrosion resistance, and biocompatibility. These attributes are primarily due to its unique crystalline structure, which enables it to exhibit superelastic behavior—allowing the wire to stretch up to 10% more than conventional metals without permanent deformation. Moreover, the combination of nickel and titanium imparts excellent fatigue resistance, making nitinol an ideal candidate for applications requiring repeated loading cycles.

The Role of Shape Memory Alloy

The term shape memory alloy refers specifically to materials like nitinol that can remember their original shape after being deformed. When subjected to specific temperature changes, nitinol transforms between two phases: a low-temperature martensitic phase and a high-temperature austenitic phase. This property is what gives superelastic nitinol wire its magical ability; when cooled down or deformed at lower temperatures, it can revert back once warmed up—effectively remembering its initial form.

Advantages of Using Memory Metal

Using memory metal alloys such as superelastic nitinol wire offers numerous advantages over traditional materials. First off, their ability to recover from large strains without permanent deformation leads not only to enhanced performance but also increased longevity in products like stents and guidewires used in medical devices. Additionally, their lightweight nature combined with strength means that engineers can design smaller yet highly effective components—a crucial factor in industries where space and weight are critical considerations.

Applications in Medical Devices

The versatility of super elastic nitinol wire has revolutionized the medical device industry, offering unique solutions that enhance patient care and treatment outcomes. This remarkable material, composed of nickel titanium, exhibits extraordinary properties as a shape memory alloy, making it ideal for various applications. From stents to guidewires, nitinol nickel titanium continues to prove itself as a game changer in modern medicine.

Use in Stents and Guidewires

Stents made from super elastic nitinol wire have become the gold standard in cardiovascular interventions due to their exceptional flexibility and strength. The unique properties of this memory metal allow it to expand and contract seamlessly within the body, adapting to the natural movements of blood vessels without compromising structural integrity. Furthermore, the biocompatibility of nitinol nickel titanium ensures that these devices minimize adverse reactions while promoting healing.

Guidewires crafted from this innovative memory alloy are equally impressive, providing clinicians with enhanced maneuverability during complex procedures. The ability of super elastic nitinol wire to return to its original shape after deformation allows for precise navigation through tortuous anatomy. As a result, these guidewires improve overall procedural success rates and reduce patient recovery times.

Innovations in Orthopedic Surgery

In orthopedic surgery, super elastic nitinol wire is paving the way for groundbreaking innovations that enhance surgical techniques and patient outcomes. Surgeons are increasingly utilizing this shape memory alloy for applications such as bone fixation devices and implants due to its remarkable strength-to-weight ratio and flexibility. By incorporating nitinol nickel titanium into orthopedic tools, medical professionals can achieve better alignment and stabilization during complex procedures.

One notable application is the development of self-expanding screws that utilize the unique properties of this memory metal alloy to adapt dynamically within bone structures. These screws provide superior fixation compared to traditional materials while reducing trauma during insertion. As a result, patients benefit from quicker recovery times and improved long-term results.

Reliability in Implantable Devices

The reliability of implantable devices is paramount in ensuring patient safety over extended periods; here’s where super elastic nitinol wire shines brightly! Its inherent fatigue resistance makes it an excellent choice for long-term implants such as pacemakers or orthopedic supports made from nickel titanium alloys. With minimal risk of failure or deformation over time, these devices offer peace of mind both for patients and healthcare providers alike.

Moreover, the corrosion resistance inherent in nitinol nickel titanium contributes significantly to its longevity inside the human body—an essential factor when considering implantable medical devices exposed to bodily fluids over years or even decades! This durability reinforces why so many manufacturers are turning towards this remarkable memory metal when designing cutting-edge solutions tailored specifically for individual needs.

Aerospace Applications of Nitinol

When it comes to aerospace applications, super elastic nitinol wire is nothing short of revolutionary. The unique properties of nitinol nickel titanium allow for lightweight yet robust designs that can withstand the rigors of space travel. As the industry pushes boundaries, memory metal and its shape memory alloy capabilities are becoming indispensable.

Impact on Space Exploration Technologies

Super elastic nitinol wire has made significant contributions to space exploration technologies, providing solutions that traditional materials simply can't match. Its ability to return to a predetermined shape when heated makes it ideal for components that need to endure extreme conditions, such as temperature fluctuations and high-stress environments in outer space. The resilience of nitinol nickel titanium not only enhances performance but also reduces the overall weight of spacecraft, which is crucial for fuel efficiency.

GEE SMA’s Contributions to Missions

GEE SMA has been at the forefront of integrating super elastic nitinol wire into various aerospace missions, showcasing its versatility and reliability. Their innovative use of nickel titanium in actuators and other mechanical systems has improved mission success rates by ensuring components function flawlessly under pressure. By harnessing the unique properties of memory metal alloy, GEE SMA is paving the way for future advancements in aerospace engineering.

Benefits of Memory Alloy in Aerospace

The benefits of using memory alloy in aerospace applications extend beyond mere functionality; they also address safety and operational efficiency concerns. Super elastic nitinol wire can absorb shock and adapt to dynamic conditions without permanent deformation, making it an excellent choice for critical systems like landing gear or satellite mechanisms. Moreover, with ongoing research into nickel and titanium alloys, we can expect even more innovative uses for this remarkable material in future aerospace endeavors.

Manufacturing and Sourcing Nitinol Wire

When it comes to the manufacturing and sourcing of super elastic nitinol wire, several key factors come into play. The selection process involves understanding the specific requirements for applications, such as tensile strength, fatigue resistance, and thermal properties. Additionally, sourcing from reputable suppliers ensures that the nitinol nickel titanium wire meets industry standards and delivers optimal performance in various applications.

Key Factors in Selection

Choosing the right super elastic nitinol wire isn't just about picking a shiny new material off the shelf; it requires careful consideration of multiple factors. First, users should evaluate the mechanical properties of nickel titanium, including its ability to return to a predetermined shape under stress—an essential feature of shape memory alloys. Moreover, compatibility with other materials is crucial; ensuring that your memory metal integrates seamlessly into existing designs can save time and resources down the line.

Another important aspect is understanding how different manufacturing processes affect the final product's performance characteristics. For instance, certain heat treatments can enhance the superelastic properties of nitinol nickel titanium wire, making it more suitable for demanding applications like medical devices or aerospace components. Lastly, potential suppliers should be assessed on their ability to provide consistent quality and reliable delivery times—because no one wants to be left waiting for essential components when deadlines loom.

GEE SMA’s Quality Assurance Process

Each batch undergoes extensive testing to ensure compliance with ASTM F2063 standards; this guarantees that every strand of nickel titanium meets stringent safety and performance criteria before reaching customers' hands. From initial material selection through final inspection, GEE SMA maintains meticulous documentation that tracks every step of production.

In addition to standard testing protocols, GEE SMA employs advanced techniques such as microstructural analysis and mechanical property assessments to further validate their products' reliability in critical applications. This commitment not only assures customers they are getting top-quality memory alloy but also fosters trust in long-term partnerships across various industries—from medical devices to aerospace technologies. With GEE SMA’s dedication to quality assurance, clients can confidently rely on their super elastic nitinol wire for even the most challenging projects.

Understanding Sizes and Specifications

Navigating through sizes and specifications for super elastic nitinol wire can feel like trying to solve a Rubik's Cube blindfolded—daunting but entirely manageable with some guidance! It's essential first to understand that this memory metal comes in various diameters and lengths tailored for specific uses; knowing your project's requirements will help streamline your selection process significantly. Common sizes range from thin wires used in delicate medical instruments to thicker gauges suited for structural components in aerospace applications.

Moreover, each specification has unique implications on how effectively a piece of nickel titanium will perform under stress or temperature changes; therefore, consulting with experienced manufacturers is advisable when determining which size best fits your needs. Keep an eye out for any additional specifications related to heat treatment or surface finish as these can greatly influence functionality too! By arming yourself with this knowledge about sizes and specifications within nitinol nickel titanium products, you’ll be better equipped for successful sourcing decisions.

The Future of Nitinol Technology

Nitinol technology is on the brink of exciting advancements that could redefine its applications across various sectors. As researchers delve deeper into the properties of nickel titanium, they are discovering novel ways to manipulate its characteristics for enhanced performance. The future holds promise for super elastic nitinol wire as it continues to evolve, paving the way for innovations in both existing and new industries.

Emerging Innovations in Memory Metals

The realm of memory metals is witnessing groundbreaking innovations that enhance the functionality and versatility of materials like nitinol nickel titanium. Researchers are exploring advanced processing techniques that can improve the fatigue resistance and shape recovery capabilities of these alloys, leading to even more reliable applications. With ongoing studies focusing on hybrid materials combining nickel and titanium with other elements, we may soon see a new generation of memory metal alloys that outperform current standards.

Potential New Industries for Nitinol

While nitinol has made significant strides in medical devices and aerospace applications, its potential stretches far beyond these fields. Industries such as robotics, automotive engineering, and even consumer electronics are beginning to recognize the benefits offered by super elastic nitinol wire.

Sustainability and Nitinol Production

As we look toward a sustainable future, production methods for nickel titanium must also evolve to minimize environmental impact while maximizing efficiency. Innovative recycling processes for memory metal can significantly reduce waste while ensuring a steady supply chain for super elastic nitinol wire manufacturers. By adopting greener practices in sourcing and production, the industry can not only meet growing demand but also contribute positively towards a more sustainable planet.

Conclusion

In wrapping up our exploration of super elastic nitinol wire, it's clear that this remarkable material has revolutionized various industries, particularly in medical and aerospace applications. The unique properties of nitinol nickel titanium, with its ability to return to a predetermined shape when heated, make it an invaluable asset in creating innovative solutions. From stents that adapt seamlessly within the human body to components used in space exploration technologies, the versatility and reliability of memory metal are undeniable.

Recap of Nitinol Superelastic Wire Benefits

The benefits of super elastic nitinol wire stem from its incredible properties as a shape memory alloy. This nickel titanium combination allows for exceptional flexibility and strength while maintaining its original form under stress. Moreover, the ability of this memory alloy to recover from deformation means that devices made from nitinol can endure repeated use without compromising their integrity—an essential feature for both medical devices and aerospace components.

Importance of Quality Standards like ASTM F2063

Quality standards such as ASTM F2063 play a crucial role in ensuring the safety and efficacy of products made from nitinol nickel titanium. These standards provide guidelines for material composition, mechanical properties, and performance testing—ensuring that manufacturers produce reliable memory metal products that meet industry requirements. Adhering to these standards not only enhances product quality but also fosters trust among consumers who rely on these advanced materials for critical applications.

Thinking Ahead: The Future of Nitinol Applications

Looking ahead, the future holds exciting possibilities for super elastic nitinol wire across various sectors beyond what we currently envision. Emerging innovations in memory metals could lead to breakthroughs in fields such as robotics or even consumer electronics, where adaptability is paramount. Additionally, as sustainability becomes increasingly important in production processes, advancements in the manufacturing of nickel titanium alloys promise eco-friendly solutions without sacrificing performance or reliability.