Introduction

In the ever-evolving landscape of robotics, the SMA actuator stands out as a remarkable innovation that utilizes shape memory alloy technology to deliver precise movements and responses. These actuators are not just mechanical components; they embody a blend of physics and engineering that allows for significant versatility in applications. With the ability to transform energy into motion, SMA actuators are reshaping how we think about automation and control.

What is an SMA Actuator

An SMA actuator is a type of device that leverages shape memory alloys to create movement in response to temperature changes or electrical signals. When heated, these alloys can change shape, enabling the actuator to contract or expand much like muscles do in biological systems. This unique characteristic sets SMA wire actuators apart from traditional linear actuators, making them ideal for applications where space is limited and precision is paramount.

Advantages of SMA Technology

One of the standout advantages of SMA technology is its ability to operate without complex electrical wiring systems typically required by other types of actuators, such as heating actuators or linear actuators. This simplicity not only reduces overall system weight but also enhances reliability by minimizing potential points of failure. Additionally, SMA actuators are known for their energy efficiency and quiet operation, making them suitable for environments where noise reduction is essential.

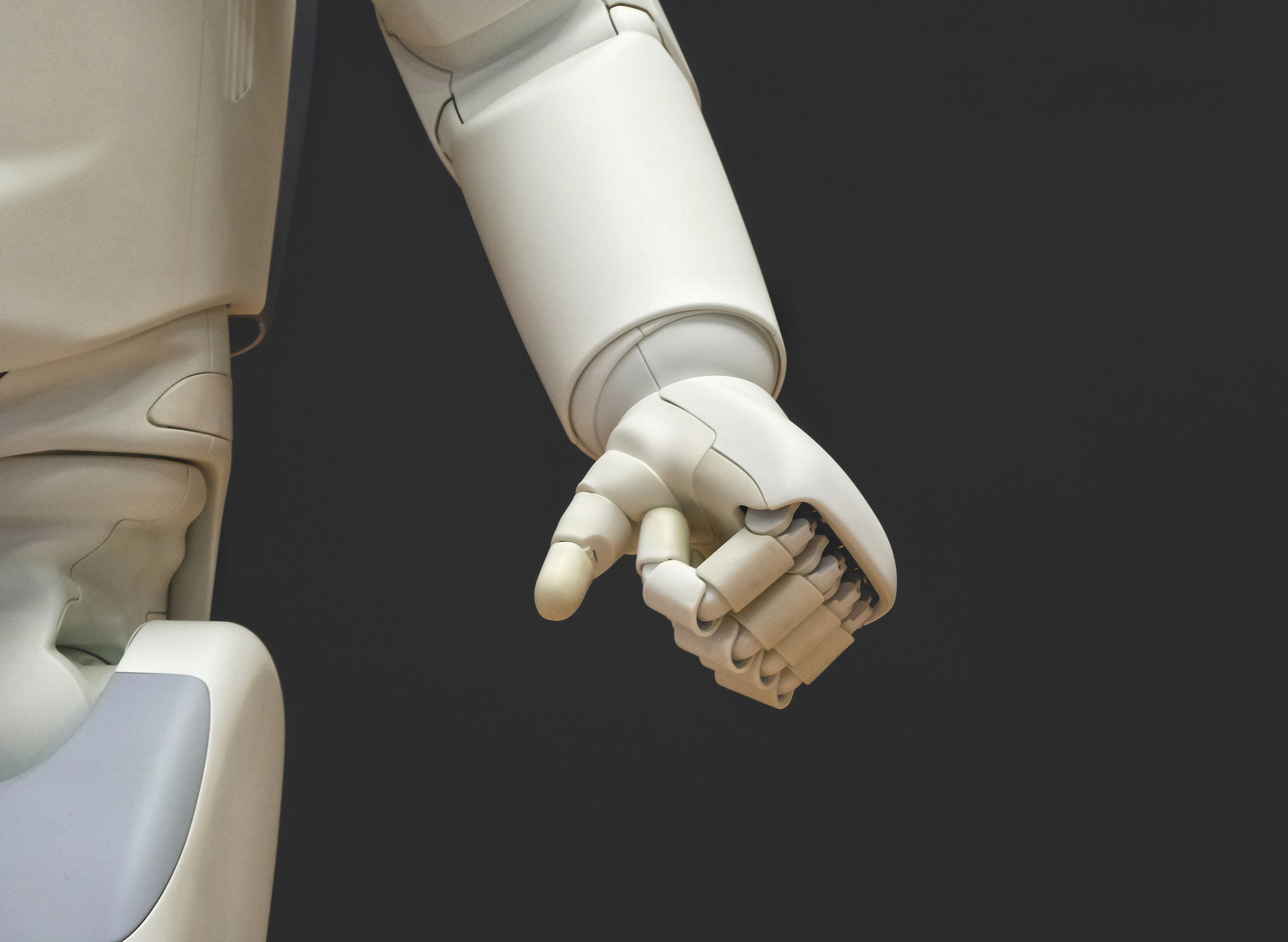

Applications in Modern Robotics

SMA actuators have found their niche across various sectors within modern robotics, from medical devices that require delicate manipulation to industrial automation systems demanding robust performance. Their compact size allows integration into consumer electronics where traditional linear actuator solutions might be too bulky or power-hungry. As robotics continues to advance, the role of SMA wire actuators will likely expand even further, driving innovations that enhance functionality and efficiency.

Understanding SMA Actuators

SMA actuators are fascinating devices that harness the unique properties of shape memory alloys to perform mechanical work. These innovative components convert thermal energy into motion, offering a compact and efficient alternative to traditional actuators. In this section, we’ll dive into the mechanics behind SMA technology, explore the various types of SMA actuators, and examine how a sma wire actuator operates.

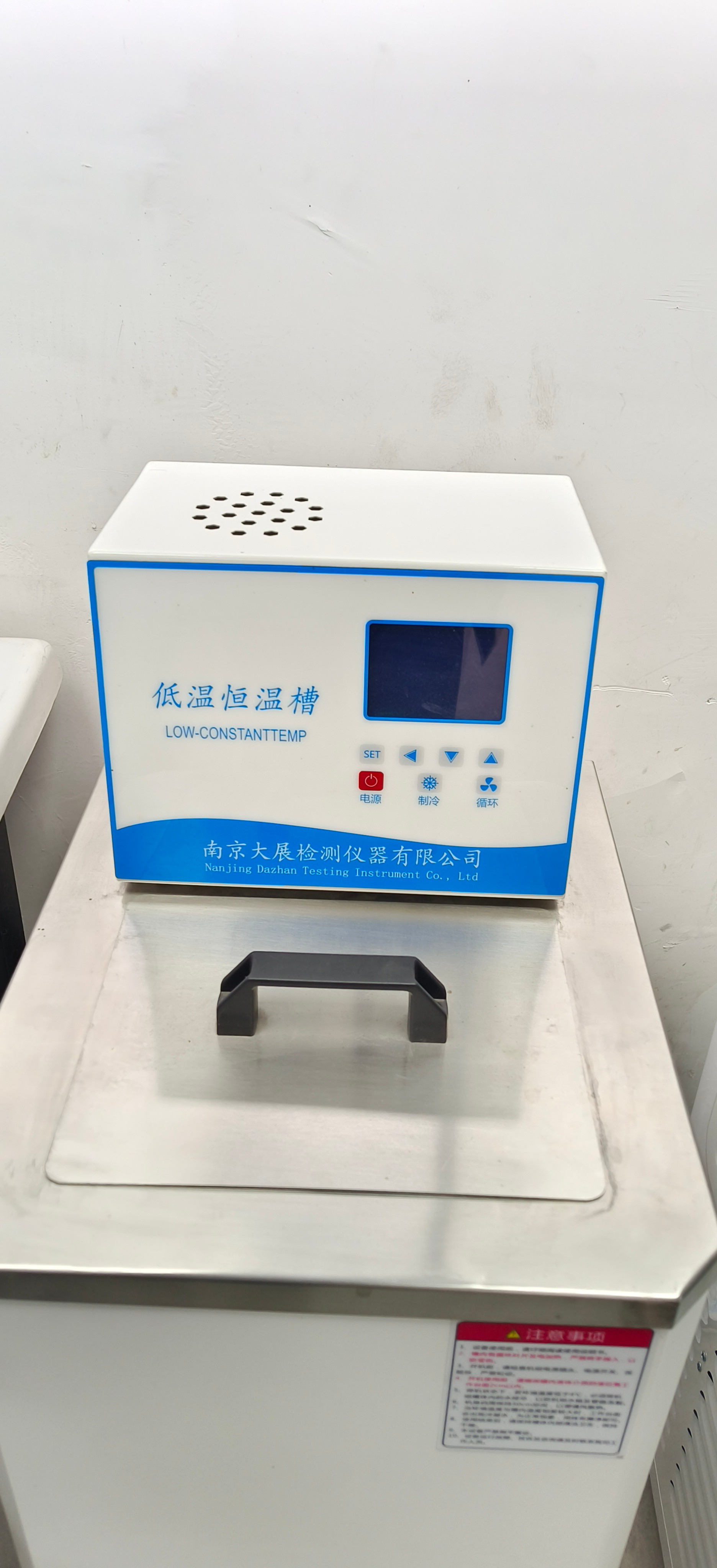

Mechanics Behind SMA Technology

At the core of SMA technology is the ability of certain alloys to remember a predefined shape when subjected to heat. This property is due to phase transformation within the material: when heated, an SMA changes from a martensitic state (deformed) to an austenitic state (original form). This transition generates enough force for movement, making it ideal for applications where space is limited or where lightweight solutions are preferred over bulky linear actuators.

The transformation process is highly efficient; as the temperature rises, so does the actuator's ability to exert force. This means that with minimal electrical wiring and control systems, an sma actuator can deliver significant performance without the need for complex mechanisms often found in heating actuators. Consequently, engineers can create more streamlined designs that enhance overall system efficiency.

Types of SMA Actuators

SMA actuators come in various forms, each tailored for specific applications and operational needs. The most common types include rotary actuators and linear actuators—often referred to as actuador linear in Spanish contexts—each serving distinct purposes in robotics and automation. Rotary SMA actuators are designed for rotational movement while linear versions facilitate straight-line motion; both capitalize on the unique properties of shape memory alloys.

Another interesting type is the hybrid actuator that combines traditional technologies with SMA elements for enhanced performance characteristics. By integrating these systems with advanced actuator controllers, users can achieve precise motion control tailored to their specific requirements. Whether you're looking at medical devices or robotic arms, understanding these different types allows designers to select the optimal solution for their projects.

How SMA Wire Actuator Works

The operation of an sma wire actuator is both simple and ingenious; it utilizes thin strands of shape memory alloy wire that contract when heated and return to their original length upon cooling. When current flows through this wire via electrical wiring connected to an actuator controller, it heats up rapidly due to its resistance characteristics—resulting in contraction that translates into mechanical motion.

As it cools down after being energized, the wire returns to its original state without requiring additional power input—a feature not commonly found in heating actuators which often need continuous energy supply for operation. This cycle allows sma wire actuators not only greater efficiency but also longevity since they avoid excessive wear associated with conventional motors or gears used in linear actuation systems.

In summary, understanding how these components function sheds light on why they are becoming increasingly popular across numerous industries—from robotics innovation all the way down to consumer electronics—where compactness and efficiency reign supreme.

Comparing SMA Actuators to Traditional Actuators

When it comes to the world of actuators, not all are created equal. SMA actuators, with their unique shape memory alloy technology, stand apart from traditional options like linear actuators and heating actuators. This section delves into the key differences that set SMA wire actuators ahead of the competition.

Differences from Linear Actuators

Linear actuators are known for their straightforward motion along a single axis, often powered by electric motors or hydraulic systems. In contrast, SMA actuators utilize the fascinating properties of shape memory alloys to create movement through thermal activation, allowing for more compact designs and lightweight applications. While a linear actuator typically requires complex electrical wiring and bulky designs to achieve its motion, an SMA actuator can deliver similar results in a more streamlined form factor.

Another significant difference lies in energy consumption; linear actuators often require continuous power to maintain position, while SMA wire actuators only draw power during actuation. This energy efficiency can lead to longer battery life in mobile applications or reduced operational costs in industrial settings. Moreover, the simplicity of an SMA actuator's design means fewer components are needed compared to traditional linear systems.

Advantages Over Heating Actuators

Heating actuators rely on heat generation to produce motion but come with their own set of challenges—namely slow response times and potential overheating issues. In contrast, SMA actuators provide rapid actuation without the risk of excessive heat buildup because they only activate when necessary. This not only enhances performance but also increases safety in applications where overheating could be catastrophic.

Furthermore, while heating actuators may require extensive cooling mechanisms or insulation due to their heat generation, an SMA actuator operates at lower temperatures and thus eliminates these concerns altogether. The compact nature of sma wire actuator designs allows for easier integration into smaller devices without compromising functionality or safety standards. Ultimately, this leads to greater versatility across various applications.

Cost-Effectiveness Insights

Cost-effectiveness is a critical factor when evaluating different types of actuators for specific applications. Although initial investment costs might seem higher for advanced sma actuator systems compared to conventional options like heating or linear actuators, the long-term savings often paint a different picture. Lower energy consumption combined with reduced maintenance requirements makes SMA technology attractive over time.

Moreover, with fewer components involved in an sma wire actuator system—thanks largely to its efficient design—the overall manufacturing and assembly costs can decrease significantly as well. Businesses looking at automation solutions will find that investing in advanced actuator controllers paired with smart integration techniques can yield substantial returns on investment over time due to increased productivity and reduced downtime.

Key Components in SMA Systems

Understanding the key components of SMA systems is crucial for harnessing the full potential of SMA actuators. These components work in unison to ensure that the actuator operates efficiently and effectively, allowing for precise control and functionality in various applications. Let's delve into three essential elements: actuator controllers, electrical wiring, and the integration of SMA with other technologies.

The Role of Actuator Controllers

Actuator controllers are pivotal in managing the performance of SMA actuators. They regulate the electrical signals that control the heating and cooling processes of the sma wire actuator, enabling it to expand and contract as needed. By providing feedback mechanisms, these controllers ensure that movements are accurate, allowing for better precision than traditional linear actuators.

In many applications, actuator controllers can be programmed to respond to specific conditions or inputs, making them incredibly versatile. For instance, they can adjust parameters based on temperature changes or load requirements, optimizing the operation of heating actuators as well. This adaptability is what sets SMA technology apart from more conventional options like linear actuators.

Moreover, advancements in actuator controller technology are continually improving how we utilize SMA systems across various industries. As these controllers become more sophisticated, they enable smoother transitions and more complex movements within robotic applications—an essential feature for modern robotics development.

Importance of Electrical Wiring

Electrical wiring plays a critical role in connecting all components within an SMA system effectively. The quality and arrangement of electrical wiring directly influence how well an sma actuator performs its functions; inadequate wiring can lead to inefficiencies or even failures during operation. Properly designed wiring ensures reliable power delivery to both the actuator controller and the sma wire actuator itself.

Additionally, good electrical wiring minimizes signal interference that could disrupt communication between components. This is particularly important when integrating multiple systems where precision is crucial; any disruption could lead to unexpected behavior reminiscent of traditional heating actuators' limitations. Thus, investing time into planning robust electrical layouts pays off significantly when deploying SMA technology.

Furthermore, innovative approaches like wireless power transmission are emerging as potential solutions for enhancing electrical connectivity in SMA systems without compromising performance or reliability. Such advancements may pave the way for even greater flexibility in design while maintaining high efficiency—a win-win scenario!

Integration of SMA with Other Technologies

The integration of sma actuators with other technologies opens up a world of possibilities across various fields such as robotics and automation. Combining these actuators with sensors allows for real-time feedback loops that enhance their responsiveness compared to conventional options like linear actuators or heating actuators alone. This synergy creates smarter systems capable of adapting dynamically to changing environments.

Moreover, integrating artificial intelligence (AI) algorithms into actuator controls can further optimize performance by predicting necessary adjustments based on historical data patterns—something traditional methods struggle with due to their rigid structures! Such intelligent designs will likely revolutionize industries ranging from medical robotics where precision matters most down through consumer electronics where compactness is key.

Lastly, partnerships between different technological domains—like combining 3D printing techniques with sma wire actuation—can lead us toward entirely new innovations previously thought impossible! As engineers continue exploring these integrations creatively, we can expect exciting developments shaping tomorrow's robotic landscape.

Real-World Applications of SMA Actuators

SMA actuators are making waves across various industries, thanks to their unique properties and versatility. From medical robotics to industrial automation and consumer electronics, the adaptability of these devices is revolutionizing how systems operate. Let's dive into some exciting real-world applications that showcase the potential of SMA technology.

Use in Medical Robotics

In the realm of medical robotics, SMA actuators are proving to be game-changers. Their compact size and lightweight nature allow for intricate designs in surgical tools, enhancing precision during delicate procedures. For instance, SMA wire actuators are utilized in minimally invasive surgeries where traditional linear actuators might be too bulky or cumbersome, providing surgeons with better control and flexibility.

Moreover, SMA technology contributes significantly to robotic prosthetics and exoskeletons that assist individuals with mobility challenges. The actuator controller can fine-tune the movements based on user feedback, allowing for a more natural gait or hand movement. As a result, patients experience improved functionality and quality of life thanks to these innovative devices.

Advancements in Industrial Automation

The industrial sector is also reaping the benefits of SMA actuators as they replace traditional heating actuators in certain applications. These smart devices provide rapid actuation without the need for extensive electrical wiring typically associated with conventional systems. This not only simplifies installation but also reduces maintenance costs over time.

SMA actuators enable precise control in automated assembly lines where speed and accuracy are paramount. Their ability to respond quickly to changes allows manufacturers to optimize production processes efficiently while minimizing downtime caused by mechanical failures common with linear actuators. Overall, incorporating SMA technology boosts productivity while maintaining high-quality standards.

Innovations in Consumer Electronics

In consumer electronics, SMA actuators are paving the way for sleek designs and enhanced functionality that appeal to tech-savvy consumers. Devices like smartphones and wearables benefit from miniature versions of these actuators that allow for features such as haptic feedback or adjustable components without adding bulkiness. This innovation leads to more aesthetically pleasing products while still delivering impressive performance.

Additionally, integrating SMA wire actuator technology into home automation systems provides a seamless user experience through smart controls that adjust appliances based on user preferences automatically. The simplicity of electrical wiring needed for these systems makes them easy to install compared to more complex alternatives involving traditional heating actuators or other mechanisms. As consumer demands evolve towards smarter solutions, it's clear that SMA technology is here to stay.

The Future of SMA Actuators in Robotics

As we peer into the crystal ball of robotics, it’s clear that SMA actuators are poised to play a pivotal role in shaping the industry. With their unique ability to convert thermal energy into mechanical motion, these innovative devices are set to revolutionize how we think about movement and control in machines. Trends such as miniaturization, energy efficiency, and smart technologies are driving the development of SMA actuators, making them more versatile and applicable across various fields.

Trends Shaping SMA Development

Several trends are currently shaping the development of SMA actuators that promise to enhance their functionality and efficiency. One notable trend is the integration of advanced actuator controllers that allow for more precise control over motion, making it easier for engineers to program complex movements with minimal effort. Additionally, there is a growing emphasis on improving electrical wiring systems within SMA applications to reduce energy consumption while maximizing performance—an essential factor for both industrial automation and consumer electronics.

Another exciting trend is the shift towards hybrid systems that combine SMA wire actuators with traditional linear actuators or heating actuators. This approach not only enhances overall system performance but also opens up new avenues for innovation in robotics design. As these trends continue to evolve, we can expect SMA technology to become increasingly sophisticated and widely adopted across various sectors.

GEE SMA’s Contributions to the Industry

GEE SMA has emerged as a significant player in advancing SMA actuator technology by pushing boundaries through research and development initiatives. Their commitment to innovation has led to breakthroughs in actuator controllers that improve responsiveness and reliability in real-world applications. By focusing on refining electrical wiring solutions specifically tailored for SMA systems, GEE has enhanced efficiency while minimizing size—making their products ideal for compact robots operating in tight spaces.

Moreover, GEE's dedication extends beyond just product enhancements; they actively collaborate with universities and research institutions worldwide to foster an ecosystem where cutting-edge ideas can flourish into practical solutions. This collaborative spirit accelerates advancements not only within their organization but also throughout the entire industry landscape surrounding sma actuators. As they pioneer new methodologies, GEE sets a benchmark for quality and performance standards that others aspire to meet.

Potential Challenges and Solutions

Despite the promising future of SMA actuators in robotics, several challenges could impede their widespread adoption if not addressed promptly. One major hurdle is ensuring compatibility between various components such as actuator controllers and electrical wiring systems across different platforms—standardization will be crucial here! Additionally, although sma wire actuators offer many advantages over traditional linear or heating actuators regarding weight reduction and energy efficiency; manufacturers must find ways to mitigate issues related to thermal fatigue over prolonged use.

To tackle these challenges head-on requires innovative thinking from both engineers developing new technologies as well as stakeholders investing resources into research initiatives aimed at overcoming existing limitations within this field. Collaboration among industry leaders can facilitate knowledge sharing around best practices while fostering an environment conducive towards collective problem-solving efforts—ultimately paving smoother pathways forward!

Conclusion

In the rapidly evolving world of robotics, SMA actuators are carving out a significant niche. Their unique properties and advantages over traditional actuators, such as linear actuators and heating actuators, make them increasingly important in various applications. As industries continue to innovate, the role of SMA wire actuators will only expand, reshaping how we think about movement and control in machines.

The Growing Importance of SMA Actuators

SMA actuators are gaining traction due to their lightweight design and energy efficiency compared to conventional actuator systems. Unlike linear actuators that rely on bulky components, SMA technology offers a compact solution that can deliver impressive force with minimal space requirements. Moreover, the simplicity of electrical wiring in SMA systems allows for easier integration into existing designs, making them a go-to choice for engineers looking to enhance performance without the complications.

Impact on Robotics Evolution

The advent of SMA technology has fundamentally changed the landscape of robotics by enabling more sophisticated movements and functionalities. As robots become more integrated into everyday life—from medical robotics assisting surgeries to industrial automation—SMA wire actuators are proving essential for achieving precision and reliability. This evolution not only enhances robotic capabilities but also opens doors for innovations that were previously unimaginable with traditional heating actuators or linear actuator systems.

GEE SMA's Role in SMA Advancements

GEE SMA stands at the forefront of these advancements, driving research and development in the field of shape memory alloys. Their commitment to improving actuator controllers and refining electrical wiring solutions is helping push the boundaries of what’s possible with SMA technology. By addressing potential challenges head-on—such as durability and scalability—GEE SMA is ensuring that these remarkable sma actuators continue to thrive in an ever-changing technological landscape.