Introduction

In the ever-evolving landscape of technology, Shape Memory Alloys (SMAs) stand out as remarkable materials that exhibit unique properties, particularly in the realm of automation. These materials can remember their original shapes and return to them when subjected to specific stimuli, making them invaluable in various applications, especially within robot automation. The versatility of SMA actuators has opened up new avenues for motion control systems, allowing for more efficient and responsive designs than traditional motor systems.

Overview of Shape Memory Alloys

Shape Memory Alloys are metallic materials that undergo a phase transformation, enabling them to revert to a predetermined shape when heated or subjected to stress. This fascinating property is primarily attributed to the unique composition of these alloys, which often includes nickel and titanium—commonly known as Nitinol. The ability of SMA wire actuators to change shape under different temperature conditions makes them ideal candidates for applications requiring precision and adaptability.

Importance in Modern Automation

In modern automation, the role of SMA actuators cannot be overstated; they provide innovative solutions that enhance performance across various sectors. Their compact size and lightweight nature allow for integration into robotic systems without adding significant bulk or weight, which is crucial for maintaining agility in robot automation. Moreover, their energy efficiency means less power consumption compared to traditional motor control systems, leading to longer operational lifespans and reduced maintenance costs.

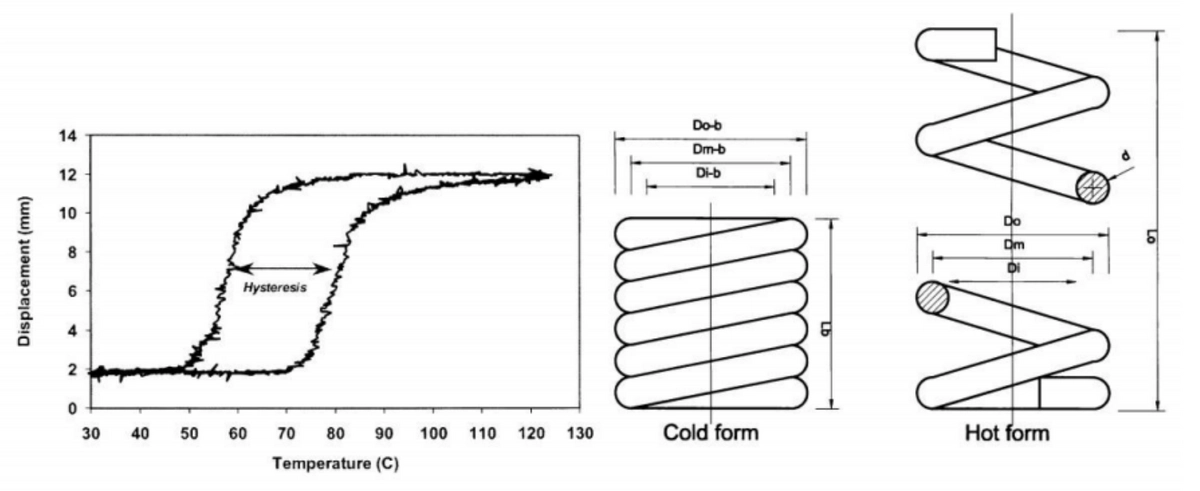

How SMA Actuators Work

SMA actuators operate on a simple yet effective principle: when an electrical current passes through the SMA wire actuator or when it is heated above a certain temperature threshold, it transforms from one phase (martensite) to another (austenite), causing it to contract or expand. This transformation generates movement that can be harnessed for precise motion control tasks in robotic applications. By controlling the temperature or electrical input precisely, engineers can manipulate these actuators' movements with remarkable accuracy.

Understanding Shape Memory Alloys

Shape memory alloys (SMAs) are fascinating materials that possess a unique ability to return to a predetermined shape when subjected to specific thermal conditions. This remarkable property makes them ideal for various applications, particularly in the realm of robot automation and motion control systems. The versatility of SMAs, especially in the form of SMA actuators, has revolutionized how we design and implement robotic systems.

Definition and Composition

At its core, a shape memory alloy actuator is a metallic material that can remember its original shape after being deformed. Typically composed of elements such as nickel and titanium, these alloys exhibit the ability to undergo phase transformations between two distinct crystalline structures—martensite and austenite—when exposed to temperature changes. This composition allows SMA actuators to perform precise movements in response to thermal stimuli, making them invaluable in advanced motor control applications.

The Science Behind Shape Memory Effect

The science behind the shape memory effect is rooted in the transformation between different crystal structures within SMAs. When an SMA wire actuator is heated above its transformation temperature, it shifts from the martensitic phase (deformed state) back to its original austenitic phase, effectively remembering its initial shape. This transition enables smooth motion control in robotic systems by converting thermal energy into mechanical movement with high precision.

Common Materials Used in SMA

While nickel-titanium (Nitinol) is perhaps the most well-known shape memory alloy used today, other compositions also play important roles in various applications. Copper-based SMAs are frequently utilized due to their cost-effectiveness and favorable mechanical properties for certain environments. The choice of material often depends on specific requirements such as temperature range, strength-to-weight ratio, and desired actuation speed within robot automation frameworks.

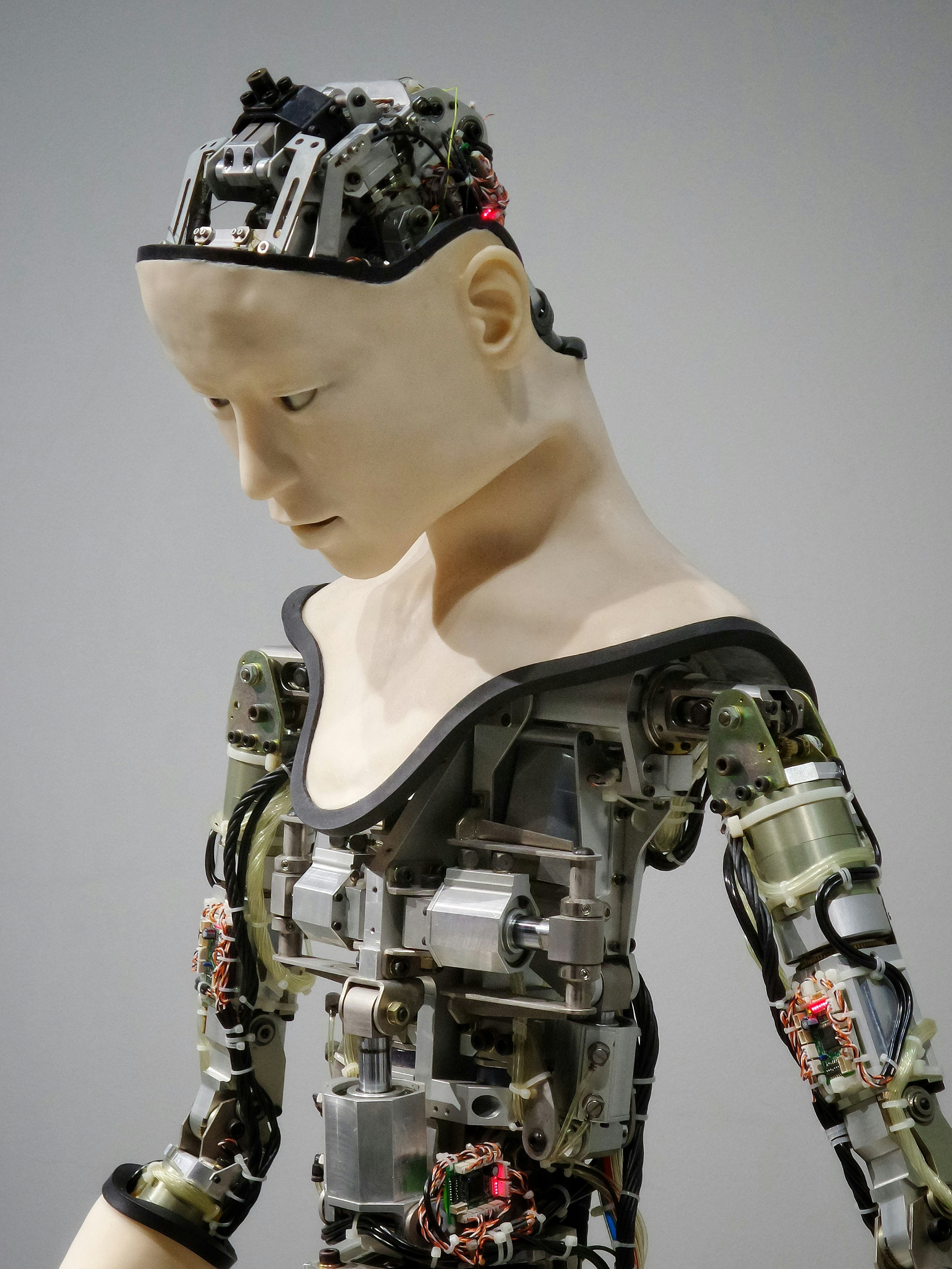

Applications in Robot Automation

The integration of shape memory alloy actuators in robot automation has revolutionized how we design and implement motion control systems. These innovative devices leverage the unique properties of shape memory alloys to create compact, lightweight, and efficient robotic systems. As industries continue to demand more precision and adaptability, SMA actuators are becoming indispensable in modern robotics.

Role of SMA Actuators in Robotics

SMA actuators play a crucial role in enhancing the functionality of robotic systems by providing smooth and precise motion control. Unlike traditional motor control methods that can be bulky and energy-consuming, SMA wire actuators offer a sleek alternative that can easily fit into tight spaces within robots. This flexibility allows for more creative designs while maintaining high performance levels, making them ideal for applications ranging from industrial automation to delicate surgical robots.

In many cases, the ability of shape memory alloy actuators to return to a predetermined shape when heated offers unique advantages over conventional actuation methods. This characteristic enables robots to perform tasks with an impressive range of motion without the need for complex mechanical linkages or extensive wiring. Consequently, SMA technology is paving the way for more sophisticated robotic movements, enhancing their utility across various sectors.

Examples of Robotic Systems Using SMA

Several pioneering robotic systems have successfully incorporated SMA technology into their designs, showcasing its versatility and effectiveness in real-world applications. For instance, soft robotics often utilize shape memory alloy actuators due to their lightweight nature and ability to mimic biological movement patterns—think grippers that gently grasp delicate objects without causing damage! Additionally, some humanoid robots have adopted SMA wire actuators for joint movements that require both agility and precision.

Another notable example includes medical robots designed for minimally invasive surgeries where precision is paramount; these systems benefit significantly from the compact size and responsiveness of SMA actuators. Moreover, drones equipped with shape memory alloy components can achieve impressive maneuverability while reducing overall weight—key factors in enhancing flight efficiency. The successful implementation of these technologies demonstrates how far robot automation has come thanks to innovative actuator solutions.

Benefits of SMA in Robot Motion Control

The benefits of using shape memory alloys in robot motion control are numerous and compelling. First off, their lightweight characteristics significantly reduce the overall mass of robotic systems, which translates into improved energy efficiency during operation—an essential factor as industries strive towards sustainability goals! Furthermore, since SMA actuators operate silently compared to traditional motors, they are especially advantageous in environments where noise reduction is critical.

Another significant advantage lies in their simplicity; fewer moving parts mean less wear-and-tear over time and reduced maintenance costs—a win-win scenario for manufacturers looking to streamline operations! Additionally, the inherent compliance offered by SMAs allows robots equipped with these actuators to adapt better during contact with objects or surfaces—crucial when handling fragile items or navigating unpredictable environments.

In summary, incorporating shape memory alloy actuators into robot automation not only enhances performance but also promotes longevity and efficiency across various applications—from manufacturing floors to surgical suites!

SMA Actuators in Motion Control Systems

Shape memory alloy actuators are revolutionizing motion control systems, particularly in the realm of robot automation. These innovative devices leverage the unique properties of shape memory alloys to provide precise and efficient motion control that traditional motor systems struggle to match. By converting thermal energy into mechanical movement, SMA actuators offer a new paradigm for achieving dynamic and responsive robotic actions.

Mechanisms of Motion Control with SMA

The mechanics behind a shape memory alloy actuator are fascinating and rooted in the material's ability to undergo phase changes. When an SMA wire actuator is heated, it transforms from a martensitic (deformed) state to an austenitic (original) state, resulting in significant contraction or expansion, depending on its configuration. This transformation allows for precise control over movement, making it ideal for applications requiring fine-tuned motion control in robotics.

In practice, the actuation process involves heating the SMA wire using electrical resistance or other means to trigger its phase change. The rapid response time of these actuators enables quick adjustments during operation, which is crucial for maintaining stability and accuracy in robotic movements. Consequently, integrating shape memory alloy actuators into motion control systems enhances overall performance by providing reliable and repeatable actuation.

Advantages Over Traditional Motor Systems

When pitted against traditional motor systems, SMA actuators shine with several notable advantages that make them highly desirable for robot automation applications. First off, their compact size allows for more streamlined designs without sacrificing performance—an essential factor when space is at a premium in robotic systems. Additionally, shape memory alloy actuators typically require less power than conventional motors while delivering comparable or superior force output.

Another significant benefit lies in their simplicity; SMA actuators have fewer moving parts than traditional motors, which translates to reduced wear and tear over time. This durability leads to lower maintenance costs and longer operational lifespans—a win-win scenario for manufacturers looking to optimize their robotics investment! Furthermore, because they operate silently compared to motorized systems that can be noisy during operation, they are well-suited for environments where noise reduction is paramount.

Real-World Motion Control Applications

The versatility of shape memory alloy actuators has led them to find applications across various fields within robot automation—each showcasing their remarkable capabilities in motion control systems. For instance, they are often used in soft robotics where gentle yet precise movements are essential; think robotic grippers that can handle fragile items without causing damage! Similarly, these actuators play a pivotal role in medical robots designed for minimally invasive surgeries by providing delicate maneuverability.

Additionally, industries such as aerospace utilize SMA technology for adaptive structures that respond dynamically to changing conditions—imagine wings that adjust automatically based on airflow! In consumer electronics too, we see the potential of shape memory alloy actuators being harnessed; devices like smart locks employ these innovative components for seamless locking mechanisms powered by heat instead of bulky motors. As we continue exploring this technology's potential across various sectors, it's clear that SMA wire actuators will remain at the forefront of advancing motion control solutions.

Innovations in Motor Control Technology

The world of motor control technology is rapidly evolving, and shape memory alloy actuators (SMA actuators) are at the forefront of this transformation. These unique devices leverage the fascinating properties of shape memory alloys to deliver precise motion control in robot automation applications. As engineers and researchers continue to innovate, SMA wire actuators are being integrated into increasingly sophisticated systems, paving the way for a new era in motion control.

SMA Wire Actuator Developments

Recent developments in SMA wire actuators have opened up exciting possibilities for various applications. These advancements include enhanced response times and improved energy efficiency, making them ideal candidates for modern robot automation systems. With their ability to return to a predetermined shape when heated, SMA wire actuators offer unparalleled simplicity and effectiveness compared to traditional motor systems.

Moreover, researchers are exploring new alloy compositions and fabrication techniques that enhance the performance of these shape memory alloy actuators even further. For instance, innovations such as multi-functional wires that can simultaneously sense temperature changes while providing actuation capabilities promise to revolutionize motion control applications. As these developments continue, we can expect SMA wire actuators to play an increasingly vital role in robotics and other industries.

Integration with Advanced Control Systems

The integration of SMA actuators with advanced control systems is another significant trend reshaping motor control technology. By combining these smart materials with sophisticated algorithms and sensors, engineers can create highly responsive robotic systems capable of adapting to dynamic environments. This synergy between shape memory alloy actuators and cutting-edge control technologies enhances precision in motion control while reducing energy consumption.

One notable example is the implementation of feedback loops that allow SMA actuator systems to self-adjust based on real-time performance data. Such integration not only improves accuracy but also increases reliability in critical applications like medical devices or aerospace technology where failure is not an option. As we continue down this path of innovation, the future looks bright for robot automation powered by advanced SMA actuator technologies.

Future Trends in Motor Control with SMA

Looking ahead, several trends indicate a promising future for motor control using shape memory alloys (SMAs). One significant direction involves miniaturization; as products become smaller yet more capable, compact SMA wire actuators will be essential for maintaining performance without sacrificing space or weight constraints. This trend aligns perfectly with emerging applications such as wearable technology and micro-robotics.

Additionally, sustainability will drive innovation as industries seek greener alternatives to traditional motor systems; here again, SMAs shine due to their low energy requirements during operation compared to conventional motors. The ongoing research into biodegradable materials for constructing these shape memory alloy actuators could further enhance their appeal within eco-conscious markets. Ultimately, the evolution of motor control technology featuring SMAs promises not only enhanced efficiency but also greater adaptability across various sectors.

GEE SMA and Nitinol Applications

Shape memory alloys (SMAs) have revolutionized various industries, particularly in the realm of robot automation and motion control. Among the key players in SMA technology is GEE SMA, which has made significant contributions to the development of advanced shape memory alloy actuators. Their innovations not only enhance the performance of SMA actuators but also expand their applicability across numerous sectors.

GEE SMA’s Contributions to SMA Technology

GEE SMA has been at the forefront of research and development in shape memory alloys, focusing on enhancing the functionality and reliability of SMA wire actuators. Their commitment to innovation has led to breakthroughs that improve response times and efficiency, making these actuators ideal for modern automation applications. By integrating cutting-edge materials science with practical engineering solutions, GEE SMA is paving the way for smarter motor control systems.

Unique Offerings and Custom Solutions

One of GEE SMA's standout features is its ability to provide unique offerings tailored to specific needs within robot automation. Whether it's a specialized shape memory alloy actuator designed for a niche application or a custom solution that integrates seamlessly with existing systems, GEE SMA excels in delivering what clients require. This level of customization not only enhances motion control capabilities but also allows engineers to push the boundaries of what's possible with traditional motor control technologies.

Nitinol in Medical Devices and Aerospace

Nitinol, a specific type of shape memory alloy known for its exceptional elasticity and biocompatibility, has found widespread use in medical devices and aerospace applications. In medical technology, nitinol's properties allow for minimally invasive procedures through devices like stents or guidewires that can change shape when activated by temperature changes—essentially functioning as advanced shape memory alloy actuators within the human body. In aerospace, its lightweight yet strong characteristics make it an ideal choice for components requiring precise motion control under varying environmental conditions.

Conclusion

In wrapping up our exploration of shape memory alloy actuators, it's clear that these remarkable materials are transforming the landscape of robot automation and motion control. The unique properties of SMA allow for compact designs and efficient energy use, making them a go-to choice for cutting-edge applications. As we look to the future, the potential for innovation in this field continues to expand.

Key Benefits of Using SMA Actuators

The advantages of using shape memory alloy actuators are numerous and compelling. One standout benefit is their ability to generate significant force relative to their size, making them ideal for applications where space is at a premium. Additionally, SMA actuators consume less power compared to traditional motor control systems, leading to enhanced efficiency in robot automation tasks.

Another key benefit lies in their inherent simplicity; SMA wire actuators have fewer moving parts than conventional motors, which reduces wear and tear over time. This translates into lower maintenance costs and longer lifespans for robotic systems employing these innovative components. Moreover, the smooth motion control provided by SMAs allows for more precise movements in robotics, enhancing overall performance.

The Future of Automation with Shape Memory Alloys

As we peer into the horizon of automation technology, shape memory alloys are poised to play an increasingly vital role in shaping our robotic future. With advancements in material science and engineering techniques, SMA technology is expected to evolve further, leading to even more sophisticated applications across various industries. From aerospace to medical devices, the versatility of SMA actuators will enable new possibilities that were previously unimaginable.

Moreover, as industries strive for greater efficiency and sustainability, the energy-saving characteristics of SMA wire actuators will become even more appealing. The integration of smart technologies with shape memory alloys can also pave the way for adaptive systems capable of adjusting their behavior based on real-time feedback—an exciting prospect for motion control applications in dynamic environments.

Final Thoughts on SMA Innovation

In conclusion, the innovation surrounding shape memory alloy actuators is not just about enhancing current technologies; it’s about reimagining what’s possible within robot automation and motion control systems. Their unique properties offer distinct advantages that can address many challenges faced by engineers today while driving forward-thinking solutions tomorrow. As we continue exploring new frontiers with SMAs at our side, one thing is certain: these materials will remain at the forefront of technological advancement.