Introduction

In a world where precision and customization are paramount, choosing tailored OEM solutions can be the game-changer your project needs. Customized Nitinol flowers, crafted from nitinol nickel titanium, offer unique properties that set them apart from traditional materials. Their remarkable capabilities make them indispensable in various industries, highlighting the importance of selecting the right materials for specific applications.

Why Choose Customized OEM Solutions

The demand for customized OEM solutions has surged as businesses seek to differentiate themselves in competitive markets. With Nitinol flowers, companies can leverage the unique characteristics of this shape memory alloy to create products that meet precise specifications and performance requirements. By investing in tailored designs, organizations not only enhance functionality but also optimize costs associated with standard materials like titanium metal.

The Unique Qualities of Nitinol Flowers

Nitinol flowers possess extraordinary qualities that stem from their composition of nickel material and titanium elements, making them a standout choice for engineers and designers alike. This innovative shape memory alloy can return to its original form after deformation when exposed to specific temperatures—a feature not commonly found in conventional materials like titanium steel or other metals. The versatility of nitinol nickel titanium allows it to adapt seamlessly across various applications, from medical devices to aerospace components.

Key Applications for Nitinol Materials

The applications for Nitinol materials are as diverse as they are impressive; these advanced alloys have made significant strides in fields such as healthcare and robotics. In medical technology, nitinol flowers are utilized in stents and guidewires due to their ability to navigate complex anatomical structures while maintaining strength and flexibility. Additionally, industries focused on automation increasingly rely on nitinol's unique properties to develop innovative solutions that challenge traditional approaches using titanium material or other metals with higher price points.

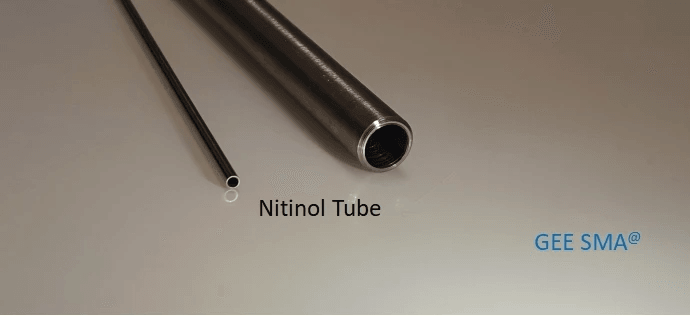

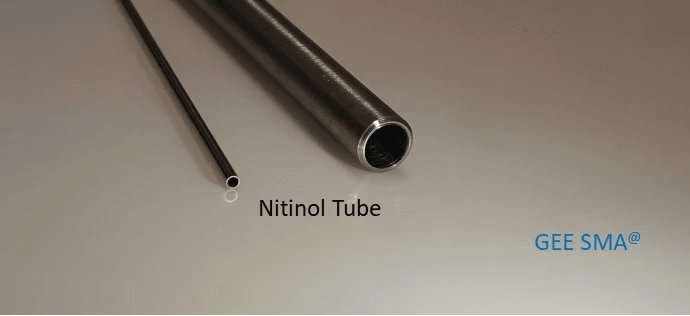

Understanding Nitinol and Its Composition

Nitinol is a remarkable alloy that has garnered attention across various industries due to its unique properties. Composed primarily of nickel and titanium, this shape memory alloy exhibits the ability to return to a predetermined shape when heated above a certain temperature. This fascinating characteristic makes nitinol flowers particularly valuable in applications ranging from medical devices to robotics.

What is Nitinol?

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is an innovative alloy that combines nickel material and titanium in specific proportions, typically around 50% of each element. This balance is crucial as it allows the material to exhibit its distinctive shape memory effect and superelasticity. The versatility of nitinol flowers stems from their ability to adapt their form under varying conditions, making them indispensable in fields like aerospace and medical technology.

The Role of Nickel in Nitinol

Nickel plays a pivotal role in the composition of nitinol, significantly influencing its mechanical properties and thermal behavior. As a key component, nickel enhances the ductility and corrosion resistance of the alloy while also contributing to its unique phase transformation characteristics. The presence of nickel material not only improves performance but also allows for more precise control over the transformation temperatures, which is essential for applications requiring specific thermal responses.

How Shape Memory Alloy Works

The magic behind shape memory alloys like nitinol lies in their ability to remember shapes based on temperature changes. When heated above a certain threshold, nitinol can revert from a deformed state back to its original configuration; this process is known as the shape memory effect. Additionally, this alloy exhibits superelasticity at body temperature—allowing it to undergo significant deformation without permanent changes—making it ideal for creating intricate designs such as nitinol flowers that can be used effectively across various industries.

The Benefits of Customized Nitinol Flowers

Customized Nitinol flowers offer a plethora of advantages that cater to various industrial needs. These unique structures, composed primarily of nitinol nickel titanium, can be specifically designed to fit the exact requirements of diverse applications. By tailoring these materials, businesses can leverage the unique properties of shape memory alloys for enhanced performance and efficiency.

Tailoring to Specific Applications

One of the standout benefits of customized Nitinol flowers is their ability to be tailored for specific applications across multiple industries. Whether it’s medical devices requiring precise functionality or aerospace components needing lightweight yet durable materials, these nitinol flowers can be engineered accordingly. The versatility offered by nitinol nickel titanium allows manufacturers to address unique challenges while optimizing performance in their specific fields.

Enhancing Performance Through Customization

Customization does not merely serve aesthetic purposes; it significantly enhances the overall performance of Nitinol flowers in practical applications. By adjusting parameters such as size, shape, and even alloy composition, businesses can unlock the full potential of shape memory alloys like nitinol. This level of customization ensures that each product meets stringent industry standards while delivering superior functionality compared to standard offerings.

Cost-Effective Solutions with Customized Designs

In an era where budget considerations are paramount, customized Nitinol flowers provide cost-effective solutions without compromising quality or performance. While titanium prices fluctuate due to market dynamics related to titanium material price and titanium steel price variations, investing in tailored nitinol designs often proves more economical in the long run. Not only do these custom solutions minimize waste during production, but they also reduce operational costs by enhancing durability and effectiveness in their intended applications.

GEE SMA: Your Go-To Supplier

When it comes to sourcing high-quality Nitinol flowers, GEE SMA stands out as a trusted partner. With years of experience in the industry, our expertise in Nitinol flower production is unmatched. We understand the unique properties of nitinol nickel titanium and how to leverage them for various applications, ensuring that our clients receive products tailored to their specific needs.

Expertise in Nitinol Flower Production

At GEE SMA, we pride ourselves on our deep understanding of the intricacies involved in producing Nitinol flowers. Our team is skilled in manipulating the unique characteristics of nickel material and shape memory alloy technology to create products that perform exceptionally well under diverse conditions. By focusing on nitinol nickel titanium's remarkable features, we ensure that our offerings are not only effective but also innovative.

Commitment to Quality and Innovation

Quality is at the forefront of everything we do at GEE SMA. We employ rigorous testing and quality control measures throughout the production process to guarantee that every Nitinol flower meets industry standards. Our commitment to innovation drives us to continuously explore new ways to improve our nitinol products, making sure they remain competitive against alternatives like titanium metal while also being cost-effective compared to fluctuating titanium material prices.

Successful Applications in Space Missions

GEE SMA has played a pivotal role in several successful space missions by providing advanced solutions using Nitinol flowers. The unique properties of shape memory alloy have made our products invaluable for aerospace applications where reliability and performance are critical. As space exploration continues to evolve, our expertise with nitinol nickel titanium will be essential for meeting future challenges while keeping an eye on cost-effectiveness compared to traditional materials like titanium steel.

Comparative Analysis: Titanium Prices

When it comes to materials like titanium and nitinol, understanding the pricing dynamics can be quite the endeavor. Various factors influence titanium material prices, including global supply chain fluctuations, mining costs, and demand in industries such as aerospace and medical devices. As these sectors evolve, the pricing of titanium metal can be quite volatile, making it essential for manufacturers to stay informed about market trends.

Factors Influencing Titanium Material Price

Several elements contribute to the price of titanium material that manufacturers must consider. First off, the extraction process of titanium is resource-intensive; this involves mining titanium ore and then processing it into usable forms, which adds significant costs. Additionally, geopolitical factors can impact availability—countries rich in titanium resources may impose export restrictions or tariffs that drive up prices.

Moreover, competition with other high-performance alloys also plays a role in determining titanium prices. With alternatives like nitinol nickel titanium gaining traction due to their unique properties—such as shape memory alloy capabilities—the demand for traditional titanium metal may fluctuate accordingly. As industries increasingly seek advanced materials that offer both performance and cost-effectiveness, understanding these influences on pricing becomes critical.

Understanding Titanium Steel Price Variations

Titanium steel price variations are another layer in this complex landscape of material costs. The integration of titanium into steel alloys enhances strength and corrosion resistance but can significantly raise production costs due to the high price of pure titanium itself. Consequently, manufacturers must weigh the benefits against potential budget constraints when considering whether to use pure titanium or a blended alloy.

Additionally, market demand for specific applications drives price variations within this segment; for instance, aerospace applications often command higher prices due to stringent performance requirements compared to more general industrial uses. The interplay between supply-demand dynamics further complicates matters; when demand spikes—like during technological advancements or increased defense spending—prices tend to soar accordingly. This makes strategic sourcing decisions vital for companies looking to balance quality with cost.

Nitinol's Cost Effectiveness Against Titanium

When comparing nitinol's cost-effectiveness against traditional titanium options, several key advantages emerge that make nitinol flowers an attractive alternative for various applications. Nitinol nickel titanium offers unique properties such as shape memory effects and superelasticity at a competitive price point compared to conventional titanium materials. This means that industries looking for innovative solutions can save significantly while benefiting from enhanced performance characteristics inherent in nitinol.

Moreover, because nitinol can be tailored through customized designs—such as those offered by GEE SMA—it allows businesses not only to cut costs but also optimize functionality based on specific application needs without sacrificing quality or performance standards found in higher-priced materials like pure titanium metal or alloys. Therefore, when evaluating overall lifecycle costs—including fabrication processes and operational efficiencies—nitinol presents itself as a savvy choice over traditional options.

As companies continue exploring advanced materials for their projects while keeping an eye on budgets amid fluctuating market conditions, it's clear that nitinol flowers could pave the way forward in terms of both innovation and economic feasibility.

The Future of Nitinol Flowers in Industries

The future of Nitinol flowers in various industries is looking exceptionally bright, thanks to the continuous evolution of shape memory alloys. As advancements are made in material science, Nitinol—composed primarily of nickel and titanium—continues to carve out a niche for itself. With its unique properties and versatility, the demand for customized Nitinol solutions is expected to rise significantly.

Emerging Trends in Shape Memory Alloys

Shape memory alloys (SMAs) like Nitinol are experiencing a surge in popularity across multiple sectors, including medical devices and robotics. Innovations such as 3D printing technology are making it easier to create intricate designs with Nitinol flowers that were previously unimaginable. This trend not only enhances functionality but also allows manufacturers to tailor products more closely to specific applications, ultimately improving performance.

Another emerging trend involves the integration of smart technologies with shape memory alloys. For instance, researchers are exploring how Nitinol can be used in soft robotics that mimic biological movements more effectively than traditional materials. As these trends continue to develop, we can expect a broader range of applications for Nitinol flowers that leverage their unique properties.

The Role of Nitinol in Advanced Technologies

Nitinol's role in advanced technologies cannot be overstated; it has become essential for innovations ranging from medical implants to aerospace applications. The ability of nitinol nickel titanium to return to its original shape after deformation makes it ideal for devices that require reliability under stress or extreme conditions. In aerospace engineering, lightweight structures made from this alloy can significantly improve fuel efficiency while maintaining strength—a key factor as industries strive for sustainability.

Moreover, the versatility of Nitinol flowers allows them to be utilized creatively within various technological frameworks. For example, they can act as actuators or sensors within complex systems due to their unique thermal and mechanical properties. As industries push toward automation and miniaturization, the importance of incorporating advanced materials like nitinol cannot be overlooked.

Sustainability Considerations in Material Selection

Sustainability is becoming an increasingly important factor when selecting materials for production processes across all industries. Compared with traditional titanium metal options—which often come with high environmental costs—Nitinol offers a more sustainable alternative due mainly to its efficient manufacturing processes and long lifespan once deployed in products. Additionally, the recyclability of both nickel material and titanium components contributes positively towards reducing overall waste.

As companies seek eco-friendly solutions without sacrificing performance or quality, customized Nitinol flowers emerge as an attractive option on the market today. They not only provide superior functionality but also align well with corporate sustainability goals by minimizing resource consumption over time compared to other metals like titanium steel or standard titanium alloys.

In conclusion, as we move forward into an era where technology meets environmental responsibility head-on, the potential applications for nitinol will continue expanding rapidly across diverse fields.

Conclusion

In conclusion, the world of customized solutions is rapidly evolving, and Nitinol flowers stand out as a prime example of innovation in material science. By leveraging the unique properties of nitinol nickel titanium alloys, industries can tailor products to meet specific needs, enhancing performance and efficiency. This adaptability not only fosters creativity but also drives cost-effective solutions that can outperform traditional materials like titanium.

The Value of Customized Solutions

Customized solutions are invaluable in today’s competitive landscape, particularly when it comes to specialized applications involving shape memory alloys such as Nitinol flowers. The ability to tailor designs using nitinol allows companies to address specific challenges while optimizing functionality and reliability. Moreover, with ongoing advancements in technology, the customization process has become more efficient and accessible, making it an attractive option for various industries.

GEE SMA’s Role in Innovation

GEE SMA has established itself as a leader in the production of Nitinol flowers by emphasizing quality and innovation in its offerings. With a deep understanding of nitinol nickel titanium properties, GEE SMA continually pushes the boundaries of what is possible with shape memory alloys. Their commitment to excellence not only enhances product performance but also contributes significantly to successful applications across diverse fields, including aerospace and medical devices.

Choosing the Right Nitinol Supplier

When selecting a supplier for Nitinol flowers, it's crucial to consider factors such as expertise in nitinol production and a proven track record in quality assurance. As prices for titanium materials fluctuate due to market dynamics—like titanium price variations or titanium steel price changes—having a reliable supplier becomes even more essential for maintaining cost-effectiveness without compromising on quality. Ultimately, choosing the right supplier can make all the difference between success and mediocrity in your projects involving advanced materials like nitinol.