Introduction

Nitinol Alloy Foil is a remarkable material known for its unique properties and versatility in various applications. This shape-memory alloy, composed primarily of nickel and titanium, exhibits extraordinary characteristics such as superelasticity and the ability to return to a predetermined shape when heated. As industries increasingly seek innovative solutions, Nitinol Sheet has emerged as a game-changer across multiple sectors.

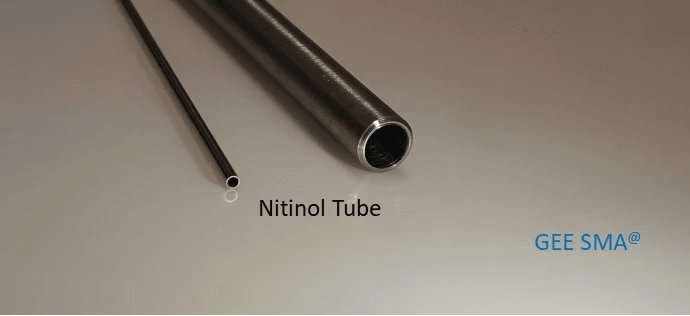

Overview of Nitinol Alloy Foil

Nitinol Alloy Foil stands out due to its distinctive ability to undergo significant deformation while maintaining its structural integrity. This characteristic allows it to be utilized in applications where flexibility and strength are paramount. The manufacturing process of Nitinol Sheet enables precise control over its properties, making it an ideal choice for cutting-edge technologies.

Key Properties of Nitinol Sheet

The most notable features of Nitinol Sheet include its shape-memory effect and superelastic behavior, which make it suitable for dynamic environments where traditional materials might fail. When subjected to temperature changes, Nitinol can revert to its original form, providing exceptional performance in various applications. Additionally, the corrosion resistance and biocompatibility of Nitinol Alloy Foil further enhance its appeal across diverse industries.

Industries Leveraging Nitinol Applications

From medical devices that save lives to aerospace innovations that push the boundaries of technology, the applications of Nitinol are vast and varied. Automotive engineering also benefits from the lightweight nature of Nitinol Sheet, contributing to safer and more efficient vehicles. Furthermore, consumer electronics increasingly incorporate this advanced material for enhanced durability and functionality, showcasing the widespread adoption of Nitinol in modern design.

Medical Devices

Nitinol, a remarkable alloy of nickel and titanium, has carved out a niche in the medical device industry thanks to its unique properties such as shape memory and superelasticity. These characteristics allow Nitinol Alloy Foil to be utilized in various applications, enhancing patient outcomes and revolutionizing surgical techniques. From stents to orthopedic implants, the versatility of Nitinol Sheet is truly impressive.

Stents and Implants

One of the most significant contributions of Nitinol Sheet to medicine is in the design of stents and implants. The ability of Nitinol Alloy Foil to expand upon heating makes it an ideal material for self-expanding stents that can navigate through complex vascular pathways before expanding to support blood vessels effectively. This dynamic capability not only ensures a better fit but also reduces the risk of complications during procedures.

Moreover, its biocompatibility allows for long-term implantation without adverse reactions, making it a preferred choice for orthopedic devices like bone screws and plates. As medical technology continues to advance, the use of Nitinol in these applications is likely to expand even further, leading to improved patient care and innovative treatment options.

Surgical Tools and Instruments

Nitinol Alloy Foil isn't just limited to implants; it's also making waves in surgical tools and instruments that require precision and reliability. Surgical devices made from Nitinol Sheet are often lighter yet stronger than traditional materials, allowing surgeons greater dexterity during procedures. The superelastic properties mean that tools can bend without breaking, providing flexibility where it's needed most.

In addition, many surgical instruments utilizing Nitinol are designed with minimal invasiveness in mind—think about those nifty laparoscopic tools that make surgeries less traumatic for patients! This innovation not only speeds up recovery times but also enhances overall surgical outcomes by reducing tissue damage.

Orthopedic Applications

The orthopedic field has embraced Nitinol's unique properties with open arms; after all, who wouldn’t want materials that can adapt dynamically? From spinal implants designed with shape memory capabilities to fracture fixation devices made from Nitinol Alloy Foil, these innovations are changing how orthopedic conditions are treated today. The lightweight nature of Nitinol Sheet significantly reduces stress on bones while still providing robust support.

Additionally, its ability to return to a predetermined shape means that surgeons can implant devices with confidence—they know it will perform as expected within the body over time. With ongoing research into new applications for this remarkable material, we can anticipate even more breakthroughs in orthopedic treatments powered by Nitinol's incredible versatility.

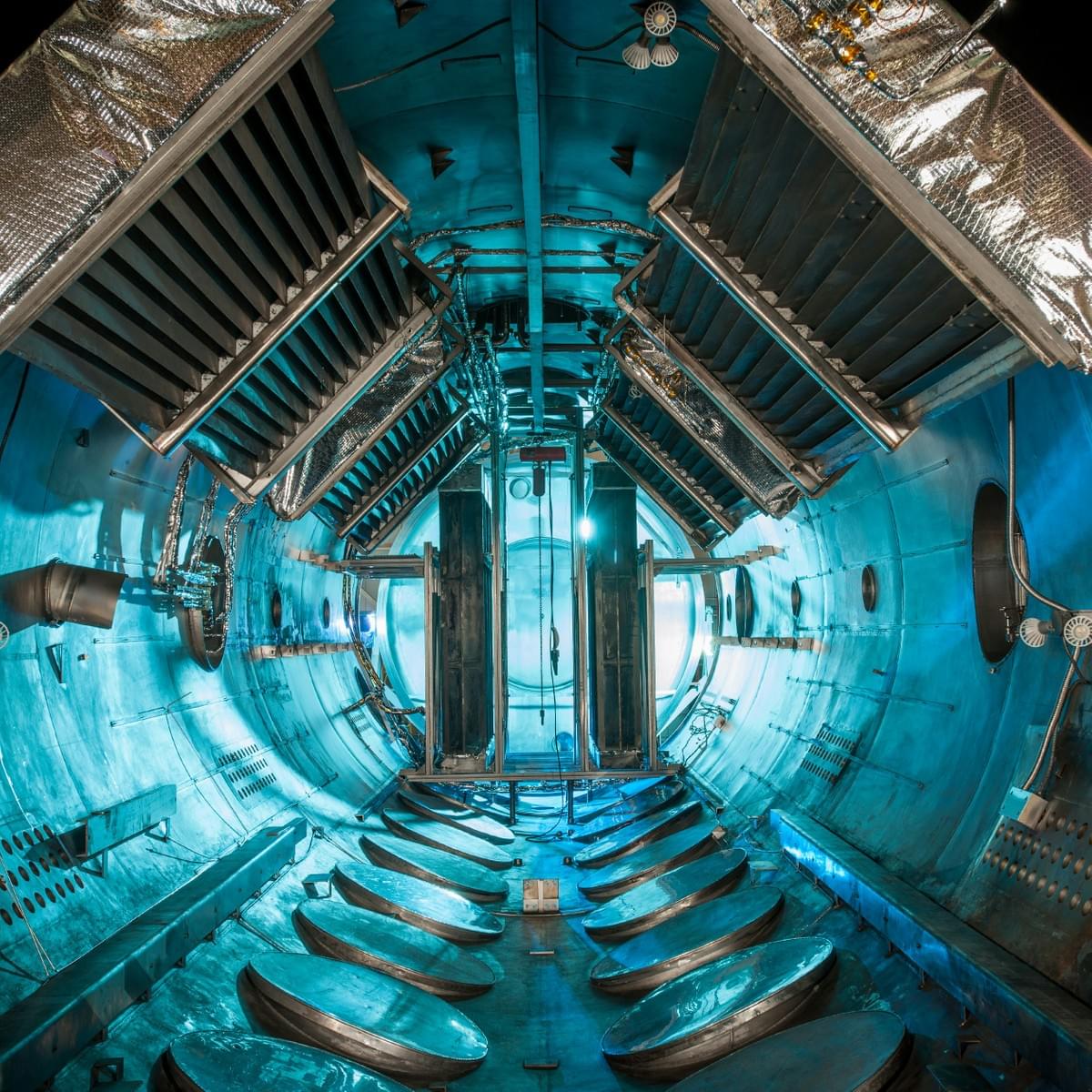

Aerospace Innovations

The aerospace industry is continuously evolving, and Nitinol Alloy Foil is at the forefront of this transformation. With its unique properties, this remarkable material is being harnessed for a variety of applications in space missions, enhancing performance and reliability. As we explore the role of Nitinol Sheet in aerospace innovations, it becomes clear that its versatility can lead to groundbreaking advancements.

Nitinol in Space Missions

Nitinol Alloy Foil has found a niche in space missions due to its exceptional strength-to-weight ratio and ability to undergo shape memory effects. This means that components made from Nitinol can return to their original shape after deformation, which is particularly useful in environments where extreme conditions are prevalent. From deployable structures to actuators used in satellite systems, the incorporation of Nitinol Sheet can significantly enhance mission success rates while minimizing weight.

Moreover, the resilience of Nitinol against temperature fluctuations makes it ideal for space applications where thermal extremes are common. Engineers are increasingly turning to Nitinol for critical components that must withstand harsh environments without compromising functionality or safety. As more missions venture into deep space, the role of Nitinol Alloy Foil will likely expand even further.

Temperature-Responsive Components

One of the standout features of Nitinol is its temperature-responsive nature, which allows it to change shape or stiffness based on thermal input. This characteristic opens up a realm of possibilities for aerospace applications where precise control over component behavior is essential. For instance, devices utilizing Nitinol Sheet can automatically adjust their configuration based on temperature changes encountered during flight or re-entry.

This adaptability not only enhances performance but also contributes to energy efficiency by reducing reliance on external power sources for actuation mechanisms. In addition, such temperature-responsive components can improve safety by ensuring that systems react appropriately under varying conditions encountered during missions. The integration of these advanced materials into aerospace technology exemplifies how innovation drives progress.

Benefits for Satellite Technologies

The benefits of using Nitinol Alloy Foil extend beyond just individual components; they encompass entire satellite systems as well. By integrating lightweight yet robust materials like Nitinol Sheet into satellite designs, engineers can achieve significant weight reductions without sacrificing structural integrity or functionality. This reduction in weight translates directly into cost savings during launch operations—an ever-important consideration when budgets are tight.

Furthermore, satellites equipped with temperature-responsive components made from Nitinol offer enhanced operational capabilities and longevity in orbit. These innovations allow for greater flexibility and responsiveness to environmental factors—crucial when satellites must adapt quickly to unforeseen circumstances or changing mission parameters. In summary, leveraging the unique properties of Nitinol Alloy Foil positions aerospace technologies at the cutting edge while paving the way for future advancements.

Automotive Engineering

The automotive industry is rapidly evolving, and Nitinol Alloy Foil is leading the charge in innovative solutions that enhance safety, efficiency, and performance. With its unique properties, including shape memory and superelasticity, Nitinol Sheet is becoming a go-to material for various automotive applications. As manufacturers seek to improve vehicle designs while meeting stringent safety regulations, the incorporation of Nitinol is proving to be a game changer.

Nitinol in Safety Features

Safety features are paramount in modern vehicles, and Nitinol plays a crucial role in enhancing these systems. The unique properties of Nitinol Alloy Foil allow it to be used in advanced seatbelt mechanisms and airbag deployment systems that can respond more effectively during an impact. By leveraging the shape memory effect of Nitinol Sheet, engineers can create components that automatically adjust to provide optimal protection for passengers.

Moreover, the flexibility and reliability of Nitinol make it ideal for crumple zones designed to absorb energy during collisions. These zones can be engineered with Nitinol components that adapt their shape upon impact, dissipating energy more efficiently than traditional materials. As car manufacturers continue to prioritize passenger safety, the integration of Nitinol will undoubtedly lead to smarter and more robust safety features.

Efficiency in Engine Components

Nitinol Alloy Foil isn't just about safety; it's also making waves under the hood with its application in engine components. The lightweight nature of Nitinol Sheet allows for significant weight reduction without compromising strength or durability—an essential factor as automakers strive for improved fuel efficiency and reduced emissions. This advantage positions Nitinol as an attractive alternative to conventional metals used in engine design.

Additionally, the temperature-responsive characteristics of Nitinol enable it to function effectively across varying thermal conditions within an engine compartment. By incorporating smart actuators made from this remarkable alloy into engine control systems, manufacturers can achieve better precision in managing fuel mixtures and combustion processes. This not only enhances performance but also contributes to overall vehicle efficiency.

Reducing Weight with Nitinol Alloy Foil

One of the most significant advantages of using Nitinol Alloy Foil in automotive engineering is its ability to reduce weight without sacrificing structural integrity. In an industry where every ounce counts towards fuel economy and performance metrics, lightweight materials like Nitinol Sheet are invaluable assets for modern vehicle design teams aiming for innovation while adhering to environmental standards.

By integrating this versatile material into various components—from suspension systems to chassis elements—automakers can create lighter vehicles that consume less fuel yet maintain high levels of performance and safety standards. Furthermore, as electric vehicles gain popularity, reducing weight becomes even more critical for extending battery life and maximizing range—areas where the use of Nitinol could prove transformative.

In conclusion, as we look toward a future where sustainability meets cutting-edge technology within automotive engineering, it's clear that materials like Nitinol Alloy Foil will play a pivotal role in shaping how we drive forward—literally!

Consumer Electronics

The consumer electronics sector is experiencing a revolution, and Nitinol Alloy Foil is at the heart of this transformation. With its unique properties, such as shape memory and superelasticity, Nitinol Sheet is proving to be an invaluable material for various applications. From wearables to flexible displays, the versatility of Nitinol is paving the way for innovative products that enhance user experience.

Nitinol for Wearable Technology

Nitinol's lightweight and flexible characteristics make it an ideal choice for wearable technology. Devices like fitness trackers and smartwatches benefit from Nitinol Alloy Foil due to its ability to conform to the body's movements while maintaining structural integrity. This adaptability not only improves comfort but also allows manufacturers to create sleeker designs that cater to style-conscious consumers.

Moreover, the temperature-responsive nature of Nitinol Sheet enables wearables to monitor body temperature or even adjust their fit based on environmental conditions. Imagine a smartwatch that tightens or loosens based on your wrist's temperature—this could soon be a reality thanks to Nitinol's innovative properties. As more companies explore these possibilities, we can expect a surge in advanced wearable technologies that leverage the advantages of Nitinol.

Flexible Displays and Sensors

The demand for flexible displays has skyrocketed in recent years, with consumers craving devices that seamlessly blend functionality with portability. Nitinol Alloy Foil plays a pivotal role in this evolution by providing essential support structures that allow screens to bend without compromising performance. The integration of Nitinol Sheet into display technology ensures durability while enabling manufacturers to push the boundaries of design.

In addition, sensors made from or reinforced with Nitinol can offer enhanced responsiveness and durability compared to traditional materials. These sensors can adapt their shape or position based on external stimuli, making them perfect for applications ranging from smartphones to smart home devices. As innovations continue in this area, we are likely to see more exciting products featuring flexible displays powered by cutting-edge materials like Nitinol.

Enhancing Durability of Devices

Durability is paramount in consumer electronics; nobody wants a device that breaks at the first drop! Here’s where Nitinol Alloy Foil steps up its game—its remarkable resilience makes it an excellent choice for reinforcing devices against accidental impacts or stressors. By incorporating Nitinol Sheet into their designs, manufacturers can produce gadgets that withstand daily wear and tear while remaining lightweight and stylish.

Furthermore, because of its superelastic properties, devices using Nitinol can recover from deformation without permanent damage—think about how advantageous this would be for everyday items like earbuds or cases! The use of this alloy not only enhances longevity but also reduces replacement costs for consumers over time. As brands recognize these benefits, we anticipate a growing trend toward incorporating advanced materials like Nitonl into future electronics design strategies.

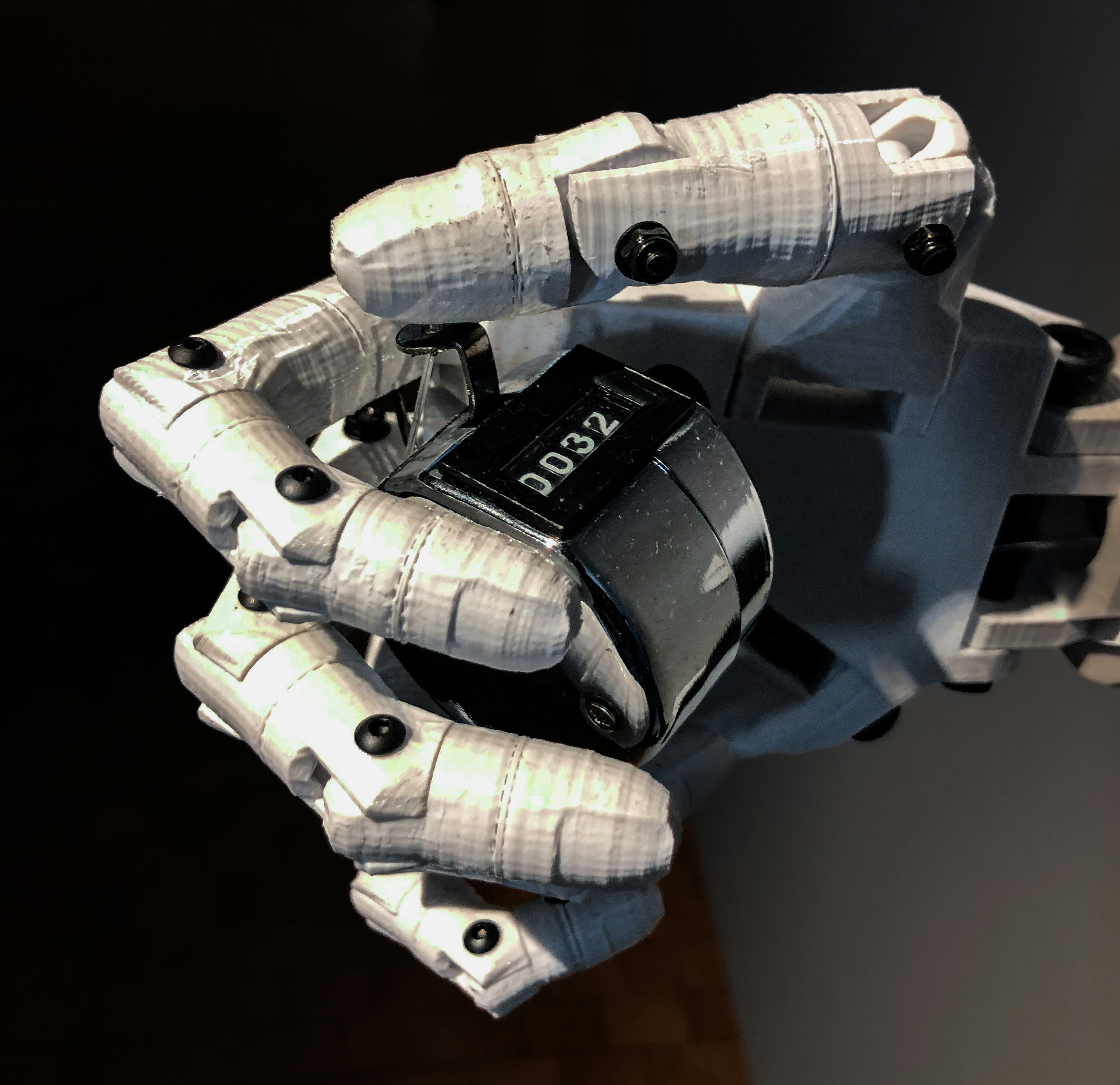

Robotics and Actuation

The integration of Nitinol Alloy Foil into robotics is revolutionizing the way machines interact with their environment. This unique material, with its shape memory and superelastic properties, allows for more sophisticated and responsive designs in robotic systems. As industries increasingly seek automation solutions, the demand for innovative materials like Nitinol Sheet is on the rise.

Nitinol in Robotic Grippers

Nitinol's remarkable characteristics make it an ideal choice for robotic grippers that require precision and adaptability. By utilizing Nitinol Alloy Foil, engineers can create grippers that respond dynamically to varying loads and shapes of objects they handle. This adaptability not only enhances efficiency but also reduces the risk of damaging delicate items during manipulation.

Moreover, robotic grippers made from Nitinol Sheet can achieve a lighter design without sacrificing strength or functionality. This weight reduction is crucial in applications where speed and agility are paramount, such as assembly lines or surgical robots. As a result, incorporating Nitinol into these devices leads to improved performance and greater versatility across diverse tasks.

Smart Actuation Solutions

The field of smart actuation has seen tremendous advancements thanks to Nitinol's unique properties. With its ability to change shape in response to temperature changes, Nitinol Alloy Foil enables the development of compact actuators that can perform complex movements with minimal energy consumption. These smart actuation solutions are not only efficient but also highly responsive, making them perfect for applications ranging from prosthetics to automated machinery.

Incorporating Nitinol Sheet into actuators allows for designs that can integrate seamlessly into existing technologies while providing enhanced functionality. For example, these actuators can be programmed to mimic human-like motions or adapt their grip based on the object being handled—an invaluable feature in fields like rehabilitation robotics or manufacturing automation. The potential for customization further solidifies the role of Nitinol in creating smarter machines capable of performing intricate tasks.

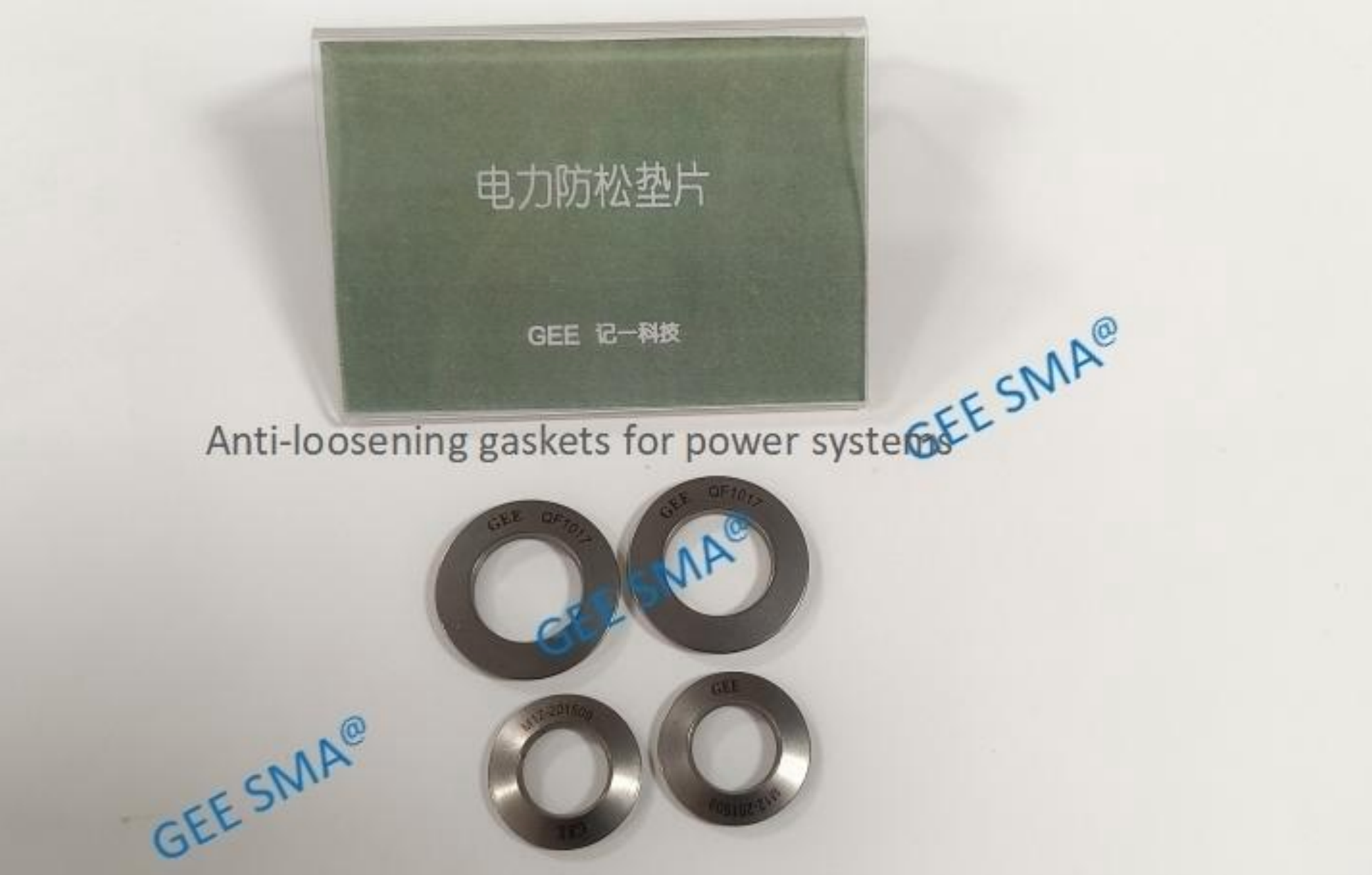

GEE SMA's Role in Advancements

GEE SMA has positioned itself at the forefront of innovations involving Nitinol Alloy Foil within robotics and actuation technologies. By focusing on research and development tailored toward optimizing the properties of Nitinol Sheet, GEE SMA is pioneering new applications that push the boundaries of what's possible in robotics today. Their commitment to advancing this material ensures that future robotic systems will be more efficient, adaptable, and capable than ever before.

Through collaborations with industry leaders and investment in cutting-edge technology, GEE SMA continues to expand its influence across various sectors utilizing robotics powered by Nitinol solutions. Their dedication not only enhances product performance but also drives forward-thinking approaches within engineering design principles—ultimately redefining how we perceive automation's role in our daily lives.

Conclusion

In wrapping up our exploration of Nitinol alloy foil, it's clear that this remarkable material boasts an impressive range of applications across various industries. From medical devices to aerospace innovations, the versatility of Nitinol sheet is simply astounding. As we look to the future, it’s exciting to consider how this unique alloy will continue to evolve and find new uses.

Nitinol Alloy Foil's Versatility

Nitinol alloy foil stands out for its unique properties, including shape memory and superelasticity, making it a game-changer in numerous sectors. This versatility allows engineers and designers to innovate without the constraints typically associated with traditional materials. Whether used in complex medical instruments or advanced aerospace components, the Nitinol sheet adapts seamlessly to meet diverse needs.

Future of Nitinol Applications

The future of Nitinol applications is bright and full of potential. As technology advances, we can expect further integration of Nitinol alloy foil into emerging fields such as robotics and consumer electronics. The ongoing research into enhancing its properties will likely lead to even more groundbreaking uses that we can't yet imagine.

GEE SMA's Commitment to Innovation

GEE SMA has consistently demonstrated a commitment to innovation in the field of shape memory alloys, particularly with their focus on developing high-quality Nitinol sheet products. Their dedication not only supports current applications but also paves the way for future advancements in various industries. With GEE SMA at the helm, we can anticipate exciting developments that will push the boundaries of what’s possible with Nitinol alloy foil.