Introduction

In the realm of advanced materials, the Niti sheet stands out as a remarkable innovation. Composed primarily of nitinol, an alloy of nickel and titanium, this unique sheet metal exhibits extraordinary properties, making it indispensable in various cutting-edge applications. Understanding the significance of Niti sheets is crucial for anyone involved in modern engineering and manufacturing.

What is a Niti Sheet?

A Niti sheet is a specialized form of sheet metal made from nitinol, which is an alloy consisting of nickel and titanium. This combination gives the Niti sheet its unique ability to undergo shape memory effects and superelasticity, setting it apart from traditional nickel materials. Unlike standard nickel plates, which lack these advanced properties, Niti sheets can return to their original shape after deformation when exposed to specific temperature conditions.

Importance of Nitinol in Innovative Projects

Nitinol plays a pivotal role in innovative projects across multiple industries due to its versatility and performance characteristics. Its unique properties allow for advancements in medical devices, aerospace components, and automotive technologies that were previously thought impossible with conventional materials. As engineers seek solutions that combine strength with flexibility, the demand for nitinol—and consequently for Niti sheets—continues to rise.

Overview of Applications in Various Industries

The applications of Niti sheets span a wide array of industries, showcasing their adaptability and effectiveness. In the medical field, nitinol is utilized in stents and guidewires that benefit from its superelasticity; meanwhile, aerospace innovations leverage its lightweight yet robust nature for improved fuel efficiency and performance. Automotive manufacturers are also exploring nitinol technology to enhance safety features and reduce vehicle weight—demonstrating that this remarkable material has become integral to modern engineering solutions.

Understanding Niti Sheets

Niti sheets, made from the remarkable alloy known as Nitinol, have garnered attention across various industries due to their unique properties. This section will delve into the composition and properties of Nitinol, highlight how it stands out from other nickel materials, and discuss the advantages of utilizing Nitinol sheets in manufacturing and design.

Composition and Properties of Nitinol

Nitinol is an intriguing alloy primarily composed of nickel and titanium, typically featuring a composition of about 55% nickel and 45% titanium. This specific ratio gives rise to its exceptional properties, including shape memory effect and superelasticity—meaning it can return to its original shape after deformation when heated above a certain temperature. Such characteristics make the nitinol sheet not only versatile but also invaluable in applications where precision and resilience are paramount.

The unique phase transformation that occurs within Nitinol allows it to exhibit different mechanical behaviors depending on temperature changes. When cooled below its transformation temperature, a nitinol sheet can be deformed easily; however, once heated above this threshold, it regains its pre-deformed shape with remarkable force. These extraordinary attributes set nitinol apart from conventional nickel plates or other nickel materials typically used in industrial applications.

How Nitinol Differs from Other Nickel Materials

While many may associate nickel with strength and corrosion resistance, Nitinol takes these qualities to new heights through its innovative alloying with titanium. Unlike traditional nickel materials that remain rigid at varying temperatures, the nitinol sheet's ability to undergo phase transformations provides unmatched flexibility in design options for engineers and designers alike. This means that products made from nitinol can perform effectively under dynamic conditions without compromising structural integrity.

Moreover, while standard nickel plates may corrode over time or lose their effectiveness when subjected to stress or strain, nitinol exhibits superior fatigue resistance thanks to its unique microstructure. The combination of these properties allows for longer-lasting products that require less maintenance—a crucial factor for industries like medical devices where reliability is non-negotiable. Thus, understanding how nitinol differs fundamentally enhances appreciation for why it's becoming increasingly popular across multiple sectors.

Advantages of Using Nitinol Sheets

The advantages of using nitinol sheets extend beyond just their fascinating properties; they offer practical benefits that appeal to various industries seeking innovative solutions. For instance, the lightweight nature of a nitinol sheet makes it an ideal choice for aerospace applications where weight reduction is critical for fuel efficiency without sacrificing performance or safety standards. In addition to being lightweight, their inherent biocompatibility makes them perfect candidates for medical devices such as stents or guidewires.

Another significant advantage lies in cost-effectiveness over time; although the initial nitinol price may be higher than traditional nickel materials like standard nickel plates or sheets due to complex manufacturing processes involved in producing high-quality alloys, the longevity and reduced maintenance costs often outweigh initial investments significantly. Furthermore, manufacturers benefit from increased design freedom since these sheets can be shaped into complex geometries that would otherwise be impossible with conventional metals.

In conclusion, understanding the composition and unique properties of nitinol—alongside recognizing how it differs from other nickel materials—highlights why industry leaders are turning toward this innovative material solution more than ever before while reaping numerous advantages associated with using a nimble yet robust medium like a nitinol sheet.

Applications of Niti Sheets

Niti sheets, made from the remarkable nitinol nickel titanium alloy, are revolutionizing various industries with their unique properties. Their shape memory and superelastic characteristics make them ideal for a range of applications that require flexibility and resilience. Let's dive into some specific fields where nitinol is making waves.

Medical Devices Utilizing Nitinol

In the medical field, nitinol's unique attributes have led to groundbreaking innovations in device design and functionality. From stents to guidewires, the use of Niti sheets allows for minimally invasive procedures that can adapt to the body's natural movements. The biocompatibility of nitinol nickel titanium also plays a crucial role in ensuring patient safety and comfort, making these devices not just effective but also reliable.

Moreover, the shape memory effect of nitinol enables medical devices to return to a predetermined shape when heated, allowing for precise deployment within the body. This characteristic is particularly beneficial in applications like vascular stenting, where a flexible yet strong material is essential. With ongoing advancements in technology, we can expect even more innovative uses for Niti sheets in medical applications.

Aerospace Innovations with Nitinol

The aerospace industry is another domain where Niti sheets are proving invaluable due to their lightweight and durable nature. Engineers are increasingly incorporating nitinol into aircraft components to enhance performance while reducing weight—a critical factor in aviation efficiency. The ability of nitinol to withstand extreme temperatures and stresses makes it an ideal candidate for applications ranging from actuators to structural components.

Nitinol's superelastic properties also allow for innovative designs that can adapt under varying conditions without permanent deformation. This adaptability could lead to safer and more efficient aircraft designs as engineers explore new possibilities with this versatile nickel material. As aerospace technology continues to advance, we can anticipate further integration of nitinol sheet metal into future innovations.

Automotive Uses of Nitinol Technology

In the automotive sector, the application of Niti sheets is gaining traction as manufacturers seek materials that enhance vehicle performance while reducing weight and improving fuel efficiency. The use of nitinol nickel titanium components can lead to advancements in areas such as active suspension systems or temperature-responsive actuators that adjust automatically based on driving conditions.

Additionally, because Niti sheets can exhibit both strength and flexibility under stress, they offer promising solutions for safety features such as crumple zones designed to absorb impact energy during collisions effectively. As automotive technology evolves towards greater sustainability and efficiency, integrating nitinol technology will likely play a significant role in shaping future vehicles.

Nitinol Price Factors

When it comes to the pricing of nitinol, several factors come into play that can influence how much you’ll pay for this innovative material. As the demand for nitinol sheets grows across various industries, understanding market trends becomes essential for manufacturers and consumers alike. The interplay between supply and demand, along with production costs, creates a dynamic pricing environment that anyone interested in nitinol must navigate.

Market Trends in Nitinol Pricing

In recent years, the market for nitinol sheets has seen significant fluctuations in pricing due to varying demand levels across different sectors. Industries such as medical devices and aerospace are driving the need for high-quality nitinol nickel titanium products, which can lead to increased prices as suppliers strive to meet these demands. Additionally, global economic conditions and trade policies can impact the availability of raw materials used in producing nitinol sheets, further affecting their price.

Influences on Nitinol Cost

Several factors contribute to determining the cost of nitinol beyond mere market trends; raw material sourcing is one of them. The composition of nitinol includes nickel and titanium, both of which have their own price volatility based on mining output and geopolitical factors affecting supply chains. Furthermore, manufacturing processes specific to producing sheet metal from these materials add additional costs—whether it’s machining or heat treatment—ultimately influencing the final price tag on a nitinol sheet.

Comparing Nitinol to Traditional Nickel Plates

When comparing nitinol sheets to traditional nickel plates, it's crucial to consider not only the upfront costs but also the long-term benefits associated with each material type. While traditional nickel plates may appear more affordable initially, they often lack the unique properties that make nitinol so appealing—such as shape memory and superelasticity—which can provide significant advantages in applications like medical devices or aerospace components. Therefore, while you might pay a premium for a nitinol sheet today, its exceptional performance could save you money over time by reducing maintenance or replacement needs.

Niti Sheet in Manufacturing

The manufacturing of Niti sheets involves several specialized processes that ensure the unique properties of nitinol nickel titanium are preserved and enhanced. These processes not only cater to the physical attributes of the material but also facilitate its application across various industries. Understanding these processes is crucial for anyone looking to leverage the advantages of Niti sheets in their projects.

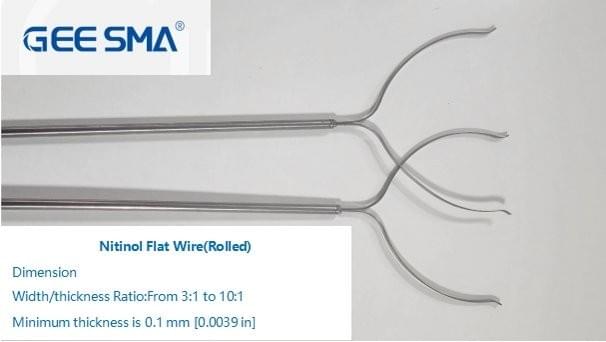

Common Processes for Nitinol Sheet Metal

Nitinol sheet metal undergoes a series of intricate processes that begin with alloying nickel and titanium in precise ratios to create an optimal nitinol composition. Once the alloy is created, techniques such as hot rolling and cold working are employed to achieve desired thicknesses and mechanical properties, transforming raw materials into flexible yet durable Niti sheets. Post-processing steps like annealing are vital, as they enhance shape memory characteristics, making these sheets ideal for applications such as medical devices and aerospace components.

Additionally, cutting methods like laser or waterjet cutting are commonly used to shape nitinol sheet metal into specific designs while maintaining high precision. The ability to manipulate these sheets without compromising their integrity is what sets nitinol apart from traditional nickel plates, offering engineers innovative solutions tailored to their needs. As demand grows, manufacturers continually refine these processes, ensuring that quality remains paramount while meeting market requirements.

Quality Control in Nitinol Production

Quality control is a non-negotiable aspect when it comes to producing reliable nitinol products; after all, even minor defects can lead to significant failures in critical applications like medical devices or aerospace technologies. Manufacturers implement rigorous testing protocols at each stage of production—from raw material inspection through final product evaluation—to guarantee that every batch meets stringent industry standards for performance and safety. Techniques such as X-ray diffraction and scanning electron microscopy help identify any irregularities within the structure of Niti sheets.

Moreover, adherence to international standards ensures that the nitinol produced is consistent in quality and performance across batches, which is essential when comparing prices against other nickel materials like traditional nickel plates. By investing in state-of-the-art equipment and skilled personnel dedicated to quality assurance, manufacturers can confidently supply high-quality Nitinol sheet products that meet diverse industry demands without compromising on safety or efficacy.

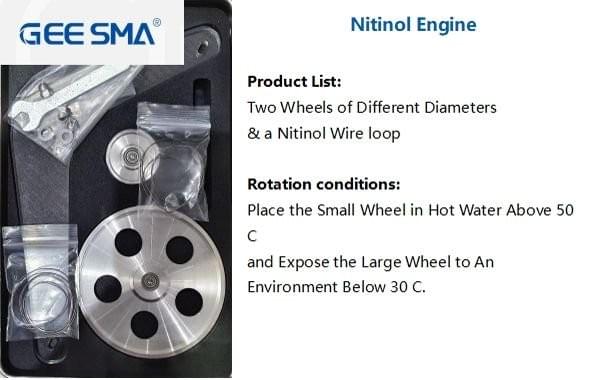

Case Study: GEE SMA's Role in Nitinol Manufacturing

GEE SMA has carved out a niche in the competitive landscape of nitinol manufacturing by focusing on innovation and quality control throughout their production process. Their commitment to utilizing advanced techniques allows them not only to produce high-quality nitinol sheets but also ensures they remain competitive regarding nitinol price compared to other manufacturers. By investing heavily in research and development, GEE SMA has pioneered new methods for enhancing the properties of their Niti sheets while maintaining cost-effectiveness.

One notable achievement includes their proprietary annealing process designed specifically for optimizing shape memory effects within their nitinol products—an essential characteristic for applications ranging from stents in medical devices to actuators in aerospace engineering. Through strategic partnerships with various industries, GEE SMA continues pushing boundaries by integrating customer feedback into product development cycles—ensuring that each new iteration meets real-world challenges head-on while reinforcing its reputation as a leader in Nitinol manufacturing.

Future Innovations with Nitinol

Nitinol, the remarkable nickel titanium alloy, is poised for a future filled with innovation and transformative applications. As industries continue to explore the unique properties of Niti sheets, we can expect groundbreaking advancements in technology and engineering. From medical devices to aerospace applications, the versatility of nitinol sheet metal is just beginning to be realized.

Emerging Technologies Using Nitinol

The emergence of smart materials has opened up exciting avenues for the use of nitinol in various technologies. For instance, in robotics, nitinol's shape memory effect allows for the creation of actuators that can mimic natural muscle movements; this is particularly useful in prosthetics and soft robotics. Moreover, developments in self-healing materials are also leveraging nitinol’s properties to create components that can return to their original shape after deformation.

In addition to robotics, sectors like telecommunications are exploring how Niti sheets can enhance signal transmission through flexible antennas made from this nickel material. These antennas not only improve performance but also reduce weight—a critical factor in modern devices. Furthermore, innovations in energy harvesting systems are incorporating nitinol due to its ability to convert thermal energy into mechanical work efficiently.

Predictions for Nitinol Advancements

Looking ahead, it’s anticipated that advancements in manufacturing techniques will significantly lower the nitinol price while enhancing quality and availability. The development of new alloys and processing methods could lead to even more robust applications across industries like automotive and aerospace—fields where every gram counts towards efficiency and performance. As research continues into optimizing the characteristics of Niti sheets, we may see them integrated into everyday consumer products as well.

Moreover, with increasing investment in nanotechnology, it’s likely that we’ll witness miniaturization trends where tiny components made from nitinol revolutionize electronics and wearable tech. This trend could pave the way for a new generation of devices that respond dynamically to environmental changes or user inputs seamlessly—thanks largely to their flexible yet durable nature derived from nickel titanium alloy properties.

The Role of Nitinol in Sustainability

Sustainability is becoming a pivotal focus across all industries; here too, nitinol shows promise as an eco-friendly alternative compared to traditional nickel plates or other materials that may not offer similar benefits without environmental trade-offs. The ability of Niti sheets to undergo significant deformation without permanent damage means they can contribute toward reducing waste during manufacturing processes—leading towards more sustainable production practices overall.

Additionally, because nitinol offers longevity due its fatigue resistance compared with conventional metals used today, products made from this innovative sheet metal might have longer lifespans—further minimizing resource consumption over time. As companies strive toward greener solutions while maintaining performance standards required by modern engineering demands, incorporating nitrile technology could serve as a key strategy toward achieving sustainability goals.

Conclusion

In wrapping up our exploration of Niti sheets, it’s clear that these innovative materials are at the forefront of modern engineering. The unique properties of nitinol nickel titanium make it a game-changer across various industries, from medical devices to aerospace innovations. Understanding the advantages and applications of nitinol sheets provides insight into why they are becoming indispensable in today's technological landscape.

Key Takeaways on Niti Sheets

Niti sheets, made from a specialized alloy of nickel and titanium, offer remarkable flexibility and shape memory characteristics that set them apart from traditional nickel plates. Their ability to return to a predetermined shape upon heating makes them ideal for applications requiring precision and reliability. As we’ve seen, the versatility of nitinol sheet metal allows for diverse uses, making it an essential material in innovative projects.

The Importance of Nitinol in Modern Engineering

Nitinol's significance in modern engineering cannot be overstated; its unique properties enable advancements that were once thought impossible. From enhancing the functionality of medical devices to improving the performance of aerospace components, nitinol is paving the way for future innovations. As industries increasingly turn to this exceptional nickel material, we witness a transformation in design possibilities and operational efficiencies.

Future Trends in Nitinol Applications

Looking ahead, the future trends surrounding nitinol applications are exciting and promising. Emerging technologies will likely harness the incredible capabilities of nitinol sheets to create even more sophisticated solutions across various sectors. With sustainability becoming a central focus globally, nitinol's potential role in eco-friendly designs further emphasizes its importance as we move toward a greener future.