Introduction

Nitinol, a unique alloy of nickel and titanium, has carved out a niche in various industries due to its remarkable properties. From medical devices to aerospace applications, the versatility of Nitinol sheets is unmatched, making them a go-to choice for engineers and designers alike. Understanding the intricacies of Nitinol and its applications is essential for anyone considering this innovative material.

Understanding Nitinol and Its Applications

Nitinol stands out not just for its composition but also for its incredible functionality in real-world applications. This metal plate alternative exhibits superelasticity and shape memory characteristics, allowing it to return to a predetermined shape when heated or deformed. Whether it's in stents that expand within arteries or robotic actuators that mimic human motion, Nitinol sheets are revolutionizing how we approach design challenges across multiple sectors.

The Advantages of Superelastic and Memory Alloys

One of the primary benefits of using Nitinol over traditional materials like titanium alloy or steel sheet is its superelastic behavior. This means that under stress, Nitinol can undergo significant deformation without permanent change—something conventional titanium plates simply can't match. Additionally, the memory alloy properties allow these sheets to remember their original shapes, providing unparalleled functionality in dynamic environments like robotics and medical devices.

Key Factors Influencing Nitinol Sheet Price

When considering the investment in Nitinol sheets, understanding what drives their price is crucial for budget-conscious projects. Factors such as raw material costs (including comparisons with nickel sheet or titanium alloy material), manufacturing processes, and market demand all play significant roles in determining the final price tag. By weighing these elements carefully against your project requirements, you can make informed decisions about whether to choose high-quality Nitinol over more conventional options like steel sheets or titanium plates.

What is Nitinol?

Nitinol, a remarkable alloy of nickel and titanium, is known for its unique properties that set it apart from traditional metals. This innovative material exhibits both shape memory and superelasticity, making it a popular choice in various industries, including medical devices and robotics. Understanding the composition and properties of Nitinol is essential for grasping its applications and advantages over other materials such as titanium alloys or steel sheets.

Composition and Properties

Nitinol's composition consists primarily of nickel (about 55%) and titanium (approximately 45%), which together create an alloy with extraordinary characteristics. The specific ratio can be adjusted to enhance certain properties, making Nitinol versatile for different applications. One of its most notable features is its ability to undergo significant deformation at room temperature while returning to its original shape when heated—a phenomenon that sets it apart from more conventional materials like titanium plates or metal plates.

The unique properties of Nitinol include high fatigue resistance, biocompatibility, and excellent corrosion resistance, which are crucial in medical applications where reliability is paramount. These attributes make Nitinol sheets an attractive option compared to alternatives like nickel sheets or steel sheets, which may not perform as well under similar conditions. Moreover, the ability to remember shapes makes Nitinol particularly valuable in creating devices that require precision and adaptability.

Comparison with Titanium Alloy Material

When comparing Nitinol with titanium alloy material, several factors come into play that highlight the strengths of each option. While titanium alloys are known for their strength-to-weight ratio and corrosion resistance, they lack the unique superelasticity that characterizes Nitinol sheets. This difference becomes especially significant in applications requiring dynamic movement or flexibility—areas where traditional titanium plate solutions might fall short.

Furthermore, the processing techniques for both materials vary considerably; while titanium alloys often require extensive machining due to their hardness, Nitinol can be formed into complex shapes through simpler methods due to its inherent flexibility when heated above a certain temperature threshold. This ease of fabrication can ultimately impact production costs—something worth considering when evaluating Nitinol sheet price versus that of titanium materials or steel sheets.

Lastly, it's essential to note that while both materials offer impressive mechanical properties, the choice between them often depends on specific application requirements such as weight constraints or environmental factors. For instance, industries focusing on lightweight structures may prefer Nitinol despite potentially higher costs compared to cheaper options like nickel sheets or standard metal plates.

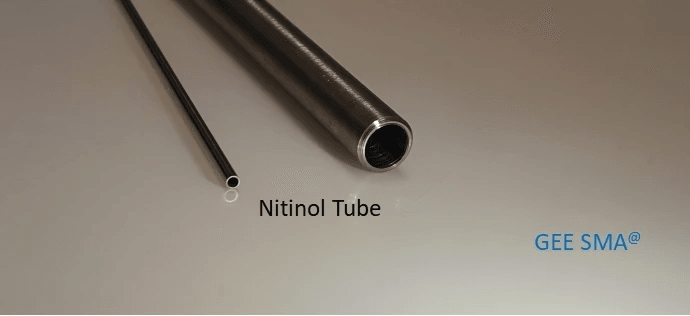

Unique Characteristics of Nitinol Sheets

Nitinol sheets boast several unique characteristics that distinguish them from other metal options available in today’s market. One standout feature is their superelastic behavior at body temperature—allowing them to absorb energy during deformation without permanent change—which makes them ideal for use in medical devices such as stents or guidewires where flexibility is crucial. Unlike traditional materials like steel sheets or even some forms of titanium alloy material that may fracture under stress, Nitinol maintains integrity while adapting to external forces.

Moreover, these unique characteristics extend beyond just mechanical performance; they also include exceptional biocompatibility due to their nickel-titanium composition being well-tolerated by human tissue. This quality makes them highly sought after within the biomedical sector where safety cannot be compromised—an area where alternatives like standard metal plates would likely fail without further treatment or coating processes.

In summary, understanding what makes up these remarkable alloys helps illuminate why they are becoming increasingly popular across various fields—from aerospace engineering requiring lightweight components capable of enduring harsh conditions to robotics benefiting from adaptable parts designed for intricate movements—all while keeping an eye on factors such as overall cost and availability related to current trends in pricing for products like the ever-intriguing Nitinol sheet price.

Exploring Superelasticity in Nitinol

This unique behavior allows Nitinol to undergo significant deformation and return to its original shape without permanent changes, making it an incredibly versatile option for various applications. Understanding how this phenomenon works is crucial for industries looking to leverage the advantages of superelastic materials over traditional options like titanium alloy or steel sheets.

How Superelastic Behavior Works

Superelasticity in Nitinol occurs due to its unique crystalline structure, which enables the material to absorb considerable stress and strain without yielding. When deformed beyond a certain limit, the material transforms from austenite to martensite and can revert back when the stress is removed, showcasing a fascinating interplay of physics and metallurgy. This ability not only enhances performance but also reduces failure rates compared to conventional metal plates or titanium plate alternatives.

The transformation temperatures of Nitinol are critical; they can be tailored during production, allowing manufacturers to customize properties based on specific applications. This adaptability is one reason why Nitinol sheet prices may vary significantly based on desired specifications and performance criteria. By understanding these mechanisms, industries can better appreciate why investing in high-quality Nitinol sheets may yield superior results compared with nickel sheets or traditional steel sheets.

Applications in Medical Devices

One of the most prominent applications of superelastic Nitinol is in medical devices such as stents and guidewires. The combination of flexibility and strength allows these devices to navigate complex anatomical structures while maintaining their integrity under pressure—a feat that traditional titanium alloy materials might struggle with under similar conditions. As healthcare technology advances, the demand for reliable components made from superelastic materials continues to rise.

Nitinol's biocompatibility further enhances its appeal within medical applications; it poses minimal risk of adverse reactions when implanted into the human body compared to some metal plates or other alloys that may cause complications over time. The unique characteristics of Nitinol also allow for designs that are less invasive while providing optimal support—an essential consideration in modern surgical practices where patient recovery times are paramount. With the growing trend towards minimally invasive procedures, understanding Nitinol sheet price becomes vital for companies aiming at cost-effective yet high-performance solutions.

Advantages Over Traditional Metal Plates

When comparing Nitinol sheets with traditional metal plates made from steel or titanium alloy material, several advantages become evident. First off, superelasticity means that devices crafted from Nitinol can absorb shocks and stresses much more effectively than their rigid counterparts—think of it as having a flexible friend who can bounce back after every challenge! This resilience translates into enhanced durability and longevity for products used in demanding environments like aerospace or robotics.

Moreover, weight considerations cannot be overlooked; lighter materials lead to improved efficiency in various applications—from reducing energy consumption during transport processes to enhancing user comfort in wearable technology devices. In many cases, investing in high-quality Nitinol may prove more economical than opting for heavier titanium plates or nickel sheets when considering long-term performance outcomes versus initial costs associated with manufacturing processes involving different metals.

In summary, as industries increasingly recognize the potential benefits offered by superelastic materials such as Nitinol over traditional options like steel sheets or titanium alloy materials—both regarding functionality and overall value—demand will likely continue rising alongside awareness about competitive pricing strategies related specifically around varying qualities within this innovative category.

Memory Alloys: The Magic of Nitinol

Nitinol is often referred to as a memory alloy due to its unique ability to return to a predetermined shape when heated. This fascinating property allows Nitinol sheets to be used in various applications where flexibility and durability are paramount. The magic lies in the transformation that occurs at specific temperatures, making it a standout material compared to traditional metal plates like steel or even titanium alloy materials.

How Nitinol Sheets Remember Shapes

The secret behind how Nitinol sheets remember shapes is rooted in their crystalline structure, which can shift between two distinct phases: martensite and austenite. When the material is deformed at lower temperatures, it retains this new shape until it is heated above a certain threshold, prompting it to revert back to its original form. This remarkable feature not only enhances the performance of devices made from Nitinol but also offers significant advantages over conventional options like titanium plates and nickel sheets.

In practical terms, this means that engineers can design components that can change shape under specific conditions without permanent deformation. As industries increasingly seek innovative solutions, understanding how these memory alloys function becomes crucial for harnessing their potential effectively. With rising interest in advanced materials, the Nitinol sheet price reflects its sophisticated capabilities and unique properties.

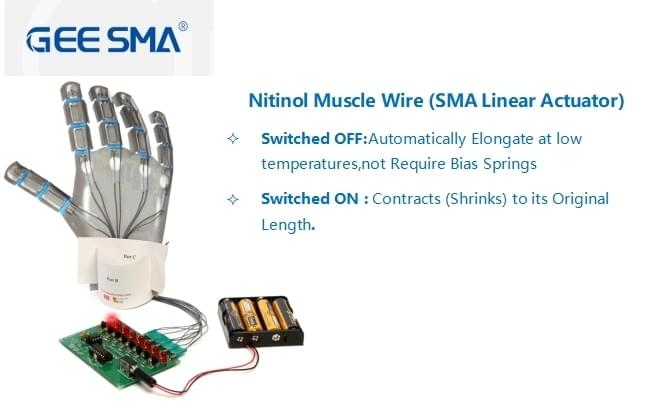

Uses in Aerospace and Robotics

Nitinol's memory alloy characteristics make it particularly appealing for applications in aerospace and robotics where weight reduction and reliability are essential. In aerospace engineering, components made from Nitinol can adapt dynamically during flight conditions, leading to enhanced performance while minimizing overall weight compared to traditional materials like steel sheets or titanium alloy materials. These features enable engineers to design more efficient systems that can withstand extreme environments while maintaining structural integrity.

Robotics also benefits immensely from the unique properties of Nitinol; actuators made from this material can perform complex movements with minimal power consumption due to their superelasticity and shape memory effects. This allows for more compact designs without sacrificing functionality or efficiency—an important consideration when evaluating alternatives like titanium material or other metal plates. As industries continue exploring cutting-edge technologies, the role of Nitinol will likely expand further into various applications across sectors.

The Role of GEE SMA in Advancements

GEE SMA has been at the forefront of advancements involving Nitinol technology by providing high-quality products tailored for diverse industrial needs. Their commitment ensures that customers receive reliable solutions that leverage the exceptional properties of memory alloys without compromising on quality or performance—key factors influencing both project success rates and cost-effectiveness against alternatives such as nickel sheets or titanium plate options available on the market today.

Moreover, GEE SMA’s innovations have led to developments that enhance production efficiency while keeping an eye on competitive pricing structures within the industry—making them a valuable partner for businesses looking into incorporating advanced materials like Nitinol into their operations without breaking the bank on high-end options alone. As demand continues growing for lightweight yet resilient solutions across multiple fields—from robotics engineering projects aiming for precision control capabilities down through aerospace design considerations—the contributions from GEE SMA stand out prominently among competitors striving toward similar goals.

Cost Analysis: Nitinol Sheet Price Breakdown

Factors Affecting Nitinol Pricing

The Nitinol sheet price is primarily influenced by its composition and the manufacturing process involved in creating these specialized alloys. The intricate balance of nickel and titanium in the alloy affects both performance and cost; more precise compositions often lead to higher prices due to increased processing requirements. Additionally, advancements in technology for producing high-quality Nitinol sheets can also drive up costs as manufacturers invest in better equipment and techniques.

Another significant factor is market demand within industries such as aerospace, medical devices, and robotics where Nitinol's unique properties are indispensable. As industries increasingly turn towards innovative materials for enhanced performance—like metal plates that can adapt under stress—the competition for high-quality Nitinol sheets rises accordingly. This heightened demand can create a ripple effect on pricing structures across different types of metal sheets.

Comparison to Nickel Sheets and Steel Sheets

When comparing the Nitinol sheet price with nickel sheets or steel sheets, it's clear that while steel remains one of the most cost-effective options for general applications, it lacks the advanced properties found in Nitinol. Steel sheets are durable but do not possess superelasticity or shape memory capabilities like those offered by titanium alloy materials or specifically designed titanium plates. Consequently, while nickel sheets might have similar elemental components as Nitinol, they cannot match its performance characteristics—making them less suitable for specialized applications.

Moreover, when you consider long-term value rather than just upfront costs, investing in quality Nitinol may actually be more economical over time due to lower failure rates and maintenance needs compared to traditional metal plates or even premium titanium alloy materials. In sectors where reliability is paramount—like medical devices—the initial higher investment into a superior product pays off significantly through enhanced safety and functionality.

Value of Investing in Quality Nitinol

Investing in quality Nitinol not only brings superior performance but also ensures longevity which is crucial across various applications—from aerospace engineering to cutting-edge robotics designs. While the initial purchase may reflect a higher price tag compared to alternatives like steel or nickel sheets, this investment translates into fewer replacements and repairs down the line due to its exceptional durability under varying conditions.

Furthermore, companies that choose high-quality titanium material or advanced titanium alloy materials find themselves at an advantage when it comes to innovation; they can leverage unique features such as superelasticity which opens doors for new design possibilities that simply aren’t feasible with conventional metal plates or lower-grade alloys. Henceforth, when evaluating options based on overall functionality versus mere cost metrics alone reveals how investing wisely into premium products like top-tier Nitinol pays dividends well beyond mere numbers.

Choosing the Right Nitinol Sheet

When it comes to selecting the right Nitinol sheet for your project, there are several factors to consider. First and foremost, you need to determine the specific requirements of your application, including mechanical properties and thermal behavior. Additionally, understanding how Nitinol compares to alternatives like titanium alloy materials or steel sheets can help you make an informed decision that aligns with your budget and performance expectations.

Considerations for Your Project

Before diving into the world of Nitinol sheets, it's essential to assess the unique demands of your project. Are you looking for superelastic properties that outperform traditional metal plates? Or perhaps you're in need of a shape memory effect that only a high-quality Nitinol sheet can provide? By clarifying these needs, you can better evaluate how Nitinol compares not only with titanium material but also with nickel sheets and titanium plates.

Another critical consideration is the environment in which your chosen material will be used. Factors such as temperature fluctuations, exposure to corrosive substances, and mechanical stress levels all play a role in determining whether a Nitinol sheet is suitable for your application. This is particularly important when weighing options against other materials like steel sheets or various titanium alloy materials.

Lastly, don’t overlook budget constraints when analyzing Nitinol sheet prices. While they may initially seem higher than alternatives like nickel sheets or even some types of titanium alloy material, investing in quality often pays off in terms of durability and performance over time.

GEE SMA's Nitinol Offerings

GEE SMA specializes in providing a diverse range of high-quality Nitinol products tailored to meet various industry needs. Their offerings include standard sheets as well as custom sizes designed specifically for unique applications across sectors such as aerospace, robotics, and medical devices. With their competitive pricing strategy on Nitinol sheet price compared to other metals like steel or titanium plates, GEE SMA ensures that customers receive exceptional value without sacrificing quality.

One standout feature of GEE SMA's product line is their commitment to rigorous testing and quality assurance processes that guarantee optimal performance under demanding conditions. This dedication not only enhances the reliability of their products but also instills confidence among clients who understand that they are investing in superior materials compared to traditional metal plates or even other alloys like titanium alloy material.

Furthermore, GEE SMA provides comprehensive support during the selection process—helping customers navigate through technical specifications while offering insights on how their products stack up against competitors’ offerings including nickel sheets and other similar materials.

Customer Testimonials and Case Studies

The proof is always in the pudding—or rather, in customer experiences! Numerous testimonials highlight how businesses have thrived after choosing GEE SMA’s high-quality Nitinol sheets over traditional options such as steel or titanium alloy materials. Customers frequently rave about improved efficiency and reduced failure rates due to the unique properties inherent in these advanced alloys.

In one case study involving a medical device manufacturer, switching from conventional metal plates made from stainless steel resulted in significant weight savings without compromising structural integrity thanks to GEE SMA's superelastic Nitinol sheets. Similarly, aerospace engineers have reported enhanced performance metrics after integrating these innovative solutions into their designs—showing just how transformative quality materials can be compared to more common alternatives like nickel sheets or standard titanium plate options.

With such compelling success stories backing them up, it’s clear why choosing GEE SMA for your next project could be one of the smartest investments you make—especially when considering long-term value against fluctuating market prices on items like Nitinol sheet price!

Conclusion

In summary, Nitinol has emerged as a game-changer in various industries, thanks to its unique properties and applications. The future of Nitinol in industry looks bright, with ongoing research and development paving the way for innovative uses that could further enhance its appeal over traditional materials like titanium alloy or steel sheet. As more sectors recognize the advantages of Nitinol, we can expect to see an increase in demand, which may influence Nitinol sheet price positively.

The Future of Nitinol in Industry

The potential for Nitinol is vast and spans across numerous fields such as medicine, aerospace, and robotics. With advancements in technology and material science, the versatility of Nitinol sheets is likely to expand even further, making them a preferred choice over conventional options like titanium plate or nickel sheet. As industries continue to seek lightweight yet durable materials that can withstand extreme conditions, the role of Nitinol will only grow stronger.

Exploring More Options Beyond Nitinol

While Nitinol offers remarkable benefits, it’s essential to consider other materials that may complement or compete with it in specific applications. Titanium alloy material and steel sheet remain popular choices for their strength and affordability; however, they lack some unique characteristics found only in memory alloys like Nitinol. Exploring these alternatives can provide valuable insights into how different materials can work together or serve distinct functions within various projects.

Why GEE SMA Stands Out in Quality

When it comes to sourcing high-quality materials like Nitinol sheets, GEE SMA sets itself apart from competitors by offering consistent quality and exceptional customer service. Their extensive range of products ensures that clients find exactly what they need without compromising on performance or reliability—qualities often associated with traditional metal plates like titanium material or nickel sheets. Plus, customer testimonials highlight not just satisfaction but also successful project outcomes directly tied to using GEE SMA's superior offerings.