Introduction

In the realm of advanced materials, few have garnered as much attention as Nitinol, a remarkable alloy known for its unique shape memory properties. This extraordinary capability allows Nitinol bar stock to revert to a predetermined shape when subjected to specific temperatures, making it an invaluable resource in various industries, especially medicine. As we delve deeper into the significance of Nickel Titanium Alloy Round Bar, it becomes clear that its applications are both innovative and life-saving.

Understanding Nitinol Shape Memory Alloys

Nitinol is a nickel-titanium alloy that exhibits two fascinating phenomena: superelasticity and the shape memory effect. These characteristics arise from the alloy's unique crystalline structure, which enables it to undergo significant deformation while returning to its original form upon heating. This makes Nitinol bar stock not only flexible but also incredibly reliable in high-stress environments, setting it apart from traditional metals.

The Significance of NiTi Bar in Medicine

The medical field has embraced Nickel Titanium Alloy Round Bar for its biocompatibility and versatility in various applications. From stents that expand within arteries to wires used in orthodontics, the significance of NiTi bars cannot be overstated; they offer solutions that enhance patient outcomes while minimizing invasive procedures. With their ability to conform and adapt within biological systems, Nitinol components are transforming how we approach medical device design.

Applications of Nickel Titanium Alloy Round Bar

The applications of Nickel Titanium Alloy Round Bar extend far beyond traditional uses; they are at the forefront of innovation in minimally invasive surgeries and advanced surgical tools. In addition to cardiovascular devices like stents and catheters, these alloys are being explored for use in orthopedic implants and even robotic surgery instruments. As technology continues to advance, the potential for Nitinol bar stock appears limitless, promising exciting developments on the horizon.

What is Nitinol?

Nitinol, a remarkable alloy of nickel and titanium, has garnered attention for its unique properties and applications, particularly in the medical field. This innovative material stands out due to its ability to undergo significant transformations in shape and structure under varying temperatures. Understanding the composition and properties of Nitinol is essential for appreciating its role in modern technology.

Composition and Properties of Nitinol

Nitinol is composed primarily of nickel (approximately 55-60%) and titanium (around 40-45%), which together create a unique intermetallic compound. This specific ratio contributes to its exceptional mechanical properties, including high strength, flexibility, and resilience. When discussing Nitinol bar stock, it’s crucial to highlight that these properties make it particularly suitable for applications where durability is paramount.

In addition to its chemical composition, Nitinol exhibits remarkable characteristics such as superelasticity and biocompatibility. Superelasticity allows the Nickel Titanium Alloy Round Bar to return to its original shape after deformation when subjected to stress at body temperature. Furthermore, its biocompatibility ensures that it can be safely used within the human body without adverse reactions.

The Unique Shape Memory Effect

One of the most fascinating features of Nitinol is its shape memory effect—a phenomenon where the material remembers its original form even after being deformed. When heated above a specific temperature known as the transformation temperature, deformed Nitinol can revert back to its pre-deformed shape with impressive precision. This property makes Nickel Titanium Alloy Round Bar an invaluable asset in various medical devices that require precise functionality.

The shape memory effect not only enhances device performance but also enables innovative designs that were previously thought impossible with traditional materials. For instance, stents made from Nitinol can expand once inserted into blood vessels due to this unique property, providing better support while minimizing trauma during placement. Such capabilities underscore why many manufacturers are turning towards using Nitinol bar stock for cutting-edge medical technology.

Differences Between Nitinol and Other Metals

When comparing Nitinol with other metals commonly used in medical applications—such as stainless steel or cobalt-chromium alloys—it becomes clear why this alloy has gained popularity among engineers and designers alike. While stainless steel offers strength and corrosion resistance, it lacks the flexibility inherent in Nickel Titanium Alloy Round Bar that allows for intricate designs required by modern devices.

Moreover, unlike conventional metals that may suffer from fatigue over time due to repeated stress cycles, Nitinol maintains its integrity even after extensive use thanks to its unique properties like superelasticity and shape memory effect. This durability translates into longer-lasting medical devices that require less frequent replacements or adjustments—a win-win scenario for both patients and healthcare providers alike!

In summary, understanding what makes Nitinol so special compared to other metals reveals why this alloy continues to dominate discussions surrounding advanced medical technology today.

Advantages of Nitinol Bar Stock in Medical Devices

Nitinol bar stock is revolutionizing the medical device industry, bringing a plethora of advantages that make it a go-to material for various applications. Its unique properties not only enhance the functionality of devices but also improve patient outcomes significantly. Let’s dive into what makes Nickel Titanium Alloy Round Bar an invaluable asset in modern medicine.

Flexibility and Biocompatibility

One of the standout features of Nitinol bar stock is its remarkable flexibility, which allows for intricate designs that can adapt to the human body’s contours. This flexibility means that medical devices made from Nickel Titanium Alloy Round Bar can navigate through complex anatomical structures with ease, reducing the risk of damage during insertion or maneuvering. Moreover, Nitinol is biocompatible, meaning it can coexist with bodily tissues without causing adverse reactions, making it ideal for long-term implants and surgical instruments.

Resistance to Corrosion and Fatigue

Nitinol bar stock exhibits exceptional resistance to corrosion, ensuring that medical devices maintain their integrity even in harsh environments within the body. This property extends the lifespan of devices made from Nickel Titanium Alloy Round Bar, minimizing replacement surgeries and enhancing patient safety. Additionally, Nitinol's fatigue resistance means it can withstand repeated stress without losing its shape or functionality—an essential trait for devices like stents that experience constant movement over time.

Lightweight yet Strong Design

When it comes to medical applications, weight matters; that's where Nitinol bar stock shines again! The lightweight nature of Nickel Titanium Alloy Round Bar allows for easier handling during procedures while ensuring that strength isn't compromised. This perfect balance between being lightweight yet robust translates into less invasive surgeries and improved overall patient comfort—two aspects every healthcare provider aims to achieve.

Key Medical Applications of NiTi Bars

Nitinol bar stock, due to its remarkable properties, has found a multitude of applications in the medical field. The unique characteristics of Nickel Titanium Alloy Round Bar make it an essential material for devices that require precision and reliability. From stents to surgical tools, the versatility of Nitinol is truly transformative.

Use in Stents and Catheters

One of the most significant applications of Nitinol bar stock is in the production of stents and catheters. The shape memory effect allows these devices to expand automatically once positioned within the body, providing optimal support for blood vessels or other structures. This innovative feature not only enhances patient comfort but also improves the efficacy of treatments by ensuring that these devices maintain their intended shape under varying physiological conditions.

Furthermore, the biocompatibility of Nickel Titanium Alloy Round Bar means that patients experience fewer adverse reactions when using Nitinol-based stents and catheters. This attribute is crucial for long-term implants where compatibility with bodily tissues is paramount. As a result, healthcare professionals are increasingly opting for Nitinol in critical procedures, knowing they can rely on its performance.

Innovations in Surgical Tools

The use of Nitinol bar stock has revolutionized surgical tools, making them more effective and user-friendly than ever before. Surgical instruments made from Nickel Titanium Alloy Round Bar benefit from enhanced flexibility while maintaining strength, allowing surgeons to navigate complex anatomical structures with ease. This innovative design reduces fatigue during lengthy procedures and increases precision during delicate operations.

Moreover, many modern surgical tools incorporate mechanisms that leverage the unique properties of Nitinol to adapt their shapes dynamically during surgery. For instance, graspers or scissors can change form based on the surgeon's needs without compromising their integrity or effectiveness. Such advancements not only improve surgical outcomes but also contribute to shorter recovery times for patients.

Role in Minimally Invasive Procedures

Minimally invasive procedures have gained immense popularity due to their numerous benefits over traditional surgeries—reduced recovery time, less pain, and minimal scarring are just a few perks patients enjoy. Here’s where Nitinol bar stock shines; its ability to be deployed through small incisions makes it ideal for such techniques. Devices crafted from Nickel Titanium Alloy Round Bar can be maneuvered easily within confined spaces while still providing robust support when needed.

Additionally, the shape memory effect inherent in Nitinol allows instruments used in minimally invasive surgeries to return to their original form after deployment—ensuring they fit perfectly within anatomical confines without causing damage or discomfort during insertion or removal processes. This capability significantly enhances both safety and efficacy during procedures like laparoscopic surgeries or endovascular repairs.

In conclusion, as we witness ongoing advancements in medical technology driven by materials like Nitinol bar stock, it's clear that Nickel Titanium Alloy Round Bar will continue playing a pivotal role across various applications—from life-saving stents to cutting-edge surgical tools designed for minimally invasive approaches.

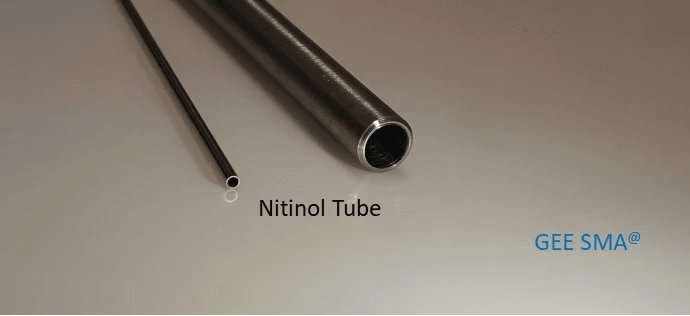

GEE SMA: Leading the Nitinol Market

When it comes to Nitinol bar stock, GEE SMA stands out as a beacon of expertise in the field. With years of experience under their belt, they have honed their skills in producing high-quality Nickel Titanium Alloy Round Bar that meets the demanding needs of various industries, particularly in medicine and aerospace. Their commitment to pushing the boundaries of what’s possible with Nitinol has solidified their reputation as a leader in this specialized market.

Overview of GEE SMA’s Expertise

GEE SMA specializes in the intricate world of Nitinol, leveraging cutting-edge technology and deep industry knowledge to deliver superior products. Their team consists of engineers and metallurgists who understand the unique properties of Nickel Titanium Alloy Round Bar, ensuring that each piece meets rigorous standards for performance and reliability. This expertise translates into a range of applications from medical devices to advanced engineering solutions, making them a go-to source for those seeking top-notch Nitinol bar stock.

Commitment to Quality and Innovation

At GEE SMA, quality is not just a buzzword; it’s woven into the fabric of their operations. They adhere to strict quality control measures at every stage—from sourcing raw materials to final production—ensuring that their Nitinol bar stock is consistently reliable and effective. Coupled with an unwavering commitment to innovation, GEE SMA continuously explores new methods and technologies that enhance the performance characteristics of their Nickel Titanium Alloy Round Bar, keeping them ahead in a competitive landscape.

Notable Projects in Space Missions

GEE SMA has made significant contributions beyond just medical applications; they have also ventured into space missions where precision materials are crucial. Their Nitinol bar stock has been utilized in various aerospace projects where flexibility and strength are paramount under extreme conditions. These notable projects showcase not only the versatility of Nickel Titanium Alloy Round Bar but also highlight GEE SMA's role as a pivotal player in advancing technology both on Earth and beyond.

Future Trends in Nitinol Usage

The future of Nitinol usage is bright, with ongoing advancements that promise to reshape the landscape of medical technology and beyond. As we delve deeper into the capabilities of Nitinol bar stock, it becomes evident that its unique properties will drive innovations across various sectors. From enhancing medical devices to exploring new applications, Nickel Titanium Alloy Round Bar is poised for significant growth.

Advancements in Medical Technology

Medical technology continues to evolve at an unprecedented pace, and Nitinol bar stock plays a crucial role in this transformation. With its remarkable shape memory effect and biocompatibility, the Nickel Titanium Alloy Round Bar is becoming a staple in the design of cutting-edge medical devices. Innovations such as self-expanding stents and advanced catheter systems are just the beginning; researchers are now exploring how these materials can improve patient outcomes through personalized medicine.

Moreover, as minimally invasive procedures gain traction, the demand for flexible yet strong materials like Nitinol will only increase. The ability to create intricate shapes that adapt to complex anatomical structures makes Nickel Titanium Alloy Round Bar an ideal choice for surgical tools designed for precision and efficiency. This trend suggests a future where surgeries become less invasive and recovery times shorten significantly.

Potential in Emerging Fields

Beyond traditional medical applications, the potential for Nitinol extends into emerging fields such as robotics and aerospace engineering. The unique characteristics of Nitinol bar stock make it suitable for creating components that require both strength and flexibility—think robotic grippers or actuators that mimic human motion with ease. As industries seek more efficient solutions, Nickel Titanium Alloy Round Bar could be at the forefront of innovative designs that enhance functionality while reducing weight.

In addition to robotics, there’s growing interest in utilizing Nitinol within wearable technology. Imagine smart devices equipped with sensors made from this versatile alloy—offering not only durability but also adaptability based on user needs or environmental conditions. The possibilities are endless as researchers continue to explore new avenues where Nickel Titanium Alloy Round Bar can play a transformative role.

The Ongoing Research and Development

Continuous research into Nitinol's properties is essential for unlocking its full potential across various industries. Scientists are investigating new processing techniques aimed at enhancing the performance characteristics of Nitinol bar stock while keeping costs manageable—a crucial factor for widespread adoption in commercial applications. By refining manufacturing methods, companies can produce high-quality Nickel Titanium Alloy Round Bar more efficiently than ever before.

Moreover, interdisciplinary collaboration is becoming increasingly important as experts from different fields come together to push boundaries further than ever imagined. This synergy could lead to breakthroughs not just limited to medicine but extending into other sectors like automotive design or even renewable energy solutions using shape memory alloys effectively within systems requiring dynamic responses.

As we look ahead, it's clear that ongoing research will pave the way for innovative applications of Nitinol that we have yet to envision fully—making it an exciting time for both researchers and manufacturers involved with Nickel Titanium Alloy Round Bar.

Conclusion

In the grand tapestry of modern medicine, Nitinol is a thread that weaves together innovation, efficiency, and reliability. This unique material has transformed various medical applications, making procedures safer and more effective for patients worldwide. As we reflect on the significance of Nickel Titanium Alloy Round Bar, it becomes clear that its contributions to healthcare are not just substantial; they are revolutionary.

The Role of Nitinol in Modern Medicine

Nitinol's role in modern medicine cannot be overstated; it serves as the backbone for many advanced medical devices. Its shape memory effect allows tools to adapt seamlessly within the human body, offering solutions that were previously unimaginable. From stents that expand upon reaching their destination to catheters that navigate complex vascular pathways, Nitinol bar stock has redefined what is possible in patient care.

The ability of Nickel Titanium Alloy Round Bar to return to a predetermined shape after deformation is particularly significant in minimally invasive surgeries. Surgeons can perform delicate procedures with greater precision and less trauma to surrounding tissues. This not only enhances recovery times but also improves overall patient outcomes, showcasing how vital Nitinol is in contemporary medical practices.

Why Choose Nickel Titanium Alloy Round Bar

Choosing Nickel Titanium Alloy Round Bar means opting for flexibility and resilience in medical device manufacturing. The inherent properties of Nitinol bar stock—such as biocompatibility and corrosion resistance—make it ideal for long-term use within the human body. These advantages ensure that devices maintain their integrity over time while minimizing risks associated with metal fatigue or rejection.

Moreover, the lightweight yet strong design of Nitinol allows for innovative designs without compromising on strength or durability. Medical professionals can rely on these materials for tools that provide both performance and safety during critical procedures. In an industry where every detail matters, selecting Nickel Titanium Alloy Round Bar is a decision rooted in quality and trust.

GEE SMA: A Partner for Precision Solutions

When it comes to sourcing high-quality Nitinol bar stock, GEE SMA stands out as a leader in the field. With extensive expertise and a commitment to innovation, they have positioned themselves at the forefront of the Nitinol market. Their dedication to quality ensures that each product meets stringent standards necessary for medical applications.

GEE SMA’s notable projects extend beyond conventional uses; their involvement in space missions illustrates their versatility and forward-thinking approach to material science. By collaborating with GEE SMA, manufacturers gain access to precision solutions tailored specifically for modern challenges in medicine and beyond. Choosing GEE SMA means aligning with a partner who understands both the technical intricacies and practical needs of today’s healthcare landscape.