Introduction

Niti coil springs have carved out a niche in various industries due to their unique properties and versatility. These innovative springs are made from Nitinol, a shape memory alloy that can return to its original shape after deformation, making them ideal for numerous applications. Understanding what a Niti open coil spring is used for is essential for anyone looking to utilize this technology effectively.

Understanding Niti Coil Springs

Niti coil springs, or Nitinol coil springs, are distinct because they possess both elasticity and the ability to remember their original form when subjected to heat. This characteristic allows them to perform exceptionally well in environments where traditional steel springs may fail. By grasping the fundamentals of how these springs operate, users can appreciate their advantages in fields ranging from medical devices to automotive engineering.

Importance of Proper Use

Using a Niti coil spring correctly is crucial for ensuring optimal performance and longevity. Misapplication can lead to premature failure or reduced effectiveness, which can be costly in both time and resources. Knowing what are the two types of coil springs—compression and extension—can help users select the right type for their specific needs.

Common Applications of Niti Coil Springs

Niti coil springs find applications across diverse sectors such as robotics, aerospace, and medical devices due to their unique properties. For instance, they are often employed in stents that expand within blood vessels or in actuators that require precise movement control. Understanding which is the best coil spring buffer for a particular application enhances performance and reliability across various use cases.

Overview of Niti Coil Springs

Niti coil springs, made from Nitinol—a nickel-titanium alloy—are a versatile and innovative solution in various mechanical applications. Their unique properties, including shape memory and superelasticity, make them ideal for situations where traditional materials might falter. Understanding what a Niti open coil spring is used for can help you appreciate its significance in modern design.

What is a Niti open coil spring used for?

A Niti open coil spring is primarily utilized in applications requiring flexibility and adaptability under varying loads. These springs excel in environments that demand precise movement or actuation, such as robotics, medical devices, and aerospace components. By leveraging the unique characteristics of Nitinol, these springs can return to their original shape after deformation, making them invaluable in dynamic systems.

Benefits of Niti Coil Springs in various industries

The benefits of using Niti coil springs span multiple industries due to their remarkable properties. In the medical field, for example, they are employed in stents and guidewires where biocompatibility and reliability are crucial. Similarly, in automotive engineering, these springs enhance performance by providing consistent force over time while resisting fatigue better than conventional steel alternatives—making them a smart choice for engineers everywhere.

Differences between Niti coil springs and other types

When comparing Niti coil springs to other types like compression or extension springs made from steel or plastic composites, several key differences emerge. Firstly, the superelastic behavior of Nitinol allows it to undergo significant deformation without permanent damage—something standard materials struggle with under similar conditions. Additionally, while traditional coils may lose tension over time due to fatigue or environmental factors, the resilience of a niti coil spring ensures longevity and reliable performance across diverse applications.

Identifying the Best Coil Spring for Your Needs

Selecting the right coil spring can significantly impact the performance of your application. In this section, we will explore the two primary types of coil springs, key factors to consider during selection, and how to determine which is the best coil spring buffer for your specific needs. By understanding these aspects, you’ll be better equipped to make informed decisions regarding Niti coil springs.

What are the two types of coil springs?

When it comes to coil springs, there are two main types: compression and extension springs. Compression springs are designed to resist axial loads and compress when a force is applied; they return to their original length when the load is removed. Conversely, extension springs work by resisting stretching forces; they elongate when pulled apart and are typically used in applications requiring a pulling or tensioning mechanism.

Understanding these distinctions is essential for determining what is a Niti open coil spring used for in various applications. Niti (nickel-titanium) alloy's unique properties make it suitable for both compression and extension uses, providing flexibility and resilience that traditional materials may lack. Thus, knowing which type suits your needs can greatly enhance performance and longevity.

Factors to consider when selecting a coil spring

Choosing the right Niti coil spring involves several critical factors that can influence its effectiveness in your application. First and foremost is load capacity—understanding how much weight or force your spring will need to handle ensures you select one that won’t fail under pressure. Additionally, consider environmental conditions such as temperature fluctuations or exposure to corrosive substances; certain Niti alloys perform better in specific environments.

Another factor includes understanding the required dimensions—both free length (the uncompressed length) and wire diameter play significant roles in determining a spring’s strength and flexibility. Finally, think about whether you need an open or closed end on your Niti coil spring; this can affect installation ease as well as overall performance in your application context.

How to determine the best coil spring buffer

Determining which is the best coil spring buffer requires analyzing several components of your system’s design requirements and operational parameters. Start by assessing how much shock absorption or vibration dampening you need; this will help gauge whether a softer or firmer buffer material would be more appropriate alongside your chosen Niti coil spring type.

Next, evaluate compatibility with other components within your assembly—ensuring that any buffers work harmoniously with surrounding parts enhances overall functionality while preventing premature wear on both coils and buffers alike. Lastly, don’t underestimate testing different configurations; sometimes hands-on experimentation helps clarify what works best in real-world scenarios.

Installation Tips for Niti Coil Springs

Installing a Niti coil spring may seem straightforward, but there are nuances that can make the process smoother and ensure optimal performance. Understanding how to properly install these springs can significantly enhance their longevity and effectiveness in various applications. Below are some essential tips to guide you through the installation of your Niti coil springs.

How to open a coil spring?

Opening a coil spring, particularly a Niti open coil spring, requires careful handling to avoid damaging the material or compromising its functionality. First, ensure that you have enough space to work and that the area is free from any obstructions. To open a coil spring safely, apply even pressure along its length using appropriate tools; this will help maintain the integrity of the spring while allowing it to expand smoothly.

When asking yourself, “What is a Niti open coil spring used for?”, consider its application in devices needing controlled motion or energy absorption. The unique properties of Niti allow it to return to its original shape after deformation, making it ideal for various uses such as in automotive suspensions and medical devices. Remember that handling these springs with care during installation can prevent potential issues down the line.

Essential tools for safe installation

Using the right tools is crucial when installing Niti coil springs effectively and safely. At minimum, you'll need safety goggles, gloves, and specific tools like pliers or specialized spring compressors designed for use with Niti materials. These tools not only protect you during installation but also help ensure that you handle the coils correctly without risking injury or damage.

Additionally, it's wise to have a torque wrench on hand if you're working with components that require precise tension settings related to your chosen Niti coil spring type. Understanding “What are the two types of coil springs?” can also guide your tool selection since different types may necessitate different approaches during installation. Having everything organized and ready will streamline your project and minimize mistakes.

Common installation mistakes to avoid

Even seasoned professionals can overlook details when installing Niti coil springs; however, avoiding common pitfalls can save time and resources in the long run. One frequent mistake is failing to check compatibility between your chosen Niti coil spring and other components involved in your project—this could lead to poor performance or even failure of parts over time.

Another error often made is not following proper opening techniques; remember how important it is “How to open a coil spring?” correctly! Applying uneven pressure or using inappropriate tools can lead not only to damage but also potentially dangerous situations if parts snap unexpectedly under stress. Lastly, overlooking maintenance needs post-installation is another misstep—regular checks on your installed coils will ensure they remain functional over time.

Maintenance and Care for Longevity

Taking care of your Niti coil springs is essential for ensuring they last and perform optimally. Regular maintenance not only extends their lifespan but also enhances their functionality in various applications. By following a few simple practices, you can keep your Niti coil springs in excellent condition.

Regular inspection practices

Checking for signs of wear, corrosion, or deformation should be part of your routine—especially if you're using them in critical applications. Remember, knowing what a Niti open coil spring is used for will help you identify any issues early on; whether it's in automotive suspensions or medical devices, regular checks can prevent catastrophic failures.

Cleaning methods for Niti coil springs

Cleaning your Niti coil springs is another vital aspect of maintenance that shouldn't be overlooked. Use a soft brush or cloth to remove dirt and debris that may accumulate over time; this ensures the springs operate smoothly without hindrance. When considering how to open a coil spring for cleaning, always ensure you're using appropriate techniques to avoid damaging the material or its shape.

Signs that your coil springs need replacement

Knowing when to replace your Niti coil springs can save you from unexpected breakdowns and costly repairs. Common signs include visible cracks, excessive rusting, or if they no longer return to their original shape after compression—these indicate it's time for a change. If you're unsure about which is the best coil spring buffer for your needs during replacement, consulting with professionals can provide valuable insights tailored to your specific application.

Troubleshooting Common Issues

These springs are designed for durability and flexibility, but they can still face performance problems due to various factors. Understanding what is a Niti open coil spring used for and recognizing the signs of failure will help you maintain optimal performance.

Identifying Performance Problems

Identifying performance problems in your Niti coil spring begins with observing any unusual behavior during operation. If you notice excessive noise, reduced responsiveness, or visible deformation, these could be indicators that something is amiss. Additionally, understanding what are the two types of coil springs—compression and extension—can help you narrow down potential issues based on the specific application of your Niti coil spring.

Another sign of trouble is when the spring fails to return to its original shape after being compressed or extended. This failure not only affects functionality but may also pose safety risks in applications where precision is crucial. Regular inspections can catch these problems early, ensuring that your Niti coil spring continues to perform as intended.

Solutions for Coil Spring Failure

When faced with coil spring failure, there are various solutions available depending on the severity of the issue. For minor deformations or misalignments, simply adjusting or repositioning the Niti coil spring may suffice; however, if it’s a more serious issue like breakage or fatigue, replacement might be necessary. Knowing which is the best coil spring buffer for your specific application can also mitigate future failures by absorbing shocks more effectively.

In cases where cleaning and lubrication are required, ensure you're using appropriate methods tailored for Niti materials to avoid corrosion or damage. If a replacement is needed due to extensive wear and tear, consider sourcing high-quality alternatives that meet industry standards for longevity and performance. Remember that proactive maintenance often leads to fewer failures down the line.

When to Consult a Professional

While many issues with Niti coil springs can be resolved independently with some troubleshooting skills, certain situations warrant professional assistance. If you find yourself asking How to open a coil spring? without success or if you're unsure about installation techniques after multiple attempts—it's time to call in an expert who specializes in these components.

Additionally, if you've identified significant performance problems that persist despite following troubleshooting steps outlined above, consulting a professional becomes essential. They have access to specialized tools and knowledge about advanced techniques that could save your equipment from further damage caused by faulty springs.

In summary, while many common issues with Niti coil springs can be addressed through careful observation and maintenance practices—knowing when it’s time for professional intervention ensures both safety and reliability in their use.

Innovations in Niti Coil Spring Technology

The world of Niti coil springs is constantly evolving, driven by advancements in materials and engineering practices. These innovations not only enhance the performance of Niti coil springs but also expand their applications across various industries. As we delve into this topic, we’ll explore the latest developments in Nitinol shape memory alloys, contributions from industry leaders like GEE SMA, and the exciting future trends shaping coil spring technology.

Advances in Nitinol Shape Memory Alloys

Nitinol shape memory alloys have taken the mechanics of a Niti coil spring to new heights. These alloys possess unique properties that allow them to return to their original shape after deformation when exposed to specific temperatures. This remarkable characteristic makes them ideal for applications where flexibility and strength are paramount, answering the question: What is a Niti open coil spring used for? From medical devices to automotive components, the versatility of these materials continues to grow.

Moreover, advances in processing techniques have allowed manufacturers to create more reliable and efficient Niti coil springs with enhanced fatigue resistance. This means that users can expect longer lifespans from their springs without compromising on performance or safety. With ongoing research into optimizing these alloys further, we can anticipate even more innovative uses for Nitinol-based technologies.

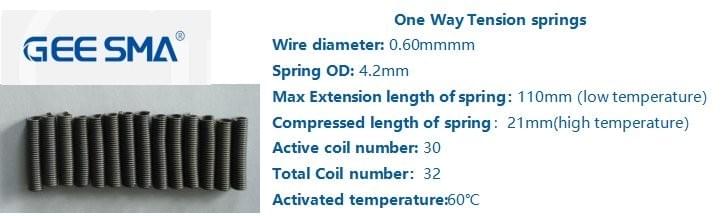

GEE SMA's contributions to coil spring development

GEE SMA has emerged as a frontrunner in the field of shape memory alloy technology, particularly with their focus on developing high-performance Niti coil springs. Their commitment to innovation has led to breakthroughs that improve not just the mechanical properties but also manufacturing processes for these specialized components. By leveraging advanced engineering techniques and materials science, GEE SMA is redefining what is possible with coil springs.

Their products are designed with end-users in mind—offering solutions that minimize installation difficulties while maximizing performance longevity. So if you’re pondering which is the best coil spring buffer for your application, GEE SMA’s offerings might be worth considering due to their superior design and reliability features. The company's continuous investment in R&D ensures that they remain at the forefront of this rapidly evolving sector.

Future trends in coil spring applications

Looking ahead, several exciting trends are emerging within the realm of Niti coil springs that promise transformative impacts across industries. The integration of smart technologies into these springs is one such trend; imagine a future where your coils can provide real-time feedback on performance or wear! This would revolutionize maintenance protocols and could address questions like how to open a coil spring safely without damaging it during routine checks.

Additionally, sustainability will play an increasingly critical role as manufacturers seek eco-friendly materials and processes for creating Niti coil springs. As industries shift toward greener practices, innovations will likely focus on reducing waste while enhancing product life cycles—ensuring that these essential components remain both effective and environmentally responsible.

As we embrace these advancements together with established knowledge about what makes a great Niti open coil spring suitable for specific tasks—like understanding what are the two types of coil springs—we can look forward confidently toward an exciting future filled with possibilities!

Conclusion

In wrapping up our exploration of Niti coil springs, it's clear these remarkable components have a significant role in various applications. Understanding what a Niti open coil spring is used for can help you appreciate its versatility and efficiency in industries ranging from automotive to medical devices. By recognizing the two types of coil springs and their unique characteristics, users can make informed decisions that enhance performance and longevity.

Key Takeaways on Effective Niti Coil Spring Use

When considering which is the best coil spring buffer for your needs, remember that Niti coil springs offer distinct advantages thanks to their shape memory properties. They are designed to perform optimally under stress while returning to their original shape, making them ideal for applications requiring resilience and precision. Ultimately, selecting the right type of Niti coil spring—whether it’s an open or closed design—will significantly impact your project's success.

Emphasis on Maintenance and Care

Maintaining your Niti coil springs is crucial for ensuring they function efficiently over time. Regular inspection practices can help identify any wear or damage early on, allowing you to take action before problems escalate. Additionally, knowing how to open a coil spring safely will not only protect the component but also extend its lifespan through proper care.

The Future of Niti Coil Springs in Technology

Looking ahead, innovations in Niti coil springs promise exciting developments across various fields. Advances in materials science are likely to lead to even more efficient designs that enhance performance while reducing costs. As industries continue to explore new applications for these versatile components, we can expect the demand for high-quality Niti coil springs to grow significantly.