Introduction

Nitinol material, a remarkable alloy of nickel and titanium, has captured the attention of scientists and engineers alike due to its unique properties and wide-ranging applications. But what type of material is nitinol? It’s not just any ordinary metal; it possesses extraordinary characteristics like shape memory effect and superelasticity that set it apart from traditional materials. In this introduction, we will explore the fascinating history of nitinol, delve into its technical properties, and highlight why it has become a go-to choice in various industries.

Understanding Nitinol Material Basics

To truly appreciate nitinol material, one must first grasp its fundamental composition and behavior. This unique alloy exhibits two primary phenomena: the ability to return to a predetermined shape when heated (shape memory effect) and the capacity to undergo significant deformation without permanent change (superelasticity). These properties make nitinol an exceptional candidate for applications ranging from medical devices to automotive innovations.

The Fascinating History of Nitinol

Nitinol's journey began in the 1960s when researchers at the Naval Ordnance Laboratory accidentally discovered this intriguing alloy while experimenting with nickel-titanium combinations. The name nitinol itself is derived from its origins—Nickel Titanium Naval Ordnance Laboratory. Since then, this material has evolved significantly, leading to groundbreaking advancements in various fields; however, questions still linger: Is nitinol stronger than titanium? And how does it compare with other materials?

Nitinol's Unique Properties Explained

What makes nitinol so special? Its unique technical properties allow it to excel in demanding environments where conventional materials may falter. However, despite its numerous advantages, there are also considerations regarding limitations—what are the disadvantages of nitinol? Additionally, understanding why is nitinol so expensive can help clarify its value proposition in industrial applications.

What Makes Nitinol So Special

Nitinol material stands out in the world of metallurgy due to its unique properties that are both fascinating and practical. This section delves into two of its most remarkable characteristics: the shape memory effect and superelasticity, as well as its technical properties and applications. Understanding these features helps clarify why nitinol is often the material of choice across various industries.

Exploring Shape Memory Effect

The shape memory effect is one of the most intriguing aspects of nitinol material. Essentially, this means that when deformed at a certain temperature, nitinol can return to its original shape upon heating above a specific threshold. This property has significant implications for various applications, particularly in medical devices like stents and guidewires, where reliability and performance are paramount.

When we ask ourselves, What type of material is nitinol? it's essential to recognize that it’s an alloy primarily made from nickel and titanium that exhibits this remarkable ability. The mechanism behind the shape memory effect lies in the alloy's crystalline structure, which changes between two different forms depending on temperature. This unique behavior allows for innovative designs in products ranging from eyeglass frames to automotive components.

The Role of Superelasticity

Superelasticity is another defining feature that makes nitinol stand out among other materials like titanium or stainless steel. Unlike traditional elastic materials that only return to their original form after removing stress, superelastic nitinol can undergo significant deformation without permanent damage when exposed to temperatures above its transformation range. This characteristic allows it to absorb energy efficiently, making it ideal for applications requiring high flexibility and durability.

Is nitinol stronger than titanium? While both materials have impressive strength-to-weight ratios, superelasticity gives nitinol an edge in dynamic environments where flexibility is key. Its ability to withstand repeated stress cycles without losing integrity further enhances its appeal across various sectors.

Nitinol Technical Properties and Applications

Nitinol technical properties encompass a range of features including high corrosion resistance, biocompatibility, and lightweight nature—qualities that make it highly sought after in industries such as aerospace, automotive, and medical fields. In medical applications alone, it's utilized for devices like stents due to its ability to conform seamlessly within bodily structures while maintaining strength under stress.

However, potential users should also consider what are the disadvantages of nitinol? For instance, while it offers many advantages such as enhanced performance and lightweight characteristics, it does come with a higher price tag compared to more conventional materials like stainless steel or aluminum—leading us to ponder why is nitinol so expensive? The intricate manufacturing processes required for producing this specialized alloy contribute significantly to its cost but often justify itself through superior performance outcomes.

In summary, understanding these unique properties not only highlights what makes nitinol so special but also underscores its versatility across various applications—from life-saving medical devices to cutting-edge engineering solutions.

Comparing Nitinol to Other Materials

When it comes to materials science, Nitinol stands out in a league of its own. However, comparing it to other well-known materials like titanium and stainless steel can shed light on its unique attributes and limitations. In this section, we’ll explore whether nitinol is stronger than titanium, pit nitinol against stainless steel in a head-to-head comparison, and answer the burning question: what type of material is nitinol?

Is Nitinol Stronger Than Titanium?

To determine if nitinol is stronger than titanium, we must consider the context of strength. While titanium boasts impressive tensile strength and is often the go-to material for aerospace applications, nitinol brings something different to the table with its unique technical properties. Although pure titanium can handle high stress levels without deforming permanently, the shape memory effect of nitinol allows it to return to its original shape after deformation, which makes it incredibly resilient under certain conditions.

That said, in terms of raw strength metrics such as yield strength or ultimate tensile strength, titanium typically comes out on top. However, when factoring in flexibility and adaptability—especially in medical devices—nitinol’s ability to remember shapes gives it an edge that can't be ignored. So while one might argue that nitinol isn’t technically stronger than titanium in a conventional sense, its unique capabilities offer advantages that are unmatched by traditional metals.

Nitinol vs Stainless Steel: A Head-to-Head

Nitinol and stainless steel both have their merits but serve different purposes based on their properties. Stainless steel has long been celebrated for its corrosion resistance and overall durability; however, it lacks the remarkable shape memory effect that defines nitinol material. When comparing these two materials side by side, it's essential to weigh factors like application requirements and environmental conditions.

In terms of mechanical properties, stainless steel generally exhibits higher tensile strength compared to most forms of nitinol; yet again, this doesn't account for the unique benefits offered by nitinol's superelasticity. For instance, in medical applications like stents or guidewires where flexibility is paramount—even under stress—nitinol shines due to its ability to withstand significant deformation while still returning to its original form. Thus while stainless steel may win some battles on paper regarding raw strength metrics or cost-effectiveness (which leads us into our next discussion about why is nitinol so expensive?), it's clear that each material has distinct advantages depending on the specific application.

What Type of Material is Nitinol?

Understanding what type of material nitinol is requires diving into its composition and properties. Nitinol is an alloy primarily composed of nickel and titanium; hence the name Niti from nickel (Ni) and nol from titanium (Ti). This unique combination gives rise not only to exceptional mechanical characteristics but also enables phenomena like shape memory effect—whereby the material can 'remember' a specific form even after being deformed.

Moreover, classifying nitinol as simply an alloy would be doing it a disservice since it possesses qualities that transcend traditional metal categorizations due to its phase transformation behavior at certain temperatures. These features make it particularly useful across various industries including medicine and aerospace engineering where reliability under dynamic conditions matters most! So while asking “What type of material is nitinol?” might seem straightforward at first glance—it opens up a fascinating dialogue about how advanced alloys are reshaping our understanding of materials science today.

Industrial Applications of Nitinol

Nitinol material has found its way into various industries due to its unique properties, making it a game-changer in applications ranging from medicine to aerospace. This versatile alloy is not just a scientific curiosity; it’s a practical solution that meets the demands of modern engineering challenges. Let's dive into how nitinol is revolutionizing these sectors.

Medical Uses of Nitinol Material

In the medical field, nitinol material stands out for its remarkable biocompatibility and shape memory effect, which allow it to return to a predetermined shape when heated. This makes it ideal for applications like stents, guidewires, and orthopedic implants where flexibility and strength are crucial. With its ability to adapt to body temperature, nitinol offers enhanced patient comfort and improved outcomes in minimally invasive surgeries.

Moreover, the technical properties of nitinol enable it to withstand the rigors of bodily environments without degrading over time. This durability means fewer complications and longer-lasting devices compared to traditional materials. As medical technology advances, the use of nitinol is expected to expand further, addressing more complex challenges in healthcare.

Automotive Innovations with Nitinol

The automotive industry is also tapping into the potential of nitinol material for innovative solutions that enhance vehicle performance while reducing weight. With growing emphasis on fuel efficiency and sustainability, manufacturers are exploring how this unique alloy can replace heavier components without sacrificing strength or reliability. Imagine car parts that can reshape themselves under stress—thanks to nitinol’s superelasticity!

Additionally, using nitinol in actuators and sensors allows for more responsive systems that improve overall vehicle functionality. Whether it's adaptive suspension systems or self-adjusting seat belts, the applications are as diverse as they are exciting! However, one must consider what type of material is nitinol when designing these components since its properties can vary based on formulation.

Aerospace Engineering and Nitinol

Aerospace engineering is yet another field where nitinol material shines brightly due to its lightweight nature combined with high strength-to-weight ratios—crucial factors for flight performance! Engineers are increasingly utilizing this alloy in components such as control surfaces and actuators because they require materials that can handle extreme conditions while remaining lightweight. The ability of nitinol to revert back to specific shapes after deformation makes it perfect for applications involving dynamic stresses.

Moreover, as we push toward more efficient aircraft designs with lower emissions, incorporating advanced materials like nitinol could lead us closer to achieving those goals while maintaining safety standards. Yet one must ponder: why is nitinol so expensive? The manufacturing processes involved contribute significantly to costs but offer unparalleled benefits that justify the investment.

In summary, whether it's in medicine or aerospace engineering, the industrial applications of nitinol illustrate how this remarkable alloy continues shaping our world through innovation driven by its unique technical properties.

Advantages of Using Nitinol

Nitinol material is gaining traction across various industries due to its remarkable advantages. Its unique properties allow for innovative solutions that were once thought impossible, making it a go-to choice for engineers and designers alike. From medical devices to automotive applications, the benefits of nitinol are hard to overlook.

Lightweight and Durable Characteristics

One of the standout features of nitinol material is its impressive strength-to-weight ratio, which makes it both lightweight and durable. This characteristic is particularly advantageous in applications where reducing weight without sacrificing strength is crucial, such as in aerospace engineering or medical devices. When comparing materials, many ask, Is nitinol stronger than titanium? While titanium has its merits, nitinol often outperforms it in terms of flexibility and resilience under stress.

The lightweight nature of nitinol also contributes to ease of handling and installation in various applications, further enhancing its appeal. Engineers appreciate how this property can lead to more efficient designs without compromising structural integrity. As industries strive for sustainability and efficiency, the demand for materials like nitinol that offer significant weight savings continues to grow.

Corrosion Resistance in Extreme Conditions

Nitinol material exhibits exceptional corrosion resistance, even in extreme environmental conditions—a key advantage that sets it apart from many other materials. This property ensures longevity and reliability in challenging settings such as marine environments or chemical processing plants. For those wondering about the technical properties of nitinol, this corrosion resistance stems from its unique composition and crystalline structure.

The ability to withstand harsh conditions means reduced maintenance costs over time; equipment made from nitinol can often outlast alternatives that succumb to wear and tear more quickly. In sectors such as aerospace or medical technology where failure isn't an option, this reliability becomes paramount. The question What are the disadvantages of nitinol? often arises when discussing cost versus longevity; however, the long-term performance typically outweighs initial expenses.

Enhanced Flexibility and Performance

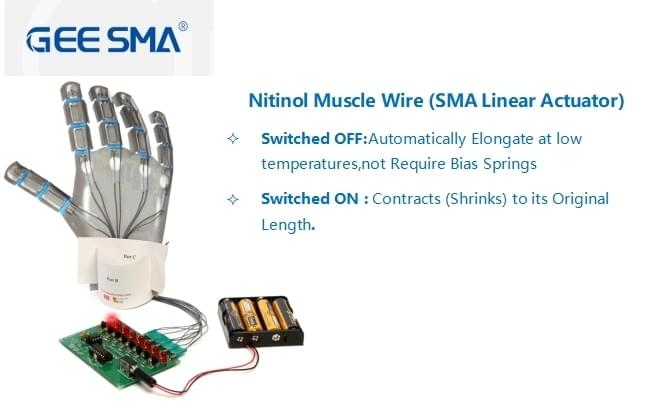

Another compelling advantage of using nitinol material lies in its enhanced flexibility combined with high performance under stress—thanks largely to its shape memory effect and superelasticity properties. These characteristics allow components made from nitinol to return to their original shapes after deformation or bending, making them ideal for applications requiring dynamic movement or adaptability. This leads many engineers to inquire about what type of material is nitinol? It’s a smart choice for projects demanding both resilience and versatility.

In practical terms, this means that products designed with nitinol can perform better than those made from traditional metals under similar conditions—think stents that expand automatically within body vessels or flexible connectors in robotics systems that need precision movement without breaking down over time. As industries continue exploring new frontiers with materials like this one, it's clear that the enhanced flexibility offered by nitinol could redefine standards across various fields.

Conclusion

In conclusion, the journey of understanding nitinol material reveals a world of innovation and potential that is only just beginning to unfold. As we look forward, advancements in nitinol applications promise to revolutionize various industries, from medical devices to aerospace technology. The unique properties of this remarkable alloy make it a compelling choice for engineers and designers seeking innovative solutions.

The Future of Nitinol Material

The future of nitinol material is bright, with ongoing research aimed at enhancing its technical properties even further. Innovations in processing techniques may lead to more cost-effective methods of production, addressing the question: why is nitinol so expensive? As demand grows across multiple sectors, including robotics and consumer electronics, we can expect exciting developments that will enhance its usability and affordability.

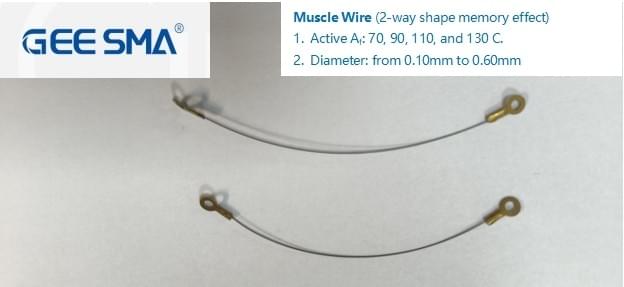

Tailored Solutions with GEE SMA

GEE SMA offers tailored solutions for industries looking to harness the unique capabilities of nitinol material. By customizing design parameters specific to applications, GEE SMA helps businesses leverage the shape memory effect and superelasticity that make nitinol so special. This adaptability not only addresses common concerns—like what are the disadvantages of nitinol?—but also ensures optimal performance in diverse environments.

Why Choose Nitinol for Your Needs

Choosing nitinol for your needs means opting for a material that combines strength with versatility; but is nitinol stronger than titanium? While both materials have their merits, the unique technical properties of nitinol often allow it to outperform traditional metals in specific applications. Ultimately, selecting this innovative alloy can lead to enhanced durability and functionality in products designed for challenging conditions.