Introduction

The world of Nitinol engines is a captivating intersection of materials science and engineering innovation. These unique devices harness the extraordinary properties of Nitinol, an alloy known for its remarkable shape memory effect, to create powerful and efficient heat engines. As we delve deeper into what a Nitinol engine truly is, it becomes clear that understanding this technology is crucial for appreciating its potential impact on modern engineering.

The Intriguing World of Nitinol Engines

Nitinol engines represent a fascinating advancement in the realm of energy conversion technologies. By leveraging the unique characteristics of Nitinol, these engines can transform thermal energy into mechanical work in ways that traditional engines cannot match. The question arises: what is a nitinol engine? It’s not just another gadget; it’s a glimpse into the future of efficient energy solutions.

Understanding Nitinol: A Miracle Alloy

Nitinol, an alloy composed primarily of nickel and titanium, boasts some astonishing properties that make it stand out in engineering applications. Its most notable feature, the shape memory effect, allows it to return to its original shape after deformation when subjected to heat—an attribute that has far-reaching implications for designing more efficient systems like nitinol engines. This miraculous alloy isn’t just about novelty; it’s about pushing the boundaries of what we thought was possible in mechanical design.

Why Nitinol Engines Matter Today

In today's world grappling with energy efficiency and sustainability challenges, nitinol engines offer exciting possibilities worth exploring further. But why aren't nitinol engines used more widely? The answer lies in their potential efficiency compared to traditional systems and their ability to pave the way for reversible heat engines—an aspect that could revolutionize how we think about energy use and conservation moving forward.

What is a Nitinol Engine?

Nitinol engines are fascinating devices that harness the unique properties of nitinol, a nickel-titanium alloy known for its shape memory and superelasticity. But what is a nitinol engine exactly? It’s essentially a heat engine that utilizes these properties to convert thermal energy into mechanical work, offering an alternative to traditional engines. As we delve deeper into this innovative technology, we will explore the basics of nitinol, the remarkable shape memory effect it exhibits, and its diverse applications in modern engineering.

Basics of Nitinol Technology

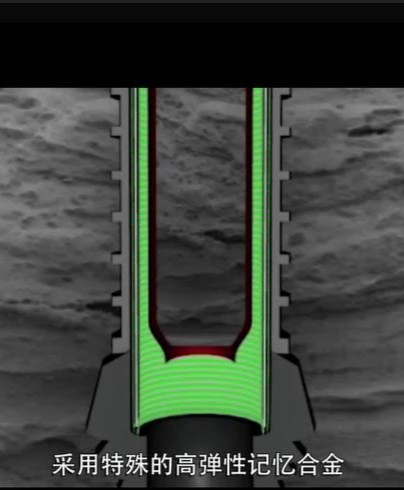

At the heart of understanding what is a nitinol engine lies knowledge about nitinol itself. This remarkable alloy can return to its original shape when heated after being deformed at lower temperatures—a property that sets it apart from other materials. The ability to undergo phase transformations between martensite and austenite phases allows nitinol engines to efficiently convert heat energy into motion, making them an exciting prospect for various applications.

The composition of nitinol typically consists of around 55% nickel and 45% titanium, but slight variations can enhance specific properties needed for certain applications. These alloys perform exceptionally well under varying temperature conditions, which is crucial for any engine design aiming for efficiency. As we explore further into why aren't nitinol engines used more widely today, it's essential to appreciate the foundational technology that makes them unique.

The Shape Memory Effect Explained

The shape memory effect (SME) is one of the most captivating aspects of nitinol technology and plays a critical role in how these engines operate. When subjected to specific temperature changes, a deformed piece of nitinol can regain its original shape—this phenomenon occurs due to changes in crystalline structure within the material. Essentially, when you heat up a bent or twisted piece of nitinol beyond its transformation temperature, it remembers its original form and returns there with impressive force.

This effect not only allows for efficient energy conversion but also raises intriguing questions: Are reversible heat engines possible? In theory, they could be designed using this very principle as they would continuously cycle through heating and cooling phases while maintaining efficient performance levels. Understanding SME is crucial as it directly influences both what is the efficiency of the nitinol engine and how effectively it can operate compared to traditional alternatives.

Applications in Modern Engineering

Nitinol's unique characteristics have led to various applications across multiple fields such as robotics, medical devices, and even aerospace engineering—demonstrating just how versatile this alloy truly is! For instance, in robotics, actuators made from nitinol provide precise movements while consuming less power compared to conventional motors; thus enhancing overall efficiency in robotic systems. Meanwhile, medical devices like stents utilize the shape memory effect for safe deployment within arteries—showing real-world benefits derived from what is a nitinol engine's underlying principles.

However, despite these promising applications and advancements in technology regarding their efficiency—what is the efficiency of the nitinol engine compared to traditional models? Current research indicates that while they may not yet surpass conventional engines entirely in terms of raw power output or cost-effectiveness at scale; their potential remains largely untapped due to ongoing challenges related primarily to production costs and material consistency across larger components.

In summary, while many industries are beginning to recognize the advantages offered by this extraordinary material; understanding why aren't nitinol engines used more extensively requires addressing both economic barriers as well as technical challenges inherent in implementation across diverse sectors.

Historical Journey of Nitinol Engines

The evolution of the nitinol engine is a fascinating tale marked by groundbreaking discoveries and innovative engineering. Since its inception, researchers have relentlessly pursued advancements that unlock the potential of this remarkable alloy, transforming it from a curiosity into a serious contender in energy applications. Understanding this historical journey sheds light on why nitinol engines are not yet mainstream and what their future might hold.

Key Innovations Over the Decades

The history of nitinol engines is punctuated by key innovations that have significantly enhanced their design and functionality. Initially discovered in the 1960s, nitinol's unique properties sparked interest among engineers looking for alternatives to traditional heat engines. Over the decades, innovations such as improved alloy compositions and advanced manufacturing techniques have propelled research into what is a nitinol engine today, making it more efficient and versatile than ever before.

Furthermore, breakthroughs in understanding the shape memory effect have allowed for more sophisticated applications of nitinol technology in heat engines. This phenomenon enables materials to return to a predetermined shape when heated, providing opportunities for increased efficiency—leading many to ask: what is the efficiency of the nitinol engine compared to conventional designs? The ongoing quest for optimization continues to inspire new ideas that could revolutionize energy conversion technologies.

Notable Figures in Nitinol Development

Behind every scientific advancement are visionary individuals who dared to dream beyond existing boundaries. In the case of nitinol engines, figures like William J. Buehler played pivotal roles in recognizing and harnessing the potential of this extraordinary alloy during its early days at NASA's Langley Research Center. His work laid foundational principles that would later inform engineers about why aren't nitinol engines used more widely today.

Other notable contributors include researchers from universities and private institutions who have dedicated their careers to exploring various applications of nitinol technology. Their collective efforts not only advanced our understanding but also sparked interest across industries—from aerospace to automotive—highlighting how versatile a nitinol engine can be when integrated into modern engineering solutions.

Milestones in Heat Engine Design

Milestones in heat engine design utilizing nitinol reflect both triumphs and challenges faced by researchers over time. Early prototypes demonstrated promising results but were often limited by technical challenges related to material properties and operational conditions—prompting questions about whether reversible heat engines are possible using this technology. Each milestone has been an important stepping stone toward refining designs that optimize performance while overcoming inherent limitations.

In recent years, several experimental models have emerged showcasing enhanced efficiency levels compared to traditional counterparts, igniting further interest in commercial applications for what is a nitinol engine? These developments signify not just progress but also hope for broader adoption as engineers continue pushing boundaries within this exciting field.

The Efficiency of Nitinol Engines

Nitinol engines have generated a buzz in the engineering community, particularly due to their unique properties and advantages over traditional engines. When we explore the efficiency of the nitinol engine, it becomes apparent that they offer intriguing possibilities for energy conversion and sustainability. However, understanding what is the efficiency of the nitinol engine requires a deeper dive into its mechanics and applications.

Comparing Nitinol Engines to Traditional Engines

When we stack up nitinol engines against traditional combustion engines, the differences are striking. Traditional engines rely on burning fuel to create motion, which often leads to significant energy losses through heat and friction. In contrast, a nitinol engine utilizes the shape memory effect of this remarkable alloy to convert thermal energy directly into mechanical work, potentially achieving higher efficiencies with lesser waste.

Moreover, while traditional engines typically operate within a narrow temperature range for optimal performance, nitinol engines can harness varying thermal gradients more effectively. This flexibility allows them to be used in diverse environments where conventional engines may falter. As such, it's crucial to ask: why aren't nitinol engines used more widely despite their promise?

Factors Affecting Efficiency

The efficiency of any engine hinges on multiple factors, and nitinol engines are no exception. One significant aspect is the temperature differential; for maximum efficiency in a nitinol engine, there must be an adequate heat source and sink to facilitate effective energy transfer. Additionally, material properties such as fatigue resistance and thermal conductivity play critical roles in determining how well these systems perform over time.

Another factor influencing what is the efficiency of the nitinol engine lies in its design complexities—optimizing geometry and operational parameters can enhance performance but also complicate manufacturing processes. Furthermore, external conditions like ambient temperature can affect how efficiently these engines operate compared to their traditional counterparts. Thus, while promising high efficiency potential exists within nitinol technology, practical implementation poses several challenges.

Case Studies from Leading Researchers

Leading researchers have undertaken various case studies examining the capabilities of nitinol engines under different scenarios. For instance, one notable study demonstrated that a specially designed nitinol engine could achieve efficiencies exceeding 30%, significantly higher than many conventional designs under similar conditions—this raises exciting questions about are reversible heat engines possible using this technology?

Another research project focused on optimizing thermodynamic cycles specifically tailored for nitinol applications revealed that fine-tuning operational parameters could yield even greater efficiencies than initially predicted by theoretical models alone. These findings suggest that with continued innovation and exploration into what is a nitinol engine's design potential—combined with advancements in materials science—the future holds considerable promise for enhanced performance metrics.

In conclusion, while there remain hurdles regarding widespread adoption—such as cost-effectiveness and technical challenges—it’s clear that understanding how efficient these systems can be opens doors for further research into sustainable energy solutions.

Are Reversible Heat Engines Possible?

The concept of reversible heat engines has long captivated engineers and scientists alike, sparking curiosity about their potential applications in various technologies, including the nitinol engine. A reversible heat engine operates on the principle of reversibility, meaning it can convert thermal energy into mechanical work and vice versa with minimal energy loss. This idea is not just theoretical; it opens doors to greater efficiency in energy systems, which is especially relevant when discussing what is a nitinol engine.

The Concept of Reversible Engines

Reversible engines are designed to maximize efficiency by minimizing entropy during the thermodynamic cycles they undergo. In essence, these engines can operate in both directions: they can extract work from heat or use work to transfer heat. The pursuit of such designs aligns perfectly with the quest for sustainable energy solutions, making it an exciting area of research for those investigating why aren't nitinol engines used more widely today.

Achievements in Nitinol Engine Research

Recent advancements in nitinol engine research have showcased promising results that hint at the feasibility of reversible designs. Researchers have successfully demonstrated how nitinol's unique properties—especially its shape memory effect—can be harnessed to create more efficient thermal cycles that mimic reversible processes. These achievements highlight a growing understanding of what is the efficiency of the nitinol engine and how it compares favorably with traditional engines.

Future Directions for Reversible Designs

Looking ahead, there’s a bright horizon for integrating reversible designs into nitinol engines as technology continues to evolve. Innovations in material science and engineering could lead to breakthroughs that enhance performance while addressing existing challenges related to cost and implementation—key factors behind why aren't nitinol engines adopted on a larger scale today. By focusing on developing hybrid systems that leverage both traditional methods and cutting-edge nitinol technology, researchers may unlock new possibilities for sustainable energy solutions.

Why Aren't Nitinol Engines Used?

Despite the fascinating potential of nitinol engines, they remain on the fringes of mainstream technology. This section delves into the barriers that prevent these innovative systems from becoming household names, examining economic factors and technical challenges that complicate their implementation. Understanding why nitinol engines aren't widely adopted is crucial for anyone interested in their future.

Barriers to Mainstream Adoption

One of the primary barriers to mainstream adoption of nitinol engines is a lack of awareness and understanding about what a nitinol engine truly is. Many people are still unfamiliar with this remarkable alloy and its unique properties, such as the shape memory effect, which could revolutionize energy conversion methods. Additionally, established industries often resist incorporating new technologies due to existing investments in traditional systems, making it hard for nitinol engines to gain traction.

Moreover, regulatory hurdles can pose significant challenges for introducing any new technology into established markets. The rigorous testing and certification processes required for new engine types can be lengthy and costly, discouraging companies from pursuing nitinol technology further. As a result, despite its potential benefits, the journey toward widespread adoption remains rocky.

Economic Considerations

When pondering why aren't nitinol engines used more extensively, economic considerations come into play as a significant factor. The initial costs associated with developing and producing nitinol engines can be prohibitively high compared to traditional alternatives like internal combustion or electric motors. Manufacturers often hesitate to invest in new technologies without clear evidence of long-term cost savings or efficiency improvements.

Furthermore, market demand plays a critical role in shaping production decisions; if consumers are not clamoring for more efficient energy solutions like those offered by a nitinol engine, manufacturers may prioritize other projects instead. This creates a catch-22 situation where low demand stifles innovation while high upfront costs deter potential users from exploring these advanced options further.

Lastly, existing supply chains are well-established around conventional engine technologies; transitioning to new materials like nitinol requires rethinking entire production processes—something many companies are reluctant to do when profit margins are already tight.

Technical Challenges in Implementation

The technical challenges surrounding the implementation of nitinol engines cannot be overlooked when discussing their limited use today. For starters, while we know what is the efficiency of the nitinol engine could potentially be quite high due to its unique properties, achieving that efficiency consistently in real-world applications remains elusive at this stage of development. Engineers face numerous hurdles related to material performance under varying operational conditions that need addressing before these engines can become reliable contenders on the market.

Additionally, integrating a nitinol engine into existing systems poses compatibility issues with current infrastructure designed around traditional power sources—an aspect that isn't easily overcome without significant investment and redesign efforts across multiple sectors. This complexity adds layers of risk for businesses considering adopting such technologies since failure points multiply when introducing novel components into established frameworks.

Finally, ongoing research is essential if we want answers regarding whether reversible heat engines powered by this alloy will ever become viable options down the line—after all: Are reversible heat engines possible? As researchers tackle these questions head-on through experimentation and innovation over time will determine how soon we might see widespread adoption take flight!

GEE SMA: A Leader in Nitinol Production

In the dynamic landscape of nitinol technology, GEE SMA stands out as a pioneering force. Their commitment to innovation has positioned them at the forefront of nitinol engine development, addressing both technical challenges and market needs. By continuously refining their processes and products, GEE SMA is shaping the future of this remarkable alloy.

Overview of GEE SMA's Innovations

GEE SMA has made significant strides in advancing nitinol engine technology by introducing cutting-edge manufacturing techniques. Their innovations include enhanced shape memory alloys that improve performance and efficiency, which raises the question: What is a nitinol engine? These advancements not only optimize energy conversion but also open doors to new applications that were previously deemed impractical.

The company's research teams are actively exploring potential breakthroughs in reversible heat engines, asking if are reversible heat engines possible with today’s technology? With each development, GEE SMA contributes valuable insights into how nitinol can revolutionize energy systems across various industries.

Commitment to Quality and Customer Needs

Quality assurance is at the heart of GEE SMA’s operations, ensuring that every nitinol engine component meets rigorous standards. This dedication to quality translates into reliable performance for customers who might wonder why aren't nitinol engines used more widely? By addressing concerns about durability and efficiency head-on, GEE SMA builds trust within the engineering community.

Furthermore, their customer-centric approach involves collaborating closely with clients to tailor solutions that fit specific requirements. This commitment not only fosters innovation but also enhances overall satisfaction among users eager for efficient alternatives like the nitinol engine.

Impact on the Nitinol Engine Landscape

GEE SMA's influence on the nitinol engine landscape cannot be overstated; they are setting benchmarks for what can be achieved with this extraordinary material. Their contributions have sparked interest from various sectors looking to improve energy efficiency—prompting discussions on what is the efficiency of the nitinol engine compared to traditional methods? As more researchers explore these possibilities, it becomes clear that GEE SMA is paving a path toward broader acceptance and utilization of nitinol technologies.

Additionally, their focus on overcoming barriers to adoption has led to practical solutions that address economic considerations and technical challenges in implementation—two critical factors why aren't nitinol engines used more extensively? By leading by example, GEE SMA inspires confidence in stakeholders eager to embrace this innovative technology.

Future Prospects for Nitinol Engines

The future of nitinol engines is brimming with potential, especially as the world increasingly prioritizes energy efficiency. With a growing emphasis on sustainable technologies, nitinol engines are poised to play a significant role in various applications. Innovations in this field could redefine how we think about energy consumption and mechanical systems.

Emerging Trends in Energy Efficiency

As industries strive to reduce their carbon footprint, emerging trends highlight the efficiency of the nitinol engine. These engines leverage the unique properties of nitinol, particularly its shape memory effect, to harness energy more effectively than traditional systems. The increasing demand for renewable energy solutions has sparked interest in exploring what is the efficiency of the nitinol engine compared to conventional options.

Moreover, advancements in materials science are paving the way for enhanced performance and reliability in nitinol technology. This ongoing evolution will likely lead to further improvements in energy conservation techniques and operational effectiveness. As organizations adopt these cutting-edge innovations, we may witness a shift towards more eco-friendly practices across multiple sectors.

Potential Industries for Growth

The versatility of nitinol engines opens doors to numerous industries ripe for growth and innovation. From automotive applications seeking lightweight alternatives to aerospace engineering requiring reliable thermal management systems, nitinol technology can transform how businesses operate. Additionally, medical devices that rely on precise movements can benefit significantly from what is a nitinol engine's unique capabilities.

Renewable energy sectors such as solar and geothermal power also stand to gain from integrating these innovative engines into their systems. By enhancing efficiency and reducing waste through advanced heat conversion processes, companies can achieve better sustainability outcomes while addressing global energy challenges. The question remains: why aren't nitinol engines used more widely? Addressing this issue will be crucial for unlocking their full potential.

Role of Research and Development

Research and development (R&D) play an essential role in advancing the future prospects of nitinol engines. Ongoing studies aim to tackle existing barriers that hinder widespread adoption by exploring new designs and configurations—especially concerning reversible heat engines possible with this technology. By focusing on overcoming technical challenges related to durability and performance consistency, researchers will pave the way for commercial viability.

Investments in R&D also foster collaboration between academia and industry leaders, encouraging knowledge exchange that drives innovation forward. As scientists uncover new applications for what is a nitinol engine beyond traditional uses, we can expect breakthroughs that reshape our understanding of mechanical engineering principles altogether. Ultimately, sustained commitment to R&D will determine how quickly we embrace this exciting frontier.

Conclusion

The exploration of nitinol engines reveals a fascinating intersection of material science and engineering innovation. With their unique properties, nitinol engines offer significant advantages in efficiency and design flexibility. As we look toward the future, understanding what a nitinol engine can achieve becomes crucial for industries seeking sustainable solutions.

The Unique Benefits of Nitinol Engines

Nitinol engines are not just your average heat engines; they boast remarkable characteristics like the shape memory effect and superelasticity, which allow them to operate efficiently across various temperature ranges. These features enable nitinol engines to convert thermal energy into mechanical work with impressive effectiveness compared to traditional engines. Additionally, their lightweight nature and compact design make them suitable for applications in aerospace, automotive, and even medical devices.

Overcoming Hurdles in Adoption

Despite their potential, one might wonder why aren't nitinol engines used more widely? The answer lies in several barriers that hinder mainstream adoption: high production costs, limited awareness among industry stakeholders, and technical challenges related to scaling up manufacturing processes. Addressing these issues will require concerted efforts from researchers, manufacturers, and policymakers alike to pave the way for broader implementation.

Embracing the Future of Nitinol Technology

Looking ahead, are reversible heat engines possible with nitinol technology? The answer is promising; ongoing research is exploring innovative designs that could lead to breakthroughs in energy efficiency and sustainability. By embracing advancements in this field and investing in R&D initiatives focused on what is the efficiency of the nitinol engine, we can unlock new possibilities for clean energy solutions that meet our growing global demands.