Introduction

Nitinol, a fascinating alloy of nickel and titanium, is revolutionizing various industries with its unique capabilities. But what is Nitinol composed of? This remarkable material boasts a distinctive structure that enables it to exhibit extraordinary properties, such as shape memory and superelasticity. These characteristics make Nitinol not just a scientific curiosity but a game-changer in fields ranging from medicine to aerospace engineering.

Understanding Nitinol and Its Composition

At its core, Nitinol's composition consists primarily of nickel (about 55%) and titanium (around 45%), which together create an alloy that behaves in ways unlike most metals. The specific ratio of these elements can be adjusted to tailor the properties of Nitinol for different applications, making it incredibly versatile. Understanding this composition is essential for grasping how the unique properties of Nitinol come into play across various sectors.

The Unique Properties of Nitinol

The properties of Nitinol are nothing short of remarkable; it can return to its original shape after being deformed when heated above a certain temperature. This phenomenon, known as the shape memory effect, is what makes Nitinol wire particularly appealing for numerous applications—from medical devices to robotics. Additionally, its superelasticity allows it to undergo significant deformation without permanent change, further expanding its utility in demanding environments.

Industries Capitalizing on Nitinol

Industries are increasingly capitalizing on the advantages offered by this extraordinary alloy; from medical devices like stents and guidewires to components in aerospace engineering that withstand extreme conditions. As companies explore what is nitinol used for in their products, they discover innovative solutions that enhance functionality and performance while reducing weight and complexity. With growing interest comes the question: what about the economic aspects? The price trends associated with Nitinol reflect its rising demand across these industries—it's clear that this alloy's potential is just beginning to be realized.

Nitinol in the Medical Field

Nitinol, a remarkable alloy primarily composed of nickel and titanium, has transformed the medical field in ways previously thought to be science fiction. Its unique properties allow it to return to a predetermined shape when heated, making it an ideal candidate for various medical devices and implants. With growing interest in Nitinol's applications, understanding what nitinol is composed of becomes crucial for innovators looking to harness its potential.

Medical Devices and Implants

When discussing what is nitinol used for in medicine, one cannot overlook its role in medical devices and implants. The structure of Nitinol allows it to be both flexible and resilient, which is vital for stents and guidewires that navigate through the human body. These devices benefit from the properties of Nitinol, as they can expand once positioned correctly, reducing trauma during procedures.

Moreover, the biocompatibility of Nitinol composition makes it suitable for long-term implantation within the body without causing adverse reactions. This quality has led to an increase in demand for Nitinol-based products as hospitals seek effective solutions that minimize patient recovery times. As such, monitoring trends like Nitinol price can provide insights into how this material will shape future innovations.

Minimally Invasive Surgical Tools

Minimally invasive surgical tools have revolutionized how surgeries are performed, with Nitinol wire being a key player in this transformation. Surgeons now utilize tools made from this alloy due to its ability to adapt and maneuver easily within tight spaces while maintaining strength—an essential feature when precision is paramount. The unique properties of Nitinol ensure these instruments can perform complex tasks without requiring large incisions.

Additionally, as healthcare continues to advance towards less invasive techniques, the demand for tools utilizing Nitinol structure is expected to soar. This trend not only enhances patient outcomes but also reduces hospital stays and overall costs associated with surgical procedures. Consequently, understanding what does nitinol stand for becomes increasingly relevant as more healthcare professionals recognize its vital role in modern medicine.

Innovations in Orthodontics

In orthodontics, innovations powered by Nitinol have changed how braces function today compared to traditional methods. The elasticity of Nitinol wire allows braces to exert continuous pressure on teeth while adapting comfortably over time—a game-changer for patient comfort during treatment periods that can often stretch years. Orthodontists appreciate how this alloy's unique properties lead to more efficient tooth movement with fewer adjustments required.

Furthermore, advancements using what is nitinol composed of extend beyond just wires; they include self-ligating brackets that reduce friction during tooth alignment processes. By integrating these innovative materials into their practice, orthodontists can offer patients faster results with less discomfort—a win-win scenario! As we see ongoing research into new applications within orthodontics driven by the versatile nature of this material, it's clear that understanding its composition will continue shaping future developments.

Nitinol in Aerospace Engineering

Nitinol, a remarkable alloy of nickel and titanium, is making significant waves in aerospace engineering. Its unique properties, such as shape memory and superelasticity, have opened new avenues for innovation in space exploration. As we delve into the applications of Nitinol in this field, it becomes clear that its composition and structure are pivotal to its functionality.

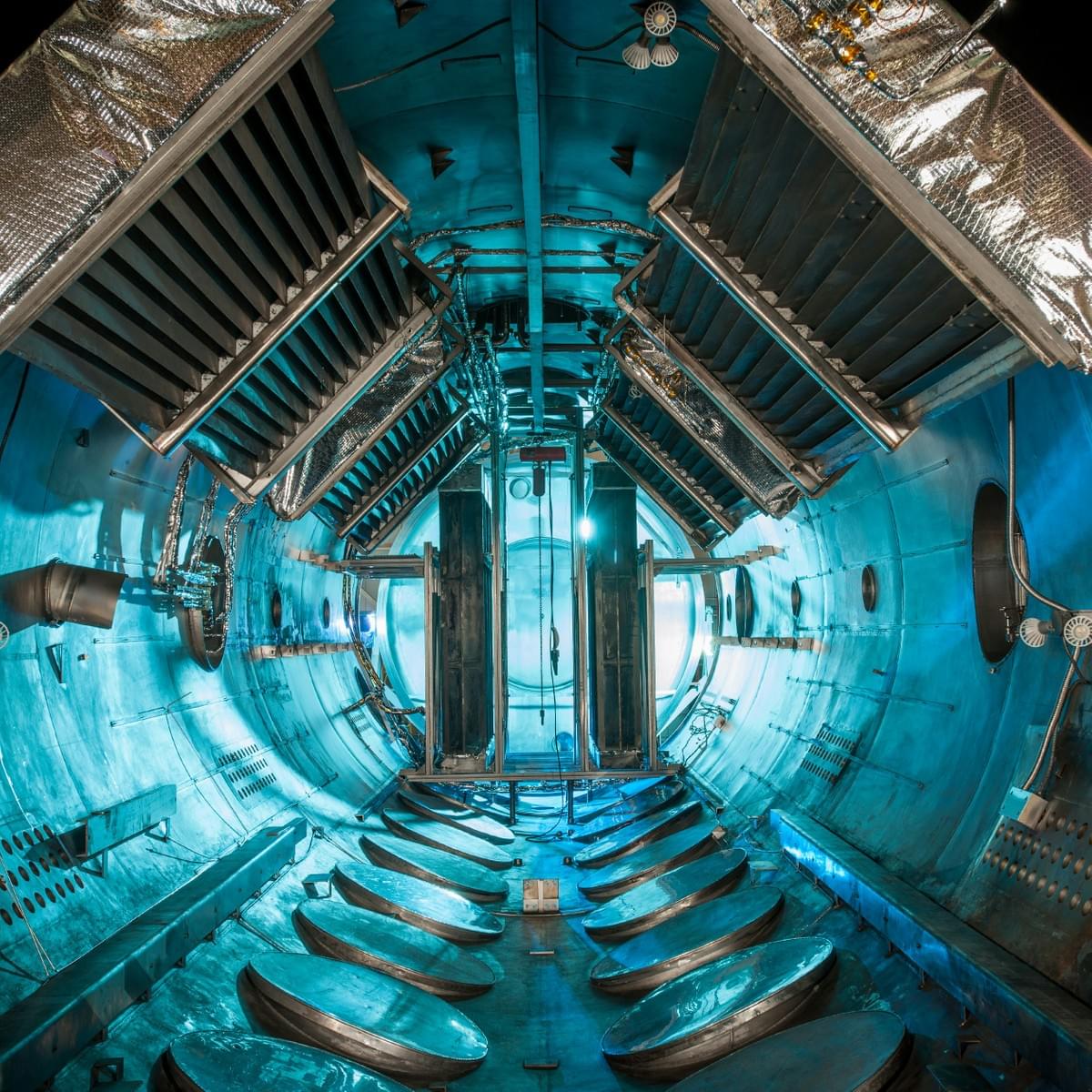

Applications in Space Exploration

In the realm of space exploration, Nitinol is proving to be an invaluable asset due to its lightweight nature and remarkable resilience. What is Nitinol used for in this context? Engineers employ Nitinol wire and components for deployable structures like antennas and solar panels that need to withstand extreme conditions while maintaining reliability. The properties of Nitinol allow these structures to return to their original shape after being deployed, a crucial feature when dealing with the vacuum of space.

GEE SMA Contributions to Space Missions

The Global Engineering Excellence (GEE) has been at the forefront of integrating Shape Memory Alloys (SMA), including Nitinol, into various space missions. What does Nitinol stand for? It stands for Nickel Titanium Naval Ordnance Laboratory, reflecting its origins and composition that lend it extraordinary capabilities. GEE's innovative use of Nitinol has led to advancements in spacecraft mechanisms that require precise actuation under varying temperatures—an essential factor during missions where thermal extremes are commonplace.

Reliability in Extreme Environments

One of the standout features of Nitinol is its reliability under extreme environmental conditions—a characteristic that makes it a favorite among aerospace engineers. The ability of Nitinol wire to maintain performance despite fluctuations in temperature or pressure ensures that critical systems function smoothly during missions beyond our atmosphere. With ongoing research into reducing the cost associated with producing this alloy—often referred to as Nitinol price discussions—the future looks promising for expanding its applications even further within aerospace engineering.

Nitinol in Automotive Technology

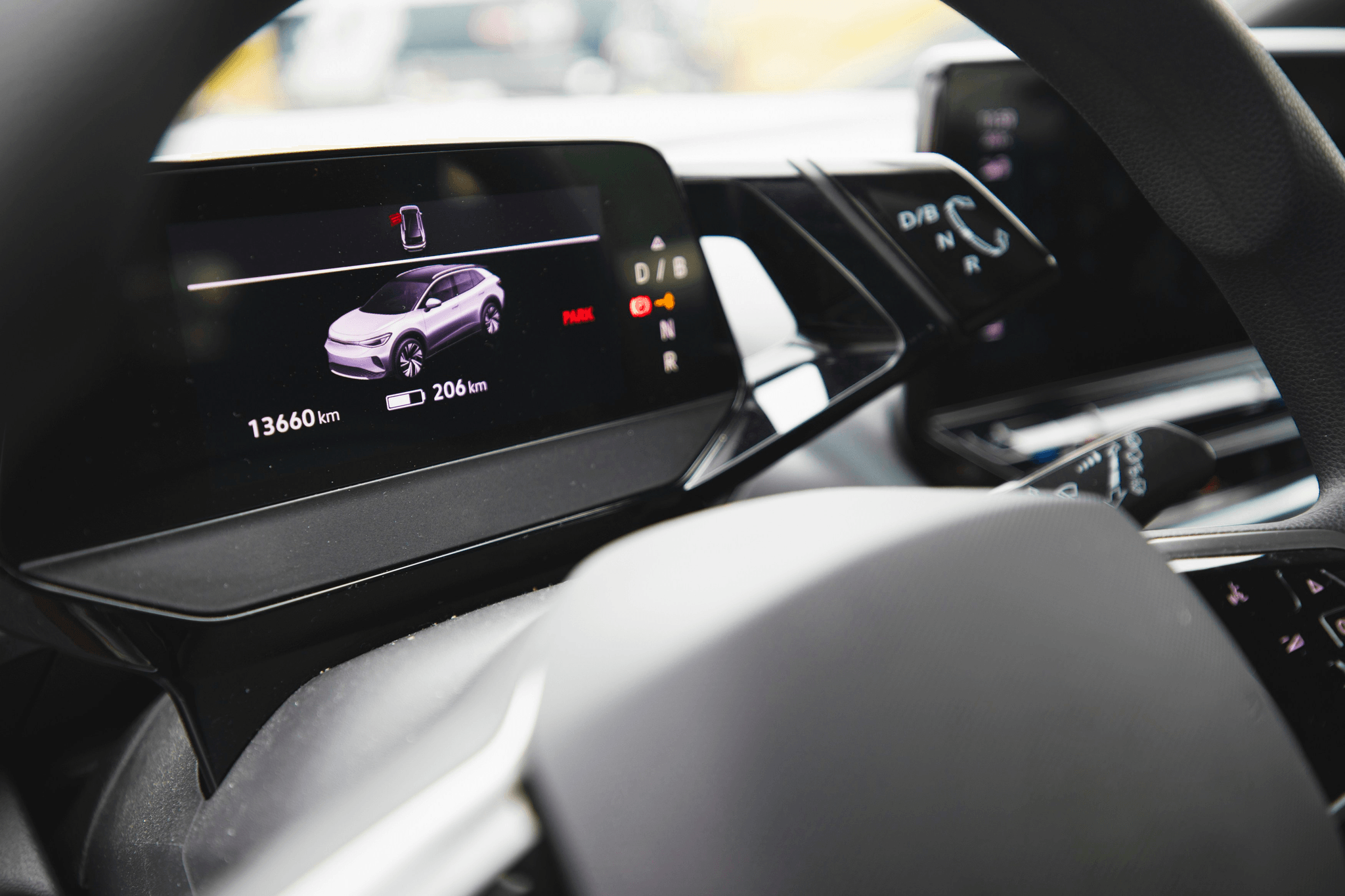

Nitinol, the fascinating shape memory alloy made from nickel and titanium, is making waves in the automotive industry. With its unique properties of flexibility and strength, this material is not just a one-hit wonder; it’s revolutionizing how vehicles are designed and operated. From smart sensors to safety mechanisms, Nitinol's composition plays a crucial role in enhancing automotive technology.

Smart Sensors and Actuators

Smart sensors and actuators are at the forefront of modern automotive innovation, and Nitinol wire is leading the charge. These devices utilize the properties of Nitinol to respond to temperature changes or electrical stimuli, allowing for precise control over vehicle functions. Whether it's adjusting seat positions or controlling airbag deployment, understanding what Nitinol is used for in these applications highlights its versatility.

The unique structure of Nitinol enables it to return to a predetermined shape after deformation, making it ideal for actuators that require reliable movement without bulky components. This means that cars can be lighter while maintaining functionality – a win-win! As manufacturers continue to explore what does Nitinol stand for in this context, we can expect even more innovative uses in smart technology.

Enhancing Fuel Efficiency

Fuel efficiency remains a hot topic among automakers striving for greener vehicles, and here’s where Nitinol really shines. By incorporating Nitinol into various systems within vehicles, manufacturers can optimize performance while reducing weight—essentially getting more bang for their buck! The properties of Nitinol allow for smaller components without sacrificing strength or reliability.

For instance, using Nitinol in exhaust systems can help manage heat better than traditional materials, leading to improved engine performance and lower emissions. Plus, with the rising discussion around Nitinol price trends—often influenced by demand—automakers are keen on finding cost-effective solutions that don’t compromise quality or sustainability.

Innovations in Safety Mechanisms

Safety is paramount when it comes to automotive design; that's where innovations involving Nitinol take center stage. The alloy's ability to undergo significant deformation before breaking makes it an excellent candidate for safety mechanisms like crumple zones and airbags. By utilizing what is nitinol composed of effectively within these designs, automakers can enhance passenger protection during collisions.

Moreover, as research continues into advanced applications like self-repairing materials using shape memory effects from Nitinol structure characteristics, we might soon see cars that automatically adjust their form after minor accidents! This breakthrough could redefine safety standards across the industry as well as influence consumer perceptions about vehicle resilience.

Nitinol in Robotics and Automation

Nitinol, a remarkable alloy primarily composed of nickel and titanium, is revolutionizing the field of robotics and automation. Its unique properties, including shape memory and superelasticity, make it an ideal candidate for applications that require precise movement and adaptability. Understanding what nitinol is used for in robotics can provide insight into its transformative potential across various industries.

Shape Memory Alloys in Robotics

Shape memory alloys (SMAs) like nitinol are capable of returning to a predetermined shape when heated above a specific temperature. This property allows robotic systems to perform complex tasks with minimal energy consumption, offering a sustainable alternative to traditional actuators. As researchers continue to explore the properties of nitinol, they are uncovering innovative ways to integrate this versatile material into robotic designs.

Incorporating nitinol into robotic applications not only enhances performance but also simplifies mechanical structures by reducing the number of moving parts required. The lightweight nature of nitinol contributes to improved efficiency in robots that need to navigate challenging environments or perform delicate operations. Consequently, understanding what does Nitinol stand for becomes essential in grasping its significance within the realm of robotics.

Nitinol Wire for Actuation

Nitinol wire serves as a critical component in many actuation systems due to its ability to contract when heated and expand upon cooling. This unique behavior allows for precise control over movement, making it ideal for applications ranging from micro-robots to larger automated systems. The versatility of nitinol wire means that it can be used in various configurations, adapting easily to different design requirements.

The integration of Nitinol wire into automation technology leads to advancements in fields such as manufacturing and healthcare where precision is paramount. For instance, surgical robots benefit immensely from the flexibility offered by nitinol actuation mechanisms, improving both accuracy and safety during procedures. As industries increasingly recognize the advantages associated with Nitinol's composition—particularly its lightweight yet robust structure—the demand continues to grow.

Advancements in Prosthetics

The world of prosthetics has seen significant advancements thanks to the incorporation of nitinol technology. By utilizing the properties of Nitinol, prosthetic limbs can now mimic natural movements more effectively than ever before; this includes bending and flexing as if they were real limbs! These innovations not only enhance user experience but also empower individuals with disabilities by providing greater mobility.

Moreover, prosthetic devices made with Nitinol offer durability while remaining lightweight—a crucial factor when considering comfort over extended periods of use. As researchers delve deeper into understanding what is nitinol composed of, they are finding new ways to optimize these materials further for enhanced functionality and cost-effectiveness; thus addressing concerns around Nitinol price trends as well! The future looks bright as we continue exploring how this extraordinary alloy can redefine robotics and automation across multiple sectors.

Nitinol in Consumer Products

Nitinol, a remarkable alloy of nickel and titanium, is finding its way into everyday consumer products, transforming how we interact with technology and design. From innovative gadgets to stylish accessories, the unique properties of Nitinol are being harnessed to create items that are not only functional but also aesthetically pleasing. The versatility of Nitinol composition allows it to be adapted for various applications, making it a sought-after material across multiple industries.

Everyday Innovations Using Nitinol

What is nitinol used for in everyday life? Beyond its medical and aerospace applications, nitinol is making waves in consumer products like eyeglass frames and mobile phone components. The shape memory properties of Nitinol wire allow these items to retain their shape after deformation, providing durability and flexibility that traditional materials simply cannot match.

For instance, the ability of nitinol to respond to temperature changes means that some eyeglasses can self-adjust for comfort or fit when exposed to heat. This innovation not only enhances user experience but also demonstrates how the unique properties of nitinol can simplify our daily routines. As more companies recognize the potential of this alloy, we can expect an influx of creative solutions that leverage its remarkable characteristics.

Fashion and Wearable Technology

In the realm of fashion and wearable technology, what does Nitinol stand for? It stands for creativity intertwined with functionality! Designers are increasingly incorporating nitinol into jewelry and smart wearables due to its lightweight nature and ability to return to its original shape after bending or twisting.

Take bracelets made from nitinol wire; they can be designed in intricate shapes without fear of them losing form over time. Not only do these pieces offer a modern aesthetic appeal, but they also embody resilience—a perfect metaphor for today's lifestyle. As wearable technology evolves, expect more innovations utilizing the dynamic properties of Nitinol composition that blend style with cutting-edge functionality.

Unique Applications in Sporting Goods

When it comes to sporting goods, what is nitinol composed of? This incredible alloy's nickel-titanium structure lends itself well to creating high-performance equipment such as golf clubs or fishing rods that benefit from enhanced flexibility and strength. Athletes appreciate how these products can withstand rigorous use while maintaining their integrity—thanks largely to the unique properties inherent in nitinol.

Moreover, some sporting goods manufacturers have started integrating Nitinol into safety gear like helmets or protective pads where impact resistance is crucial. By employing this advanced material, companies are redefining performance standards while ensuring athletes' safety during intense activities. As innovation continues within this space, we may soon see even more groundbreaking uses for nitinol across various sports disciplines.

Conclusion

As we wrap up our exploration of Nitinol, it’s clear that this remarkable material is poised for an exciting future across various industries. From its unique properties to innovative applications, Nitinol stands at the forefront of technological advancement. As industries continue to discover what Nitinol is used for, its significance will only grow.

The Future of Nitinol across Industries

Looking ahead, the future of Nitinol seems bright and full of potential. With ongoing research into its properties and composition, innovators are finding new ways to harness what does Nitinol stand for in fields like medicine and aerospace engineering. As understanding deepens around the structure of Nitinol, we can expect even more groundbreaking applications that leverage its shape memory effect and superelasticity.

Economic Aspects: Nitinol Price Trends

When discussing the economic aspects surrounding this material, it's essential to consider the fluctuations in Nitinol price over time. As demand increases due to expanding applications—from medical devices to automotive technology—the market dynamics will inevitably shift. Understanding these trends can help industries better prepare for future investments in technologies that utilize Nitinol wire or other forms.

The Ever-Evolving Nitinol Landscape

The landscape surrounding Nitinol is ever-evolving as researchers continually uncover new possibilities within this alloy's unique composition. Innovations are emerging not just in specialized fields but also in consumer products where everyday innovations using Nitinol enhance functionality and design. With every breakthrough in understanding the properties of Nitinol, we inch closer to a future where this extraordinary material reshapes our world.