Introduction

Nitinol metal, a remarkable alloy of nickel and titanium, has captured the attention of industries ranging from medical to aerospace due to its unique properties. Known for its shape memory and superelastic capabilities, this memory metal can return to a predetermined shape when heated, making it invaluable in various applications. As we explore the composition and science behind Nitinol alloys, we will uncover why this innovative material is becoming increasingly vital in modern manufacturing.

Understanding Nitinol Metal Basics

At its core, Nitinol metal consists primarily of nickel and titanium, with specific ratios that influence its behavior and properties. The unique combination results in an alloy that exhibits both shape memory effects and superelasticity under certain conditions. Understanding the Nitinol metal composition is crucial for engineers and manufacturers looking to harness its potential across diverse applications.

The Science Behind Nitinol Alloys

The fascinating science behind Nitinol alloys involves phase transformations that occur at specific temperatures, allowing the material to remember its original shape after deformation. This transformation is what makes Nitinol wire so versatile; it can be used in everything from stents in medical procedures to actuators in robotics. By delving into the mechanics of these phase changes, we gain insights into how Nitinol can outperform traditional metals in many scenarios.

Importance of Nitinol in Modern Manufacturing

The importance of Nitinol in modern manufacturing cannot be overstated; it offers solutions that enhance product performance while reducing costs. With applications like the use of Nitinol metal stents revolutionizing healthcare by providing less invasive options for patients, this alloy is paving the way for innovation across sectors. In addition to transforming industries, understanding factors such as the fluctuating Nitinol metal price helps stakeholders make informed decisions about production and investment strategies.

What is Nitinol Metal?

Nitinol metal is a fascinating alloy that has captured the attention of various industries due to its unique properties and versatile applications. This remarkable material, primarily composed of nickel and titanium, exhibits behaviors that set it apart from traditional metals. Understanding the composition and characteristics of Nitinol can illuminate its significance in modern manufacturing, particularly in fields like medicine, aerospace, and robotics.

Composition of Nitinol Metal

The composition of Nitinol metal typically consists of approximately 55% nickel and 45% titanium, although slight variations can occur depending on specific applications. This unique blend creates an alloy that possesses both shape memory and superelasticity—two standout features that make Nitinol so desirable for various uses. The precise balance between nickel and titanium is crucial; even minor adjustments can significantly influence the mechanical properties and performance of Nitinol wire or other forms.

Unique Properties of Nitinol

What truly sets Nitinol apart are its extraordinary properties: shape memory effect (SME) and superelasticity. The shape memory effect allows the material to return to a pre-defined shape when heated above a certain temperature, making it ideal for applications like nitinol metal stents used in medical procedures. Superelasticity enables the material to undergo significant deformation without permanent damage—an attribute that proves invaluable in fields ranging from robotics to aerospace engineering.

Nitinol vs. Traditional Metals

When comparing Nitinol to traditional metals, the differences are striking. While conventional materials like steel or aluminum may excel in strength or weight considerations, they lack the unique capabilities found in nitinol alloys such as shape recovery or extreme flexibility under stress. This makes nitinol metal a game-changer for industries looking for advanced solutions; it's not just about strength anymore—it's about adaptability and functionality tailored to specific needs.

Nitinol Uses Across Industries

Nitinol metal, known for its unique properties, has found a plethora of applications across various industries. Its exceptional ability to return to a predetermined shape upon heating, often referred to as memory, sets it apart from traditional materials. This section delves into the diverse uses of Nitinol and how it is revolutionizing sectors such as medicine, aerospace, and robotics.

Medical Applications of Nitinol

In the medical field, Nitinol's properties are nothing short of miraculous. One of the most notable applications is in the creation of Nitinol metal stents, which are used to keep arteries open in patients with cardiovascular issues. The flexibility and biocompatibility of Nitinol alloy make it an ideal choice for various surgical tools and implants, ensuring patient safety while enhancing performance.

Moreover, Nitinol wire is frequently utilized in minimally invasive surgeries due to its ability to be manipulated easily without losing its structural integrity. The unique composition of Nitinol allows for devices that can adapt to different body temperatures and conditions, making them more effective than traditional metal counterparts. As demand for innovative medical solutions grows, the role of Nitinol in healthcare continues to expand.

Nitinol in Aerospace Engineering

The aerospace industry has also embraced the advantages offered by this remarkable material. With its lightweight nature combined with high strength-to-weight ratios, Nitinol is an excellent candidate for components that require durability without adding excessive weight—think aircraft frames or engine parts! Additionally, when subjected to temperature changes during flight operations, the memory metal properties allow components made from Nitinol alloy to return to their original shape reliably.

Nitinol's resistance to corrosion further enhances its appeal in aerospace applications where environmental factors can be harsh and unforgiving. As engineers continue exploring new materials that can withstand extreme conditions while being cost-effective—especially concerning fluctuating Nitinol metal prices—the future looks bright for this versatile alloy in aviation technology.

Nitinol in Robotics and Automation

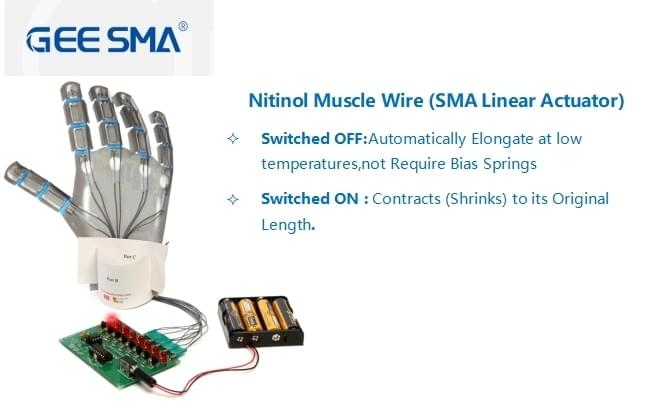

Robotics is another field where the unique characteristics of nitinol metal shine brightly. Engineers leverage its shape memory effect for actuators that mimic human muscle movements—an innovative approach that enhances robotic functionality while keeping designs compact and lightweight. The use of nitinol wire in robotic systems enables precise control over motion and adaptability under varying loads or temperatures.

Moreover, automation technology benefits from incorporating nitinol alloys into devices requiring reliable actuation mechanisms without bulky motors or complex systems. This not only streamlines designs but also reduces overall production costs associated with traditional materials—an important factor considering current trends regarding manufacturing economics around nitinol metal composition and price fluctuations. As robotics advances toward more sophisticated applications like soft robotics or wearable tech, nitinol will undoubtedly play a pivotal role.

Prototyping with Nitinol Metal

Prototyping with Nitinol metal opens up a realm of possibilities due to its unique properties, including shape memory and superelasticity. This metal is not only fascinating but also versatile, making it an ideal candidate for various prototypes across industries. The ability to manipulate Nitinol wire into complex shapes and forms allows engineers and designers to explore innovative applications that were previously unattainable.

Developing Prototypes Using Nitinol Wire

Creating prototypes using Nitinol wire involves understanding its composition and how it behaves under different conditions. The process often starts with selecting the appropriate Nitinol alloy based on the desired mechanical properties and thermal characteristics required for the prototype. Once the right alloy is chosen, designers can craft intricate components such as springs or actuators that respond dynamically to temperature changes, showcasing the remarkable capabilities of this memory metal.

In medical applications, for example, a Nitinol metal stent can be developed through precise prototyping methods that ensure optimal performance within the human body. The flexibility and strength of Nitinol make it ideal for creating devices that need to withstand significant stress while maintaining their shape over time. As innovations in manufacturing techniques advance, developing prototypes using Nitinol wire becomes more efficient and cost-effective.

Challenges in Nitinol Prototyping

Despite its advantages, prototyping with Nitinol presents several challenges that require careful consideration. One major hurdle is managing the costs associated with Nitinol metal price fluctuations, which can impact project budgets significantly. Additionally, working with this specialized material necessitates a deep understanding of its unique properties; improper handling or processing can lead to undesirable outcomes in prototype performance.

Another challenge lies in achieving precise control over the heat treatment processes necessary for activating the shape memory effect in Nitinol alloys. Designers must ensure that their prototypes undergo proper thermal cycling to unlock their full potential as functional components in various applications. Furthermore, limited availability of certain grades of nitinol wire may pose difficulties when sourcing materials for large-scale prototyping efforts.

Case Studies: Successful Nitinol Prototypes

Several success stories highlight the effectiveness of prototyping with nitinol metal across diverse fields. One notable case includes the development of advanced medical devices like self-expanding stents made from nitinol alloy; these devices have revolutionized minimally invasive surgeries by providing superior flexibility and biocompatibility compared to traditional materials. Their ability to adapt seamlessly within vascular systems showcases how innovative use of nitinol can enhance patient outcomes significantly.

In aerospace engineering, engineers have successfully utilized nitinol's unique properties in actuators designed for aircraft wings; these prototypes demonstrate how shape memory effects can contribute to improved aerodynamics and fuel efficiency during flight operations. Such applications underscore not only the versatility but also the transformative potential inherent in developing successful prototypes using this remarkable metal.

As more industries recognize nitinol's advantages—whether through deploying it as a critical component or leveraging its unique characteristics—the future looks bright for continued innovation driven by effective prototyping strategies.

Manufacturing Techniques for Nitinol

Nitinol metal, known for its unique properties and diverse applications, requires specialized manufacturing techniques to harness its potential fully. The processes involved in creating Nitinol products, from alloys to wires and stents, are crucial in maintaining the integrity and functionality of this remarkable material. Understanding these techniques not only sheds light on the complexities of Nitinol but also highlights the innovations driving its use across various industries.

Additive Manufacturing of Nitinol Alloy

Additive manufacturing, or 3D printing, has revolutionized how we produce complex geometries with nitinol alloy. This technique allows manufacturers to create intricate designs that traditional methods may struggle with, particularly when dealing with the unique properties of nitinol metal. With additive manufacturing, it’s possible to optimize the performance of nitinol wire by tailoring its microstructure and composition during production.

The versatility of additive manufacturing means that applications such as Nitinol metal stents can be customized for specific medical needs, enhancing patient outcomes significantly. Additionally, this method reduces material waste compared to subtractive processes, making it more environmentally friendly while potentially lowering nitinol metal price over time. As industries continue to embrace 3D printing technology for nitinol uses, we can expect a surge in innovative products that leverage this memory metal's capabilities.

Traditional Methods for Nitinol Metal Fabrication

While additive manufacturing is gaining popularity, traditional methods still play a vital role in fabricating nitinol metal components. Techniques such as forging and machining remain essential for producing high-quality products like Nitinol wire and other structural components used in various applications. These methods ensure that the specific nitinol metal composition is maintained throughout the production process.

Traditional fabrication techniques allow manufacturers to achieve precise tolerances required for critical applications like medical implants or aerospace components where reliability is paramount. However, these processes often come with higher costs associated with labor and material waste compared to newer approaches like additive manufacturing. Nevertheless, understanding both traditional and modern methods is crucial for optimizing production strategies while balancing quality and cost-effectiveness.

Quality Control in Nitinol Production

Quality control is a cornerstone of successful nitinol production; ensuring consistency in properties such as shape memory effect and superelasticity is essential for performance across all applications. Rigorous testing protocols are implemented at every stage—from raw material selection based on nitinol metal composition through processing techniques—to guarantee that final products meet stringent industry standards. This meticulous attention ensures that items like Nitinol metal stents function reliably within their intended environments.

In addition to mechanical testing, advanced technologies such as X-ray diffraction and scanning electron microscopy are employed to analyze microstructures thoroughly during quality assessments. By understanding how variations in processing affect the final properties of nitinol alloy products, manufacturers can fine-tune their approaches accordingly—ultimately leading to better-performing components at competitive prices amidst fluctuating market conditions surrounding nitinol metal price trends. Ensuring high-quality standards not only enhances product reliability but also fosters trust among consumers who depend on these innovative materials.

The Economics of Nitinol Metal

Nitinol metal has garnered significant attention in various industries due to its unique properties and applications. However, understanding the economics behind this remarkable material is crucial for manufacturers and businesses alike. Factors such as production costs, market demand, and pricing strategies play a pivotal role in shaping the future of Nitinol metal.

Factors Influencing Nitinol Metal Price

The price of nitinol metal is influenced by several factors, including its composition, production methods, and raw material availability. For instance, the specific alloy ratios used in creating nitinol can significantly impact costs; variations in nickel and titanium percentages lead to different mechanical properties that cater to diverse applications like nitinol wire or nitinol stents. Additionally, fluctuations in the global market for raw materials can cause ripples in the pricing structure of nitinol metal.

Supply chain dynamics also play a critical role in determining the Nitinol metal price. As demand increases across sectors such as medical devices and aerospace engineering, manufacturers must adapt their production capabilities accordingly. This adaptation often leads to increased operational costs that are subsequently passed on to consumers through higher prices for products utilizing Nitinol alloy.

Lastly, technological advancements may influence pricing by improving manufacturing efficiency or introducing cost-effective alternatives for producing nitinol memory metal. Innovations such as additive manufacturing techniques could reduce waste and lower overall expenses while maintaining high-quality standards essential for applications like medical implants or robotic components.

Analyzing the Market Demand for Nitinol

The demand for nitinol metal has surged over recent years due to its versatile applications across various fields. In particular, sectors like healthcare are experiencing an increasing reliance on nitinol wire and other forms of this unique alloy for creating innovative solutions like stents and surgical tools. As more industries recognize the benefits of using nitinol—such as its shape memory effect—the market demand continues to grow exponentially.

Another significant driver of demand is the ongoing research into new uses for nitinol materials beyond traditional applications. Emerging technologies within robotics and automation have opened up exciting possibilities where Nitinol's unique characteristics can enhance performance—think flexible actuators or smart devices that respond dynamically to stimuli! Consequently, companies are eager to invest in R&D focused on harnessing these properties further.

However, it’s important not just to focus on current trends but also anticipate future shifts in market dynamics that could affect demand patterns for Nitinol alloy products. With sustainability becoming an increasingly important consideration globally, manufacturers will need to explore eco-friendly practices while ensuring they meet evolving consumer expectations regarding product performance and environmental impact.

Cost-Effective Strategies for Nitinol Production

To navigate the complexities surrounding Nitinol production costs effectively, companies must adopt strategic approaches tailored specifically toward maximizing efficiency without compromising quality standards associated with this specialized material. One possible strategy involves investing in advanced manufacturing technologies capable of producing high-quality nitinol wire at lower operational costs—think automated processes or improved casting techniques!

Moreover, fostering strong relationships with suppliers can lead to better pricing arrangements when sourcing raw materials essential for crafting high-performance alloys like those used in medical devices or aerospace components featuring innovative designs utilizing shape memory effects inherent within Nitino lmetal composition itself! By negotiating favorable contracts based on consistent purchase volumes over time rather than one-off transactions could yield significant savings that directly influence overall profitability margins related specifically back down through supply chains leading into end-user markets where these products find application daily!

Lastly—and perhaps most importantly—companies should continually assess their production processes through regular audits aimed at identifying areas ripe for improvement or potential bottlenecks hindering output levels necessary meet surging demands placed upon them by growing interest surrounding various uses attributed specifically back towards versatility found within those amazing properties exhibited throughout every inch encompassing what we know today simply put: “NITINOL METAL.”

Conclusion

In summary, the versatility and unique properties of Nitinol metal have paved the way for groundbreaking innovations across various industries. From medical devices like Nitinol metal stents to aerospace applications, the demand for Nitinol continues to grow as its advantages become increasingly recognized. As we look ahead, it's clear that the journey of Nitinol is just beginning.

Innovations in Nitinol Applications

The landscape of Nitinol uses is expanding rapidly, particularly in the medical field where its superelasticity and shape memory properties are game-changers. For instance, Nitinol wire is being utilized in minimally invasive surgeries due to its ability to return to a predetermined shape after deformation, making procedures safer and more efficient. Beyond healthcare, industries such as robotics are leveraging this remarkable material for actuators and sensors that can adapt dynamically to their environments.

Future Trends for Nitinol Metal Manufacturing

As technology advances, we can expect significant developments in Nitinol metal manufacturing techniques that will enhance efficiency and reduce costs. With fluctuating market conditions impacting the Nitinol metal price, manufacturers are exploring innovative production methods such as additive manufacturing to optimize resource use while maintaining high quality standards. Furthermore, ongoing research into new alloys and compositions promises even more specialized applications tailored to specific industry needs.

GEE SMA's Role in Advancing Nitinol Technology

GEE SMA stands at the forefront of advancing Nitinol technology by focusing on research and development that harnesses the full potential of this extraordinary material. Their commitment to innovation has led to breakthroughs in customizing Nitinol alloy compositions for diverse applications ranging from biomedical devices to aerospace components. By prioritizing quality control and cost-effective strategies in production, GEE SMA is not only shaping the future of Nitinol but also making it accessible for a broader range of uses.