Introduction

In the ever-evolving world of materials science, titanium ingots stand out due to their exceptional properties and diverse applications. These solid blocks of titanium are essential in various industries, from aerospace to medical devices, thanks to their lightweight yet robust nature. Understanding the nuances of titanium ingot price is crucial for manufacturers and consumers alike, as it directly influences project budgets and material choices.

Understanding Titanium Ingots

Titanium ingots are produced through a complex process that transforms raw titanium into a usable form for manufacturing. Composed primarily of pure titanium, these ingots exhibit remarkable strength-to-weight ratios and corrosion resistance. Their unique characteristics make them a preferred choice for high-performance applications across multiple sectors.

Importance of High Purity Materials

High purity materials like pure titanium ingots play a pivotal role in ensuring product reliability and performance. The presence of impurities can significantly affect the mechanical properties and overall durability of the final product. Industries that prioritize safety and efficiency, such as aerospace and healthcare, often seek high purity titanium to enhance their operational standards.

Overview of Titanium Ingot Price Trends

The price trends for titanium ingots have seen fluctuations influenced by various market dynamics over recent years. Factors such as global demand, production costs, and sourcing practices contribute to changes in the price of titanium per kg. Keeping an eye on these trends helps businesses make informed decisions regarding their purchases while navigating the complexities associated with pricing structures like titanium ingot price per gram.

What are Titanium Ingots?

Titanium ingots are solid blocks of titanium metal that serve as the primary form from which various titanium products are manufactured. These ingots are produced through a complex process that involves melting high-purity titanium sponge or scrap, followed by casting and cooling to create a dense, homogeneous material. The end result is a versatile and durable product with applications across numerous industries, making it crucial for understanding the dynamics of titanium ingot price.

Definition and Composition

At its core, a titanium ingot is defined as a large piece of titanium that has been melted and cast into a specific shape for further processing. The composition typically includes at least 90% titanium, with small amounts of other alloying elements such as aluminum or vanadium to enhance its mechanical properties. This purity level is essential because the price of titanium per kg largely hinges on the quality and composition of the metal used in manufacturing these ingots.

High Purity Titanium Characteristics

High purity titanium is characterized by its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, making it an ideal choice for demanding applications. This type of pure titanium ingot often boasts low levels of impurities, which directly influence its mechanical properties and overall performance in various environments. As a result, industries that require high-performance materials often pay close attention to the titanium ingot price per gram when sourcing their materials.

Applications in Various Industries

Titanium ingots find their way into multiple sectors due to their unique properties; aerospace, medical devices, automotive components, and marine applications are just a few examples where they shine. In aerospace applications, for instance, lightweight yet strong components made from pure titanium can significantly improve fuel efficiency while maintaining structural integrity under extreme conditions. Consequently, understanding the factors affecting the price of titanium per kg becomes essential for businesses looking to invest in high-quality materials without breaking the bank.

Factors Influencing Titanium Ingot Price

Understanding the factors that influence titanium ingot price is crucial for buyers and sellers alike. The market dynamics, sourcing strategies, and production costs all play pivotal roles in determining the final price of titanium per kg. By analyzing these elements, stakeholders can make informed decisions regarding their purchases and investments in pure titanium ingots.

Market Demand and Supply Dynamics

Market demand and supply dynamics are fundamental to understanding the fluctuations in titanium ingot price. As industries such as aerospace, medical devices, and automotive continue to grow, the demand for high-purity titanium ingots increases correspondingly. When demand outpaces supply, prices tend to rise; conversely, an oversupply can lead to lower prices per kg.

Additionally, geopolitical factors can impact supply chains significantly. For instance, disruptions in mining operations or export restrictions from major producing countries can create bottlenecks that hike up the price of titanium per kg. Thus, staying updated on global market trends is essential for anyone involved in purchasing or selling titanium products.

Material Sourcing and Production Costs

The sourcing of raw materials plays a critical role in determining the overall cost structure for producing titanium ingots. High-quality raw materials are often more expensive due to their scarcity and extraction challenges. Consequently, these elevated sourcing costs directly affect the final pricing of pure titanium ingots.

Production methods also contribute significantly to material expenses; advanced techniques like vacuum arc remelting (VAR) or electron beam melting (EBM) require substantial investment but yield higher purity levels that justify a higher price per gram or kg. Therefore, manufacturers must balance quality with cost-efficiency when setting their pricing strategies for titanium ingots.

Comparison of Titanium Ingot Price per kg

When comparing titanium ingot price per kg across different suppliers or markets, it’s essential to consider several factors such as purity levels and production methods used by each supplier. Prices may vary widely based on these criteria; hence buyers should conduct thorough research before making commitments.

For example, while some suppliers may offer lower prices on standard-grade titanium ingots, they might not meet specific industry standards required for critical applications—leading customers back to higher-priced options that guarantee quality and reliability over time. Understanding this landscape helps consumers appreciate why pure titanium ingot prices can fluctuate so dramatically from one vendor to another.

Pure Titanium Ingot: Benefits and Applications

Pure titanium ingots are celebrated for their remarkable properties, making them a preferred choice in various industries. One of the standout advantages of pure titanium is its impressive strength-to-weight ratio, which allows for robust applications without the added bulk. Additionally, its corrosion resistance ensures longevity in demanding environments, contributing to lower maintenance costs and increased reliability over time.

Advantages of Using Pure Titanium

The benefits of using pure titanium extend beyond just physical properties; they also encompass economic factors. For instance, while the titanium ingot price may be higher than some alternatives, the durability and performance often justify this premium cost. Furthermore, the versatility of pure titanium means it can be used across a multitude of applications—from aerospace to medical devices—making it a smart investment for industries that prioritize quality.

Another advantage lies in its biocompatibility; pure titanium is widely used in medical implants due to its ability to integrate with human tissue without causing adverse reactions. This characteristic not only enhances patient safety but also opens new avenues for innovation in healthcare technology. Ultimately, when considering the price of titanium per kg against its myriad benefits, it's clear that investing in high-quality materials pays off.

Key Industries Utilizing Pure Titanium Ingots

Several key industries have recognized the exceptional value of pure titanium ingots and are leveraging their unique properties to enhance their products and services. The aerospace sector is one such industry where weight reduction is critical; aircraft manufacturers utilize pure titanium to construct lighter components that improve fuel efficiency and performance while maintaining structural integrity. As a result, these companies often keep a close eye on fluctuations in titanium ingot price per kg.

In addition to aerospace, the automotive industry has begun incorporating pure titanium into high-performance vehicles where strength and weight savings can significantly impact speed and efficiency. Similarly, marine engineering sectors benefit from pure titanium's corrosion resistance when fabricating components exposed to harsh saltwater environments. With growing demand across these sectors, understanding the factors influencing the price of titanium per kg becomes increasingly important for manufacturers.

Case Studies of Pure Titanium Ingot Applications

Examining real-world examples helps illustrate how businesses effectively utilize pure titanium ingots while navigating market dynamics like pricing trends. One notable case involves Boeing’s use of high-purity titanium alloys in their 787 Dreamliner aircraft; this innovative design approach not only reduced overall weight but also enhanced fuel efficiency—demonstrating how investments in premium materials can lead to substantial operational savings despite higher initial costs associated with purchasing quality ingots.

Another compelling example comes from the medical field where companies are producing orthopedic implants using pure titanium due to its biocompatibility and strength characteristics—proving essential for patient recovery outcomes while justifying higher production costs related to sourcing quality materials at competitive prices like those seen with current trends in titanium ingot price per gram.

These case studies highlight how companies strategically leverage pure titanium's advantages despite varying market conditions affecting pricing structures—ultimately leading them towards sustainable growth aligned with innovations within their respective industries.

Breakdown of Pricing: Titanium Ingot Price per Gram

When it comes to understanding the titanium ingot price, it's essential to break down how pricing structures work. The price of titanium per kg can fluctuate based on various market dynamics, including demand and production costs. By examining the pricing per gram, buyers can gain a clearer perspective on what they might expect when purchasing pure titanium ingots.

Understanding Pricing Structures

Pricing structures for titanium ingots often depend on multiple factors such as purity, sourcing methods, and market conditions. Typically, the titanium ingot price is calculated based on weight—usually measured in kilograms or grams—which allows for straightforward comparisons across different suppliers. For instance, while the price of titanium per kg provides an overarching view of market trends, analyzing the titanium ingot price per gram offers granular insight into specific transactions.

The Impact of Quality on Price

The quality of titanium plays a significant role in determining its overall price point. High purity materials command higher prices due to their superior properties and applications in critical industries like aerospace and medical devices. Thus, when assessing the titanium ingot price, one must consider that pure titanium ingots will typically be priced higher than those with lower purity levels; this ensures that buyers are getting materials that meet stringent industry standards.

How to Calculate Titanium Ingot Price per kg

Calculating the titanium ingot price per kg involves a straightforward formula: multiplying the weight in kilograms by the cost per gram or finding a direct quote from suppliers based on current market rates. For example, if you know that the average titanium ingot price is $50 per kilogram and you require 5 kg for your project, simply multiply 5 by 50 to arrive at $250 total cost. Understanding this calculation not only helps in budgeting but also empowers buyers to negotiate better deals based on prevailing prices.

GEE SMA and Titanium Ingots

In the realm of advanced materials, GEE SMA stands out as a pivotal player in the titanium ingot market. With a focus on innovation and quality, GEE SMA has established itself as a reliable supplier of high-purity titanium ingots, which are essential for various high-tech applications. Their commitment to excellence ensures that customers receive titanium products that meet stringent industry standards while keeping an eye on the fluctuating titanium ingot price.

GEE SMA’s Role in the Industry

GEE SMA plays a crucial role in shaping the future of titanium ingots by providing top-notch materials that cater to diverse industries such as aerospace, medical devices, and automotive manufacturing. By prioritizing the production of pure titanium ingots, they not only enhance product performance but also contribute to sustainability through responsible sourcing practices. This dedication helps stabilize the fluctuating price of titanium per kg, making it more accessible for manufacturers who rely on these critical materials.

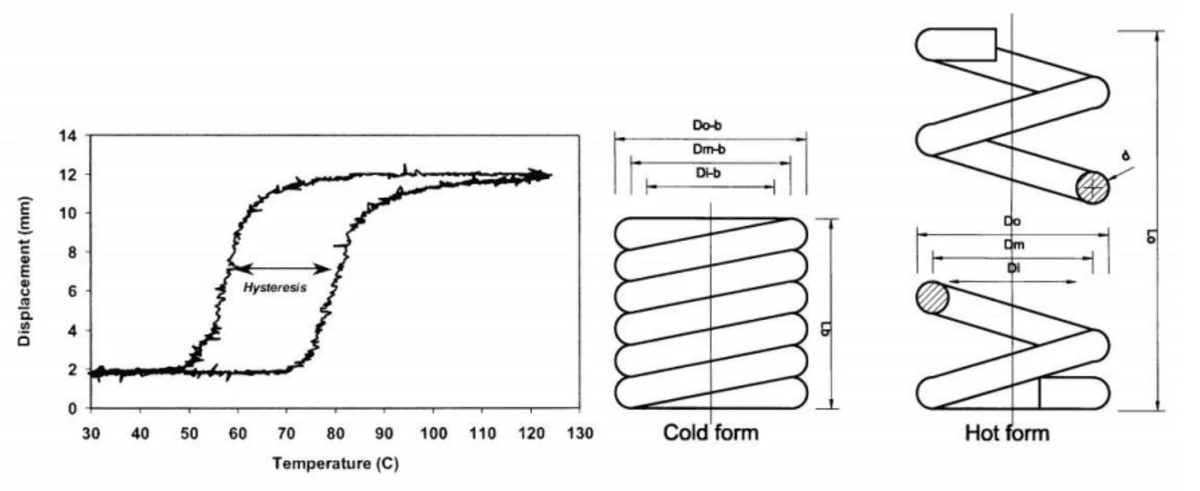

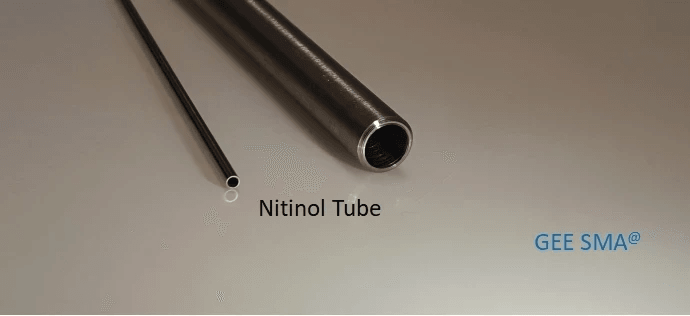

High-Quality Nitinol Shape Memory Alloys

Among their impressive offerings are high-quality nitinol shape memory alloys, which integrate seamlessly with pure titanium ingots to create innovative solutions across various sectors. These alloys exhibit unique properties that allow them to return to a predetermined shape when heated—ideal for applications requiring precision and reliability. As industries increasingly demand advanced materials at competitive prices, understanding the relationship between nitinol and pure titanium is vital for evaluating overall titanium ingot price dynamics.

Applications in Aerospace Missions

The aerospace sector is one of the most significant beneficiaries of GEE SMA's high-quality titanium products, especially when it comes to using pure titanium ingots in aircraft construction and components. The lightweight nature and exceptional strength-to-weight ratio of these materials enhance fuel efficiency while ensuring safety during missions—an essential factor given rising operational costs influenced by global market conditions affecting titanium ingot price per gram. As aerospace technology continues evolving, so too does the need for premium materials like those offered by GEE SMA.

Conclusion

The world of titanium ingots is ever-evolving, and understanding the dynamics of titanium ingot pricing is crucial for industries reliant on this versatile metal. As we look to the future, factors such as global demand, production advancements, and market fluctuations will undoubtedly shape the titanium ingot price landscape. Keeping an eye on these trends will help businesses make informed decisions about sourcing and budgeting.

The Future of Titanium Ingot Pricing

In the coming years, we can expect fluctuations in the price of titanium per kg due to varying demand from sectors like aerospace and medical industries. Additionally, geopolitical factors and environmental regulations may impact production costs, ultimately influencing the titanium ingot price per gram. Companies that proactively adapt to these changes will have a competitive edge in securing high-quality pure titanium ingots at favorable prices.

Innovations in Titanium Ingot Production

Advancements in production technologies are poised to revolutionize how pure titanium ingots are manufactured. Techniques such as additive manufacturing and improved extraction processes promise to enhance purity levels while reducing costs associated with material sourcing. These innovations not only lower the overall titanium ingot price but also open new avenues for applications across diverse industries.

Choosing the Right Supplier for Titanium Ingots

Selecting a reliable supplier for titanium ingots is critical for ensuring consistent quality and competitive pricing. Factors such as reputation, certification standards, and customer service should weigh heavily in your decision-making process when evaluating potential suppliers. By partnering with a trusted provider who offers transparent pricing structures—like clear breakdowns of titanium ingot price per kg—you can secure a steady supply of high-quality materials tailored to your specific needs.