Introduction

Nitinol processing is a fascinating and intricate journey that transforms raw materials into one of the most remarkable alloys known to man. This unique metal, composed primarily of nickel and titanium, exhibits extraordinary properties such as shape memory and superelasticity, making it a go-to material in various high-tech applications. Understanding the nuances of Nitinol manufacturing is crucial for ensuring that the final products meet stringent quality standards required in fields like medicine and aerospace.

Quality is paramount when it comes to Nitinol, as even minor deviations in processing can lead to significant variations in performance. The importance of quality in Nitinol cannot be overstated; it directly affects the reliability and functionality of devices made from this alloy. From medical stents to space components, ensuring high-quality Nitinol can mean the difference between success and failure in critical applications.

Several key factors influence Nitinol quality throughout its lifecycle—from sourcing raw materials to advanced processing techniques. What are the raw materials for Nitinol? The purity of these materials plays a pivotal role in determining the final product's characteristics. Additionally, understanding why Nitinol is so expensive involves delving into these factors alongside how nitinol is processed and what temperature conditions are ideal for annealing this remarkable material.

Raw Materials for Nitinol Manufacturing

When it comes to nitinol processing, the quality of raw materials is paramount. The unique properties of nitinol, a nickel-titanium alloy, hinge on the precise composition and characteristics of its constituent materials. Understanding what are the raw materials for nitinol? is essential for manufacturers aiming to produce high-quality products that meet demanding standards.

Sourcing High-Quality Alloys

Sourcing high-quality alloys is the first step in successful Nitinol manufacturing. Manufacturers must ensure that they obtain nickel and titanium from reputable suppliers who adhere to strict quality controls. The right alloy composition not only affects the performance of nitinol but also its cost; thus, why is nitinol so expensive? becomes a pertinent question as sourcing top-notch materials can drive up prices.

In addition to sourcing, establishing long-term relationships with suppliers can enhance reliability and consistency in material quality. This strategic partnership allows manufacturers to stay ahead in the competitive market of nitinol processing by ensuring access to premium alloys without compromising on production timelines or costs. Ultimately, investing time and resources into sourcing high-quality alloys pays off in terms of product performance and customer satisfaction.

Impacts of Material Purity

Material purity plays a critical role in determining the overall quality of nitinol products. Even trace impurities can significantly affect properties such as shape memory effect, superelasticity, and corrosion resistance—key characteristics that make nitinol desirable for various applications. Thus, understanding how is nitinol processed? involves an appreciation for how these impurities are minimized during manufacturing.

High-purity raw materials lead to enhanced mechanical properties and reliability in end-use applications like medical devices or aerospace components. Conversely, using lower-grade materials may result in defects or inconsistencies that compromise product integrity and performance over time. Hence, manufacturers must prioritize material purity as a fundamental aspect of their nitinol processing strategies.

Common Supplier Challenges

While sourcing high-quality alloys sounds straightforward, there are common supplier challenges that can complicate this process significantly. Fluctuations in market demand can lead to shortages or delays in obtaining necessary materials for Nitinol manufacturing; this unpredictability can disrupt production schedules and impact overall quality assurance efforts. Additionally, inconsistent supply chains often result in varying material qualities that challenge manufacturers striving to maintain high standards.

Another challenge lies in verifying the purity levels of supplied raw materials; not all suppliers provide transparent information regarding their testing processes or results. This lack of transparency makes it difficult for manufacturers to ensure they are working with top-tier components vital for effective nitinol processing. To navigate these hurdles successfully, forming strong partnerships with reliable suppliers who prioritize quality assurance becomes essential for maintaining excellence throughout production.

Processing Techniques in Nitinol

Nitinol processing is a fascinating blend of science and art, where the unique properties of this nickel-titanium alloy come to life through various manufacturing methods. Understanding how nitinol is processed is crucial for achieving the desired qualities that make it suitable for applications ranging from medical devices to aerospace components. In this section, we will explore the overview of nitinol manufacturing methods, delve into advanced forming and shaping processes, and highlight the critical role of heat treatment in ensuring top-notch quality.

Overview of Nitinol Manufacturing Methods

Nitinol manufacturing begins with sourcing high-quality raw materials, primarily nickel and titanium alloys, which are essential for producing this remarkable material. The process typically involves melting these metals together using vacuum induction melting or arc melting techniques to ensure homogeneity and purity—key factors that significantly influence nitinol quality. Once melted, the alloy undergoes various processing methods such as forging, rolling, or extrusion to shape it into usable forms.

In addition to traditional methods, newer techniques like additive manufacturing are gaining traction in nitinol processing. These innovative approaches allow for greater design flexibility and can produce complex geometries that were previously impossible with conventional methods. As manufacturers look to optimize their processes while maintaining high standards in nitinol quality, exploring these modern techniques becomes increasingly important.

Advanced Forming and Shaping Processes

Once the initial shapes are created through traditional methods, advanced forming techniques come into play during nitinol processing. These include processes like superelastic forming and shape memory forming that take advantage of nitinol's unique properties—its ability to return to a predetermined shape upon heating after being deformed at lower temperatures. Such capabilities make it an ideal candidate for applications requiring precise movement or actuation.

Moreover, advanced shaping processes often involve specialized tooling and equipment designed specifically for handling nitinol's unique characteristics. For instance, during cold working operations, careful control over deformation rates is necessary to prevent defects while maximizing mechanical properties. This level of precision not only enhances performance but also addresses some common supplier challenges related to consistency across batches.

Role of Heat Treatment in Quality

Heat treatment plays a pivotal role in enhancing the quality of nitinol by tailoring its mechanical properties according to specific requirements. One critical aspect is determining what the annealing temperature of nitinol should be; this temperature influences phase transformations within the alloy that dictate its final characteristics such as strength and elasticity. Properly executed heat treatment can significantly improve fatigue resistance—a vital consideration given that many applications involve repeated stress cycles.

Monitoring and controlling annealing conditions during heat treatment are equally crucial; even slight deviations can lead to undesirable outcomes affecting overall performance or even rendering components unusable. Manufacturers must employ sophisticated monitoring systems to ensure adherence to strict parameters throughout the heat treatment process—this commitment reflects why is nitinol so expensive compared to other materials on the market today! Ultimately, effective heat treatment not only enhances material properties but also contributes significantly towards maintaining high standards throughout all stages of nitinol processing.

The Critical Annealing Temperature

Understanding the critical annealing temperature of Nitinol is essential for optimizing its unique properties. This temperature, which is crucial in Nitinol processing, determines how the material will respond to stress and heat, ultimately influencing its performance in various applications. A well-controlled annealing process can significantly enhance the quality of Nitinol manufacturing.

Defining the Annealing Temperature of Nitinol

The annealing temperature of Nitinol refers to a specific range where the alloy undergoes phase transformations that are vital for its shape memory and superelastic properties. Typically, this temperature can vary between 400°C to 600°C depending on the specific alloy composition used in Nitinol manufacturing. Understanding what this temperature is and how it fits into the broader context of nitinol processing is key for manufacturers looking to achieve optimal characteristics.

Effects of Temperature on Material Properties

Temperature plays a pivotal role in determining various material properties of Nitinol, including its strength, ductility, and elasticity. At improper annealing temperatures, unwanted microstructural changes can occur, leading to diminished performance—something every manufacturer wants to avoid when considering why nitinol is so expensive. By carefully controlling these thermal conditions during nitinol processing, manufacturers can ensure that their products meet high-quality standards while maintaining desirable mechanical properties.

Monitoring and Controlling Annealing Conditions

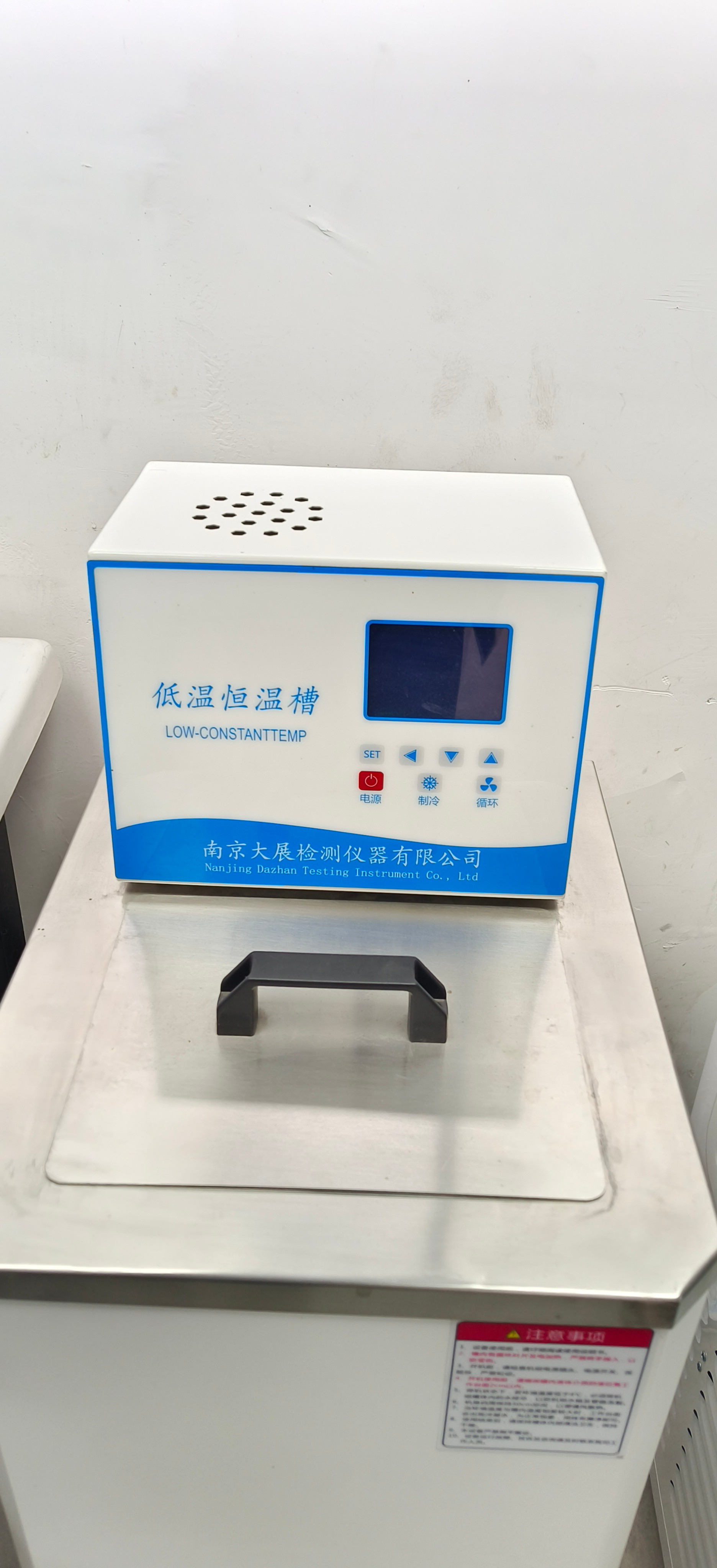

Monitoring and controlling annealing conditions are essential steps in achieving consistent results in Nitinol manufacturing. Advanced techniques such as real-time thermal monitoring allow manufacturers to precisely adjust temperatures throughout the process—ensuring that they remain within optimal ranges for desired outcomes. This level of control not only enhances product quality but also helps mitigate costs associated with wasted materials or reprocessing due to subpar results.

Cost Factors in Nitinol Quality

Nitinol, a unique alloy of nickel and titanium, is renowned for its remarkable properties, but these come at a price. The cost factors associated with nitinol quality stem from various aspects of its manufacturing process, including raw material sourcing, processing techniques, and the stringent standards required to maintain its exceptional characteristics. Understanding why nitinol is so expensive can shed light on the complexities involved in nitinol processing and production.

Why is Nitinol So Expensive?

One of the primary reasons nitinol is so expensive lies in the raw materials used for its manufacturing. Nickel and titanium are not only costly themselves but also require careful sourcing to ensure purity and quality—any impurities can significantly affect the final product's performance. Additionally, the intricate processes involved in how nitinol is processed contribute to rising costs; specialized equipment and skilled labor are essential for achieving high-quality results.

Another factor influencing cost is the extensive research and development that goes into refining nitinol's properties for specific applications. Manufacturers must invest in advanced technologies to optimize performance characteristics such as shape memory effect and superelasticity. This investment translates into higher prices for end-users who seek reliable solutions derived from high-quality nitinol.

Lastly, market demand plays a crucial role in driving up costs; as industries increasingly recognize the benefits of using nitinol—from medical devices to aerospace components—the competition for high-quality materials intensifies. This heightened demand often leads to fluctuations in pricing that further complicate budgeting for projects involving this sophisticated alloy.

Balancing Quality and Cost in Production

In the world of nitinol manufacturing, balancing quality with cost presents a formidable challenge. Manufacturers must navigate between investing in top-notch raw materials—what are the raw materials for nitinol?—and managing production expenses effectively. Striking this balance ensures that they deliver products meeting rigorous standards without compromising on affordability.

To achieve this equilibrium, companies often adopt innovative processing techniques that enhance efficiency while maintaining quality during manufacturing stages. For instance, advancements in heat treatment methods can optimize properties like memory retention without incurring excessive costs associated with lower-grade materials or inefficient processes. By refining how nitinol is processed through cutting-edge technology, manufacturers can minimize waste and maximize yield.

Moreover, collaboration with suppliers becomes critical when seeking ways to offset costs while ensuring high-quality outcomes. Establishing strong relationships allows manufacturers to negotiate better pricing on essential raw materials while remaining vigilant about material purity—ultimately enhancing overall product integrity without breaking the bank.

Economic Implications of High Standards

The economic implications of maintaining high standards in nitinol quality are significant across various sectors relying on this versatile alloy. Industries ranging from healthcare to aerospace face pressure to ensure their products meet stringent regulatory requirements while also delivering superior performance characteristics expected from premium-grade materials like those derived from advanced nitinol processing techniques.

Investing in high-quality production methods may initially seem costly; however, it often leads to long-term savings by reducing failure rates and improving product lifespan across applications—saving both time and money down the line when it comes to repairs or replacements due to inferior performance issues related back to lower-quality materials or processing methods used initially.

Furthermore, companies prioritizing excellence position themselves favorably within competitive markets where customers increasingly seek reliability over mere affordability—a trend likely driven by growing awareness about what constitutes true value beyond just price tags alone when it comes down choosing specialized alloys like Nitinol amongst alternatives available today!

Enhancing Nitinol Processing at GEE SMA

In the realm of nitinol processing, GEE SMA stands out as a pioneer, leveraging innovative techniques to elevate the standards of Nitinol manufacturing. With a commitment to quality and precision, GEE SMA has developed methods that not only enhance the material properties but also streamline production processes. This forward-thinking approach ensures that their nitinol remains at the forefront of industry demands.

Innovative Techniques at GEE SMA

The company employs cutting-edge technologies to refine how nitinol is manufactured, focusing on improving both efficiency and quality. By integrating advanced automation and real-time monitoring systems into their production lines, they can maintain stringent control over every aspect of nitinol manufacturing—from alloy composition to final product characteristics.

One standout technique involves optimizing heat treatment processes, which are crucial for achieving desired material properties in nitinol. Understanding what are the raw materials for nitinol helps GEE SMA tailor these treatments specifically for their unique alloys. The result? A superior product with consistent performance across various applications.

Tailoring Nitinol for Specialized Applications

GEE SMA excels in tailoring nitinol for specialized applications that require high performance and reliability. By understanding the nuances of different industries—be it medical devices or aerospace—the company customizes its manufacturing processes accordingly. This adaptability allows them to meet specific requirements while maintaining high standards in nitinol quality.

The ability to modify alloy compositions based on client needs further enhances their offerings; they can adjust parameters such as phase transformation temperatures and shape memory effects effectively. This level of customization is particularly important when considering why is nitinol so expensive—its versatility and high-quality standards demand meticulous attention during processing.

Furthermore, by collaborating closely with clients during development phases, GEE SMA ensures that every batch of nitinol is not just a product but a solution tailored precisely for its intended use.

GEE SMA’s Contribution to Space Missions

Their advanced manufacturing techniques have made significant contributions to aerospace projects requiring lightweight yet strong materials capable of enduring extreme conditions.

For instance, components made from specially processed Nitinol have been utilized in mechanisms such as actuators and deployable structures within spacecraft systems due to their unique properties like shape memory effect and superelasticity under stress conditions encountered in space environments.

Moreover, understanding what is the annealing temperature of nitinol plays a vital role in ensuring these components perform reliably over time—a critical factor when dealing with missions that venture far beyond our planet's atmosphere! With each successful deployment backed by robust research and development at GEE SMA, they continue shaping the future of aerospace technology.

Conclusion

In wrapping up our exploration of Nitinol processing and its intricacies, it's essential to reflect on the critical factors that shape the quality and performance of this remarkable material. From sourcing high-quality raw materials to understanding the nuances of manufacturing methods, each step in Nitinol manufacturing plays a pivotal role in determining the final product's capabilities. Moreover, key aspects such as the annealing temperature of Nitinol and advanced processing techniques significantly impact its unique properties, making it indispensable across various applications.

Recap of Key Nitinol Processing Factors

Throughout our discussion, we highlighted several key factors influencing Nitinol processing and quality. Sourcing high-quality alloys is paramount since impurities can drastically affect the mechanical properties and overall performance of Nitinol. Additionally, understanding what are the raw materials for nitinol? helps manufacturers ensure that they select suitable components that meet stringent industry standards while also addressing common supplier challenges.

Future Trends in Nitinol Manufacturing

Looking ahead, future trends in Nitinol manufacturing are poised to embrace innovative technologies that enhance efficiency and product quality. The integration of smart manufacturing processes will likely streamline operations while reducing costs—addressing concerns about why is nitinol so expensive? As researchers continue to explore new applications for this versatile material, advancements in forming techniques and heat treatment will further refine how nitinol is processed for specialized uses.

Ensuring High Standards in Nitinol Quality

To maintain high standards in Nitinol quality, companies must adopt rigorous monitoring practices throughout production processes. This includes precise control over the annealing temperature of nitinol during heat treatment to optimize its shape memory characteristics and superelasticity. By prioritizing quality assurance at every stage—from raw material selection to final processing—manufacturers can ensure their products not only meet but exceed industry expectations.