Introduction

In a world where technology is constantly evolving, the emergence of memory shape alloys has sparked a revolution across multiple industries. These remarkable materials not only exhibit unique properties but also offer innovative solutions that were once confined to the realm of science fiction. As we delve into the transformative potential of shape memory alloys, it becomes evident that their impact will only continue to expand, shaping the future of technology in ways we can only begin to imagine.

Discover the Power of Memory Shape Alloys

Memory shape alloys, particularly those made from titanium and nickel, possess an astonishing ability to return to a predetermined shape when subjected to specific temperatures. This phenomenon, known as the shape memory effect, allows these metals to be used in applications ranging from medical devices to aerospace technologies. By harnessing titanium material properties and other characteristics of these alloys, engineers are unlocking new possibilities for design and functionality.

How Memory Shape Alloys Are Transforming Technology

The integration of memory shape alloys into various sectors is nothing short of groundbreaking. In aerospace engineering, for instance, aerospace titanium alloys are being utilized for components that require lightweight yet durable materials capable of withstanding extreme conditions. Similarly, in robotics and automotive applications, the flexibility and adaptability offered by shape memory metals are enhancing performance while ensuring safety and efficiency.

The Future of Shape Memory Alloys

Looking ahead, the future of shape memory alloys appears bright and full of promise. As research continues into their capabilities and applications expands beyond our current understanding, we can anticipate even more revolutionary innovations on the horizon. With companies like GEE SMA leading efforts in developing advanced materials based on these principles, it’s clear that memory shape alloys will play a pivotal role in shaping our technological landscape for years to come.

What Are Memory Shape Alloys?

Memory shape alloys, often referred to as shape memory alloys (SMAs), are remarkable materials that can return to a predetermined shape when exposed to specific conditions, such as heat. This unique property is not just a party trick; it opens up a world of possibilities across various industries. From medical devices to aerospace engineering, the applications of memory shape alloys are as diverse as they are innovative.

Definition and Basics of Memory Shape Alloys

At their core, memory shape alloys are metallic materials that possess the ability to remember their original form after being deformed. This phenomenon occurs due to their unique crystalline structure, which can change between two distinct phases: martensite and austenite. When heated or cooled, these alloys transition between these phases, allowing them to revert back to their original shape—hence the term “shape memory alloy.”

The most commonly used memory shape alloy is Nitinol, an alloy primarily composed of nickel and titanium. Titanium material properties contribute significantly to Nitinol's strength and flexibility, making it highly desirable in applications where durability is paramount. Overall, understanding the basics of memory shape alloys sets the stage for appreciating their transformative potential in technology.

The Science Behind Shape Memory Effect

The science behind the shape memory effect (SME) is both fascinating and complex, rooted in thermodynamics and crystallography. When a memory shape alloy is deformed at lower temperatures into its martensitic phase, it can be easily manipulated into different shapes without permanent damage. Upon heating above a certain temperature threshold known as the transformation temperature, the material reverts back to its original austenitic form—this is where the magic happens.

This transformation involves changes in atomic arrangements within the alloy’s crystal lattice structure—think of it like molecular gymnastics! The ability of these materials to remember their shapes allows engineers and designers to harness this property for various applications—from tiny medical implants that expand once inside the body, to aerospace titanium alloys that deploy with precision under extreme conditions.

Real-World Applications of Memory Shape Alloys

Memory shape alloys have found applications across multiple fields thanks to their unique properties and versatility. In medicine, they’re used in stents that expand within blood vessels or surgical tools that adapt during procedures—improving outcomes while minimizing invasiveness for patients. In addition to healthcare innovations, aerospace engineers utilize these materials for mechanisms like satellite deployment systems where reliability under varying temperatures is crucial.

Moreover, automotive manufacturers are increasingly incorporating SMAs into smart vehicle technologies that enhance safety features through adaptive components responding dynamically during operation. From consumer electronics designed with flexible parts made from SMAs enhancing durability and functionality—to sustainable technologies aimed at reducing environmental impact—memory shape alloys are truly shaping our future across industries.

Nitinol: The Superhero of Shape Memory Alloys

When it comes to the realm of memory shape alloys, Nitinol stands out as a true superhero. This remarkable alloy, composed primarily of nickel and titanium, exhibits unique properties that allow it to return to a predetermined shape when heated above a specific temperature. The fascinating interplay between its composition and the science of phase transformations makes Nitinol an indispensable material in various cutting-edge applications.

The Composition and Properties of Nitinol

Nitinol is an intriguing blend of nickel and titanium, typically comprising about 55% nickel and 45% titanium by atomic percentage. This specific ratio is crucial because it influences the alloy's unique properties, including its ability to exhibit the shape memory effect—a phenomenon where the material remembers its original form after deformation. Additionally, Nitinol boasts impressive titanium material properties such as high corrosion resistance, biocompatibility, and excellent fatigue endurance, making it ideal for demanding environments.

The phase transformation characteristics of Nitinol are what truly set it apart from other shape memory metals. At lower temperatures, Nitinol exists in a martensitic state that is easily deformed; however, when heated above its transformation temperature (around 70°C), it shifts to an austenitic state and reverts to its original shape. This remarkable behavior allows engineers and designers to create innovative solutions across diverse industries—from medical devices to aerospace engineering.

Advantages of Using Nitinol in Various Industries

One of the standout advantages of using Nitinol as a memory shape alloy is its versatility across multiple industries. In healthcare, for instance, Nitinol's biocompatibility makes it perfect for applications like stents or guidewires that require both flexibility and strength during surgical procedures. Moreover, the fatigue resistance inherent in this unique alloy ensures longevity in devices that are subjected to repeated stress—making them reliable options for medical professionals.

In aerospace applications, aerospace titanium alloys often incorporate elements like Nitinol due to their lightweight nature combined with exceptional strength-to-weight ratios—crucial factors for flight efficiency. The ability of this shape memory alloy to adapt under varying conditions enhances operational reliability while reducing overall weight in aircraft designs. As such innovations continue evolving with advancements in technology, it's clear that industries are benefiting immensely from embracing this extraordinary material.

Additionally, automotive manufacturers are increasingly leveraging Nitinol's distinct properties for smart vehicle technologies—enhancing safety features like seatbelt retractors or airbag systems where rapid response times are essential during accidents. Its capacity for precise movement control enables improved performance while maintaining safety standards across various automotive components.

GEE SMA's Contributions to Nitinol Technology

GEE SMA plays a pivotal role in advancing the development and application of Nitinol technology within the realm of memory shape alloys. Their commitment not only focuses on refining production techniques but also emphasizes enhancing performance characteristics tailored specifically for various industries' needs—from aerospace engineering solutions to revolutionary medical devices.

By investing heavily in research and development efforts surrounding shape memory alloys like Nitinol, GEE SMA has positioned itself at the forefront of innovation within this field—creating high-quality materials that facilitate groundbreaking applications worldwide! Their expertise ensures that manufacturers can harness these incredible properties effectively while pushing boundaries toward sustainable advancements across multiple sectors.

As we look ahead into future possibilities with these remarkable materials at our disposal—the partnership between GEE SMA’s technological prowess combined with cutting-edge research will undoubtedly lead us toward even more exciting developments involving memory shape alloys!

Innovations in Medical Devices

The medical field is witnessing a remarkable transformation thanks to the advent of memory shape alloys. These ingenious materials, particularly shape memory alloys like Nitinol, are revolutionizing the design and functionality of medical devices. By leveraging unique properties such as flexibility and adaptability, these materials are enhancing patient care in unprecedented ways.

Shape Memory Alloys in Stents and Implants

Shape memory alloys (SMAs) play a pivotal role in the development of stents and implants, offering a blend of strength and flexibility that traditional materials simply can’t match. When deployed within the body, these memory shape metals expand to their predetermined form at body temperature, ensuring optimal performance without compromising patient comfort. The titanium material properties inherent in SMAs make them highly biocompatible, reducing the risk of rejection while promoting healing.

How Memory Shape Alloys Improve Surgical Outcomes

Memory shape alloys have dramatically improved surgical outcomes by minimizing invasiveness during procedures. Their ability to change shape allows for less traumatic insertion techniques; for instance, stents can be introduced through smaller incisions without sacrificing functionality or effectiveness. This not only leads to quicker recovery times but also reduces complications associated with traditional surgical methods.

GEE SMA Impacting Healthcare Solutions

GEE SMA is at the forefront of integrating memory shape alloy technology into healthcare solutions that prioritize patient well-being. Their innovations are setting new standards for medical devices by harnessing advanced titanium material properties to create durable yet flexible products that adapt seamlessly within the human body. As GEE SMA continues to push boundaries in this sector, we can expect further breakthroughs that will enhance surgical precision and improve overall health outcomes.

Aerospace Advancements

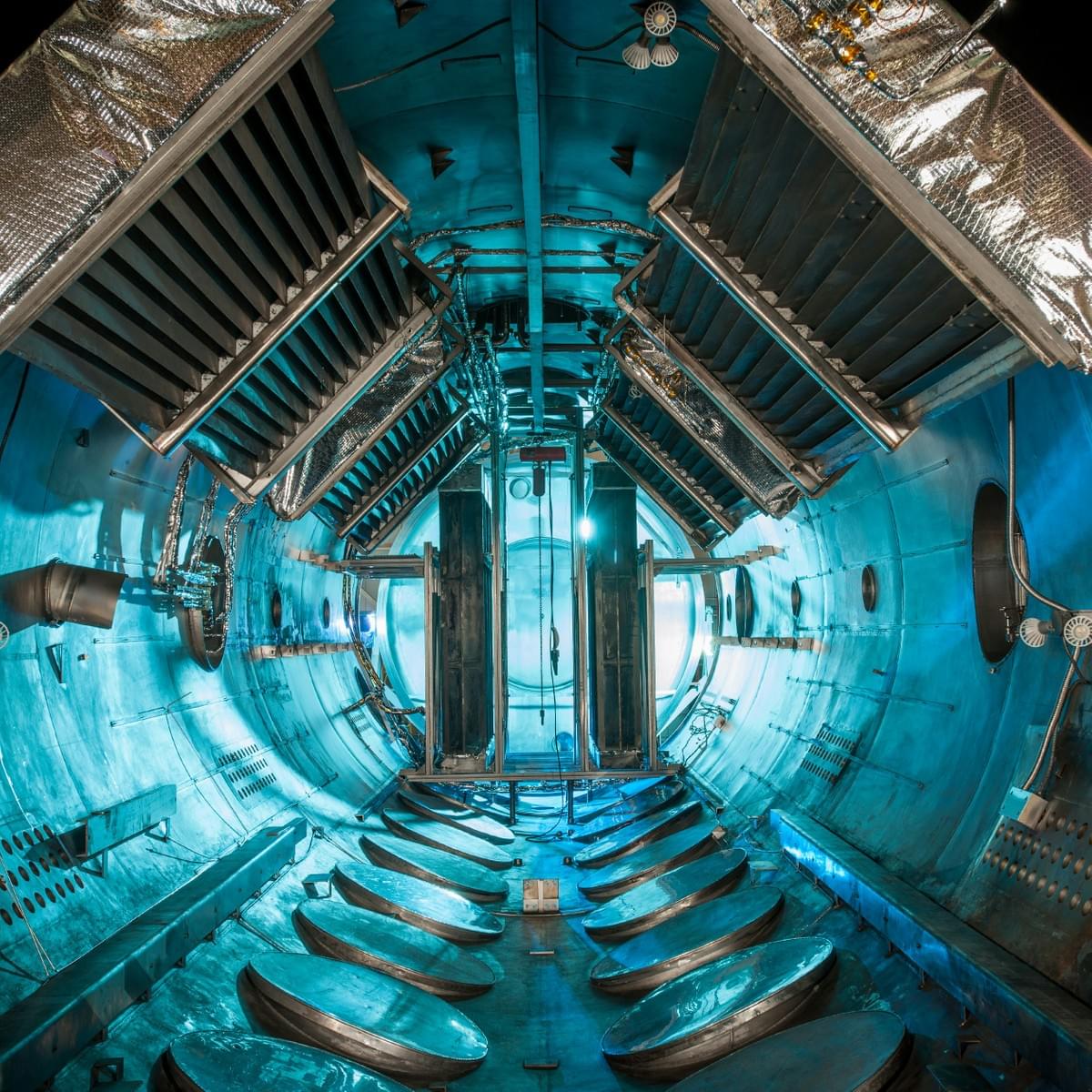

The aerospace industry is constantly pushing the boundaries of innovation, and memory shape alloys are proving to be a game-changer. These remarkable materials offer unique properties that enhance performance, durability, and efficiency in various applications. From satellite deployment mechanisms to structural components, the role of shape memory alloys in aerospace engineering is nothing short of revolutionary.

The Role of Memory Shape Alloys in Aerospace Engineering

Memory shape alloys, particularly those made from titanium material properties, are transforming aerospace engineering by providing lightweight yet robust solutions. Their ability to return to a predetermined shape after deformation allows for innovative designs that can withstand extreme conditions without compromising integrity. This adaptability not only improves the functionality of aerospace components but also contributes to fuel efficiency and overall mission success.

Moreover, the use of shape memory metals in aerospace applications leads to reduced maintenance costs and increased reliability over time. Engineers are increasingly leveraging these materials for actuators and other critical systems where precision is paramount. With advancements in manufacturing techniques and material science, the potential applications for memory shape alloys in this field continue to expand.

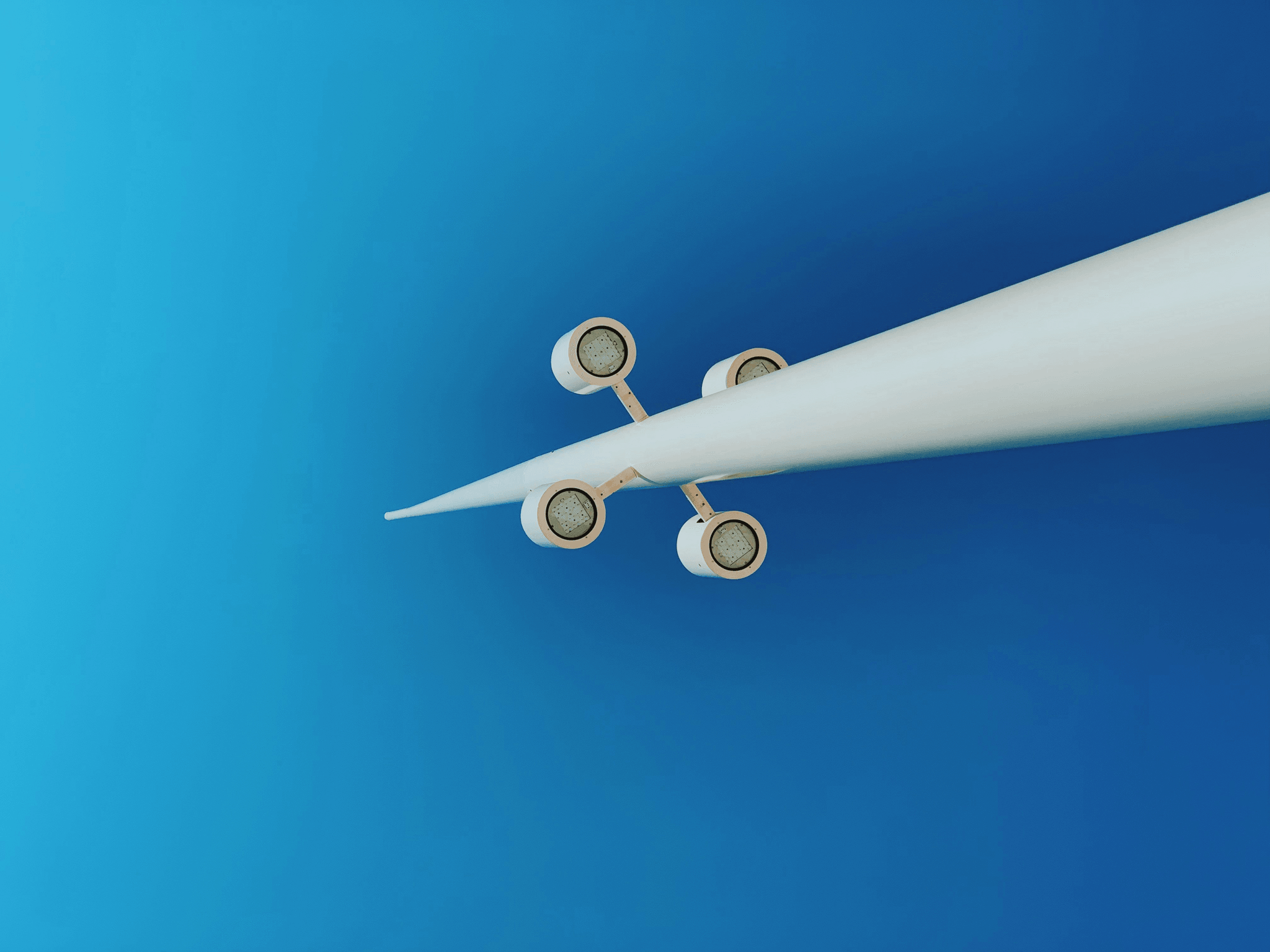

Nitinol in Satellite Deployment Mechanisms

Nitinol, a prominent type of memory shape alloy known for its exceptional properties, plays a crucial role in satellite deployment mechanisms. Its unique ability to undergo significant deformation while maintaining strength makes it ideal for compact storage during launch phases. Once deployed into space, Nitinol can efficiently return to its original form, allowing antennas and solar panels to unfold seamlessly.

The incorporation of Nitinol into satellite designs enhances overall mission effectiveness by reducing weight without sacrificing performance or reliability. This lightweight characteristic is especially important given the stringent payload limits imposed on space missions—every gram counts! As a result, aerospace engineers are increasingly turning toward titanium-based memory shape alloys like Nitinol for next-generation satellite technology.

GEE SMA Supporting Chang’e and Tianwen Missions

GEE SMA has been at the forefront of integrating memory shape alloys into groundbreaking projects such as China's Chang’e lunar exploration program and Tianwen Mars missions. By utilizing advanced titanium material properties found in their products, GEE SMA ensures that spacecraft components can withstand harsh environments while maintaining optimal functionality throughout their journeys. Their contributions exemplify how innovative materials like shape memory alloys can lead to successful interplanetary exploration.

In both missions, GEE SMA’s expertise has facilitated advancements in deployment mechanisms that allow scientific instruments to operate effectively once on-site—whether on the Moon or Mars’ surface. The combination of reliability and adaptability offered by these materials represents a significant leap forward for future aerospace endeavors as well. As we look ahead at what’s possible with memory shape alloys like Nitinol, one thing is clear: they are set to play an integral role in our quest for knowledge beyond Earth.

Robotics Revolution

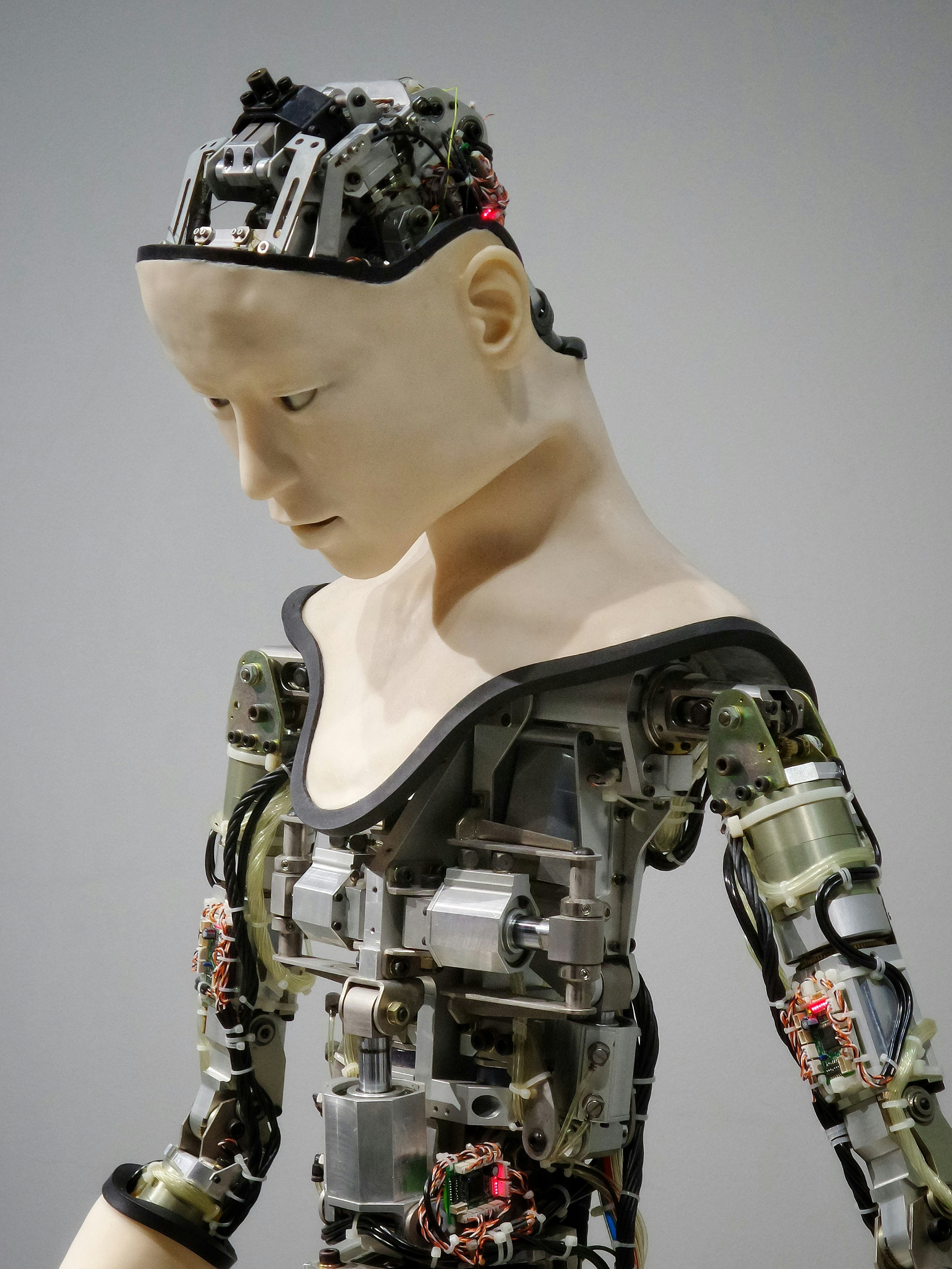

The robotics field is on the brink of a transformation, with memory shape alloys leading the charge. These remarkable materials not only enhance the capabilities of robots but also pave the way for innovative designs that were once thought impossible. As we dive into this revolution, we’ll explore how shape memory alloys are changing the game in robotics.

Utilizing Memory Shape Alloys in Robotics

Memory shape alloys are becoming essential components in robotic systems due to their unique ability to change shape in response to temperature variations. This property allows robots to perform complex movements and adapt their form dynamically, making them more versatile and efficient. With applications ranging from soft robotics to precision actuators, these materials are redefining what robots can achieve.

Moreover, the incorporation of shape memory metals enables engineers to create lighter and more compact designs without sacrificing strength or functionality. The titanium material properties found in certain memory shape alloys contribute significantly to their durability and resilience under various conditions. As a result, roboticists can push boundaries further than ever before, exploring new frontiers in automation and artificial intelligence.

Enhancing Flexibility and Movement with Shape Memory Alloys

One of the most exciting aspects of using memory shape alloys in robotics is their ability to enhance flexibility and movement. Unlike traditional rigid structures, robots utilizing these advanced materials can bend, twist, or compress as needed—just like biological organisms do! This flexibility opens doors for applications such as prosthetics that mimic human movement or robotic hands that can grasp delicate objects with precision.

Additionally, by leveraging the unique characteristics of titanium material properties within these alloys, engineers can create lightweight yet robust systems capable of performing intricate tasks with ease. The result is a new breed of machines that not only function better but also interact more naturally with their environments—think robots that can navigate through tight spaces or adjust their grip based on object weight!

The Future of Robotics with GEE SMA Materials

As we look ahead, GEE SMA materials promise to play a pivotal role in shaping the future landscape of robotics. With ongoing advancements in manufacturing techniques and material science, we expect even more sophisticated applications for memory shape alloys across various sectors—from healthcare devices to exploration drones. The potential for integrating aerospace titanium alloys into robotic systems further enhances performance while maintaining lightweight characteristics.

Moreover, as industries increasingly embrace automation and smart technologies, the demand for adaptable robots will soar; this is where memory shape alloys will shine brightest! By continuing research into these innovative materials and refining their applications within robotics, GEE SMA stands at the forefront of this evolution—ready to lead us into an era where machines seamlessly blend functionality with flexibility.

Automotive Applications

In the realm of automotive engineering, memory shape alloys are driving innovation and redefining vehicle design. These remarkable materials, particularly shape memory alloys like Nitinol, are being integrated into smart vehicle technologies to enhance performance and efficiency. With their unique ability to change shape in response to temperature variations, these alloys offer solutions that were once confined to the realm of science fiction.

Memory Shape Alloys in Smart Vehicle Technologies

Memory shape alloys are revolutionizing smart vehicle technologies by enabling adaptive components that respond dynamically to driving conditions. For instance, actuators made from shape memory metals can adjust suspension systems for improved handling and comfort based on road feedback. This adaptability not only enhances the driving experience but also contributes to energy efficiency by making real-time adjustments that optimize performance.

Moreover, the integration of these advanced materials allows for lighter components without sacrificing strength or durability. The titanium material properties of certain memory shape alloys make them ideal for applications where weight reduction is crucial—think fuel-efficient vehicles or electric cars with extended ranges. As automotive manufacturers continue to explore these possibilities, we can expect a surge in innovative designs that leverage the transformative capabilities of memory shape alloys.

How Shape Memory Alloys Enhance Vehicle Safety

Safety is paramount in automotive design, and memory shape alloys play a key role in enhancing it through advanced deployment mechanisms. These materials can be used in seatbelt systems or airbags that adapt during an accident scenario, ensuring optimal protection for passengers. By utilizing the unique properties of shape memory metals, manufacturers can create safety features that respond instantaneously when needed most.

Additionally, the ability of these materials to return to a predetermined shape after deformation means they can withstand multiple impacts without compromising integrity. This resilience is vital in crash scenarios where traditional materials might fail under stress. As such, incorporating memory shape alloys into safety systems not only boosts reliability but also increases consumer confidence in vehicle safety ratings.

GEE SMA’s Role in Automotive Innovations

GEE SMA has emerged as a leader in advancing automotive innovations through its development of cutting-edge memory shape alloy technologies. By focusing on improving titanium material properties within their products, GEE SMA ensures enhanced performance and durability across various automotive applications. Their commitment to research and development is paving the way for smarter vehicles equipped with adaptive features powered by state-of-the-art shape memory metals.

The company’s collaboration with major automakers highlights its influence on shaping future transportation solutions—think vehicles equipped with self-adjusting components that enhance both comfort and safety while reducing environmental impact through weight savings. GEE SMA's contributions reflect a broader trend towards integrating sustainable practices within automotive engineering using eco-friendly materials like aerospace titanium alloys alongside innovative manufacturing techniques. As we look ahead, it’s clear that GEE SMA will continue playing an integral role in transforming how we think about mobility.

Consumer Electronics Evolution

In the rapidly evolving world of consumer electronics, memory shape alloys are making waves as a game-changing material. These innovative materials, particularly shape memory alloys like Nitinol, are revolutionizing how gadgets are designed and function. Their unique properties allow for more compact designs and enhanced user experiences in everything from smartphones to wearables.

The Use of Memory Shape Alloys in Gadgets

Memory shape alloys have found their way into a variety of gadgets, enhancing both aesthetics and functionality. For instance, these materials can be utilized in foldable screens or adjustable components that adapt to user preferences. The flexibility offered by shape memory metals allows designers to create products that can change shape on demand, leading to innovative solutions in consumer electronics.

Improving Durability and Functionality with Shape Memory Alloys

One of the standout features of memory shape alloys is their remarkable durability, which is a significant advantage in consumer electronics. These materials can withstand extreme conditions without losing their original form or function, making them ideal for devices that endure daily wear and tear. Furthermore, the titanium material properties inherent in some shape memory alloys enhance their resistance to corrosion and fatigue, ensuring longevity while maintaining peak performance.

GEE SMA's Contributions to Cutting-Edge Electronics

GEE SMA has been at the forefront of integrating memory shape alloys into cutting-edge electronic devices. Their research focuses on developing advanced applications that leverage the unique characteristics of these materials—paving the way for smarter gadgets with improved performance metrics. By harnessing aerospace titanium alloys within consumer electronics, GEE SMA is not just enhancing product capabilities but also pushing boundaries toward sustainable innovations.

Sustainable Technologies

In a world where sustainability is becoming increasingly crucial, memory shape alloys are stepping into the spotlight as eco-friendly materials for various applications. These innovative materials not only enhance performance but also reduce environmental impact, making them a key player in the quest for greener technologies. With their unique properties, shape memory alloys can help industries transition to more sustainable practices while maintaining efficiency and functionality.

The Eco-Friendly Potential of Memory Shape Alloys

Memory shape alloys, particularly titanium-based ones, offer remarkable eco-friendly potential due to their longevity and durability. When utilized in manufacturing processes, these shape memory metals can significantly extend the lifespan of products, reducing waste and minimizing resource consumption over time. Additionally, the ability to recycle these materials means that even at the end of their life cycle, they can be repurposed rather than discarded.

The titanium material properties inherent in memory shape alloys also contribute to their sustainability profile. Their resistance to corrosion ensures that products made from these materials require less frequent replacement or maintenance, which translates into fewer resources used over time. As industries strive to meet stricter environmental regulations and consumer demands for sustainable options, incorporating shape memory alloys can provide a competitive edge.

How Shape Memory Alloys Contribute to Green Tech

Shape memory alloys play an essential role in advancing green technology across various sectors by enhancing energy efficiency and reducing waste. For instance, in renewable energy systems such as wind turbines or solar panels, these materials can be employed in mechanisms that optimize performance while minimizing energy loss during operation. This results in a more efficient use of resources and contributes significantly to lowering carbon footprints.

Moreover, aerospace titanium alloys featuring shape memory effects are being integrated into aircraft designs for weight reduction without compromising strength or safety standards. Lighter aircraft consume less fuel and produce fewer emissions during flight—an essential factor as the aviation industry seeks ways to become more environmentally friendly. Thus, the application of memory shape alloys not only supports current technological advancements but also aligns with global sustainability goals.

GEE SMA Leading the Charge in Sustainable Innovation

GEE SMA is at the forefront of harnessing the power of memory shape alloys for sustainable innovation across multiple industries. By investing heavily in research and development focused on eco-friendly applications of these advanced materials, GEE SMA is paving the way for smarter manufacturing processes that prioritize both performance and environmental responsibility. Their commitment ensures that emerging technologies will not only be effective but also align with our planet's needs.

Through collaborations with various sectors—ranging from aerospace engineering to consumer electronics—GEE SMA demonstrates how integrating shape memory metals can lead to significant advancements toward sustainability goals without sacrificing quality or performance standards. As they continue pushing boundaries with titanium material properties tailored for specific applications, GEE SMA exemplifies how innovation can drive positive change while fostering a greener future.

Conclusion

As we stand on the brink of a technological revolution fueled by memory shape alloys, it's clear that these remarkable materials are not just a novelty but rather a cornerstone for future innovations. The versatility and adaptability of shape memory alloys, particularly in sectors like aerospace, robotics, and healthcare, signal a transformative era where titanium material properties enhance performance across various applications. Embracing the future of memory shape alloys means recognizing their potential to redefine how we approach engineering challenges and everyday products.

Embracing the Future of Memory Shape Alloys

The future is bright for those willing to explore the capabilities of shape memory metals. With advancements in material science, especially regarding aerospace titanium alloys and their unique properties, we are witnessing an unprecedented integration of these materials into our daily lives. From smart devices to life-saving medical implants, the evolution of memory shape alloys promises not only enhanced functionality but also sustainability in design.

The Expanding Role of GEE SMA in Technology

GEE SMA is at the forefront of this exciting journey, pioneering innovations that leverage the incredible properties of memory shape alloys across various industries. Their commitment to developing cutting-edge solutions ensures that industries like aerospace will benefit from improved efficiency and reliability through advanced titanium material properties. As GEE SMA continues to expand its impact on technology, we can expect more groundbreaking applications that push the limits of what's possible with shape memory metals.

Your Next Steps with Memory Shape Alloys

So how can you get involved with this fascinating field? Whether you're an engineer looking to incorporate memory shape alloys into your projects or simply an enthusiast eager to learn more about their applications, there are endless opportunities waiting for you. Dive into research papers, attend industry conferences, or even consider collaborating with companies like GEE SMA that are leading the charge in harnessing the power of these innovative materials.