Introduction

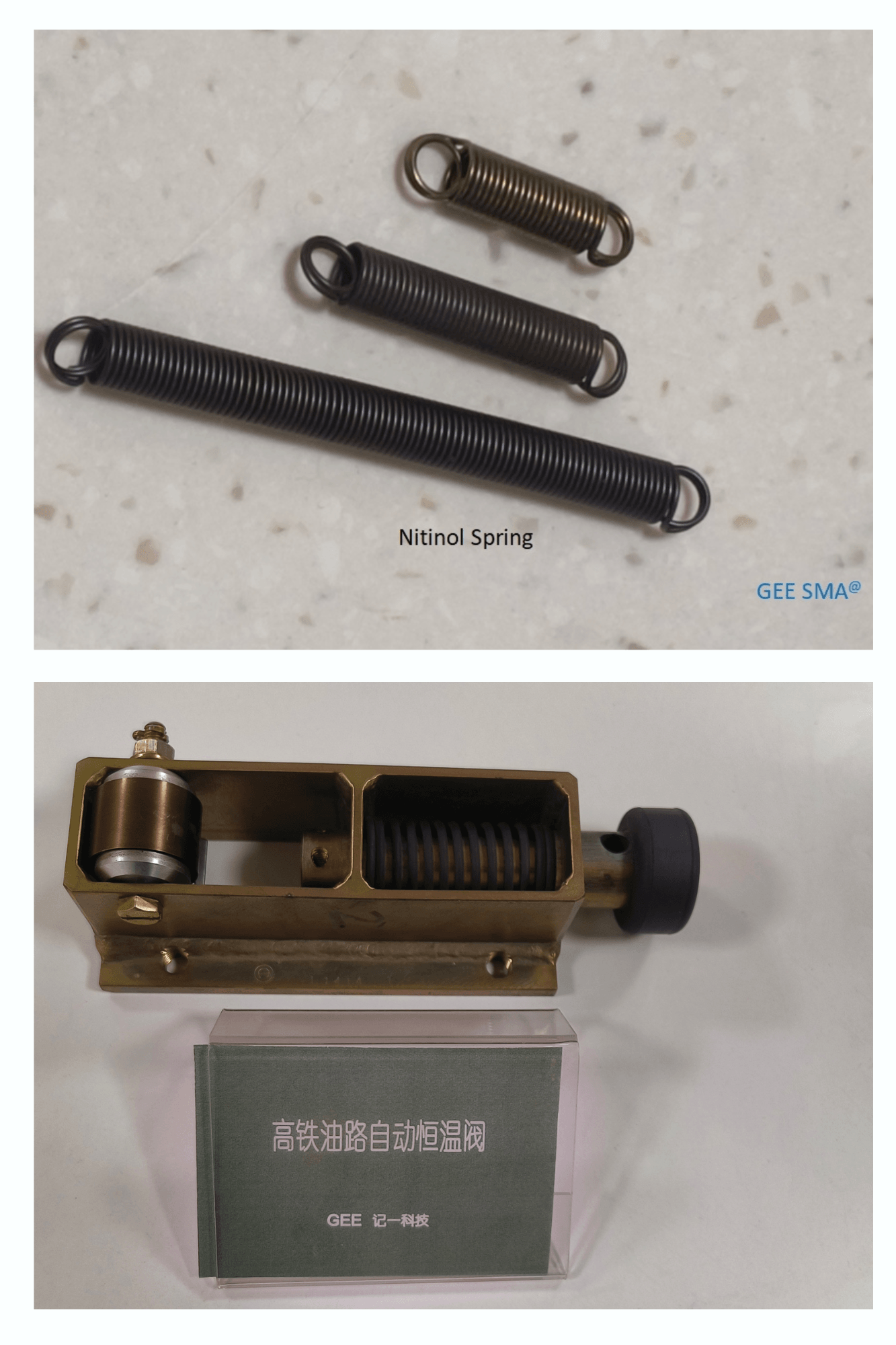

In the world of engineering and material science, few innovations have sparked as much excitement as shape memory springs. These remarkable components, primarily made from nitinol nickel titanium, possess an extraordinary ability to return to a predetermined shape when subjected to specific temperatures. This unique characteristic not only enhances their functionality but also opens up a realm of possibilities across various industries.

Understanding Shape Memory Springs

Shape memory springs are a fascinating subset of materials that can remember their original form after being deformed. When heated above a certain temperature, these nitinol springs revert back to their intended shape, showcasing their remarkable elasticity and strength. This capability makes them invaluable in applications where space is limited but functionality is paramount, such as in medical devices and aerospace components.

The Science Behind Nitinol Nickel Titanium

Nitinol is an alloy composed primarily of nickel and titanium, which exhibits both superelasticity and shape memory effect—two properties that set it apart from traditional metals. The unique atomic structure of nitinol allows it to undergo phase transformations between different crystalline forms when exposed to temperature changes. This scientific marvel not only enhances the performance of titanium springs but also enables engineers to design innovative solutions that were previously unimaginable.

Why Shape Memory Springs Matter

The significance of shape memory springs extends far beyond mere novelty; they represent a transformative technology with practical implications across multiple sectors. From revolutionizing healthcare through advanced surgical tools to enhancing automotive safety features with adaptive components, the impact of nitinol spring technology is profound. As industries continue to explore the potential of this extraordinary material, the future looks bright for innovations driven by shape metal technologies.

Medical Applications of Shape Memory Spring

Shape memory springs, particularly those made from nitinol nickel titanium, have revolutionized the medical field with their unique properties. These innovative materials can remember a specific shape and return to it when exposed to certain temperatures, making them invaluable in various medical applications. From stents to surgical tools, the versatility of nitinol springs has led to safer and more effective medical devices.

Stents and Catheters

Nitinol springs play a crucial role in the design of stents and catheters, providing flexibility and strength where it's needed most. The shape memory effect allows these devices to expand upon insertion into the body, adapting perfectly to the vessel’s dimensions while maintaining structural integrity. This adaptability not only improves patient outcomes but also reduces complications associated with traditional rigid materials.

The use of titanium compression springs in stent design enhances their performance by ensuring they remain open even under varying pressures within blood vessels. Nitinol's biocompatibility further ensures that these devices can remain in place for extended periods without causing adverse reactions. As a result, patients benefit from less invasive procedures and quicker recovery times.

Surgical Tools and Devices

Surgical tools have seen significant advancements thanks to shape memory springs made from nitinol nickel titanium. These tools can change shape during procedures, allowing surgeons greater maneuverability while minimizing trauma to surrounding tissues. For instance, certain surgical instruments can be compressed for easy insertion and then expand once inside the body, making complex surgeries more efficient.

Moreover, the durability of titanium springs means that these instruments can withstand repeated use without losing their effectiveness or precision. This is particularly important in high-stakes environments where reliability is paramount. With ongoing innovations in this field, we can expect even more sophisticated surgical devices utilizing shape metal technology.

Orthopedic Implants

In orthopedics, nitinol spring applications are increasingly popular due to their unique properties that enhance patient care significantly. Shape memory alloys allow for implants that adjust according to the body's temperature or movement patterns—providing optimal support as healing progresses. This dynamic adaptability means patients may experience less discomfort compared to traditional static implants.

Furthermore, titanium compression springs offer robust solutions for load-bearing applications within orthopedic surgery—ensuring stability without compromising on flexibility or comfort for the patient. The lightweight nature of nitinol also means that these implants do not add unnecessary weight or bulk during recovery phases. With such promising advancements in orthopedic technology driven by shape memory spring innovations, we are witnessing a new era of personalized medicine.

Aerospace Innovations Utilizing Nitinol Spring

The aerospace industry is constantly evolving, and one of the most exciting advancements comes from the use of nitinol springs. These shape memory springs made from nitinol nickel titanium are revolutionizing airframe components, actuation systems, and thermal management solutions. With their unique properties, these titanium springs provide unparalleled performance and reliability in demanding environments.

Airframe Components

Nitinol springs are finding their way into various airframe components, enhancing structural integrity while reducing weight. The lightweight nature of these shape memory springs allows for more efficient fuel consumption without compromising safety or performance. Additionally, the ability of nitinol to return to its original shape after deformation makes it an ideal candidate for applications that require resilience under stress.

Incorporating titanium compression springs into airframes can lead to innovative designs that improve aerodynamics and overall efficiency. Engineers are increasingly turning to these materials to create parts that can withstand extreme temperatures and pressures encountered during flight. As a result, nitinol spring technology is paving the way for next-generation aircraft that are not only lighter but also more robust.

Actuation Systems

Actuation systems in aerospace applications benefit significantly from the unique properties of nitinol nickel titanium alloys. These systems often require precise movements and rapid responses, which make shape memory springs an ideal solution due to their ability to change shapes at specific temperatures. This characteristic allows for more compact designs without sacrificing performance or reliability.

Nitinol springs can be used in various actuation mechanisms such as flaps, landing gear deployment systems, and thrust vectoring controls. The lightweight yet strong nature of titanium springs ensures that these systems operate efficiently while minimizing overall aircraft weight—a critical factor in aerospace engineering. As innovation continues in this field, we can expect even broader adoption of shape metal technologies in actuation systems.

Thermal Management Solutions

Effective thermal management is crucial in aerospace applications where temperature fluctuations can impact performance and safety significantly. Nitinol spring technology offers innovative approaches to managing heat through its unique thermal properties; it can absorb excess heat and release it when needed by utilizing its phase transformation characteristics effectively. This adaptability makes it a valuable asset for maintaining optimal operating conditions within aircraft systems.

Using shape memory spring mechanisms helps engineers develop smarter thermal management solutions that respond dynamically to changing environmental conditions during flight operations. Moreover, integrating titanium compression springs into cooling systems enhances efficiency by allowing for lightweight designs that do not compromise on effectiveness or durability over time. As we continue exploring new frontiers in aerospace innovation, it's clear that nitinol will play a pivotal role in shaping the future of this dynamic industry.

Automotive Advancements with Titanium Springs

The automotive industry is continually evolving, and one of the most exciting developments is the use of titanium springs, particularly those made from nitinol nickel titanium. These shape memory springs offer unique properties that can significantly enhance vehicle performance and safety. By leveraging the capabilities of these innovative materials, manufacturers are pushing the boundaries of what’s possible in automotive design.

Active Suspension Systems

Active suspension systems are a game changer for vehicle handling and comfort, and nitinol springs play a crucial role in this transformation. The ability of shape memory springs to adapt their stiffness based on driving conditions allows for improved ride quality and enhanced control during cornering. This dynamic response not only contributes to a smoother ride but also enhances overall vehicle safety by maintaining optimal tire contact with the road.

Moreover, these titanium compression springs can respond almost instantaneously to changes in terrain or driving style, adjusting their properties without the need for complex mechanical systems. This responsiveness means that drivers can enjoy greater stability at high speeds while also benefiting from plush comfort over bumps and rough surfaces. With nitinol spring technology integrated into active suspension systems, vehicles become more versatile, catering to both performance enthusiasts and everyday commuters alike.

Shape Adaptive Components

Shape adaptive components are another fascinating application of titanium springs in modern vehicles. These components utilize the unique characteristics of shape memory metal to alter their form based on specific stimuli such as temperature or force. For instance, certain parts can expand or contract when exposed to heat generated by engine operation or external conditions, enhancing efficiency and functionality.

Incorporating shape memory spring technology into various automotive elements allows manufacturers to design lighter yet stronger components that contribute to overall fuel efficiency without sacrificing performance. Imagine doors that adjust their fit automatically when temperatures fluctuate or seat frames that conform perfectly to passengers' bodies for maximum comfort—this is just a glimpse into the future enabled by nitinol nickel titanium innovations. Such advancements not only elevate user experience but also pave the way for smarter cars equipped with intelligent features.

Safety Mechanisms

Safety mechanisms are paramount in any vehicle design, and nitinol springs provide innovative solutions that enhance passenger protection during collisions or sudden stops. The inherent ability of shape memory alloys to absorb energy makes them ideal candidates for crumple zones or impact-absorbing structures within vehicles. By strategically placing these titanium compression springs throughout critical areas of a car's frame, manufacturers can significantly improve crashworthiness.

Additionally, these safety mechanisms can be designed to activate automatically under certain conditions, offering an extra layer of protection without relying solely on traditional passive safety measures like airbags alone. As vehicles become increasingly automated and connected, integrating advanced materials like shape metal ensures that safety standards evolve alongside technological advancements in automotive engineering. Ultimately, utilizing nitinol spring technology fosters innovation while prioritizing driver and passenger well-being on the road.

Consumer Electronics and Shape Metal

The integration of shape memory springs, particularly those made from nitinol nickel titanium, is transforming the consumer electronics landscape. These innovative materials allow for more compact, durable, and versatile designs in everyday gadgets. From smartphones to wearables, the applications of titanium springs are expanding rapidly, enhancing functionality while reducing weight.

Smartphone Mechanisms

Smartphones have become essential tools in our daily lives, and the incorporation of shape memory springs is taking their functionality to new heights. Nitinol spring technology enables features like self-healing screens or flexible hinges that can adapt to user preferences. By utilizing titanium compression springs in these mechanisms, manufacturers can create devices that are not only slim but also incredibly resilient against daily wear and tear.

Moreover, the ability of nitinol to return to a predetermined shape allows for innovative solutions like retractable camera lenses or expandable displays. This adaptability provides users with a seamless experience while maintaining the aesthetics of sleek smartphone designs. As technology advances, we can expect even more ingenious uses of shape metal in future smartphone models.

Wearable Technology

Wearable technology has exploded in popularity over recent years, and nitinol nickel titanium plays a crucial role in enhancing these devices' performance and comfort levels. Shape memory springs allow wearables to adjust dynamically based on user activity or environmental conditions—think fitness trackers that tighten during workouts or smartwatches that conform to your wrist's natural movements. The lightweight nature of titanium springs ensures that these devices remain comfortable for extended wear without compromising on durability.

Additionally, the unique properties of shape memory alloys enable innovative health-monitoring features within wearable tech. For instance, smart fabrics embedded with nitinol could change their thermal properties based on body temperature or activity levels—keeping users comfortable no matter what they're doing. As we move forward into an era where health tracking becomes increasingly important, wearable technology will likely leverage these advancements more than ever before.

Hinge and Joint Applications

Hinges and joints are critical components in many consumer products, from laptops to furniture—and here’s where shape memory spring technology shines bright! Nitinol's unique ability to remember its shape means it can create hinges that automatically adjust for optimal performance under varying loads or angles; imagine a laptop screen that effortlessly opens at just the right angle every time you use it! The use of titanium compression springs adds another layer of reliability by ensuring longevity even after repeated use.

Moreover, this innovation isn't limited just to electronics; it extends into areas like adjustable furniture where joints made from shape metal can provide enhanced flexibility without sacrificing strength or stability. The combination of aesthetic appeal with functional adaptability makes products featuring these materials highly desirable among consumers seeking convenience paired with modern design elements. As manufacturers continue exploring these possibilities further down the line, we may witness an entirely new wave of ergonomic designs entering our homes!

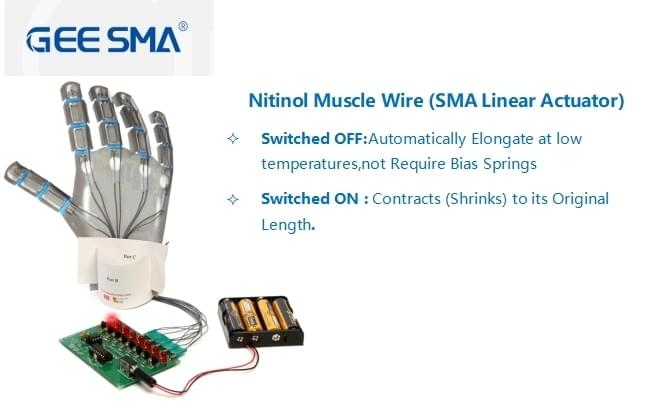

Robotics and Automation with Nitinol

Robotics and automation are on the brink of a revolution, thanks to the versatile properties of nitinol, a remarkable alloy of nickel and titanium. Nitinol springs, with their unique shape memory capabilities, are becoming essential in designing advanced robotic systems that require precision and adaptability. From actuators to grippers, these innovations highlight how shape memory springs can enhance functionality in robotics.

Actuators and Sensors

Actuators are the muscles of any robotic system, converting energy into motion. Nitinol springs serve as an ideal actuator due to their ability to return to a predetermined shape when heated, providing reliable movement without complex mechanisms. This simplicity allows for more compact designs while maintaining high efficiency in sensors that detect environmental changes or user inputs.

Incorporating nitinol nickel titanium into actuators means robots can achieve smoother movements and respond quickly to stimuli. The lightweight nature of titanium springs also contributes to energy efficiency, making them perfect for portable robotic applications where every ounce counts. Moreover, the durability of these shape memory springs ensures longevity even under repeated use, which is vital for automation systems operating continuously.

Shape Memory Alloy Grippers

When it comes to handling objects delicately yet firmly, shape memory alloy grippers take center stage in robotics. These innovative devices utilize nitinol's unique properties to adapt their grip based on the object being handled—whether it's fragile or heavy—ensuring optimal performance without damaging items. The versatility offered by titanium compression springs allows these grippers to function effectively across various industries.

The design flexibility provided by nitinol enables engineers to create lightweight yet powerful gripper systems that outperform traditional mechanical designs. As they can change shape based on temperature variations or electrical input, these grippers represent a leap forward in robotic dexterity and precision handling capabilities. With applications ranging from assembly lines to medical robotics, nitinol-based grippers are transforming how robots interact with their environment.

Self-Adjusting Mechanisms

Self-adjusting mechanisms powered by nitinol offer exciting possibilities for future robotics applications by mimicking natural movements found in living organisms. These systems leverage the unique characteristics of shape memory metals like nitinol for real-time adjustments based on environmental conditions or user interactions—think about how your body naturally adapts as you move! By integrating such mechanisms into robotic designs using titanium springs, we can create machines that respond intuitively rather than relying solely on pre-programmed instructions.

Imagine a robot arm that automatically adjusts its grip strength depending on whether it's lifting a delicate glass or a hefty toolbox; this is precisely what self-adjusting mechanisms can achieve through intelligent use of shape memory spring technology. Such advancements not only enhance performance but also improve safety by reducing the risk of accidents caused by improper handling techniques. As we continue exploring new frontiers with nitinol nickel titanium alloys in automation technology, it’s clear that self-adjusting mechanisms will play an integral role in shaping our future interactions with machines.

Conclusion

In summary, the transformative capabilities of shape memory springs made from nitinol nickel titanium are reshaping multiple industries, from healthcare to aerospace and beyond. These remarkable materials not only provide innovative solutions but also enhance the functionality and reliability of devices we use daily. The future appears bright as we continue to explore the vast potential of nitinol springs.

Revolutionizing Healthcare with Nitinol

The impact of shape memory springs in healthcare is nothing short of revolutionary. Nitinol nickel titanium is at the forefront, driving advancements in medical devices such as stents and catheters, which benefit from their unique properties. With their ability to return to a predetermined shape when heated, these titanium springs offer unparalleled precision and safety in surgical applications.

As surgeons embrace the advantages of nitinol spring technology, patients experience less invasive procedures and quicker recovery times. The versatility of shape memory alloys extends to orthopedic implants, where they adapt seamlessly within the human body for improved healing outcomes. It's clear that nitinol's role in healthcare is not just beneficial; it's life-changing.

The Future of Aerospace Engineering

In aerospace engineering, nitinol's unique attributes are paving the way for innovations that were once confined to science fiction. Shape memory springs play a critical role in airframe components and actuation systems, providing lightweight solutions that withstand extreme conditions while maintaining structural integrity. As engineers leverage these titanium springs, they can create more efficient aircraft designs that promise enhanced performance.

Thermal management solutions utilizing shape metal also stand out as vital components for next-generation aircraft systems. By adapting to temperature changes dynamically, these materials help maintain optimal operating conditions without adding unnecessary weight or complexity. The future holds exciting possibilities for aerospace applications powered by nitinol technology.

Enhancing Everyday Life Through Innovation

Nitinol doesn’t just revolutionize specialized fields; it’s also making waves in consumer electronics and everyday products we often take for granted. From smartphone mechanisms that require reliable yet flexible components to wearable technology benefiting from lightweight design principles offered by titanium compression springs—shape memory spring applications are everywhere!

Even simple hinge and joint mechanisms benefit from this innovative material’s ability to adapt under stress while returning to its original form when needed. This blend of functionality with cutting-edge design enhances user experience across various products we interact with daily, making our lives easier and more enjoyable than ever before. Clearly, shape metal innovations are enhancing everyday life through creative engineering solutions.