- Our Products

- All Products

- Material

- Components

- About Us

- …

- Our Products

- All Products

- Material

- Components

- About Us

- Our Products

- All Products

- Material

- Components

- About Us

- …

- Our Products

- All Products

- Material

- Components

- About Us

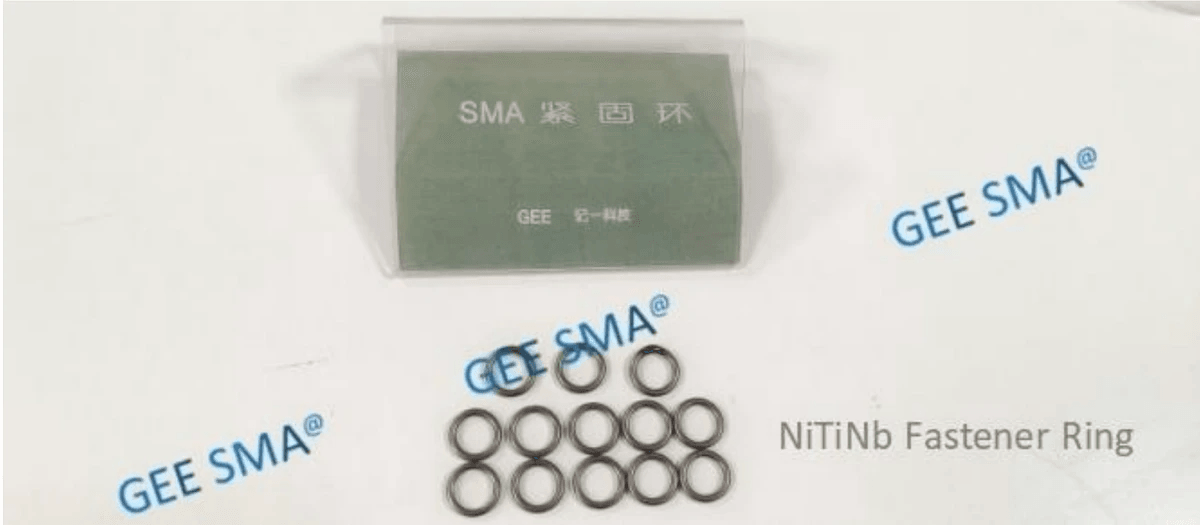

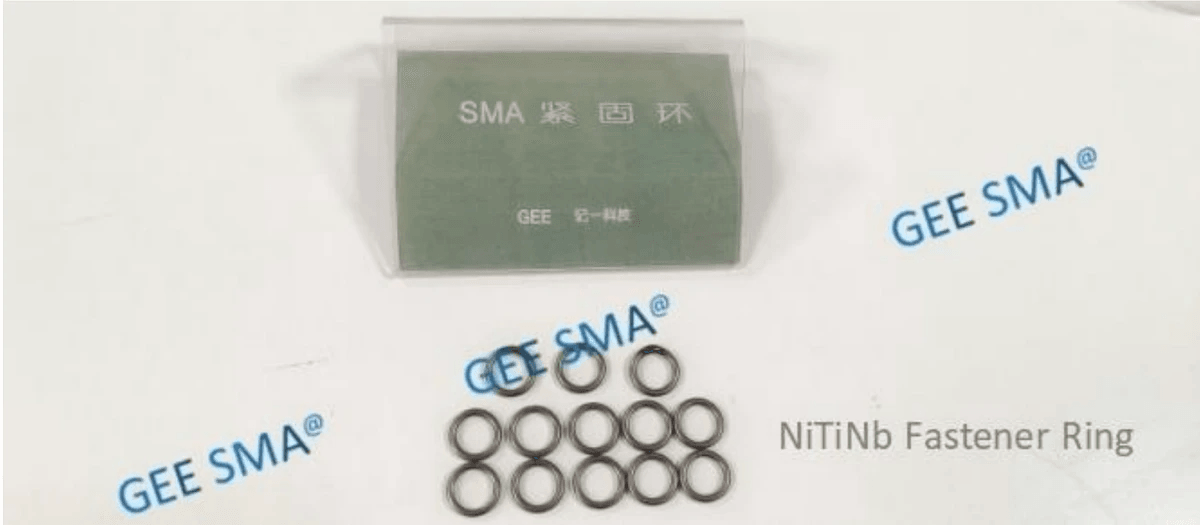

NiTiNb Ring

Nitinol rings are manufactured from various alloy formulations, each tailored for specific performance characteristics. Among these, the NiTiNb alloy is the most widely used.

NiTiNb alloy features a distinct deformation temperature (Ms + 30 °C) and a critical deformation range of 16%–20%. Within this range, deformation significantly enhances martensite stability, increases phase transformation hysteresis, and ensures high levels of strain recovery and recovery force.

Fasteners made from NiTiNb alloy can be conveniently stored at room temperature, simplifying their use in engineering applications.

The development of wide-hysteresis NiTiNb alloys has significantly broadened the application scope of mechanical couplings and fasteners.

NiTiNb rings are commonly employed in electronic and mechanical systems, including connectors, sealing mechanisms, and clamping components. They deliver dependable performance across a wide temperature range from –60 °C to 300 °C.

The alloy starts to recover at approximately 60–75 °C and achieves full clamping force between 90 °C and 115 °C. Once engaged, NiTiNb rings maintain their clamping force from –65 °C to +300 °C. For removal or adjustment, cooling the components below –120 °C using liquid nitrogen will release their grip.

Specifications

Product Parameters

Product Benefits and Application

4.1 Benefit of Ni-Ti-Nb

4.2 Benefit of NiTiNb Ring

4.3 Application

NiTiNb Ring & NiTiFe Pipe Coupling

NiTiFe Pipe Coupling

NiTiNb Rings

Subscribe to Our Newsletter