Introduction

These springs, made from a unique nickel-titanium alloy, are celebrated for their remarkable properties and versatility. As we delve into the essentials of Niti open coil springs, we'll explore what they are, their applications across various industries, and how they stack up against closed coil springs.

The Basics of Niti Open Coil Springs

Niti open coil springs are a type of helical spring that can expand and contract without losing their structural integrity. They are crafted from a specialized shape memory alloy known as Nickel-Titanium (Niti), which allows them to return to their original shape after deformation. This unique characteristic makes Niti open coil springs incredibly valuable in applications that require precise movement and reliability.

Essential Applications of Niti Open Coil Springs

So, what is a Niti open coil spring used for? Their applications span multiple sectors including medical devices, automotive systems, and consumer electronics. In medical technology, these springs play critical roles in devices like stents and surgical tools where reliability is paramount; while in automotive engineering, they contribute to suspension systems that enhance vehicle performance.

Key Differences: Open vs. Closed Coil

Understanding the differences between closed coil and open coil helical springs is essential for making informed choices in design and manufacturing. Open coil springs have gaps between coils that allow them to compress more easily under load compared to their closed counterparts which are tightly wound together. This distinction impacts performance under varying conditions—making it crucial to choose the right type based on specific project requirements.

What is a Niti Open Coil Spring?

Niti open coil springs are fascinating components that utilize the unique properties of nickel-titanium (NiTi) alloy, known for its shape memory effect. These springs are designed with an open helical structure, allowing for greater flexibility and adaptability in various applications. Understanding what a Niti open coil spring is and its characteristics can help clarify its role in multiple industries.

Definition and Characteristics

A Niti open coil spring is essentially a type of helical spring made from a nickel-titanium alloy that exhibits remarkable elasticity and shape memory capabilities. Unlike traditional springs, these open coil designs do not have tightly wound coils, which allows them to expand or contract more freely under stress. This structural configuration makes them particularly suitable for applications requiring high fatigue resistance and recovery after deformation, making one ponder: what is a Niti open coil spring used for?

Materials Used in Niti Open Coil Springs

The primary material used in manufacturing Niti open coil springs is the nickel-titanium alloy itself, which offers excellent corrosion resistance and biocompatibility—ideal for medical applications. The specific ratios of nickel to titanium can be adjusted to tailor the mechanical properties of the spring, enhancing its performance across different environments. This versatility leads us to consider: what are the differences between closed coil and open coil helical springs? While closed coils are generally more compact, Niti open coil springs provide superior adaptability due to their design.

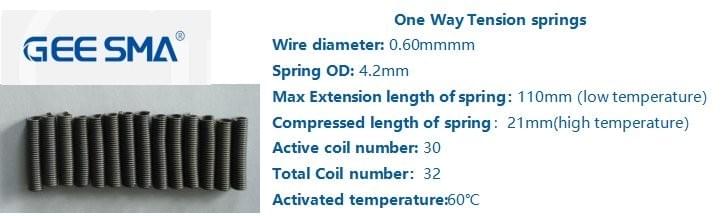

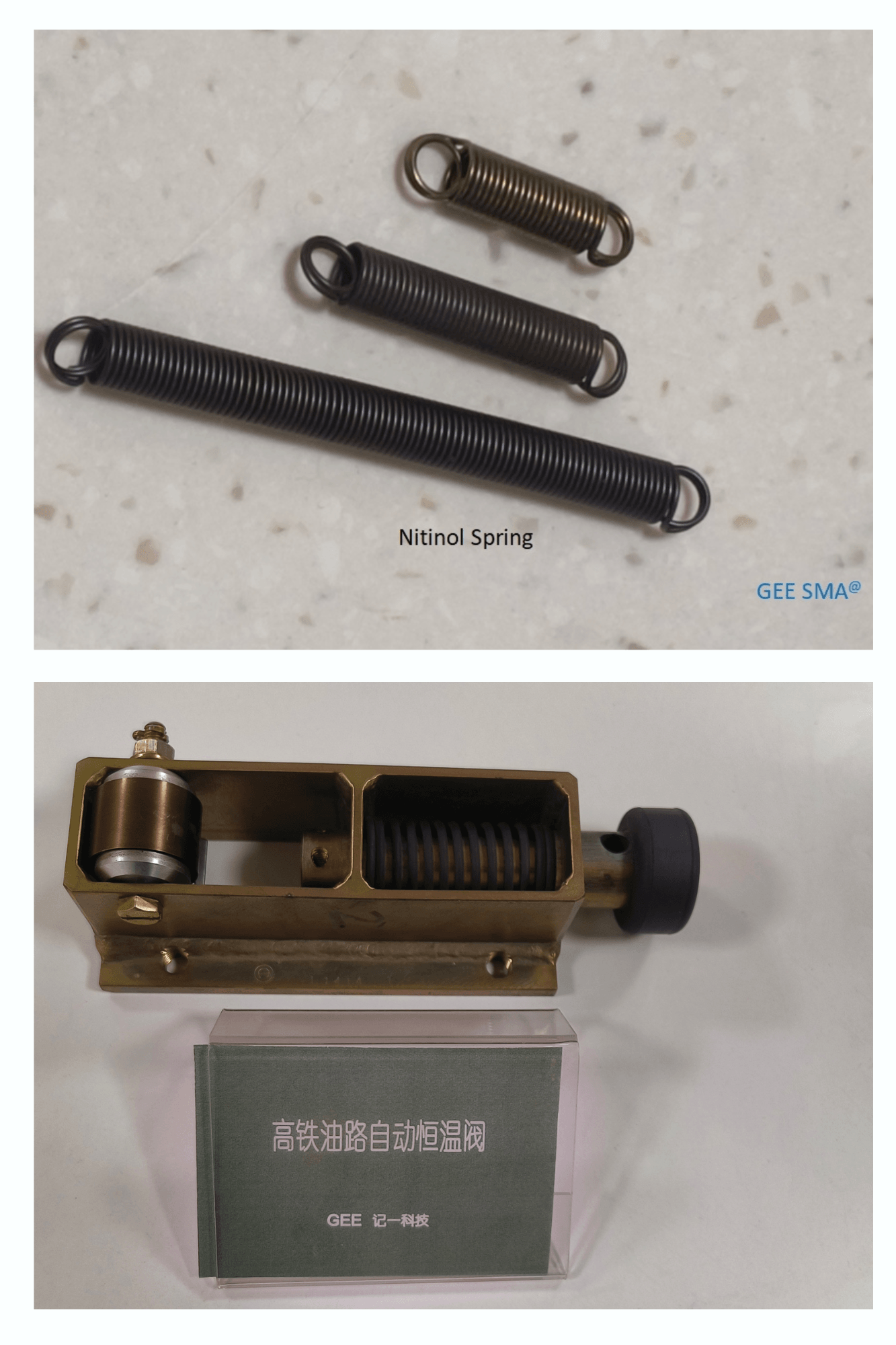

The Role of GEE SMA in Production

GEE SMA plays a pivotal role in producing high-quality Niti open coil springs by leveraging advanced manufacturing techniques that ensure precision and consistency. Their expertise allows them to optimize the properties of NiTi alloys, resulting in springs that meet stringent industry standards while maintaining performance efficiency. By focusing on innovation and quality control, GEE SMA contributes significantly to answering questions like: what are open coil springs used for? Their products find utility across diverse sectors such as medical devices, automotive systems, and consumer electronics.

What is a Niti Open Coil Spring Used For?

Niti open coil springs are versatile components that find applications across various industries, showcasing their unique properties and benefits. These springs, made from nickel-titanium alloy, adapt well to different environments and demands. Understanding what a Niti open coil spring is used for can help you appreciate its significance in modern technology.

Key Applications in Medical Devices

In the medical field, Niti open coil springs play a crucial role in devices that require precise movement and flexibility. They are commonly used in stents, which need to expand and contract within the body without compromising structural integrity. Additionally, these springs can be found in surgical instruments where reliability and responsiveness are paramount for successful outcomes.

The unique properties of Niti open coil springs allow them to respond to temperature changes, making them ideal for applications like active implants or devices that require minimal invasiveness. Their biocompatibility ensures they can safely interact with bodily tissues without adverse reactions. As medical technology continues to advance, the demand for innovative solutions like Niti open coil springs will only grow.

Uses in Automotive Industry

In the automotive industry, Niti open coil springs serve multiple functions that enhance vehicle performance and safety features. They are often utilized in suspension systems where their ability to absorb shocks significantly improves ride quality and stability on rough terrains. The lightweight nature of these springs contributes to overall fuel efficiency by reducing vehicle weight.

Moreover, Niti open coil springs are employed in various mechanical components such as actuators and valves due to their excellent fatigue resistance under cyclic loading conditions. This reliability translates into longer-lasting automotive parts that require less frequent replacements or repairs—saving manufacturers both time and costs over the lifecycle of a vehicle. As automotive technology evolves towards electric vehicles (EVs), these springs will likely find new roles within cutting-edge designs.

Role in Consumer Electronics

Consumer electronics have also embraced the functionality of Niti open coil springs, integrating them into products ranging from smartphones to wearable tech devices. In this fast-paced industry, innovation is paramount; thus, utilizing materials like nickel-titanium allows manufacturers to create more compact designs while maintaining durability and performance standards.

Niti open coil springs contribute significantly to mechanisms such as hinges or buttons that require smooth operation over thousands of cycles without failure—making them indispensable for high-quality consumer products. Furthermore, as trends shift towards more complex electronic systems featuring flexible displays or adaptable interfaces, these innovative springs will undoubtedly play an essential role in shaping future technologies.

What Are the Differences Between Closed Coil and Open Coil Helical Springs?

Structural Differences Explained

The structural differences between a Niti open coil spring and its closed coil counterpart are quite pronounced. A Niti open coil spring features widely spaced coils that do not touch each other, allowing for greater flexibility and extension under load. In contrast, closed coil springs have tightly wound coils that are in contact with one another, providing a more rigid structure designed for compression applications. This fundamental distinction plays a crucial role in determining what is a Niti open coil spring used for in practical scenarios.

Performance in Varying Conditions

Performance-wise, Niti open coil springs shine in specific conditions due to their design flexibility. They can effectively absorb shock and accommodate large deflections without permanent deformation—ideal for applications requiring resilience under stress. On the other hand, closed coil springs generally excel in scenarios where space is limited but strength is paramount; they perform better under compressive loads but may struggle with tensile stresses compared to their open counterparts.

Choosing the Right Type for Your Needs

When it comes to choosing between an open or closed coil design, understanding your needs is key—after all, you wouldn’t want to end up with the wrong type! If your project involves dynamic movements or requires a lightweight solution that can handle varying loads efficiently, then a Niti open coil spring might just be your best bet. Conversely, if you need something robust for high-load situations like automotive suspensions or heavy machinery components, then leaning towards closed coils may be more beneficial.

What Are Open Coil Springs Used For?

Open coil springs, particularly the Niti open coil spring, are versatile components found in a multitude of everyday products. Their unique characteristics, such as flexibility and resilience, make them ideal for applications that require reliable performance under varying loads. From simple household items to complex machinery, understanding what a Niti open coil spring is used for can help us appreciate its importance in modern design.

Examples in Everyday Products

Niti open coil springs are commonly found in various everyday products that enhance our daily lives. These springs play a crucial role in items such as retractable pens, where they provide the necessary tension to extend and retract the writing tip smoothly. Additionally, they can be seen in kitchen appliances like mixers and blenders, where their ability to absorb shocks contributes to the durability of these devices.

Moreover, many toys incorporate Niti open coil springs to enable movement or sound effects—think of those delightful wind-up toys that spring into action! The versatility of these springs makes them essential not just for function but also for enhancing user experience across different consumer products.

Impact on Machinery and Equipment

The impact of Niti open coil springs on machinery and equipment cannot be overstated. In industrial settings, these springs are often used in assembly lines to absorb vibrations and reduce wear on mechanical parts. By providing consistent force distribution during operation, they help maintain efficiency while extending the lifespan of machinery.

In addition to vibration dampening, Niti open coil springs contribute significantly to safety mechanisms within various machines. For example, they can act as shock absorbers in automotive suspension systems or serve as counterbalances in elevators—ensuring smooth operation even under heavy loads. This makes them indispensable components that enhance both performance and safety across numerous industries.

Benefits for Specialized Applications

Their unique properties allow them to perform exceptionally well under extreme conditions—whether it’s high temperatures or corrosive environments—making them ideal for aerospace and medical device manufacturing. This adaptability means that engineers can rely on these springs when designing equipment meant for critical functions.

Furthermore, Niti open coil springs offer significant weight savings compared to traditional materials without compromising strength or reliability. This characteristic is particularly beneficial in industries where weight reduction is essential—such as automotive engineering or portable electronic devices—leading manufacturers to increasingly ask: What is a Niti open coil spring used for?

Ultimately, whether it's improving product longevity or enabling innovative designs tailored for specific challenges, the benefits provided by Niti open coil springs make them an invaluable choice across various specialized sectors.

Is Open Coil or Pocket Spring Better?

Comparative Analysis of Support and Comfort

Support and comfort are paramount when evaluating whether a niti open coil spring or a pocket spring is better suited for your needs. Niti open coil springs provide uniform support due to their continuous wire design, distributing weight evenly across the surface. On the other hand, pocket springs operate independently; this allows them to conform more closely to body contours, offering personalized comfort that some users prefer.

Moreover, while niti open coil springs can be quite responsive in applications like mattresses or seating systems, they might not provide the same level of targeted support as pocket springs do in those scenarios. The choice ultimately depends on individual comfort preferences; those who value a firmer feel may lean towards niti open coil designs, while others seeking plushness might opt for pocket configurations. Thus, understanding what is a niti open coil spring used for can guide consumers in making informed decisions based on their specific requirements.

Cost Considerations for Manufacturers

From a manufacturing perspective, cost considerations play a significant role in determining whether to produce niti open coil springs or pocket springs. Generally speaking, niti open coil springs tend to be more economical due to simpler production processes and materials required compared to their pocket counterparts. This cost-effectiveness makes them appealing for mass-produced items where price sensitivity is crucial.

However, one cannot overlook that investing in quality often pays off long-term; manufacturers must weigh initial costs against potential customer satisfaction and product longevity when deciding which type of spring technology to employ. Additionally, niche markets may favor high-quality pocket spring options despite higher production costs because they cater directly to consumer demands for comfort and support features that are increasingly sought after today.

Consumer Preferences and Trends

Consumer preferences have evolved significantly over the years as people become more aware of their sleep quality and overall comfort levels in various products utilizing these technologies. Many consumers now actively seek out what are open coil springs used for beyond traditional applications like mattresses—these include automotive seating systems and even medical devices where flexibility is key!

Trends indicate an increasing demand for customized solutions; thus manufacturers must adapt by offering both types of spring systems depending on target demographics' needs—whether it's focused on affordability with niti open coils or premium offerings with pocket designs catering specifically towards enhanced comfort experiences.

In conclusion, while both types have distinct advantages depending on application contexts—be it cost efficiency with niti open coils or personalized support from pocket varieties—the ultimate decision rests upon individual preferences shaped by market trends today.

Conclusion

In conclusion, the future of Niti open coil springs looks promising as industries continue to innovate and adapt these versatile components in various applications. With advancements in materials and manufacturing processes, we can expect to see even more efficient and effective designs that cater to specific needs. As we move forward, understanding what a Niti open coil spring is used for will become increasingly crucial for engineers and designers alike.

Future Trends in Niti Open Coil Springs

One of the most exciting future trends for Niti open coil springs is their potential integration into smart technologies. These springs could play a vital role in adaptive systems that respond dynamically to environmental changes or user inputs, enhancing functionality across various sectors. Moreover, as sustainability becomes a priority, manufacturers may focus on developing eco-friendly production methods for Niti open coil springs to minimize their environmental impact.

Innovations from GEE SMA in Spring Technology

GEE SMA has been at the forefront of innovation in spring technology, particularly with Niti open coil springs. Their commitment to research and development has led to breakthroughs that improve performance while reducing costs for manufacturers. By leveraging advanced materials science and engineering techniques, GEE SMA continues to redefine what is possible with these essential components.

Making the Right Choice for Your Projects

When it comes to selecting the right type of spring for your project, understanding the differences between closed coil and open coil helical springs is vital. If you're pondering Is open coil or pocket spring better? consider your specific application requirements—each type offers unique advantages depending on load distribution and space constraints. Ultimately, knowing what are open coil springs used for will guide you toward making an informed decision that aligns with your project's goals.