Introduction

In the ever-evolving world of orthodontics, the introduction of Niti closed coil springs has revolutionized how dental professionals approach treatment. These innovative devices harness the unique properties of Niti wire, providing enhanced performance and versatility in orthodontic applications. Coupled with advanced spring coiler technology, these springs are setting new standards for precision and efficiency in manufacturing.

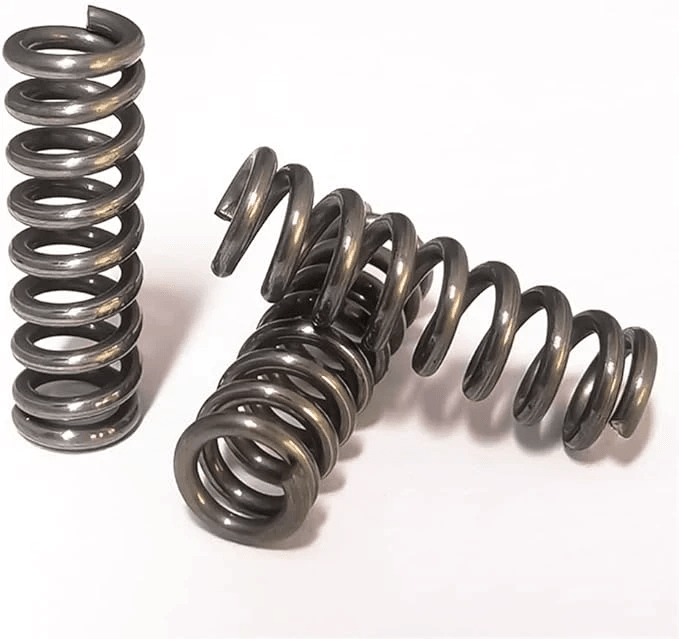

Discover Niti Closed Coil Spring Benefits

Niti closed coil springs offer a plethora of benefits that make them a go-to choice for orthodontists. Their ability to exert consistent and gentle forces on teeth facilitates smoother adjustments during treatment, leading to improved patient comfort and satisfaction. Furthermore, the durability and flexibility of these springs ensure that they maintain their shape and effectiveness over time, making them a reliable option in any orthodontic toolkit.

The Role of Niti Wire in Orthodontics

At the heart of every Niti closed coil spring lies the remarkable Niti wire, known for its shape memory effect and superelasticity. This unique combination allows orthodontic coil springs made from Niti wire to return to their original form after deformation, providing sustained force delivery without compromising performance. As a result, practitioners can achieve precise tooth movement while minimizing discomfort for patients—a win-win situation!

Overview of Spring Coiler Technology

Spring coiler technology has transformed how orthodontic coil springs are produced by enhancing both precision and efficiency in manufacturing processes. This cutting-edge technology enables manufacturers to create highly accurate coils tailored to specific treatment needs while reducing material waste significantly compared to traditional methods. With advancements like these, it's no wonder that Niti closed coil springs have become essential tools for modern orthodontics.

Understanding Niti Closed Coil Springs

Niti closed coil springs are an essential component in various orthodontic applications, providing unique advantages thanks to the properties of niti wire. Their design and functionality set them apart from traditional springs, making them a preferred choice among orthodontists and dental professionals. In this section, we will explore what makes niti closed coil springs unique, compare them with open and closed coil springs, and examine their applications in both dental and medical fields.

What Makes Niti Unique

What truly sets niti wire apart is its remarkable shape memory effect, which allows it to return to its original shape after deformation when exposed to specific temperatures. This property is crucial for creating effective orthodontic coil springs that can exert consistent forces on teeth over extended periods. Additionally, the flexibility and durability of niti closed coil springs make them an ideal choice for complex orthodontic treatments that require precise adjustments.

The unique composition of niti wire also enhances its performance in various environments, particularly in the oral cavity where exposure to moisture can lead to corrosion in other materials. Unlike titanium springs, which are renowned for their strength but may lack the same level of flexibility, niti closed coil springs offer both resilience and adaptability. These characteristics ensure that they perform reliably throughout treatment while maintaining patient comfort.

Comparison with Open and Closed Coil Springs

When comparing open and closed coil springs with their niti counterparts, several critical differences emerge that highlight the advantages of using niti closed coil spring technology. Open coil springs create less force due to their design but may not provide the continuous pressure needed for effective tooth movement; this is where the tightly wound structure of a closed coil spring shines through. The ability of a nitinol-based spring to deliver consistent force over time makes it superior for orthodontic applications.

Closed coil springs are often preferred because they minimize unwanted movements while delivering targeted pressure where needed most—something that's crucial during alignment procedures. In contrast, open coils tend to be more versatile but can sometimes lead to unpredictable results if not monitored carefully during treatment phases. This distinction emphasizes why many practitioners favor using niti wire in crafting these specialized orthodontic tools.

Applications in Dental and Medical Fields

Niti closed coil springs have found extensive applications not only within dentistry but also across various medical fields due to their exceptional properties. In orthodontics specifically, these coils are used as part of braces systems designed for aligning teeth effectively while minimizing discomfort for patients—a win-win situation! Beyond dentistry, they have been utilized in areas such as cardiovascular devices where controlled movement is necessary.

The versatility of nitinol technology has led researchers and manufacturers alike to explore innovative uses beyond traditional settings; surgical instruments featuring these advanced materials exhibit enhanced performance characteristics compared with those made from standard metals or alloys like titanium springs alone can offer limited capabilities when faced with complex requirements such as those found within intricate surgical procedures! Thus showcasing how far-reaching the impact of utilizing high-quality nitrile products extends beyond conventional boundaries into groundbreaking advancements across disciplines!

Advantages of Using Titanium Springs

When it comes to orthodontic solutions, titanium springs have carved out a niche for themselves due to their remarkable qualities. These titanium springs offer a combination of durability and flexibility that is hard to beat, making them an ideal choice for applications requiring precision and resilience. In the realm of orthodontic coil springs, their advantages over traditional materials are becoming increasingly evident.

Durability and Flexibility

One of the standout features of titanium springs is their exceptional durability without sacrificing flexibility. Unlike conventional open and closed coil springs, which can wear down over time, titanium springs maintain their shape and function even under significant stress. This durability means fewer replacements are needed, resulting in lower long-term costs for both dental practitioners and patients alike.

Moreover, the inherent flexibility of titanium allows these springs to adapt easily to various orthodontic needs. This adaptability ensures that the niti closed coil spring can exert consistent force on teeth while maintaining comfort for the patient. With advancements in spring coiler technology, creating these flexible yet strong titanium springs has never been easier or more efficient.

Resistance to Corrosion

Another compelling advantage of titanium springs is their remarkable resistance to corrosion, making them suitable for use in moist environments like the mouth. While other materials may succumb to rust or degradation over time, titanium remains unaffected by saliva or other oral substances. This property not only extends the lifespan of these orthodontic coil springs but also enhances patient safety by reducing potential reactions or complications.

This resistance leads directly to improved hygiene as well; patients can trust that their niti wire components will remain intact and functional throughout treatment without worrying about material failure due to corrosion. Consequently, this reliability fosters greater confidence in orthodontic procedures involving titanium springs compared to those using less durable options like traditional stainless steel or plastic alternatives.

Enhanced Biocompatibility

Biocompatibility is a critical factor in choosing materials for any medical application—especially in dentistry where materials come into direct contact with tissues. Titanium excels in this regard; its biocompatible properties ensure minimal risk of allergic reactions or adverse responses within the body when used as orthodontic coil springs. Patients can feel secure knowing that they are being treated with a material renowned for its compatibility with human biology.

In addition to being biocompatible, titanium's non-reactive nature further enhances its appeal as a go-to material for dental applications like niti closed coil spring designs. The ability of these coils to work harmoniously alongside natural tissues helps promote quicker healing times during treatment phases while minimizing discomfort associated with traditional metal braces made from less compatible materials.

Overall, incorporating titanium into orthodontics represents a significant leap forward—one that combines durability with comfort while ensuring patient safety remains paramount throughout treatment processes involving niti wire components.

The Science Behind Niti Wire

Niti wire, known for its remarkable properties, forms the backbone of many orthodontic applications, particularly in the creation of niti closed coil springs. Understanding the science behind this unique material reveals why it is preferred in both dental and medical fields. The interplay between its shape memory effect and temperature sensitivity makes it a game-changer in orthodontic treatments.

Shape Memory Effect Explained

The shape memory effect is one of the most fascinating characteristics of niti wire. When deformed at lower temperatures, this wire can return to its original shape when heated above a certain threshold, making it ideal for creating orthodontic coil springs that adjust to patient needs over time. This property allows niti closed coil springs to exert consistent forces on teeth, facilitating effective movement during treatment.

In practical terms, this means that orthodontists can rely on these springs to maintain their effectiveness throughout the course of treatment without frequent adjustments. The ability to revert back ensures that patients experience a more comfortable journey toward their desired smile. Thus, the shape memory effect serves as a cornerstone in the design and functionality of both open and closed coil springs.

Temperature Sensitivity and Performance

Temperature sensitivity plays a crucial role in how niti wire performs within various environments, especially in orthodontics where body heat can influence outcomes significantly. Niti closed coil springs are engineered to respond predictably to temperature changes; they become more flexible at higher temperatures while maintaining strength at cooler levels. This adaptability ensures that titanium springs can deliver optimal performance tailored to each individual's unique oral environment.

Moreover, this temperature-responsive feature enhances patient comfort since forces applied by these spring systems are gentle yet effective over time. As such, clinicians can trust that their chosen materials will operate reliably under varying conditions—an essential factor when considering long-term orthodontic care strategies. Ultimately, understanding temperature sensitivity helps practitioners make informed decisions about which spring coiler technologies will best suit their needs.

Innovations in Nitinol Technology

The evolution of nitinol technology has brought forth exciting innovations that further enhance the capabilities of niti wire in dental applications like orthodontic coil springs. Recent advancements have focused on improving manufacturing techniques and material properties to create even more efficient and reliable products for dental professionals worldwide. These innovations often involve refining production processes through sophisticated spring coiler machinery that maximizes precision while minimizing waste.

Additionally, new alloy compositions are being explored to enhance biocompatibility and mechanical properties—critical factors when considering patient safety and comfort during treatment with niti closed coil springs or titanium springs alike. Such developments not only promise improved performance but also pave the way for novel applications across various sectors beyond dentistry—showing just how versatile nitinol technology has become over time.

How Spring Coilers Improve Production

In the world of orthodontics, precision is paramount, and that's where spring coilers shine. These innovative machines are designed specifically to create orthodontic coil springs with remarkable accuracy, ensuring that each niti closed coil spring meets stringent specifications. With the ability to customize parameters for various applications, spring coilers guarantee that every niti wire component is produced to perfection.

Precision in Creating Orthodontic Coil Springs

The precision offered by spring coilers is a game-changer in the production of orthodontic coil springs. By utilizing advanced technology, these machines can produce intricate designs that cater to both open and closed coil spring configurations. This level of accuracy not only enhances the performance of titanium springs but also ensures that each niti closed coil spring functions effectively within its intended application.

Efficiency and Speed of Manufacturing

When it comes to manufacturing orthopedic components like niti closed coil springs, efficiency is key. Spring coilers significantly reduce production time compared to traditional methods, allowing manufacturers to meet increasing demand without sacrificing quality. With faster turnaround times and streamlined processes, companies can focus on innovation while maintaining a steady supply of high-quality niti wire products.

Reducing Material Waste in Production

One of the unsung benefits of using spring coilers is their ability to minimize material waste during production. By precisely calculating the required length and dimensions for each orthodontic coil spring, manufacturers can optimize their use of materials like niti wire and titanium springs. This not only lowers costs but also contributes to more sustainable manufacturing practices by reducing excess scrap from open and closed coil spring production.

GEE SMA’s Impact on the Industry

In the competitive landscape of orthodontics and medical applications, GEE SMA stands out for its unwavering commitment to producing high-quality Nitinol materials. This dedication not only enhances the performance of their niti closed coil springs but also ensures that each component meets rigorous standards for durability and reliability. By prioritizing quality in their niti wire production, GEE SMA has established itself as a trusted leader in the industry.

Commitment to Quality Nitinol Materials

GEE SMA's focus on quality begins with sourcing premium raw materials for their niti wire, which is crucial for manufacturing effective orthodontic coil springs. The meticulous selection process guarantees that every batch of Nitinol exhibits the desired properties, such as shape memory effect and flexibility, essential for creating superior closed coil springs. This commitment to excellence translates into products that dental professionals can rely on for consistent performance and patient satisfaction.

Custom Solutions for Unique Requirements

Recognizing that no two orthodontic cases are alike, GEE SMA offers custom solutions tailored to meet unique requirements in the field of orthodontics and beyond. Whether it's designing specific titanium springs or adjusting spring coiler settings to create specialized open and closed coil springs, they work closely with clients to deliver exactly what is needed. This level of customization not only enhances treatment outcomes but also fosters innovation within the industry.

Pioneering Advances in Shape Memory Alloys

GEE SMA is at the forefront of pioneering advances in shape memory alloys, particularly with their development of next-generation niti wire technologies. By investing in research and development, they continue to improve the functionality and application range of niti closed coil springs across various fields, including dentistry and orthopedics. Their innovations not only enhance product performance but also contribute significantly to advancing treatment methodologies in orthodontics.

Conclusion

As we wrap up our exploration of Niti closed coil springs and their remarkable benefits, it's clear that these innovative components are set to shape the future of orthodontics and beyond. With advancements in Niti wire technology and spring coiler manufacturing processes, the potential applications for these springs are expanding rapidly. This evolution not only enhances patient care but also drives efficiency in production, making Niti closed coil springs a go-to choice for dental professionals.

The Future of Niti Closed Coil Springs

The future of Niti closed coil springs looks brighter than ever, with ongoing research and development paving the way for new innovations. As orthodontic practices evolve, the demand for more effective and efficient solutions will continue to rise, ensuring that these springs remain at the forefront of dental technology. With their unique properties and versatility, we can expect to see even more refined designs that cater to specific orthodontic needs.

Exploring New Applications for Niti Wire

Beyond orthodontics, the potential applications for Niti wire are vast and varied. Industries such as aerospace, robotics, and medical devices are beginning to adopt this remarkable material due to its shape memory effect and flexibility. By exploring these new frontiers, we can unlock additional benefits of Niti wire that go far beyond traditional uses like open and closed coil springs.

Why Choose Niti for Orthodontic Solutions

Choosing Niti closed coil springs for orthodontic solutions is a decision backed by science and innovation. Their durability, flexibility, and biocompatibility make them an ideal choice compared to titanium springs or other materials on the market today. When it comes to achieving optimal results in treatment plans while minimizing discomfort for patients, there’s no better option than investing in high-quality Niti wire products.